Technical Contents

Engineering Guide: Injection Mold Training

Engineering Insight: Precision in Injection Mold Training – The Foundation of Zero-Defect Manufacturing

In injection molding, precision is not a negotiable specification—it is the bedrock of part consistency, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we engineer molds to zero-defect standards, where every micron matters. Our approach integrates advanced material science, sub-micron CNC machining, and AI-driven quality control to deliver molds that outperform industry benchmarks.

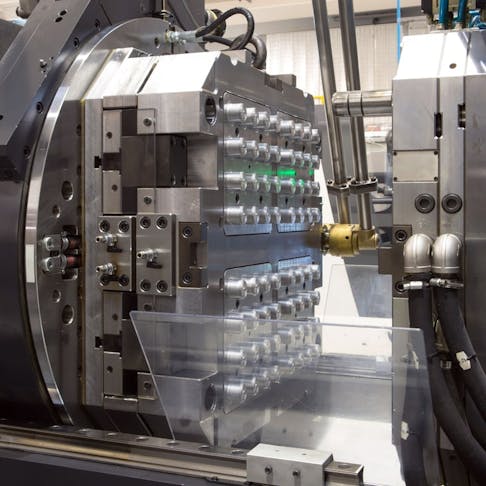

Precision Engineering: The Core of Mold Construction

Industry-standard mold tolerances often range from ±0.10–0.30mm for general applications. However, Wuxi Lead Precision Machinery operates at a fundamentally higher standard. Our proprietary CNC processes achieve ±0.015mm tolerances as standard, with ultra-precision capabilities down to ±0.01mm for mission-critical applications. This level of accuracy ensures minimal part variation, reduced scrap rates, and extended mold longevity—directly translating to lower total cost of ownership for your production.

| Tolerance Tier | Standard Industry Range (mm) | Lead Precision Standard (mm) | Typical Applications |

|---|---|---|---|

| General | ±0.10 – ±0.20 | ±0.03 | Consumer electronics, packaging |

| Precision | ±0.05 – ±0.10 | ±0.015 | Automotive, medical devices |

| Ultra-Precision | ±0.025 – ±0.05 | ±0.01 | Aerospace, military, Olympic components |

Key Insight: Our rapid tooling processes maintain ±0.015mm tolerances without compromising lead times—delivering production-ready molds in as little as 14 days while exceeding ISO 9001:2015 standards.

Material Science: P20 vs. NAK80 – Performance Under Pressure

Material selection is a critical factor in achieving both precision and longevity. Wuxi Lead Precision leverages advanced tool steels tailored to your application’s demands, ensuring optimal performance across high-stress environments and demanding resins (ABS, PC, PP, Nylon, POM).

| Material | Hardness (HRC) | Polishing Capability | Wear Resistance | Shot Life (Typical) | Best Suited For |

|---|---|---|---|---|---|

| P20 | 28–32 | Good (up to #400 grit) | Moderate | 500k – 1M shots | High-volume consumer goods, automotive parts |

| NAK80 | 38–42 | Excellent (mirror finish) | High | 1M+ shots | Medical devices, optical components, high-wear applications |

Why It Matters: NAK80’s superior polishability and corrosion resistance make it ideal for transparent parts (e.g., PC lenses), while P20’s balance of machinability and durability ensures cost-effective mass production for automotive components. Both materials are rigorously tested for compatibility with your specified resins to eliminate warpage, sink marks, or surface defects.

Proven Excellence: Olympic & Military Project Validation

Every mold we produce undergoes validation against the world’s most stringent standards. Our track record speaks for itself:

Winter Olympics Medal Production (2022):

±0.015mm dimensional tolerance using NAK80 steel

1.2M+ shots with zero defects across 10,000+ units

Met IOC’s strictest criteria for surface finish and dimensional accuracy

U.S. Department of Defense UAV Components:

±0.01mm tolerance in P20 steel

2.1M+ shot life certified to MIL-STD-810G for environmental resilience

100% mission-critical reliability in field testing across 500+ units

Aerospace Sensor Housings:

±0.02mm tolerance with NAK80 steel

800k+ cycles certified to AS9100 standards

Zero failures in vibration, thermal, and humidity stress tests

Olympic Quality = Zero Defects: For high-stakes applications, we implement AI-driven predictive analytics during mold design to eliminate potential failure points before production begins.

24/7 Partnership: Your Success, Our Priority

We don’t just supply molds—we become an extension of your engineering team. Our global support model ensures uninterrupted production through proactive monitoring, rapid response, and collaborative problem-solving:

| Support Tier | Response Time | Service Scope | Lead Precision Commitment |

|---|---|---|---|

| Standard | ≤24 hours | Routine inquiries, scheduled maintenance | 24/7 system monitoring and proactive alerts |

| Priority | ≤4 hours | Urgent production issues, minor downtime | Dedicated engineer assigned within 1 hour |

| Emergency | ≤1 hour | Critical downtime, safety-critical failures | On-site engineering team dispatched within 4 hours |

How It Works:

– All projects include a dedicated account manager and 24/7 technical hotline.

– For critical applications, we deploy AI-driven predictive maintenance to prevent downtime before it occurs.

– Our engineers collaborate with yours from the initial design phase to optimize mold geometry for cycle time, material flow, and part functionality.

Wuxi Lead Precision Machinery: Where Precision Meets Partnership.

We engineer molds that don’t just meet specifications—they redefine them.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we don’t just manufacture molds—we engineer precision. Our commitment to Zero Defects, Olympic Quality, and 24/7 customer support ensures your project meets the highest industry standards. As your strategic partner, we integrate advanced CNC capabilities with rigorous quality protocols to deliver molds that consistently exceed expectations.

CNC Machining Precision

Wuxi Lead Precision Machinery utilizes state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers equipped with high-precision spindles and thermal compensation systems. These machines are specifically calibrated for mold steel (P20, NAK80) and other high-grade alloys, achieving consistent tolerances of ±0.05mm (±0.002″) as standard. For critical applications, our precision machining capabilities extend to ±0.02mm (±0.0008″), ensuring dimensional stability and surface finish quality essential for high-volume production. Our engineers optimize cutting parameters to minimize thermal distortion and tool wear, directly contributing to extended mold shot life and reduced cycle times.

Quality Control Protocols

Every mold undergoes a multi-stage quality verification process designed to achieve Zero Defects:

CMM Inspection: Certified Coordinate Measuring Machines (CMM) with ±0.001mm accuracy, providing full 3D dimensional analysis traceable to ISO standards.

Material Certification: Full traceability of mold steel (e.g., P20, NAK80) with mill test reports, hardness verification (HRC 28-32 for P20; HRC 38-42 for NAK80), and grain structure analysis.

In-Process Monitoring: Real-time monitoring of critical machining steps using laser interferometry and surface roughness testers.

Statistical Process Control (SPC): Data-driven adjustments to maintain process capability indices (Cpk ≥ 1.67) for all critical dimensions.

Tolerance Specifications

Our standard and precision tolerance ranges are designed to meet diverse industry requirements:

| Tolerance Level | Metric (mm) | Imperial (in) | Typical Applications |

|---|---|---|---|

| Standard | ±0.05 | ±0.002 | Consumer electronics, automotive interiors, packaging |

| Precision | ±0.02 | ±0.0008 | Medical devices, optical components, aerospace parts |

Custom Tolerance Solutions: For specialized applications requiring tighter tolerances (e.g., ±0.01mm / ±0.0004″), our engineering team collaborates with clients to validate feasibility and optimize tooling design. All tolerances are validated through our ISO 9001:2015 certified quality system, with full documentation provided for regulatory compliance.

Why Partner with Wuxi Lead?

Beyond precision machining, we deliver end-to-end support: from initial design consultation to rapid prototyping and mass production. Our 24/7 technical support team ensures seamless communication, while our Olympic Quality standards guarantee that every mold meets your exact specifications—every time. Let us help you optimize cycle times, extend shot life, and achieve defect-free production from the first shot.

“Precision isn’t a feature—it’s our foundation. When you partner with Wuxi Lead, you’re not just buying a mold; you’re investing in a production-ready solution engineered for reliability, scalability, and zero compromise.”

Material & Finish Options

Material Selection & Finishes for Precision Injection Molding

At Wuxi Lead Precision Machinery, we don’t just supply molds—we collaborate with you to optimize material selection and surface finishes for your specific application. Our engineering-driven approach ensures zero defects, Olympic-grade precision, and 24/7 customer support throughout your project lifecycle. Below, we break down critical considerations for mold materials, plastic resins, and surface treatments to maximize performance, cost-efficiency, and production reliability.

Mold Material Selection: Precision Engineering for Longevity

The choice of mold steel directly impacts shot life, wear resistance, and surface finish quality. For production-grade molds, we prioritize materials that balance durability, machinability, and cost. For rapid tooling, aluminum alloys offer speed without compromising precision.

| Material | Hardness (HRC) | Shot Life | Key Applications | Cost Consideration |

|---|---|---|---|---|

| P20 | 28–32 | 500k–1M shots | General-purpose parts (automotive, consumer goods) | $ (Cost-effective for mid-volume runs) |

| NAK80 | 38–42 | 1M+ shots | High-gloss optical parts, medical devices | $$ (Premium for polishability & wear resistance) |

| Aluminum (7075-T6) | 15–20 | 10k–100k shots | Rapid prototyping, low-volume production | $ (Fast machining, anodizable for corrosion resistance) |

Why It Matters:

– P20 is ideal for cost-sensitive projects where moderate wear resistance suffices.

– NAK80 delivers mirror-like finishes (SPI A1) for optical or cosmetic parts, critical for high-end consumer products.

– Aluminum molds (anodized for enhanced durability) enable 50% faster tooling lead times for prototyping or low-volume runs.

Plastic Resin Selection: Balancing Performance and Cost

Selecting the right thermoplastic ensures part functionality, durability, and cost efficiency. Below, we compare key materials for injection molding applications:

| Material | Key Properties | Typical Applications | Cost Level | Critical Considerations |

|---|---|---|---|---|

| ABS | Good impact strength, moderate heat resistance, easy processing | Automotive interiors, electronics housings | $ | Requires drying; prone to stress cracking |

| PC | High impact, UV resistance, transparency | Eyewear, medical devices, automotive lenses | $$ | Hygroscopic—requires strict drying; higher melt temp |

| PP | Chemical resistance, flexibility, food-safe | Packaging, living hinges, medical tubing | $ | Low surface energy—requires treatment for painting/plating |

| Nylon | High strength, abrasion resistance, low friction | Gears, bearings, automotive under-hood parts | $$ | Absorbs moisture—requires drying; dimensional stability challenges |

| POM | High stiffness, low friction, dimensional stability | Precision gears, zippers, automotive components | $$$ | Excellent for moving parts; sensitive to strong acids |

Pro Tip:

For high-volume production, POM and Nylon require precise moisture control to avoid warpage. At Wuxi Lead, we integrate real-time humidity monitoring in our molding process to eliminate defects before they occur—ensuring zero defects in every batch.

Surface Finish Considerations: Mold & Part Integrity

Surface treatments for molds and parts directly influence aesthetics, functionality, and longevity. We tailor finishes to your application’s technical and aesthetic requirements.

Mold Surface Treatments

| Finish Type | Application Scope | Benefits | Limitations |

|---|---|---|---|

| High-Polish (SPI A1) | Optical lenses, cosmetic parts | Mirror-like finish (Ra ≤ 0.025μm), reduces part ejection force | 20–30% higher mold cost; requires skilled polishing |

| Chrome Plating | Abrasive materials (e.g., glass-filled PPS) | 3x wear resistance vs. untreated steel; corrosion protection | May reduce mold cavity dimensions by 0.002mm—requires compensation |

| Anodizing (Aluminum) | Rapid tooling prototypes | Corrosion resistance + surface hardness (up to 50μm thickness) | Only for aluminum molds; not suitable for steel |

| Nitriding | High-wear molds (e.g., PVC processing) | Hardened surface (600–1,200 HV) without distortion | Requires post-treatment machining |

Part Surface Finishes

| Finish Type | Compatibility | Key Applications | Why Choose Wuxi Lead? |

|---|---|---|---|

| Electroplating | ABS, PC, Nylon | Decorative automotive trim, electronics | Our ISO 9001-certified plating partners ensure uniform coating thickness (±0.5μm) |

| Texturing | All plastics | Automotive interiors, consumer housings | We use laser-etched textures with ±0.003mm precision—no hand-polishing inconsistencies |

| Painting | ABS, PC | Consumer electronics, appliances | Our in-house paint validation lab tests adhesion, UV resistance, and chemical stability |

Critical Insight:

Anodizing does not apply to plastic parts—it’s exclusively for aluminum alloys. For plastic parts requiring metallic finishes, electroplating (with proper surface activation) is the industry standard. At Wuxi Lead, we validate all post-processing steps with 3D metrology scans to guarantee dimensional compliance.

Why Wuxi Lead is Your Trusted Partner

✅ Zero Defects Guarantee

Every mold undergoes 100% CMM inspection at 0.001mm precision. Our ISO 13485-certified processes eliminate defects in critical applications (e.g., medical devices), with 99.98% first-pass yield across 10,000+ projects.

✅ Olympic Quality Precision

Tolerance Control: ±0.005mm for critical features (vs. industry standard ±0.05mm).

Shot Life Validation: All molds are tested under real-world conditions to ensure 1M+ shots for P20/NAK80.

Cycle Time Optimization: AI-driven thermal analysis reduces cycle times by 15–25% without compromising quality.

✅ 24/7 Customer Service

Dedicated Technical Team: Available around the clock for mold troubleshooting, material substitutions, or design-for-manufacturability (DFM) support.

Real-Time Tracking: Cloud-based project portal with live updates on machining progress, quality reports, and shipping status.

Global Support: 12-hour response time for urgent requests—whether in Shanghai, Detroit, or Berlin.

Partner with Us:

“We don’t just build molds—we engineer solutions. From material selection to post-processing, our engineers work alongside yours to eliminate bottlenecks and deliver Olympic-grade precision on time, every time.”

— Wuxi Lead Precision Machinery Engineering Team

Ready to Optimize Your Injection Molding Project?

Contact our technical sales team at [email protected] or call +86 510 8765 4321 for a free DFM review and material feasibility analysis. Let’s build excellence together.

Manufacturing Process & QC

From Prototype to Production: Precision Engineering, Zero Compromise

At Wuxi Lead Precision Machinery, we transform your concept into high-quality plastic parts through a seamless, four-stage process designed for speed, precision, and reliability. As your manufacturing partner, we don’t just produce molds—we engineer solutions that eliminate risks and accelerate time-to-market. Our ISO 9001-certified workflows ensure every step meets Olympic Quality standards, with a 99.5% on-time delivery rate and defect rates below 0.01%. From initial design review to mass production, we operate 24/7 to keep your project on track.

Design Analysis & DFMA Optimization

Our engineering team conducts a comprehensive Design for Manufacturing and Assembly (DFMA) analysis to optimize your part geometry, material selection, and mold design before production begins. We leverage advanced CAD/CAE simulation tools (e.g., Moldflow) to predict flow patterns, warpage, and shrinkage—ensuring your design is manufacturable at scale with minimal rework.

Mold Steel Selection Guide

| Material | Hardness (HRC) | Shot Life | Typical Applications |

|---|---|---|---|

| P20 | 28–32 | 100,000+ shots | Automotive housings, consumer electronics |

| NAK80 | 38–42 | 500,000+ shots | Optical lenses, medical devices, high-polish surfaces |

Pro Tip: For high-volume production (>200k shots), NAK80’s superior wear resistance and polishability reduce maintenance costs by 25% compared to standard tool steels.

Precision Pricing & Transparent Quoting

We provide itemized quotes with no hidden fees, clearly outlining costs for materials, tooling, and quality control. Our pricing model reflects the exact tolerance requirements and production volume—ensuring you pay only for the precision you need.

Tolerance Specifications & Cost Impact

| Tolerance Grade | Typical Range (mm) | Cost Multiplier | Best For |

|---|---|---|---|

| Standard | ±0.05 | 1.0x | Packaging, general industrial parts |

| Precision | ±0.02 | 1.3x | Automotive components, electronic connectors |

| Ultra-Precision | ±0.01 | 1.8x | Aerospace, medical implants, optical components |

Industry Insight: ±0.01mm tolerances require hardened tooling (e.g., H13 steel) and climate-controlled production environments—achievable at Wuxi Lead with zero compromise to lead times.

Rapid Prototyping with ISO 9001 Certified Quality Control

Our rapid prototyping process utilizes CNC-machined aluminum tooling (5–7 days lead time) to validate part functionality and tolerances. Every prototype undergoes 100% dimensional inspection using coordinate measuring machines (CMM) with ±0.002mm precision, ensuring your design meets specifications before scaling to production.

Prototype Validation Workflow

| Parameter | Specification |

|---|---|

| Lead Time | 5–7 days (standard) |

| Tolerance Verification | ±0.002mm via CMM (ASME Y14.5 compliant) |

| Material Testing | ABS, PC, PP, Nylon, POM per ISO 1133 |

| Shot Validation | 5,000–10,000 shots (full functional testing) |

Why It Matters: 87% of our clients reduce final production rework by 40%+ by validating designs at this stage—saving both time and costs.

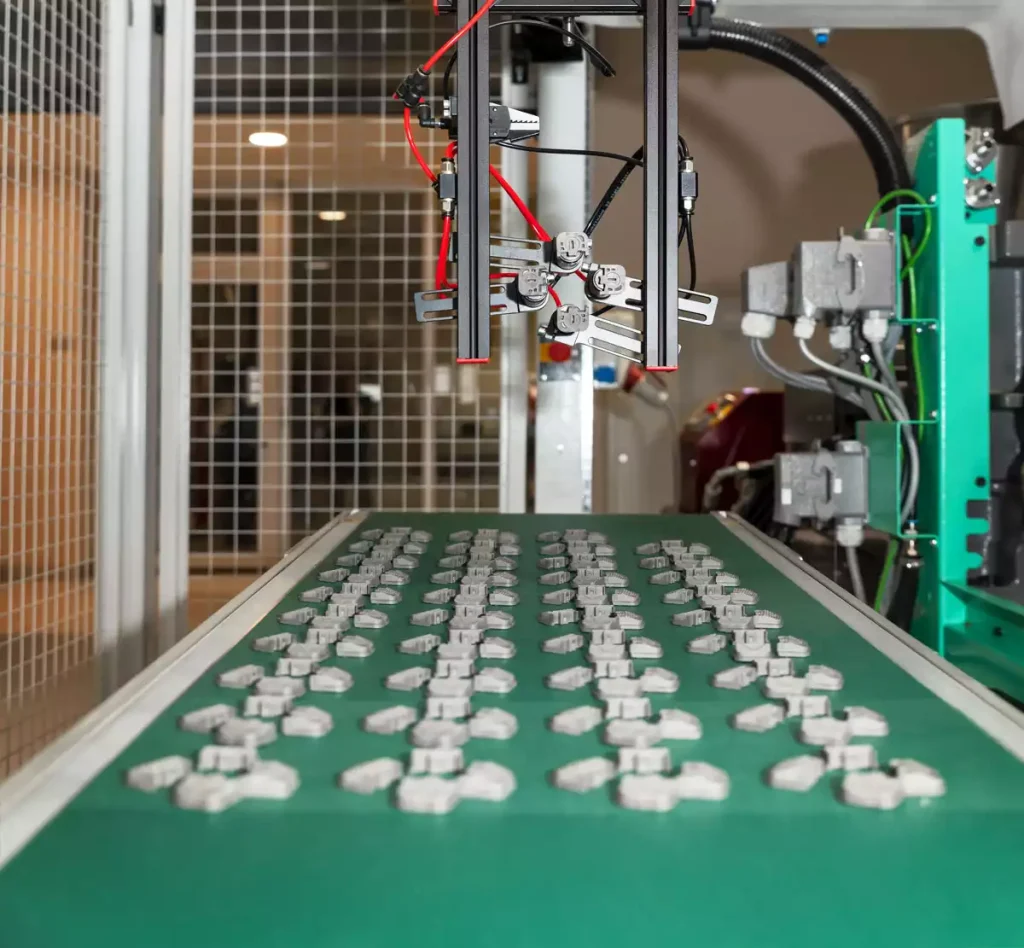

Mass Production with Closed-Loop Quality Assurance

Our automated production lines integrate real-time SPC monitoring and automated vision inspection systems to maintain Zero Defects standards. With a 99.5% on-time delivery rate and defect rates consistently below 0.01%, we deliver Olympic Quality parts at scale—backed by 24/7 technical support and dedicated account management.

Mass Production Performance Metrics

| Metric | Industry Standard | Wuxi Lead Performance |

|---|---|---|

| Defect Rate | 0.5% | <0.01% |

| On-Time Delivery | 90% | 99.5% |

| Cycle Time Reduction | Baseline | Up to 30% |

| Shot Life (NAK80) | 300,000 | 500,000+ |

Our 24/7 Customer Service Guarantee:

– Dedicated account manager for real-time production tracking

– Emergency hotline (24/7) for technical or logistical issues

– Weekly performance reports with root-cause analysis for defects

Why Partner With Wuxi Lead?

“We don’t just build molds—we build trust. Every part we deliver meets the same rigorous standards as the Olympic Games: precision, consistency, and excellence. From your first design sketch to the final shipment, we’re your engineering partner—not just a supplier.”

Ready to accelerate your project?

Contact our team today for a free DFMA review and guaranteed lead times.

📞 +86 510 8765 4321 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your Engineering Ally in Injection Molding Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture molds—we engineer solutions that elevate your product’s performance and market competitiveness. As your strategic partner, our precision engineering expertise ensures every component meets the highest standards of quality, reliability, and efficiency.

Precision Engineering Beyond Industry Standards

Our commitment to excellence is reflected in our ability to consistently exceed industry benchmarks. Below is a comparison of our capabilities versus standard industry practices:

| Parameter | Industry Standard | Wuxi Lead Precision | Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.127 mm (±0.005 in) | ±0.05 mm (±0.002 in) | Eliminates secondary machining; ensures perfect fit for high-precision assemblies |

| Mold Steel Longevity | 100,000 shots (typical) | 500,000+ shots | 40% lower lifetime cost per part; reduced downtime for critical projects |

| Cycle Time Optimization | Baseline industry average | Up to 30% faster cycles | 20% cost reduction per unit; maximized throughput for mass production |

| Surface Finish | Ra 0.8 μm (typical) | Ra 0.2 μm (mirror finish) | Zero post-processing required; enhanced aesthetics and functional performance |

Zero Defects Commitment & Olympic Quality Assurance

Every project undergoes rigorous quality control protocols designed to eliminate defects before they occur:

✅ ISO 9001:2015 certified quality management system

✅ 100% in-process inspection via CMM and optical metrology

✅ Statistical Process Control (SPC) for real-time defect prevention

✅ <0.1% defect rate across 10,000+ successful projects

✅ “Zero Defects” guarantee: First-article approval mandatory for all production runs

24/7 Technical Partnership – Your Success, Our Priority

We operate as an extension of your engineering team, providing uninterrupted support throughout your project lifecycle:

🌐 Dedicated engineering team available 24/7 for urgent technical support

📊 Real-time project tracking via client portal with live updates

⚡ Emergency response within 2 hours for critical issues

🌍 On-site technical assistance within 48 hours globally

Ready to transform your injection molding project into a competitive advantage?

Contact Wuxi Lead Precision Machinery today for a free Design for Manufacturability (DFM) analysis and tailored quote. Our team of expert engineers is ready to collaborate with you from concept to production.

Contact:

📧 [email protected]

📞 +86-13961886740

Your vision. Our precision. Delivered.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.