Technical Contents

Engineering Guide: Injection Mold Quote

Engineering Insight: The Critical Role of Precision in Injection Mold Quoting

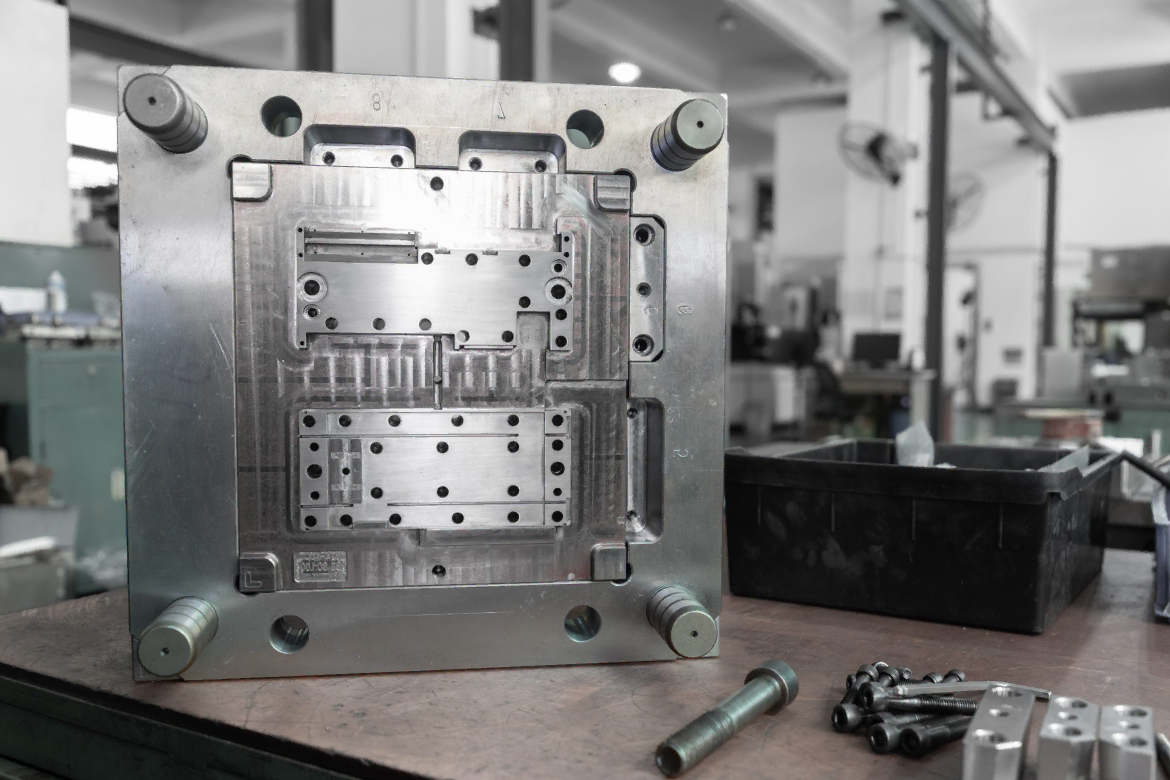

In the realm of custom metal manufacturing, an injection mold quote is far more than a price estimate—it is a technical commitment rooted in precision, material science, and engineering foresight. At Wuxi Lead Precision Machinery, we approach every mold quotation as a foundational step in a high-stakes manufacturing process where dimensional accuracy, thermal stability, and material integrity directly influence final product performance. This level of responsibility demands not only advanced machinery but also deep engineering expertise cultivated through mission-critical applications.

Precision in injection molding begins at the design stage, where tolerances as tight as ±0.002 mm must be consistently achieved across complex geometries. These tolerances are not arbitrary; they ensure proper fit, function, and repeatability in end-use components, especially in sectors such as aerospace, medical devices, and advanced automation. A mold that deviates by even a fraction of a millimeter can result in part warpage, flash, or assembly failure—costly outcomes that ripple through production timelines and quality control. Our quoting process integrates tolerance analysis, mold flow simulation, and material compatibility assessments to preempt these risks before tooling begins.

Wuxi Lead Precision Machinery brings over a decade of experience in delivering molds for applications where failure is not an option. Our engineering team has supported projects aligned with Olympic-standard equipment manufacturing and military-grade component systems, where reliability under extreme conditions is non-negotiable. These experiences have shaped our rigorous approach to mold design and validation, ensuring every quote reflects not just cost, but confidence in performance.

Our facility in Wuxi is equipped with multi-axis CNC machining centers, high-speed EDM systems, and coordinate measuring machines (CMM) that enable sub-micron verification. We utilize premium-grade tool steels such as P20, 718H, and H13, selected based on expected cycle life, corrosion resistance, and thermal conductivity. Surface finishes range from polished mirror finishes (SPI A1) to textured or matte patterns (VT series), all controlled within defined parameters to meet functional and aesthetic requirements.

Below is a summary of our standard technical capabilities for injection mold production:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Mold Base Materials | P20, 718H, H13, S136, NAK80 |

| Surface Finishes | SPI A1–C3, VT-0 to VT-3, EDM textures |

| Maximum Mold Size | 1200 × 800 × 700 mm |

| Expected Cycle Life | 500,000 to 1,000,000+ cycles |

| Lead Time (Standard) | 25–45 days, based on complexity |

| Quality Assurance | Full CMM inspection, first article reporting, mold flow analysis |

An injection mold quote from Wuxi Lead is engineered assurance. It reflects our commitment to precision, backed by proven performance in the most demanding environments. When you request a quote from us, you are not just receiving a price—you are gaining access to a legacy of accuracy, reliability, and industrial excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Injection Mold Excellence

At Wuxi Lead Precision Machinery, our technical capabilities form the bedrock of reliable, high-performance injection mold production. We specialize in transforming complex metal components with uncompromising accuracy, leveraging advanced manufacturing infrastructure and rigorous quality protocols. Our facility integrates cutting-edge 5-axis CNC machining centers, enabling us to execute intricate geometries and tight-tolerance features essential for modern mold cores, cavities, and inserts. This technology eliminates secondary setups, reduces cumulative error, and ensures exceptional surface integrity critical for part ejection and cosmetic finishes. Complex undercuts, deep ribs, and organic contours are machined in a single operation, preserving dimensional continuity and minimizing lead time. All equipment operates under controlled thermal environments with sub-micron repeatability, supported by real-time tool wear compensation and high-pressure coolant systems for optimal chip evacuation and thermal stability.

Quality control is inseparable from our manufacturing process. Every critical feature undergoes comprehensive verification via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), operating under ISO 17025-accredited protocols. Our inspection regime extends beyond dimensional validation to include surface roughness analysis (Ra 0.1 µm achievable), form deviation mapping, and GD&T compliance checks against CAD models. This data-driven approach identifies micro-variances early, preventing costly mold rework or production downtime. We provide full inspection reports with traceable calibration certificates, ensuring transparency and alignment with automotive, medical, and aerospace standards. Our engineers collaborate directly with clients during First Article Inspection (FAI), translating metrology data into actionable insights for design optimization.

The following table outlines typical achievable tolerances for machined mold components under standard production conditions. Actual specifications may vary based on material, geometry complexity, and client requirements, which our team evaluates during the quoting phase to ensure feasibility and cost efficiency.

| Feature Type | Standard Tolerance Range | Precision Capability (Optimized) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | CMM / Optical Comparator |

| Geometric Form (Flatness, Roundness) | ±0.005 mm | ±0.001 mm | CMM / Surface Plate |

| Positional Tolerance | ±0.015 mm | ±0.005 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.1 µm | Profilometer |

| Hole Diameter (Bore) | H7 (±0.007 mm) | H5 (±0.004 mm) | Air Gauge / CMM |

Key: Precision Capability requires pre-agreed process validation and may impact lead time/cost. All tolerances validated per ASME Y14.5.

Our integrated workflow—from digital twin simulation to final CMM certification—ensures molds perform predictably in high-cycle production environments. We prioritize manufacturability analysis during quoting, identifying potential tolerance conflicts or thermal distortion risks before machining begins. This proactive engineering reduces time-to-market and total cost of ownership for your injection molding operations. Partner with Wuxi Lead to convert demanding specifications into flawless, production-ready tooling.

Material & Finish Options

Material Selection for Injection Mold Tooling: Precision Engineering from Wuxi Lead Precision Machinery

Selecting the appropriate material for injection mold tooling is a critical decision that directly impacts mold longevity, production efficiency, and part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to high-demand industrial applications. Our expertise in machining aluminum, steel, and titanium enables us to deliver molds optimized for performance, durability, and cost-efficiency. Each material offers distinct advantages depending on production volume, part complexity, and environmental exposure.

Aluminum is often the preferred choice for low- to medium-volume production runs and rapid prototyping. Its excellent machinability allows for faster mold fabrication, reducing lead times significantly. Additionally, aluminum’s high thermal conductivity promotes uniform cooling, which enhances cycle times and part consistency. While not as wear-resistant as steel, modern high-grade aluminum alloys such as 7075-T6 offer impressive strength and can withstand thousands of cycles when properly maintained.

Steel remains the industry standard for high-volume injection molding due to its superior hardness, wear resistance, and dimensional stability. Tool steels such as P20, H13, and S136 are commonly used based on required polishability, corrosion resistance, and operating temperature. These materials ensure long service life even under continuous production, making steel ideal for complex, high-cavitation molds. At Wuxi Lead, our precision hardening and finishing processes ensure steel molds meet the most stringent tolerances and surface quality standards.

Titanium, while less common in mainstream mold fabrication, offers exceptional strength-to-density ratio and corrosion resistance. It is typically reserved for specialized applications where weight reduction, extreme environmental resistance, or unique mechanical performance is required. Due to its high cost and challenging machinability, titanium is selectively applied in aerospace, medical, or defense-related tooling.

Surface finish plays a pivotal role in mold performance and part ejection. Anodizing is a widely used electrochemical process, particularly for aluminum molds. It enhances surface hardness, improves wear resistance, and provides excellent adhesion for coatings. Type II (sulfuric acid) anodizing delivers a protective oxide layer with aesthetic versatility, while Type III (hardcoat anodizing) produces a thicker, more durable surface capable of withstanding abrasive environments.

Our engineering team at Wuxi Lead Precision Machinery evaluates each project’s technical demands to recommend the optimal material and finish combination. We combine advanced CNC machining with rigorous quality control to ensure every mold meets international standards and client-specific requirements.

Below is a comparative overview of key material properties relevant to injection mold applications.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Applications | Machinability |

|---|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 570 | 130 | Prototypes, low-volume production | Excellent |

| P20 Steel | 28–32 | 900 | 30 | Medium to high-volume molds | Good |

| H13 Steel | 48–52 | 1,600 | 25 | High-temperature, high-wear molds | Moderate |

| Titanium Grade 5 | 36–41 | 900 | 7 | Aerospace, medical, specialty molds | Difficult |

Manufacturing Process & QC

Precision Metal Injection Mold Production: The Zero Defects Pathway

At Wuxi Lead Precision Machinery, our injection mold production process is engineered for uncompromising quality from concept to volume output. We eliminate defects at the source through a disciplined three-phase workflow, ensuring your metal components meet aerospace, medical, and automotive standards without costly rework. This methodology reduces total project risk while accelerating time-to-market.

The Design phase begins with rigorous cross-functional analysis. Our engineers collaborate with your team to deconstruct part geometry, material flow dynamics, and thermal behavior using Siemens NX and Moldflow simulation. Critical factors like gate placement, cooling channel optimization, and stress concentration points are validated before metal cutting commences. We enforce Design for Manufacturability (DFM) protocols to preempt shrinkage, warpage, or ejection failures—addressing 95% of potential defects in virtual space. Only after sign-off on validated simulations and material compatibility reports do we proceed to toolpath generation.

Prototyping transforms digital models into physical proof. Utilizing our HAAS UMC-750 5-axis machining centers, we produce first-article molds in hardened tool steels or specialty alloys under strict environmental controls. Each prototype undergoes 72-hour thermal stability testing and 500-cycle validation runs. Dimensional accuracy is verified via Zeiss CONTURA CMM scans against CAD nominal data, with surface integrity audited per ISO 2768-mK standards. This phase isolates micro-defects invisible in simulation—such as micron-level sink marks or flash formation—allowing iterative refinement before mass production tooling. Client approval requires documented evidence of zero non-conformities across all critical-to-quality (CTQ) parameters.

Mass Production leverages our zero-defect infrastructure for sustained precision. Molds are maintained in climate-controlled cells with real-time pressure/temperature telemetry. Every cycle is monitored via integrated sensors feeding statistical process control (SPC) dashboards, triggering automatic shutdowns if deviations exceed ±0.005mm tolerance thresholds. We implement poka-yoke fixtures and 100% automated optical inspection (AOI) for critical features, ensuring Cpk ≥1.67 across 50,000+ units. All output includes traceable material certificates, first-article inspection reports, and SPC data packs—delivering consistent conformance to your specifications without hidden costs.

Critical Production Specifications

| Parameter | Standard Capability | Premium Capability | Validation Method |

|---|---|---|---|

| Tolerance Range | ±0.01 mm | ±0.005 mm | CMM (ISO 10360-2) |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm | Profilometer (ISO 4287) |

| Material Grades | P20, H13, 420SS | Maraging Steel 18Ni300 | Mill Certificates |

| Cycle Validation | 500 cycles | 2,000 cycles | In-mold pressure sensors |

| Defect Rate Target | ≤50 PPM | ≤10 PPM | SPC (AIAG MSA 4th Ed.) |

This integrated approach transforms quoting from a transactional step into a quality partnership. By front-loading engineering rigor and embedding validation at every stage, we guarantee molds that perform flawlessly in high-volume runs—eliminating scrap, downtime, and supply chain disruptions. Your zero-defect outcome starts with our process discipline, not compromise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Injection Mold Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom-engineered injection molds that meet the exacting standards of global manufacturing industries. As a trusted partner in precision metal manufacturing, we combine advanced CNC machining, expert mold design, and strict quality control to deliver molds that ensure repeatability, durability, and superior part quality. Whether you’re developing automotive components, medical devices, or consumer electronics, our engineering team works closely with yours to translate concepts into fully functional, production-ready molds.

Our facility in Wuxi, China, is equipped with state-of-the-art machinery and staffed by experienced engineers who understand the complexities of injection mold development. From initial design validation and material selection to final inspection and mold testing, we maintain full control over every stage of production. This vertical integration allows us to offer faster turnaround times, tighter tolerances, and greater cost efficiency—without compromising on quality.

We serve clients across Europe, North America, and Asia, supporting both low-volume prototyping and high-volume production runs. Our ISO 9001-certified processes ensure compliance with international standards, while our commitment to continuous improvement keeps us at the forefront of mold-making technology. When you partner with Lead Precision, you gain more than a supplier—you gain a long-term collaborator focused on your success.

Below are key technical specifications that define our injection mold manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Mold Size | 1200 mm × 800 mm × 900 mm |

| Tolerance | ±0.005 mm |

| Surface Finish | SPI A1, A2, B1, B2, VDI 10–20 (polished, textured, coated) |

| Materials | P20, 718, S136, H13, 420 Stainless Steel, Aluminum 7075 |

| Mold Base Standards | DME, LKM, HASCO, or Custom |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 25–45 days |

| Annual Production Capacity | 500+ molds |

| Quality Inspection | CMM, 3D scanning, optical comparators |

Every project begins with a detailed injection mold quote tailored to your design requirements, volume needs, and timeline. We review part geometry, gate placement, cooling channels, ejection systems, and material flow to optimize mold performance and minimize cycle times. Our team provides comprehensive feedback and design-for-manufacturability (DFM) suggestions to reduce costs and prevent defects before tooling begins.

To start your next project with confidence, contact us today at [email protected]. Our engineering and sales team will respond within 12 hours with a detailed quotation, timeline, and technical assessment. Let Wuxi Lead Precision Machinery be your trusted partner in precision injection mold manufacturing—where engineering excellence meets global reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.