Technical Contents

Engineering Guide: Injection Mold Press

Engineering Insight Precision in Injection Mold Press Systems

Precision engineering is non-negotiable in modern injection mold press operations. Micron-level deviations in clamping force, thermal stability, or alignment directly translate to part defects, material waste, and production downtime. In high-volume manufacturing, even 0.01mm variance compromises structural integrity of components used in aerospace, medical devices, or automotive systems. At Wuxi Lead Precision Machinery, we treat precision as a systemic requirement—not an afterthought—integrating metrology-grade calibration at every phase of press design and assembly. Our engineering protocols exceed ISO 2768-mK standards, ensuring repeatability under continuous 24/7 operational stress.

The foundation lies in rigid machine architecture and closed-loop control systems. We utilize finite element analysis (FEA) to eliminate deflection points in tie bars and platens, while dual-toggle mechanisms maintain uniform pressure distribution across the mold surface. Critical to this is thermal management: our hydraulic and electric press platforms regulate barrel and nozzle temperatures within ±0.5°C, preventing viscosity fluctuations that cause sink marks or short shots. Below are core specifications defining our press performance for mission-critical applications.

| Parameter | Range | Precision Standard | Application Impact |

|---|---|---|---|

| Clamping Force | 50–2500 Tons | ±0.3% repeatability | Eliminates flash in micro-featured molds |

| Platen Parallelism | Up to 1200 mm | ≤0.005 mm/m² | Ensures uniform cavity filling |

| Injection Velocity | 5–500 mm/s | ±0.15% consistency | Critical for multi-material overmolding |

| Positioning Accuracy | Full stroke | ±0.002 mm | Enables sub-0.01 mm wall thickness control |

Our validation extends beyond bench testing. Wuxi Lead has engineered press systems for Olympic-certified sports equipment molds requiring zero-defect output under extreme cycle counts. Similarly, military-grade projects demanded compliance with MIL-STD-810G vibration and thermal cycling protocols—proof that our precision withstands the most unforgiving environments. These engagements required real-time SPC (Statistical Process Control) integration, where machine data directly fed into Six Sigma quality frameworks for aerospace suppliers.

For global manufacturers, precision correlates directly with ROI. Our clients report 18–22% reduction in scrap rates and 30% faster qualification cycles when transitioning to Lead Precision presses. This stems from deterministic engineering: every component, from servo valves to platen guide pins, undergoes triple-stage validation against GD&T callouts. When tolerances define market leadership—as in electric vehicle battery housings or surgical instrument molding—our presses deliver the stability to transform design intent into flawless production reality. Partner with us to convert precision from a cost center into your competitive advantage.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-precision injection mold press components, leveraging state-of-the-art technology and rigorous quality control to meet the demanding requirements of global industrial clients. Our technical capabilities are built around a foundation of precision engineering, in-house production control, and deep expertise in custom metal manufacturing. With a focus on complex geometries and tight-tolerance parts, we serve industries including automotive, medical, aerospace, and consumer electronics, where reliability and repeatability are paramount.

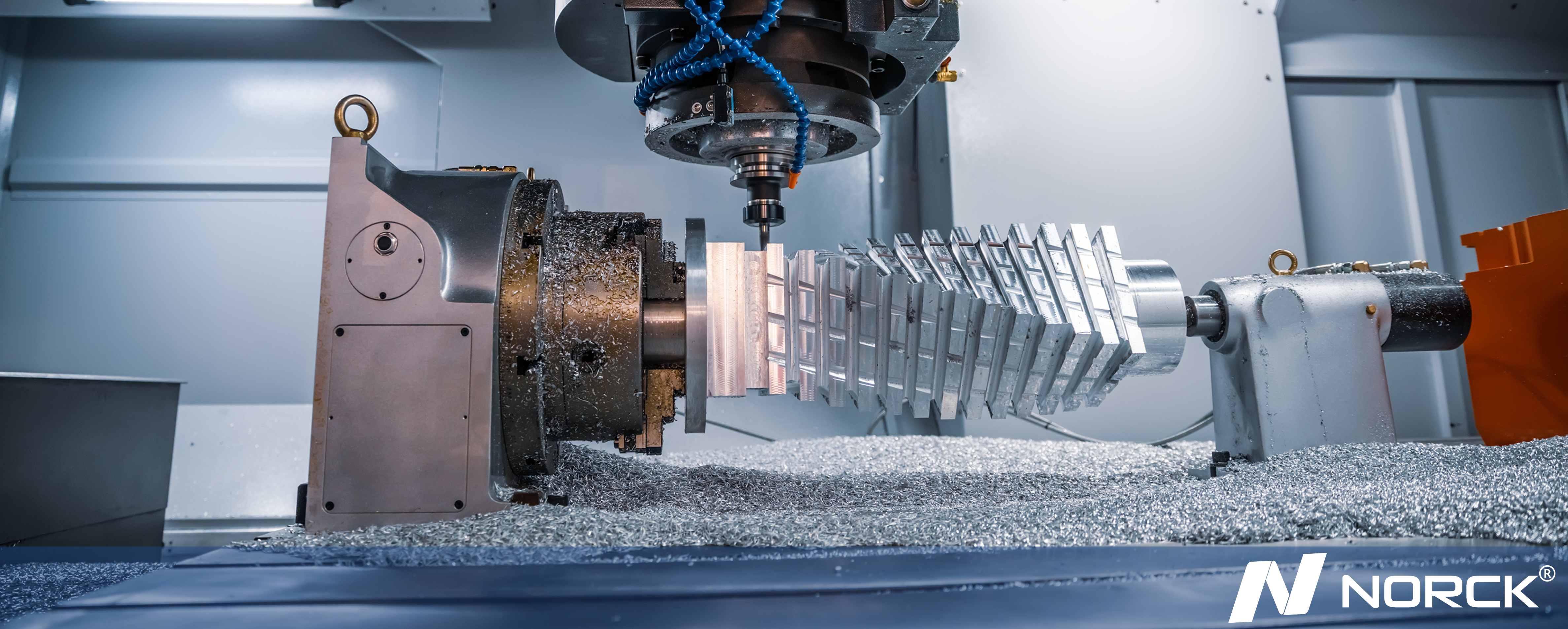

At the core of our production workflow is a comprehensive 5-axis CNC machining platform. This technology enables us to machine intricate mold bases, cavities, cores, and inserts with superior accuracy and surface finish, reducing the need for secondary operations and assembly. The simultaneous movement across five axes allows for optimal tool positioning, minimizing setup changes and enhancing dimensional consistency across high-mix, low-volume, and large-scale production runs. Our machining centers are maintained to OEM standards and operated by certified CNC programmers and machinists with over a decade of experience in mold component manufacturing.

Quality assurance is integrated at every stage of production. All critical components undergo full inspection using a Coordinate Measuring Machine (CMM) to verify geometric accuracy, form, and positional tolerances. Our CMM system is calibrated to ISO 17025 standards and supports first-article inspection reports (FAIR), production part approval protocols (PPAP), and real-time process feedback. In addition to CMM, we employ optical comparators, surface roughness testers, and hardness gauges to ensure compliance with international quality benchmarks.

The following table outlines the standard precision tolerances we consistently achieve across our injection mold press component manufacturing:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm |

| Positional Tolerance | ±0.008 mm | ±0.003 mm |

| Flatness | 0.005 mm per 100 mm | 0.002 mm per 100 mm |

| Roundness | ±0.005 mm | ±0.002 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Tolerance | ±0.001° | ±0.0005° |

These capabilities are supported by advanced CAD/CAM software for simulation and toolpath optimization, ensuring that every component meets or exceeds customer specifications. Our facility in Wuxi is equipped for full-process control—from raw material inspection to final packaging—ensuring traceability and consistency. By combining 5-axis CNC machining with systematic quality verification, Wuxi Lead Precision Machinery provides injection mold press manufacturers with reliable, high-performance metal components engineered for long service life and seamless integration.

Material & Finish Options

Material Selection for High-Performance Injection Mold Press Components

Material choice critically impacts mold longevity, thermal management, production speed, and total cost of ownership in injection molding. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your specific production volume, part complexity, and resin characteristics. Aluminum alloys excel in rapid prototyping and low-volume production due to superior thermal conductivity, enabling faster cycle times. However, their lower hardness limits use in abrasive or high-wear applications. Tool steels like P20 or H13 remain the industry standard for high-volume runs, offering exceptional wear resistance, polishability, and structural stability under prolonged thermal cycling. Titanium alloys present a niche solution for highly corrosive resin environments or ultra-lightweight mold requirements, though higher costs and machining complexity necessitate careful justification.

The following table summarizes key mechanical and thermal properties for common mold materials:

| Material | Thermal Conductivity (W/m·K) | Hardness (HRC) | Typical Applications | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061-T6 | 167 | 30-35 | Prototypes, low-volume production | Low |

| P20 Tool Steel | 28-36 | 28-32 | Medium to high-volume production | Medium |

| H13 Tool Steel | 24-29 | 48-52 | High-wear cores, cavities, hot runners | High |

| Ti-6Al-4V | 6.7 | 36-41 | Corrosive resin molds, aerospace parts | Very High |

Surface finishing, particularly anodizing, significantly enhances aluminum mold performance. Type II (sulfuric acid) anodizing provides moderate corrosion resistance and dye receptivity for identification, forming a porous 5-25μm layer. For demanding applications, Type III (hardcoat) anodizing creates a dense, wear-resistant oxide layer of 25-100μm thickness, dramatically improving surface hardness to 60-70 HRC and extending mold life in abrasive polymer processing. Steel molds benefit from nitriding or PVD coatings for similar wear protection, though anodizing remains exclusive to aluminum substrates.

Selecting the optimal material-finishing combination requires balancing thermal response, mechanical durability, and economic factors. Aluminum with hardcoat anodizing bridges the gap between prototyping speed and production durability for mid-volume runs. Steel molds with precision polishing or specialized coatings deliver maximum longevity for million-plus shot sequences. Our engineering team conducts comprehensive material lifecycle analysis, evaluating resin abrasiveness, cycle time targets, and total part cost to prescribe the most efficient solution. Partner with Wuxi Lead to transform material science into measurable production gains—contact our applications engineers for a project-specific evaluation.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the foundation of every successful injection mold press project begins with rigorous design engineering. Our team of senior mold designers utilizes advanced CAD/CAM software—such as UG NX, SolidWorks, and AutoCAD—to develop fully optimized mold structures tailored to the client’s component geometry, material properties, and production volume. Thermal analysis, flow simulation, and structural stress modeling are integrated into the design phase to anticipate potential defects such as warpage, sink marks, or incomplete filling. This proactive approach ensures that mold cavities, cooling channels, ejection systems, and gating are engineered for maximum efficiency and longevity. Each design undergoes internal peer review and is validated through Design for Manufacturability (DFM) analysis, minimizing risk before any metal is cut.

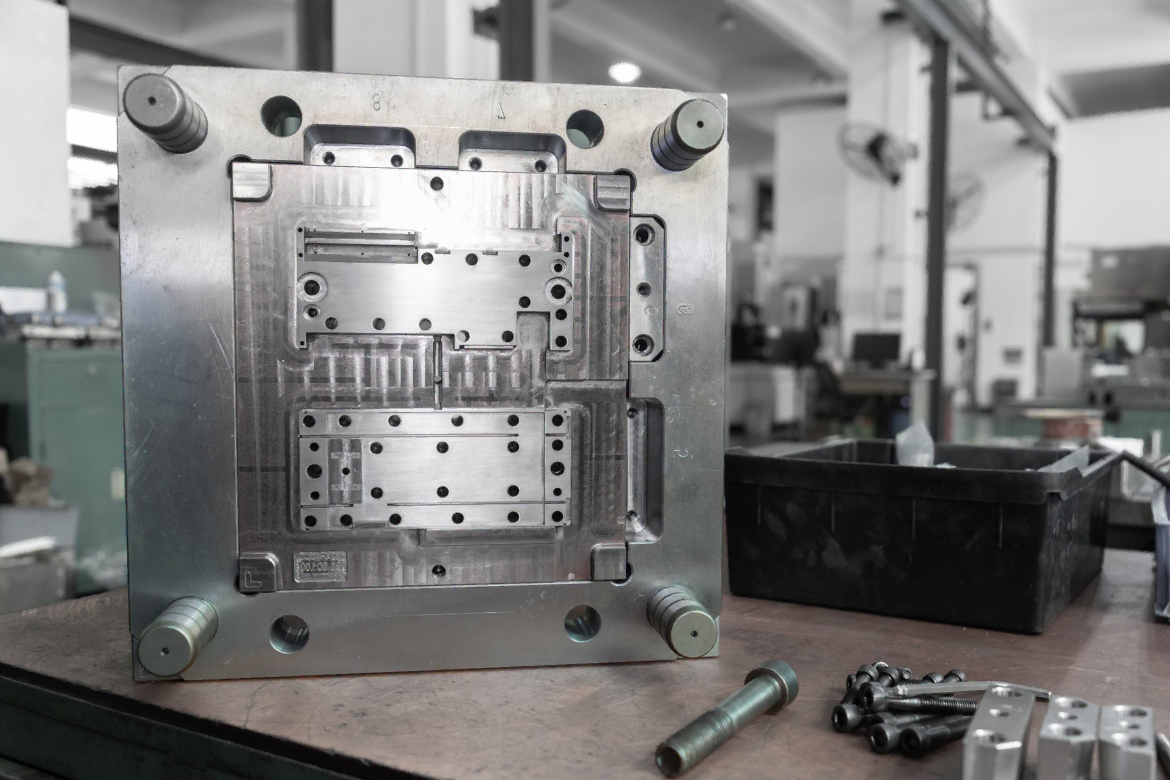

Prototyping: Validating Performance Before Scale

Once the digital model is approved, we proceed to prototype tooling using high-precision CNC machining, wire EDM, and surface grinding technologies. The prototype mold is built from pre-hardened tool steel or aluminum, depending on the required durability and testing scope. This stage enables functional validation under real injection conditions using the client’s specified resin. We conduct trial runs on our in-house hydraulic and electric injection molding machines, collecting critical data on cycle time, part dimensional accuracy, surface finish, and gate vestige. Any deviations are analyzed using CMM (Coordinate Measuring Machine) and 3D scanning, and design or process adjustments are implemented immediately. The goal is not just to produce a prototype part, but to simulate mass production conditions and confirm zero-defect capability at the earliest stage.

Mass Production: Consistency Through Control

With prototype approval, we transition to full-scale production using hardened P20, 718H, or H13 tool steels for long-life molds capable of exceeding 1 million cycles. Each production mold is manufactured under strict ISO 9001-compliant procedures, with full traceability of materials and machining parameters. Our automated production lines integrate robotic part removal, real-time pressure and temperature monitoring, and in-process SPC (Statistical Process Control) to maintain consistent quality. Every molded component undergoes 100% visual inspection and batch-level dimensional verification. We employ a closed-loop feedback system where any out-of-spec condition triggers immediate process correction, ensuring zero-defect delivery across the entire production run.

Technical Specifications Overview

| Parameter | Specification |

|---|---|

| Mold Base Material | LKM Standard, P20, 718H, H13, S136 |

| Tolerance (Mold Cavity) | ±0.005 mm |

| Surface Finish | SPI #A1, #B2, #C3, or customer specification |

| Gate Types | Hot Runner (Mold-Masters, Yudo), Cold Runner |

| Machine Tonnage Range | 50–2000 tons |

| Production Capacity | Up to 500,000 pcs/month per mold |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–55 days |

| Quality Standards | ISO 9001:2015, PPAP, FAIR Reports |

Through disciplined execution across design, prototyping, and production, Wuxi Lead Precision Machinery delivers injection mold press solutions where precision, reliability, and zero-defect performance are engineered into every phase.

Why Choose Wuxi Lead Precision

Elevate Your Injection Molding Precision with Lead Precision Engineering

Selecting the right partner for custom metal manufacturing in injection mold press production demands more than standard equipment supply. It requires an engineering collaborator who understands the critical interplay between structural integrity, thermal management, and micron-level tolerance stability under high-cycle production demands. At Wuxi Lead Precision Machinery, we engineer bespoke press solutions where material science, dynamic load analysis, and precision machining converge to deliver unmatched repeatability and longevity. Our ISO 9001-certified facility in Wuxi integrates European-grade CNC machining centers with stringent metallurgical protocols, ensuring every platen, tie bar, and hydraulic manifold exceeds OEM specifications for wear resistance and dimensional accuracy. This commitment translates directly to your operational bottom line: reduced downtime, minimized scrap rates, and consistent part quality across millions of cycles.

Our engineering team collaborates from initial concept through final validation, utilizing FEA simulation to optimize stress distribution and thermal deformation in your specific application. Whether you require high-tonnage hydraulic systems for automotive components or ultra-precise all-electric presses for medical devices, we tailor material selection, surface treatments, and control integration to your exact performance criteria. The table below outlines core specifications where our precision manufacturing delivers measurable advantages:

| Parameter | Specification | Application Impact |

|---|---|---|

| Clamping Force | 500–6,500 Tons (±0.5% accuracy) | Eliminates flash in complex geometries; ensures uniform cavity pressure |

| Platen Flatness | ≤ 0.02 mm/m² (ground & lapped) | Prevents mold misalignment; extends seal life |

| Tie Bar Parallelism | ≤ 0.015 mm/m | Reduces uneven wear; maintains consistent tonnage |

| Shot Weight | ±0.1% repeatability | Critical for medical/optical part consistency |

| Hydraulic Response | ≤ 35 ms valve reaction time | Enables micro-adjustments for thin-wall molding |

Beyond component excellence, we provide lifecycle partnership through our global technical support network. Our engineers conduct on-site press calibration, operator training, and predictive maintenance planning—transforming reactive repairs into proactive uptime optimization. We understand that mold press failures cascade through your production line; our rapid-response protocol guarantees 24-hour engineering consultation for critical failures, minimizing line stoppages. This operational certainty is why Tier 1 automotive suppliers and medical device manufacturers trust Lead Precision for mission-critical press systems.

Do not compromise on the foundation of your molding operation. Partner with an engineering team that treats your production targets as our own technical challenge. Contact our precision engineering division today to discuss how custom-engineered solutions can enhance your press performance metrics. Reach out to our technical sales team at [email protected] for a confidential capability review and ROI analysis specific to your manufacturing environment. Let us demonstrate why global leaders in high-integrity molding specify Lead Precision as their metal manufacturing partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.