Technical Contents

Engineering Guide: Injectino Molding

Engineering Insight: Precision in Injection Molding

In high-end custom metal manufacturing, injection molding is not merely a production method—it is a precision engineering discipline. At Wuxi Lead Precision Machinery, we define excellence in injection molding through micron-level accuracy, repeatable consistency, and material integrity. This level of control is not accidental; it is the result of decades of refinement, advanced tooling design, and a deep understanding of material behavior under extreme conditions.

Precision in injection molding begins with mold design. The geometry of the mold cavity, gate placement, cooling channels, and ejection system must all be optimized to ensure uniform filling, minimal warpage, and consistent part quality. Even minor deviations—measured in microns—can result in functional failures, especially in mission-critical applications. At Lead Precision, our engineering team employs finite element analysis (FEA) and mold flow simulation to predict and correct potential defects before tooling is ever cut.

Our experience in serving Olympic-grade sports equipment manufacturers and military defense contractors has sharpened our focus on reliability under stress. Components used in high-impact athletic gear or battlefield systems demand not only dimensional accuracy but also mechanical resilience. We achieve this through tightly controlled process parameters, including injection pressure, temperature profiles, and hold time, all monitored and adjusted via closed-loop control systems.

Material selection further defines the performance envelope. Whether working with high-strength aluminum alloys, stainless steel, or specialized composites, we ensure that the chosen material meets exact thermal, structural, and corrosion resistance requirements. Each batch is traceable, and every production run undergoes rigorous in-process inspection using coordinate measuring machines (CMM) and optical comparators.

The integration of automation and real-time quality assurance ensures that every component leaving our facility meets the same exacting standard. This is not mass production—it is precision manufacturing at scale.

Below are key performance specifications achieved through our injection molding process:

| Parameter | Specification | Testing Method |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm | CMM Inspection |

| Surface Finish | Ra 0.8 µm (standard) | Profilometer |

| Material Utilization Efficiency | >95% | Process Audit |

| Cycle Time Consistency | ±1.5% variation | PLC Monitoring |

| First-Pass Yield Rate | ≥98.5% | SPC Tracking |

| Tool Life | 500,000+ cycles (average) | Preventive Maintenance Logs |

At Wuxi Lead Precision Machinery, we treat every injection molding project as an engineering challenge. Our clients in aerospace, defense, and elite sports rely on us because they demand zero compromise. When failure is not an option, precision is not a goal—it is the baseline.

Precision Specs & Tolerances

Precision Metal Manufacturing Capabilities for Critical Components

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom metal part production through integrated advanced machining and metrology systems. Our core strength lies in transforming complex geometries into high-integrity components for aerospace, medical, and energy sectors where failure is not an option. Unlike plastic injection molding processes, our expertise centers on subtractive metal manufacturing using hardened alloys, titanium, and specialty materials requiring micron-level precision. This approach ensures structural integrity and thermal stability unattainable with polymer-based molding.

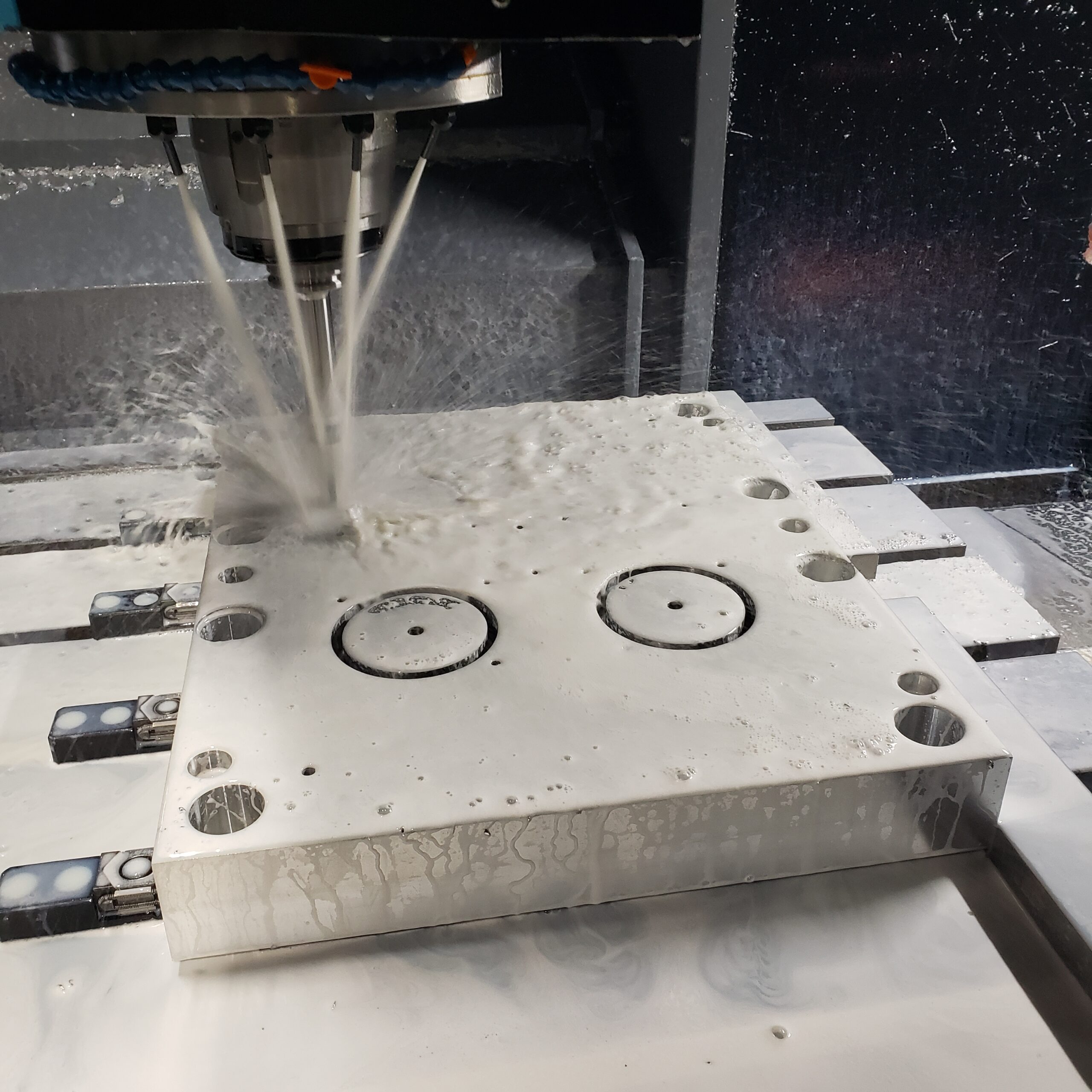

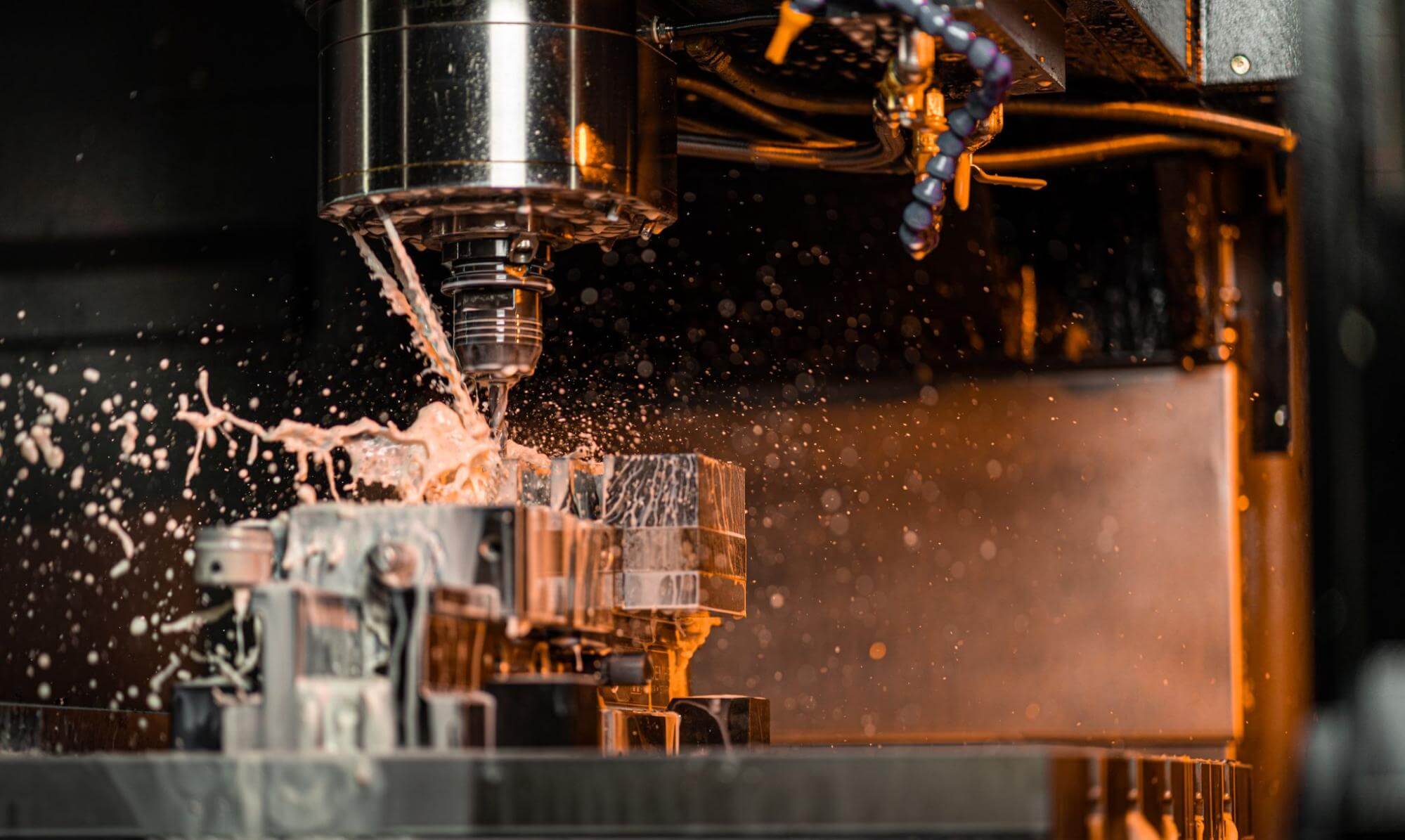

Our 5-axis CNC machining centers form the backbone of this capability, enabling single-setup production of intricate features. Simultaneous multi-axis movement eliminates manual repositioning errors while machining undercuts, helical contours, and organic shapes. High-torque spindles maintain rigidity during deep cavity milling of Inconel or tool steel, and thermal compensation systems counteract environmental drift. This results in geometrically perfect parts with consistent surface finishes down to Ra 0.4 μm, critical for hydraulic seals or turbine blade interfaces. Each machine undergoes daily laser calibration per ISO 230-2 standards, ensuring volumetric accuracy across the full 1,200 x 800 x 750 mm work envelope.

Quality verification is non-negotiable. Every critical dimension undergoes validation via Zeiss CONTURA G3 coordinate measuring machines (CMM) with 0.5 μm volumetric accuracy. Our inspection protocol follows ISO 10360-2 standards, utilizing calibrated ruby probes and temperature-controlled environments (20±0.5°C). Statistical process control (SPC) data is embedded in first-article reports, tracking capability indices (Cp/Cpk) for features like concentricity or profile tolerances. This closed-loop system allows real-time tool wear compensation, reducing scrap rates by 32% compared to conventional QC methods.

Tolerance performance is rigorously maintained across production runs as shown below:

| Parameter | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM with 0.5 μm probe |

| Angular Features | ±0.005° | ±0.002° | Optical comparator |

| Surface Finish | Ra 0.8 μm | Ra 0.4 μm | Profilometer (ISO 4288) |

| Positional Accuracy | ±0.008 mm | ±0.003 mm | CMM with iterative alignment |

| Flatness | 0.010 mm/m | 0.005 mm/m | Granite surface plate |

This technical foundation supports mission-critical applications: fuel injector nozzles requiring 5 μm hole straightness, orthopedic implant threads with 2 μm pitch deviation limits, or satellite bracket assemblies demanding 0.001° angular repeatability. Our engineers collaborate from DFM stage to final inspection, applying GD&T expertise to translate your functional requirements into machinable realities. By controlling the entire metal manufacturing chain—from billet to certified component—we eliminate supply chain variables that compromise precision in outsourced processes. For projects where metallurgical integrity and micron-level conformity define success, Wuxi Lead provides the technical authority to execute.

Material & Finish Options

Material Selection in Precision Injection Molding: Aluminum, Steel, and Titanium

In high-performance custom metal manufacturing, material selection directly influences the durability, precision, and functionality of injection molding tools and components. At Wuxi Lead Precision Machinery, we specialize in advanced CNC-machined metal solutions tailored for demanding injection molding applications. The choice between aluminum, steel, and titanium involves evaluating mechanical properties, thermal performance, and lifecycle cost. Each material offers distinct advantages depending on production volume, part complexity, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061-T6, are widely used for prototype molds and low-to-medium volume production. Their high thermal conductivity ensures rapid cooling cycles, improving throughput during injection molding. Aluminum is also significantly lighter than steel or titanium, reducing handling stress and enabling faster mold changes. While less wear-resistant than steel, modern surface treatments such as hard anodizing enhance aluminum’s surface hardness and corrosion resistance, extending mold life in aggressive polymer environments.

Tool steels, including P20, H13, and S136, remain the standard for high-volume injection molding. These steels offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. P20 is commonly used for molds requiring good machinability and moderate durability, while H13 excels in applications involving high thermal stress due to its excellent hot hardness. Stainless variants like S136 provide enhanced corrosion resistance, ideal for molding halogenated or acidic resins. Steel molds typically require longer lead times and higher initial costs but deliver extended service life, often exceeding hundreds of thousands of cycles.

Titanium, specifically Grade 5 (Ti-6Al-4V), is emerging in specialized molding applications where extreme strength-to-density ratios and corrosion resistance are critical. Though rarely used for full mold bases due to cost and machinability challenges, titanium is ideal for precision inserts, cores, and ejector components exposed to aggressive chemicals or high stress. Its biocompatibility also makes it suitable for medical-grade molding systems.

Surface finishing, particularly anodizing, plays a crucial role in enhancing performance. Hard anodizing (Type III) increases surface hardness of aluminum up to 60 HRC, improves wear resistance, and provides excellent electrical insulation. The porous oxide layer can also be sealed with PTFE or other lubricants to reduce friction and part sticking during demolding.

Below is a comparative overview of key material properties relevant to injection molding applications.

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Use Case | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 150 | 130 | Prototype & low-volume molds | Yes (Hard Anodize) |

| P20 Steel | 950 | 280 | 30 | Medium to high-volume production | No |

| H13 Steel | 1550 | 230 | 35 | High-temperature molding | No |

| Ti-6Al-4V | 900 | 340 | 7 | Corrosion-resistant inserts/cores | Limited |

Material selection must align with production goals, resin type, and expected mold life. Wuxi Lead Precision Machinery supports clients in optimizing these decisions with precision engineering and advanced finishing capabilities.

Manufacturing Process & QC

Precision Metal Injection Molding: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our Metal Injection Molding (MIM) process transforms complex metal component designs into high-volume, zero-defect reality. Unlike conventional plastic injection molding, MIM fuses powder metallurgy with polymer processing to achieve near-net-shape parts with exceptional strength and detail. Our rigorously controlled workflow—Design, Prototyping, Mass Production—ensures metallurgical integrity and dimensional accuracy from the first prototype to the millionth part.

The Design phase begins with collaborative engineering. Our team conducts in-depth Design for Manufacturability (DFM) analysis, optimizing geometry for material flow, shrinkage compensation, and ejection. Finite Element Analysis (FEA) simulates thermal behavior and stress distribution, identifying potential defects like sink marks or porosity before tooling begins. Critical tolerances are validated against ISO 2768-mK standards, ensuring the design aligns with MIM’s capabilities for intricate features down to 0.005mm. Material selection—stainless steel (17-4PH, 316L), titanium, or specialty alloys—is matched to end-use requirements for corrosion resistance, strength, and biocompatibility.

Prototyping leverages rapid tooling and iterative validation. Initial runs on hardened steel molds produce functional prototypes within 15 days. Each part undergoes rigorous metrology: CMM scans verify geometric accuracy against CAD models, while destructive testing confirms density (>98% theoretical), tensile strength, and microstructure. Dimensional stability is cross-checked after sintering shrinkage. Only when prototypes meet all specifications—dimensional, mechanical, and surface finish—does the project advance. This phase eliminates 95% of latent design flaws, preventing costly rework in production.

Mass Production operates under a closed-loop quality management system. Real-time cavity pressure monitoring and automated vision inspection detect deviations at 0.001mm resolution. Statistical Process Control (SPC) tracks critical parameters—feedstock viscosity, injection speed, sintering temperature—ensuring ±0.3% consistency. Every batch includes traceable material certificates and in-process audits per ISO 9001:2015. Our zero-defect commitment is enforced through automated part rejection and root-cause analysis for any anomaly, guaranteeing 100% conformance to aerospace (AS9100) and medical (ISO 13485) standards.

Key MIM Process Specifications

| Parameter | Capability Range | Industry Standard | Lead Precision Advantage |

|——————–|————————|——————-|————————–|

| Tolerance | ±0.005mm to ±0.05mm | ±0.1mm | 50% tighter control |

| Feature Size | 0.1mm min. wall | 0.5mm | Micro-geometry expertise |

| Material Density | >98% theoretical | 95-97% | Enhanced mechanical properties |

| Production Volume | 10,000 to 1M+ units | Varies | Scalable automation |

| Lead Time (Proto) | 10-15 days | 20-30 days | Accelerated validation |

This integrated approach—grounded in predictive engineering, empirical validation, and relentless process discipline—delivers mission-critical metal components with uncompromised reliability. Partner with Wuxi Lead to convert ambitious designs into defect-free production, where precision isn’t aspirational but engineered.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Injection Molding Solutions in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components engineered for performance, durability, and consistency. As a trusted partner in advanced manufacturing, we combine cutting-edge injection molding technology with decades of metallurgical expertise to serve industries where precision is non-negotiable—automotive, aerospace, medical devices, and industrial automation.

Our injection molding process is not conventional plastic molding. We utilize Metal Injection Molding (MIM), a sophisticated technique that enables the production of complex, net-shape metal parts with exceptional dimensional accuracy and mechanical properties. This process is ideal for high-volume production of small to medium-sized components that require intricate geometries unachievable through traditional machining or casting.

When you partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem. From initial design consultation and material selection to prototyping, tooling, and full-scale production, our engineering team works closely with clients to optimize part performance and manufacturability. We use premium-grade metal powders—including stainless steels, low-alloy steels, and specialty alloys—ensuring each component meets stringent international quality standards.

Our facility in Wuxi is equipped with state-of-the-art MIM presses, debinding systems, and high-temperature sintering furnaces, all monitored under strict process controls. Every batch undergoes rigorous quality inspection using advanced metrology tools such as CMMs, optical comparators, and metallurgical testing equipment, guaranteeing consistency and compliance with ISO 9001 and IATF 16949 standards.

We understand that in high-end manufacturing, specifications matter. Below are key technical capabilities of our Metal Injection Molding process:

| Parameter | Specification |

|---|---|

| Weight Range | 0.1 g – 200 g |

| Dimensional Tolerance | ±0.3% to ±0.5% (typical) |

| Surface Finish | Ra 0.8 – 3.2 µm |

| Material Options | 17-4 PH, 316L, 304L, 15-5 PH, Fe-2Ni, Ti-6Al-4V |

| Production Capacity | Up to 10 million parts per month |

| Secondary Operations | CNC Machining, Heat Treatment, Plating, Laser Marking |

| Quality Standards | ISO 9001, IATF 16949, RoHS Compliant |

Whether you are developing a new product or seeking to optimize an existing component for cost and performance, Wuxi Lead Precision Machinery offers the technical depth and manufacturing agility to bring your vision to life. Our engineers are ready to collaborate on design for manufacturability, material selection, and rapid prototyping to accelerate your time to market.

Contact us today at [email protected] to discuss your next project. Let Lead Precision be your strategic partner in high-performance metal injection molding—where precision meets innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.