Technical Contents

Engineering Guide: Industrial Moulding

Engineering Insight Industrial Moulding Precision as Non-Negotiable Foundation

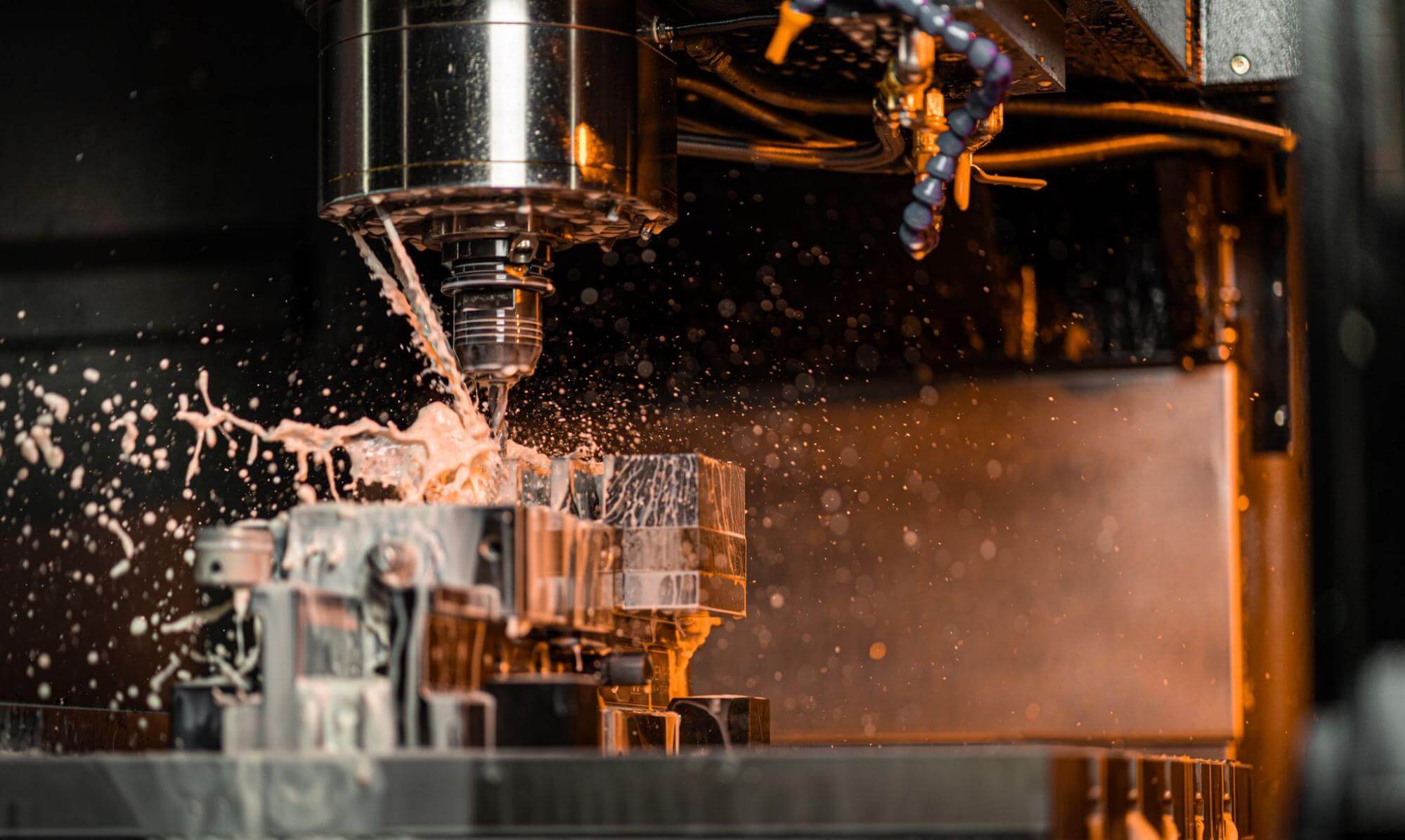

Industrial moulding transcends basic component formation. In high-stakes sectors like aerospace, defense, and elite sports infrastructure, it represents the critical convergence of material science, thermal dynamics, and micron-level geometric control. Precision here is not merely a quality metric; it is the absolute prerequisite for functionality, safety, and longevity. A deviation of mere microns can cascade into catastrophic system failure under operational stress or extreme environmental conditions. This demands moulding processes engineered beyond standard commercial tolerances, where repeatability under sustained production cycles is as vital as the initial dimensional accuracy. The integrity of the final assembly – whether a fighter jet hydraulic manifold or an Olympic timing sensor housing – hinges entirely on the fidelity achieved during the moulding phase.

Wuxi Lead Precision Machinery operates at this uncompromising tier. Our engineering heritage is defined by projects where failure is inconceivable. We engineered critical titanium and high-strength alloy components for the Beijing 2022 Winter Olympics timing systems, requiring sub-5μm positional tolerances to ensure microsecond accuracy across frigid alpine environments. Similarly, our work for Tier-1 defense contractors involves moulding complex structural brackets and fluid control units subjected to MIL-STD-810G vibration and thermal shock profiles. These engagements are not endorsements; they are rigorous validations of our process discipline. They necessitate closed-loop metrology integrated directly into the moulding cell, real-time thermal compensation algorithms, and material traceability down to the individual heat lot. This level of control ensures that every cavity, every cycle, meets the exacting demands of mission-critical applications.

Our capability stems from deep integration of advanced simulation, proprietary toolpath optimization, and relentless process validation. We treat the mould itself as a precision instrument, employing hardened tool steels with PVD coatings and multi-axis grinding to achieve cavity geometries holding true within 2μm over extended production runs. Material behavior prediction through finite element analysis (FEA) is standard practice, mitigating warpage and residual stress before the first shot. This proactive engineering approach, forged in the crucible of Olympic and military requirements, delivers consistent output where others face scrap and rework.

The table below outlines core precision capabilities underpinning our industrial moulding solutions for demanding sectors.

| Parameter | Capability Range | Measurement Standard | Typical Application Context |

|---|---|---|---|

| Geometric Tolerance | ±0.002mm to ±0.005mm | ISO 2768-fine | Aerospace actuators Military sensors |

| Surface Finish (Ra) | 0.2μm to 0.8μm | ISO 1302 | Fluidic manifolds Optical mounts |

| Material Range | Aluminum 7075-T73 to Inconel 718 | AMS/ASTM Specs | High-temp structural components |

| Production Volume | 1 to 50,000+ units | PPAP Level 3 | Prototypes to full-rate production |

| In-Process Metrology | On-machine probing CMM validation | AS9100D compliant | Zero-defect critical paths |

Precision industrial moulding is the bedrock upon which reliability is built. For Wuxi Lead Precision Machinery, it is the singular focus validated by the world’s most demanding applications. We deliver not just parts, but guaranteed performance, ensuring your systems operate flawlessly when it matters most. Partner with engineered certainty.

Precision Specs & Tolerances

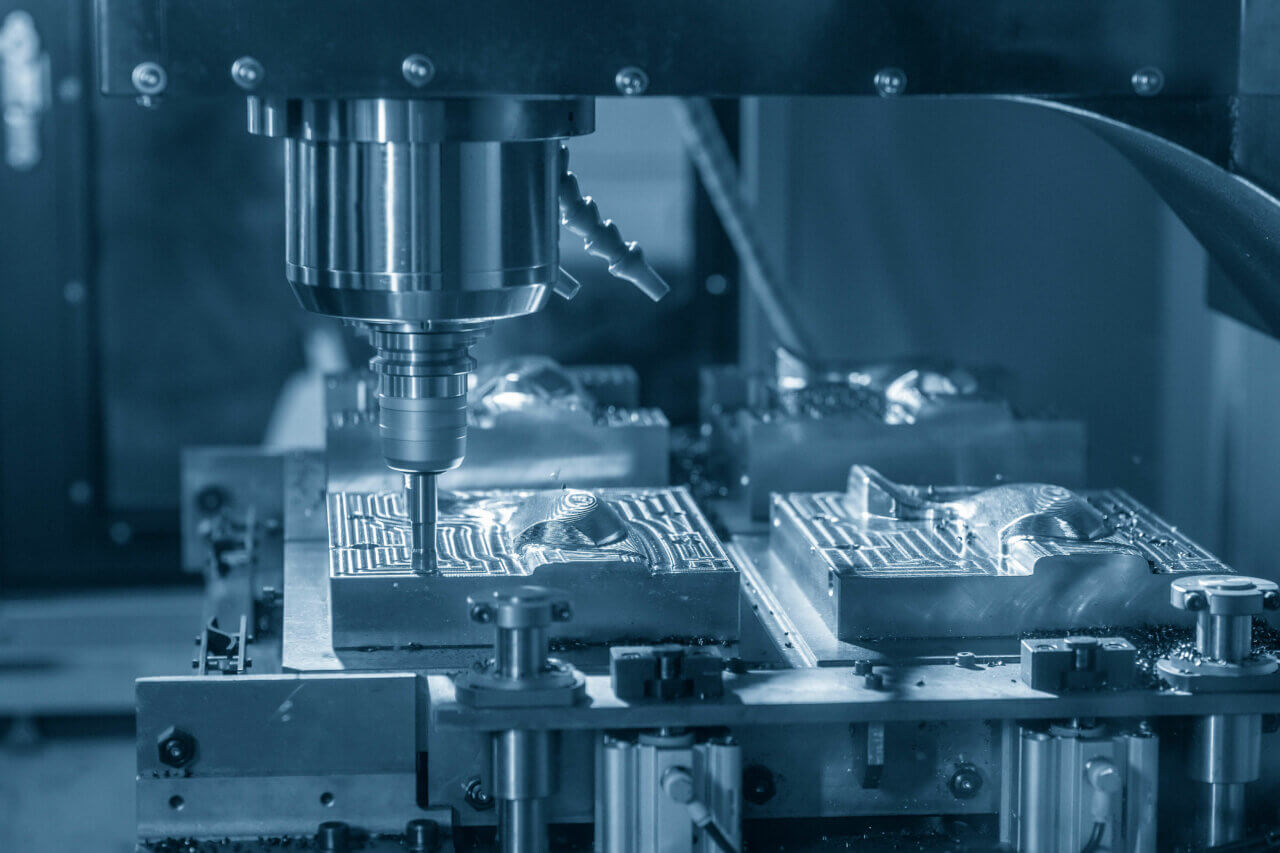

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision industrial moulding solutions for demanding global industries. At the core of our production infrastructure is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional accuracy and surface integrity. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring intricate features that would be unattainable with conventional 3-axis technology. This capability is essential for manufacturing mould components with deep cavities, undercuts, and organic forms commonly found in automotive, aerospace, medical, and energy applications.

Our 5-axis CNC centers are operated by certified machinists with extensive experience in high-tolerance metal fabrication. Each machine is maintained to OEM specifications and equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems. This ensures consistent cycle times, superior part finish, and long-term repeatability across both prototyping and high-volume production runs. Materials processed include hardened steels, aluminum alloys, titanium, stainless steel, and high-performance alloys such as Inconel, all machined in-house under controlled environmental conditions.

Quality assurance is embedded at every stage of production. All critical components undergo comprehensive inspection using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), which provides metrology-grade verification of dimensional accuracy. The CMM system utilizes tactile probing technology with sub-micron resolution, enabling full GD&T analysis, surface profile evaluation, and first-article inspection reports compliant with ISO 10360 standards. Inspection data is documented and archived for full traceability, supporting AS9100 and IATF 16949 quality requirements.

In addition to CMM validation, our quality protocol includes in-process checks, hardness testing, surface roughness measurement, and visual inspection under magnification. This multi-layered approach ensures that every mould component meets or exceeds client specifications before shipment.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.01 mm | ±0.005 mm | Up to 500 mm length |

| Geometric Tolerance (GD&T) | ±0.015 mm | ±0.008 mm | Includes flatness, concentricity, etc. |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Achieved via fine finishing passes |

| Hole Position Accuracy | ±0.01 mm | ±0.005 mm | Verified by CMM |

| Angular Accuracy | ±0.05° | ±0.02° | Critical for multi-face alignment |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom upon request | Based on current machine capacity |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC machining with rigorous quality control to deliver industrial moulding components that meet the highest standards of precision and reliability.

Material & Finish Options

Material Selection for Industrial Moulding: Precision Engineering Fundamentals

Selecting the optimal material for industrial moulding applications is a critical engineering decision directly impacting component performance, tool life, production efficiency, and final part cost. At Wuxi Lead Precision Machinery, our decades of experience in custom metal manufacturing underscore that material choice must align precisely with functional requirements, environmental exposure, and manufacturing constraints. This guide outlines key considerations for Aluminum, Steel, and Titanium alloys, alongside essential insights on Anodizing finishes.

Aluminum Alloys offer an exceptional strength-to-weight ratio and superior thermal conductivity, making them ideal for high-cycle injection moulds, die-casting dies, and lightweight structural components. Grades like 6061-T6 provide good machinability and weldability for complex geometries, while 7075-T6 delivers higher strength for demanding applications. Aluminum’s lower density reduces machine wear and energy consumption during high-speed CNC machining, significantly lowering operational costs for large production runs. However, its lower hardness compared to steel necessitates protective surface treatments for abrasive materials.

Tool Steels remain the benchmark for longevity and wear resistance in high-volume, high-pressure moulding. Alloys such as P20 offer balanced machinability and polishability for general-purpose mould bases, while H13 excels in hot-work applications like die casting due to its thermal fatigue resistance. For extreme wear scenarios, D2 or S7 tool steels provide exceptional hardness and edge retention. Steel’s superior compressive strength withstands immense clamping forces, ensuring dimensional stability over millions of cycles, though it demands more rigorous CNC machining parameters and heat treatment protocols.

Titanium Alloys, particularly Grade 5 (Ti-6Al-4V), are indispensable for aerospace, medical, and corrosive environments. Its unparalleled strength-to-weight ratio, biocompatibility, and immunity to saltwater/chloride corrosion justify the higher material and machining costs. Titanium’s low thermal expansion coefficient ensures critical dimensional stability under thermal cycling. Machining requires specialized tooling and slower speeds due to its tendency for galling, but the resulting component longevity in harsh service often provides the best total cost of ownership.

Anodizing is the premier surface enhancement for aluminum mould components and finished parts. Type II (Sulfuric Acid) anodizing creates a decorative, corrosion-resistant layer suitable for general use. For industrial moulding, Type III (Hardcoat) Anodizing is essential, producing a thick, dense, wear-resistant ceramic oxide layer (typically 25-50 µm) that dramatically extends mould life against abrasive polymer fills and sliding wear. Hardcoat anodizing significantly improves surface hardness (reaching 500-900 HV), thermal stability, and electrical insulation without dimensional compromise when controlled precisely.

Material properties dictate process viability. The following table summarizes critical specifications for common industrial moulding alloys:

| Material | Typical Grades | Tensile Strength (MPa) | Hardness (HRC) | Key Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310-570 | 15-17 (HB) | Prototype moulds, low-volume injection, lightweight fixtures |

| Tool Steel | P20, H13, D2 | 900-2100 | 28-60 | High-volume injection, die casting, extrusion dies |

| Titanium | Grade 5 (Ti-6Al-4V) | 900-1000 | 36-41 | Aerospace components, marine hardware, medical implants |

Wuxi Lead Precision Machinery leverages advanced CNC machining and metrology to transform these materials into precision moulds. Consult our engineering team early in your design phase to optimize material selection, surface treatment, and manufacturability for your specific industrial application. We ensure your mould investment delivers maximum performance and lifecycle value.

Manufacturing Process & QC

Design: Precision Engineering from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful industrial moulding project begins with comprehensive design engineering. Our team of senior CNC engineers collaborates closely with clients to translate functional requirements into detailed 3D CAD models and technical drawings. Utilizing advanced simulation software, we perform mold flow analysis, stress testing, and thermal distribution modeling to ensure optimal performance under real-world production conditions. This phase integrates material selection, tolerance specifications, and surface finish requirements, all aligned with international standards such as ISO 2768 and GD&T. The result is a fully validated digital prototype that eliminates conceptual flaws before physical development begins.

Prototyping: Validating Performance with Zero Compromise

Once the design is finalized, we proceed to prototype development using high-precision CNC machining, wire EDM, and selective laser melting (SLM) for complex geometries. These prototypes are not mock-ups—they are fully functional components produced under near-mass-production conditions. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM), optical profilometers, and 3D scanning to verify dimensional accuracy within ±0.002 mm. We conduct mechanical testing, thermal cycling, and fatigue analysis to simulate long-term operational stress. Feedback from this stage is integrated into final design refinements, ensuring that any potential failure mode is identified and corrected. This iterative validation process is central to our zero-defect philosophy, minimizing risk before scaling to full production.

Mass Production: Consistency, Control, and Traceability

With design and prototype approval, Wuxi Lead initiates mass production using automated molding cells equipped with real-time monitoring systems. Our facility deploys multi-axis CNC machines, robotic part handling, and closed-loop quality control to maintain repeatability across production runs from 1,000 to over 1 million units. Every batch is subject to in-process inspections, statistical process control (SPC), and first-article testing. We implement full material traceability, tool wear compensation algorithms, and environmental controls to ensure uniformity. All finished components are packaged under cleanroom conditions when required and delivered with comprehensive quality documentation, including PPAP, FAIR, and RoHS compliance reports.

| Specification | Detail |

|---|---|

| Dimensional Accuracy | ±0.002 mm |

| Surface Finish | Ra 0.1 – 3.2 μm (adjustable) |

| Materials Supported | Tool steels (H13, S136), aluminum alloys, titanium, Inconel, brass |

| Production Capacity | 1,000 – 1,000,000+ units per run |

| Quality Standards | ISO 9001:2015, IATF 16949, ISO 13485 (medical) |

| Lead Time (Prototype) | 10–20 days |

| Lead Time (Mass Production) | 25–45 days (varies by complexity) |

Through disciplined integration of design validation, precision prototyping, and tightly controlled manufacturing, Wuxi Lead Precision Machinery delivers industrial moulding solutions where zero defects is not a target—it is the standard.

Why Choose Wuxi Lead Precision

Precision Engineering Partnership for Industrial Moulding Excellence

In the demanding realm of industrial moulding, component integrity directly dictates production throughput, part quality, and operational longevity. Sub-micron deviations in mould cavities or cores cascade into costly scrap rates, unplanned downtime, and compromised end-product performance. Wuxi Lead Precision Machinery exists to eliminate these variables. We engineer not just components, but foundational reliability for your most critical moulding applications across aerospace, medical device manufacturing, and high-volume automotive systems. Our facility operates as an extension of your engineering team, integrating deep metallurgical expertise with advanced CNC capabilities to transform complex geometries into repeatable production reality.

Our technical infrastructure is calibrated for zero-compromise outcomes. All processes adhere to ISO 9001:2015 and IATF 16949 standards, with full traceability from raw material certification through final inspection. We deploy tolerance stack-up analysis at the design phase, ensuring manufacturability aligns with functional requirements before metal is cut. This proactive engineering approach mitigates risk and accelerates time-to-market for your next-generation mould systems.

| Capability | Specification | Application Example |

|---|---|---|

| Machining Tolerance | ±0.001 mm | Injection mould cores for micro-optics |

| Surface Finish | Ra 0.05 µm (mirror polishing) | Optical lens mould cavities |

| Material Expertise | H13, S136, Maraging Steel, Inconel | High-wear, high-temp mould bases |

| Max Work Envelope | 1200 x 800 x 750 mm | Large-scale die-casting mould inserts |

| Quality Verification | CMM, 3D Scanning, Hardness Testing | Full GD&T validation reports |

Partnering with Lead Precision means accessing a dedicated technical cell focused solely on your project’s success. Our engineers collaborate during DFMA reviews to optimize mould design for manufacturability, reducing cycle times and ejection forces. We implement real-time process monitoring during machining, with SPC data shared transparently via your secure portal. This level of integration ensures your moulds achieve target lifespans exceeding 1,000,000 cycles while maintaining dimensional stability under thermal cycling.

The cost of mould failure extends far beyond replacement hardware—it erodes production schedules, strains customer relationships, and impacts brand reputation. Proactive partnership with a precision manufacturer mitigates these systemic risks at the source. We invest in your success through rigorous first-article validation, comprehensive failure mode analysis, and continuous process refinement based on your production feedback.

Initiate a technical consultation to discuss your specific moulding challenges. Forward your CAD files and requirements to [email protected]. Our engineering team will respond within 4 business hours with a preliminary manufacturability assessment and timeline. For urgent RFQs, include “Priority Moulding Project” in the subject line. Let us demonstrate how precision engineering partnership elevates your production resilience—contact us today to secure your moulding foundation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.