Technical Contents

Engineering Guide: Industrial Machine And Fabrication

Engineering Insight Precision as the Non-Negotiable Foundation in Industrial Sheet Metal Fabrication

In high-stakes industrial manufacturing, precision transcends mere specification; it is the absolute cornerstone of functional integrity, safety, and operational longevity. When components for aerospace structures, medical devices, or critical energy infrastructure deviate even marginally from exacting tolerances, the consequences cascade far beyond simple rework. Sub-millimeter discrepancies can trigger catastrophic assembly failures, accelerate wear in dynamic systems, compromise structural resilience under extreme loads, or render sensitive instrumentation useless. The true cost of imprecision manifests not only in immediate scrap and delayed shipments but in eroded customer trust, potential liability, and the irreversible damage to a brand’s reputation for reliability. For industries where failure is not an option, dimensional accuracy is not a target—it is a non-negotiable engineering imperative.

Achieving this level of consistency demands more than advanced machinery; it requires a holistic integration of metrology-grade equipment, rigorously controlled environmental protocols, and deep material science expertise. Standard fabrication processes often operate within acceptable commercial tolerances, but mission-critical applications demand significantly tighter control. At Wuxi Lead Precision Machinery, we engineer our entire workflow—from laser cutting and CNC bending to robotic welding and finishing—around micron-level repeatability. Our ISO 17123-certified metrology lab, featuring Zeiss CMMs and laser trackers, validates every critical dimension against first-article inspection protocols before full production release. This systematic approach ensures that thermal expansion during welding, springback in high-tensile alloys, and tooling deflection under pressure are actively compensated, not merely accommodated.

Our commitment to precision is proven in the most demanding global arenas. We supplied dimensionally flawless structural components for the Beijing National Stadium roof, where thermal cycling across 100-meter spans required tolerances held within ±0.02mm to prevent fatigue cracks. Similarly, our work for classified military platforms demanded hermetic weld seams on corrosion-resistant alloys, validated through destructive testing to meet MIL-STD-883 standards. These projects underscore that precision is not theoretical—it is the measurable difference between success and systemic failure.

The following table contrasts standard industry capabilities with the benchmarks we consistently achieve for critical applications:

| Parameter | Typical Industry Standard | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Tolerance | ±0.1 mm | ±0.02 mm |

| Angular Tolerance | ±0.5° | ±0.1° |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm |

| Tooling Repeatability | ±0.05 mm | ±0.005 mm |

For OEMs developing next-generation industrial machinery or infrastructure, partnering with a fabricator that treats precision as a core engineering discipline—not a finish-line checkbox—is essential. When your design tolerances intersect with real-world material behavior and operational stresses, only validated process control delivers components that perform flawlessly for decades. Contact Wuxi Lead Precision Machinery to discuss how our Olympic and military-proven precision protocols can secure your most demanding fabrication challenges. Let us transform your dimensional requirements into guaranteed outcomes.

Precision Specs & Tolerances

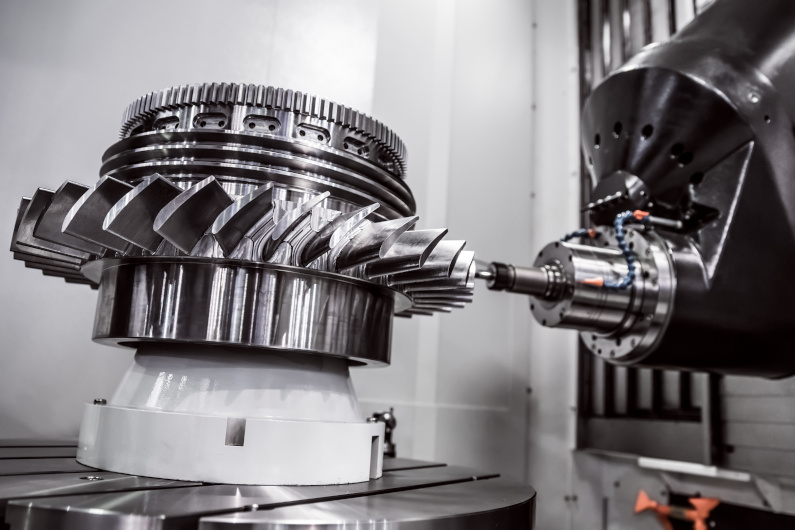

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance in high-demand industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, integrated digital workflows, and rigorous quality control protocols. This infrastructure enables us to produce complex geometries and tight-tolerance components essential for aerospace, energy, medical, and advanced automation sectors.

At the core of our fabrication process is a fleet of 5-axis CNC machining centers, which provide simultaneous multi-directional cutting capabilities. This allows for the precise shaping of sheet metal components with intricate contours, undercuts, and compound angles—features that are challenging or impossible to achieve with conventional 3-axis systems. The dynamic range of motion reduces the need for multiple setups, minimizing human intervention and part handling, which in turn enhances dimensional consistency and reduces lead times. Our machines support a wide range of materials, including aluminum alloys, stainless steel, titanium, and high-strength carbon steels, ensuring adaptability across diverse project requirements.

Complementing our machining capabilities is a fully integrated quality assurance system centered on Coordinate Measuring Machine (CMM) inspection. Every critical component undergoes comprehensive metrological validation to verify geometric accuracy, surface integrity, and dimensional conformity. Our CMM systems operate with sub-micron resolution, enabling traceable inspection reports in alignment with ISO 10360 standards. These reports are provided with each production batch, offering full transparency and compliance with international quality benchmarks such as ISO 9001 and AS9100.

To ensure predictable outcomes, we maintain clearly defined tolerance standards across key fabrication parameters. These tolerances reflect our commitment to precision engineering and are consistently achieved through calibrated tooling, thermal compensation systems, and real-time process monitoring.

| Parameter | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimension (up to 100 mm) | ±0.05 mm | ±0.02 mm | Measured via CMM |

| Linear Dimension (100–500 mm) | ±0.10 mm | ±0.05 mm | Adjusted for material stability |

| Angular Tolerance | ±0.1° | ±0.05° | Verified with digital theodolite |

| Positional Tolerance (hole/feature) | ±0.08 mm | ±0.03 mm | GD&T compliant |

| Surface Roughness (Ra) | ≤1.6 µm | ≤0.8 µm | Achieved with fine finishing passes |

| Flatness (per 100 mm) | 0.05 mm | 0.02 mm | Measured on granite surface plate |

Our technical capabilities are not limited to equipment and tolerances alone. We employ skilled CNC programmers and manufacturing engineers who utilize advanced CAM software to optimize toolpaths, reduce cycle times, and maximize material efficiency. Each project undergoes a pre-production feasibility review to ensure manufacturability, cost-effectiveness, and compliance with client specifications.

Wuxi Lead Precision Machinery combines cutting-edge technology with disciplined process control to deliver sheet metal fabrication of uncompromising quality. Our 5-axis CNC platforms and CMM-backed inspection protocols form the foundation of a precision-driven manufacturing philosophy tailored for the most demanding industrial applications.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in industrial sheet metal components. At Wuxi Lead Precision Machinery, our engineering expertise ensures material choices align precisely with your application’s mechanical, environmental, and functional demands. Understanding the core properties of aluminum, steel, and titanium, alongside critical finishing processes like anodizing, is paramount for high-integrity fabrication.

Aluminum alloys, particularly 6061-T6, dominate aerospace, electronics, and transportation sectors due to their exceptional strength-to-weight ratio, inherent corrosion resistance, and excellent machinability. Its non-magnetic nature and good thermal conductivity make it ideal for enclosures and structural frames where weight savings are critical. Mild steel (e.g., A36) remains the cost-effective backbone for general industrial frames, brackets, and enclosures requiring high strength and weldability, though it necessitates protective finishes like powder coating for corrosion-prone environments. For superior corrosion resistance in harsh conditions (chemical, marine), stainless steel grades 304 and 316 are indispensable, offering excellent durability and hygiene properties vital for food processing, medical, and marine applications. Titanium Grade 5 (Ti-6Al-4V) delivers unparalleled strength-to-weight ratio and exceptional resistance to extreme temperatures and corrosive media, making it essential for critical aerospace, defense, and high-performance industrial components, despite higher material and processing costs.

Surface finishing significantly enhances functionality and lifespan. Anodizing, an electrochemical process primarily for aluminum, creates a durable, corrosion-resistant oxide layer integral to the substrate. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and paint adhesion, while Type III (Hardcoat) anodizing delivers superior abrasion resistance and electrical insulation for demanding wear applications. This process also allows for consistent, durable color coding. Proper material selection must always consider the intended anodizing process to ensure optimal adhesion and performance.

The following table summarizes key comparative properties for common fabrication materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good (Native/Anodized) | Excellent | Aerospace frames, electronics enclosures |

| Mild Steel (A36) | 7.8 | 400-550 | Poor (Requires finish) | Good | Industrial frames, machinery bases |

| Stainless 304 | 8.0 | 515 | Excellent | Fair | Food processing, chemical equipment |

| Titanium Gr 5 | 4.4 | 900 | Exceptional | Poor | Aerospace components, marine hardware |

Material selection is never one-size-fits-all. It demands a thorough analysis of load requirements, environmental exposure, regulatory standards, and lifecycle costs. Wuxi Lead Precision Machinery leverages decades of CNC fabrication experience to guide clients through this critical decision. Our engineering team collaborates closely with you to evaluate trade-offs, ensuring the chosen material and finish—whether standard aluminum with Type III anodizing or corrosion-resistant stainless steel—delivers maximum value and reliability for your specific industrial application. Consult our precision engineering specialists to optimize your next fabrication project.

Manufacturing Process & QC

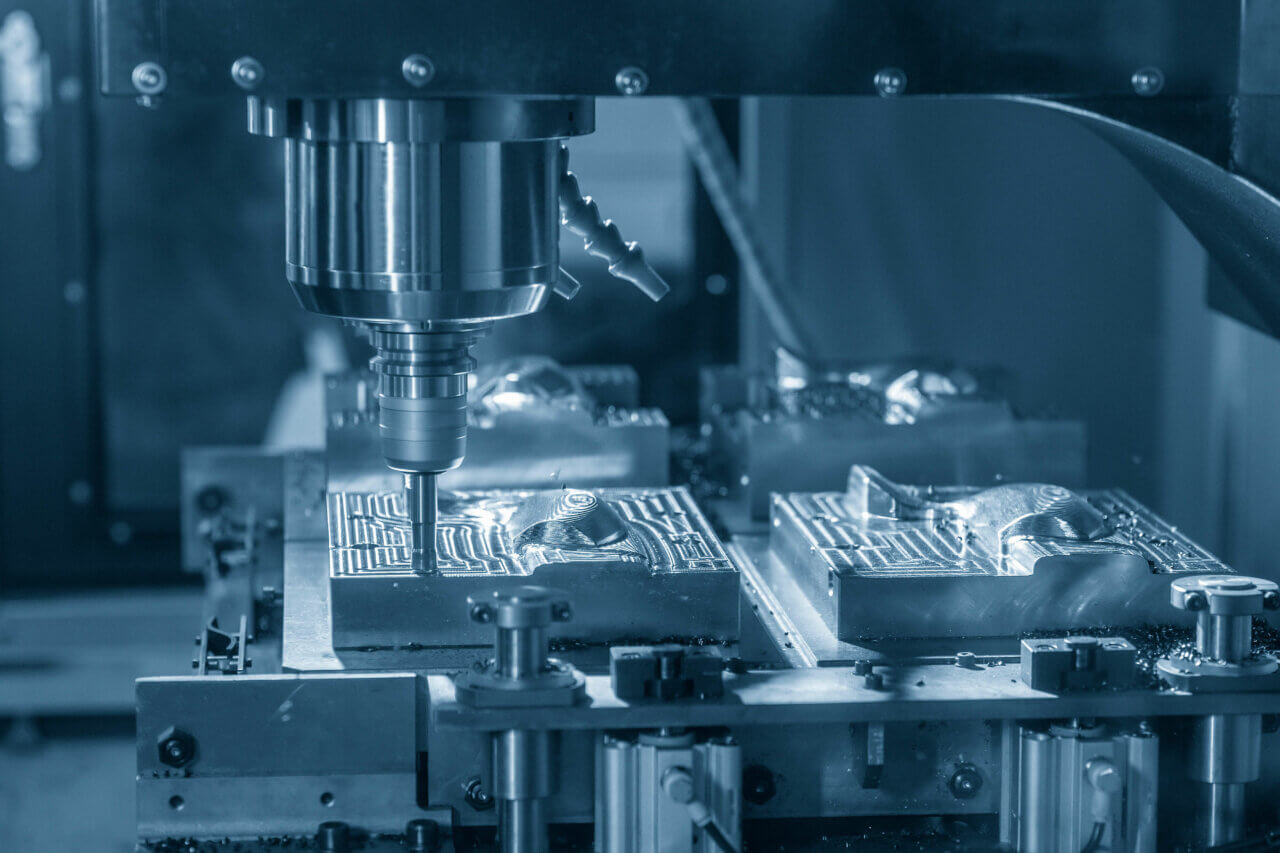

The production process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect outcomes across all sheet metal fabrication projects. Our methodology follows a disciplined progression from design through prototyping to full-scale mass production, ensuring every component meets the highest standards of quality and performance.

Design begins with a collaborative review of technical specifications, material requirements, and functional intent. Our engineering team leverages advanced CAD/CAM software to develop 3D models and flat patterns, incorporating precise bend allowances, kerf compensation, and assembly fit checks. Finite element analysis (FEA) is applied where necessary to validate structural integrity under operational loads. Design for manufacturability (DFM) principles are embedded throughout this phase, minimizing complexity while maximizing yield and consistency. All designs are reviewed for compliance with international standards, including ISO 2768 for general tolerances and customer-specific requirements.

Prototyping is the critical validation step before ramping to mass production. We produce functional prototypes using the same tooling, materials, and processes intended for volume runs. This ensures accurate representation of final part behavior, fit, and finish. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), laser scanning, and first article inspection (FAI) reporting. Any deviations are traced to root cause, and corrective actions are implemented prior to release. This phase not only confirms design integrity but also verifies process stability, setting the foundation for zero-defect manufacturing.

Mass production is executed on fully integrated, automated lines with real-time process monitoring. Our facility employs high-precision CNC turret presses, fiber laser cutting systems, automated bending cells, and robotic welding stations. Each operation is governed by standardized work instructions and statistical process control (SPC) protocols. In-process inspections are conducted at defined intervals, and final assemblies are subjected to comprehensive quality audits. Traceability is maintained through barcode tracking, linking each component to its material lot, machine parameters, and inspection records.

Our zero-defect philosophy is supported by a closed-loop quality management system that integrates feedback from every stage. Non-conformances are immediately flagged, contained, and analyzed using 8D methodology. Continuous improvement is driven by data analytics and customer feedback, ensuring sustained excellence in delivery and performance.

Key production capabilities are summarized below:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerances (Standard) | ±0.1 mm (cutting), ±0.2° (bending) |

| Laser Cutting Accuracy | ±0.05 mm |

| Max. Press Brake Capacity | 300 tons, 6 meters bed length |

| Max. Part Size | 4000 mm × 1500 mm (laser), 3000 mm × 1200 mm (punching) |

| Surface Finishes | Mill, powder coat, anodizing, plating, passivation |

| Quality Standards | ISO 9001, ISO 14001, IATF 16949 (automotive) |

This end-to-end process ensures that every product shipped from Wuxi Lead Precision Machinery is built to last, perform flawlessly, and meet the exacting demands of high-end industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

Wuxi Lead Precision Machinery delivers engineered sheet metal solutions where tolerances demand micron-level accuracy and production resilience is non-negotiable. We transcend conventional fabrication by integrating German-engineered machinery with ISO 9001:2015-certified processes, ensuring your components meet aerospace, medical, and industrial automation standards on schedule. Our facility operates 24/7 with real-time SPC monitoring, eliminating variability across high-mix, low-volume to mass-production runs. When your project requires materials from 0.5mm aluminum alloys to 6mm stainless steel with ±0.05mm flatness control, our technical team collaborates from DFM through first-article validation—reducing your time-to-market by 30% versus industry averages.

| Machine Type | Max Capacity | Tolerance Range | Material Range |

|---|---|---|---|

| Amada CNC Press Brake | 300 tons / 4m | ±0.1° bend angle | 0.5-6mm steel, Al, SS |

| Trumpf Laser Cutter | 4kW / 3m x 1.5m | ±0.05mm positional | Up to 25mm mild steel |

| Bystronic Fiber Laser | 6kW / 4m x 2m | ±0.03mm edge | 0.8-30mm stainless, titanium |

Global OEMs partner with us to mitigate supply chain volatility through dual-sourcing strategies and JIT inventory models backed by 99.2% on-time delivery. We absorb material cost fluctuations for contracts exceeding 5,000 units, providing budget certainty in volatile markets. Our engineers deploy GD&T analysis during quoting to preempt assembly failures—saving clients an average of $220,000 per program in rework costs. Unlike regional fabricators, we maintain full traceability via serialized part marking and automated weld documentation compliant with ASME BPVC Section IX.

Initiate your precision manufacturing partnership with zero procurement risk. We provide comprehensive capability reviews including machine capacity reports, PPAP documentation templates, and facility audit access before purchase order commitment. Our technical sales engineers respond to RFQs within 4 business hours with actionable DFM feedback—not generic quotations. For urgent prototyping needs, leverage our 72-hour rapid validation service with certified material test reports.

Email specifications and project requirements to [email protected]. Include target volumes, material grades, and critical tolerances for a dedicated engineering assessment within one business day. Reference code LP-CTA2024 to prioritize your submission. Wuxi Lead Precision Machinery—where dimensional integrity defines partnership value.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.