Technical Contents

Engineering Guide: Horizontal Cnc Machining Services

Engineering Insight Horizontal CNC Machining Services

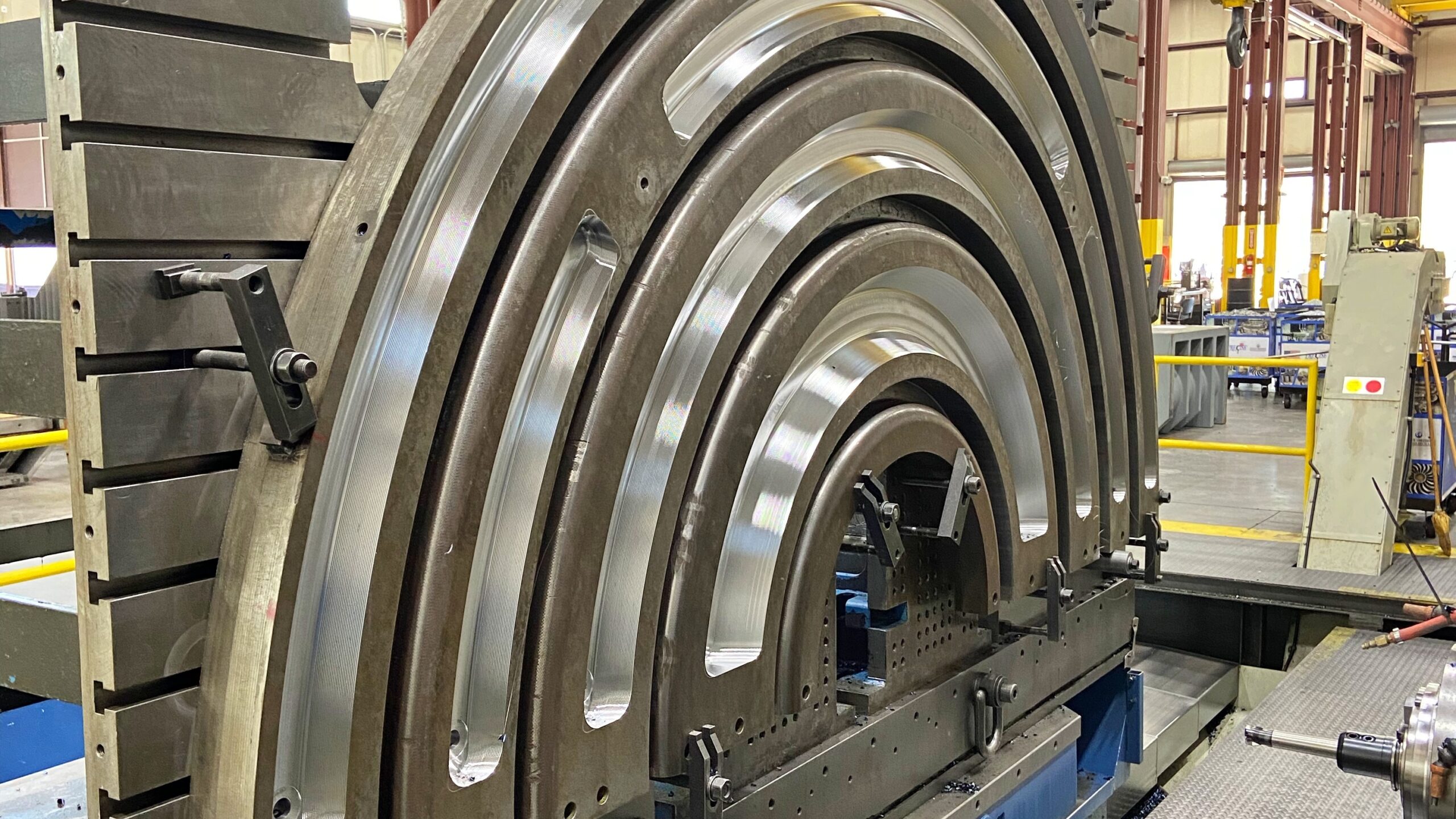

Precision in horizontal CNC machining is not merely a desirable attribute; it is the absolute foundation for mission-critical components across aerospace, defense, and advanced industrial sectors. At Wuxi Lead Precision Machinery, we understand that dimensional accuracy measured in microns directly impacts part functionality, assembly integrity, and ultimately, the safety and performance of the final product. Horizontal machining centers (HMCs) offer inherent advantages for complex, high-precision work, primarily through superior thermal stability and rigidity compared to vertical configurations. The horizontal spindle orientation minimizes gravitational deflection on the tool and workpiece, while the robust bed design of industrial-grade HMCs dampens vibration during heavy cuts or intricate contouring. This structural integrity is paramount when machining demanding materials like titanium alloys, Inconel, or hardened steels common in defense systems and high-performance machinery. Achieving consistent tolerances below ±0.005mm requires more than capable machinery; it demands rigorous process control, advanced metrology, and deep operational expertise honed over years of tackling the most exacting requirements.

Our facility’s proven capability in high-stakes environments underscores this commitment. Wuxi Lead Precision Machinery has successfully delivered precision components for Olympic-level sporting equipment where marginal gains are measured in milliseconds and structural failure is unacceptable. Furthermore, we maintain stringent quality protocols meeting military-grade specifications, producing parts where reliability under extreme conditions is non-negotiable. This experience translates directly to our commercial aerospace and energy sector clients, ensuring every component we machine adheres to the most demanding geometric dimensioning and tolerancing (GD&T) callouts and surface finish requirements. The integration of real-time thermal compensation systems, high-resolution linear encoders, and meticulously maintained machine tools forms the backbone of our precision capability. Operator expertise in fixture design, cutting strategy optimization, and in-process inspection protocols ensures theoretical machine specifications are consistently realized in the finished part.

The following table outlines the core precision specifications achievable on our primary horizontal machining platforms, reflecting the standard we apply to all client projects:

| Parameter | Specification | Significance |

|---|---|---|

| Positioning Accuracy | ±3μm (X,Y,Z) | Ensures critical feature locations align perfectly within assemblies |

| Repeatability | ±1.5μm (X,Y,Z) | Guarantees consistent part-to-part quality across production runs |

| Spindle Runout | ≤2μm (at 150mm) | Critical for fine surface finishes and tight bore tolerances |

| Table Flatness | ≤5μm over 1000mm | Maintains workpiece stability and accuracy during multi-face machining |

| Thermal Compensation | Real-time Active | Counters environmental and process-induced drift for全天候 accuracy |

Wuxi Lead Precision Machinery leverages this combination of advanced HMC technology, military and Olympic-proven process discipline, and unwavering attention to metrology to deliver horizontal machining services where precision is the only acceptable outcome. We partner with engineers to transform complex designs into reality, knowing that the integrity of their systems depends on the micron-level accuracy we consistently achieve.

Precision Specs & Tolerances

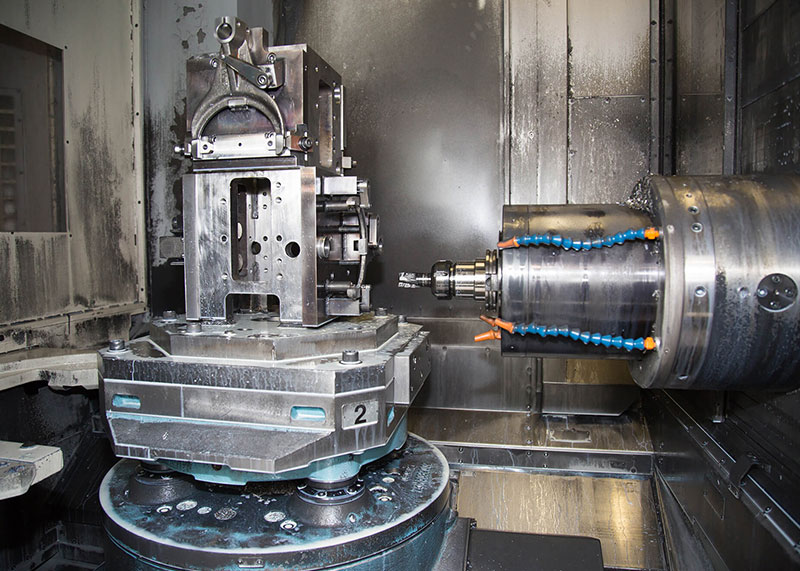

Wuxi Lead Precision Machinery delivers advanced horizontal CNC machining services engineered for high-complexity, high-precision components across aerospace, energy, medical, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling multi-directional cutting with unparalleled accuracy and efficiency. These machines allow for complex geometries to be machined in a single setup, minimizing human intervention, reducing cumulative errors, and significantly improving part consistency. The integration of horizontal machining platforms further enhances productivity through superior chip evacuation, increased tool life, and optimal workholding flexibility—especially for heavy or deep-cavity parts.

Our 5-axis horizontal CNC systems are equipped with high-torque spindles, automatic tool changers, and real-time tool length and wear compensation. This ensures continuous operation under tight tolerances while maintaining surface integrity and dimensional stability. The Y-axis travel and dual-pallet changers on select machines enable uninterrupted production, ideal for medium to high-volume precision runs with minimal downtime. All equipment is maintained to OEM specifications and operated by certified CNC engineers with over a decade of experience in high-precision manufacturing.

Quality control is embedded at every stage of production. Each machined component undergoes rigorous inspection using a Zeiss DuraMax and CONTURA G2 Coordinate Measuring Machine (CMM), ensuring full compliance with ISO 10360 standards. Our CMM system provides 3D measurement accuracy down to ±2.5 + L/300 µm, allowing for comprehensive GD&T verification, surface contour analysis, and first-article inspection reports. In addition to CMM, we deploy optical comparators, surface roughness testers, and calibrated micrometry to validate critical features.

We maintain tight process control to achieve and sustain precision across materials including aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics. Our facility is ISO 9001:2015 certified, with documented procedures for traceability, non-conformance management, and continuous improvement.

The following table outlines the standard technical tolerances achievable through our horizontal 5-axis CNC machining services under controlled conditions.

| Specification | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Tolerance | ±0.010 mm | ±0.005 mm | CMM, Micrometer |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM, GD&T Analysis |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Surface Tester |

| Angular Tolerance | ±0.05° | ±0.02° | CMM, Optical Comparator |

| Feature-to-Feature Tolerance | ±0.012 mm | ±0.006 mm | CMM, VMM |

| Maximum Work Envelope (HMC) | 1200 x 1000 x 1000 mm | N/A | Machine Specifications |

All tolerances are achievable across batch sizes from prototypes to serial production. Custom inspection plans can be developed to meet AS9100, ISO 13485, or customer-specific quality requirements. Wuxi Lead Precision Machinery combines advanced hardware, metrology-grade validation, and engineering expertise to deliver horizontal CNC machining services that meet the most demanding technical challenges in modern manufacturing.

Material & Finish Options

Material Selection for Horizontal CNC Machining: Aluminum, Steel, Titanium & Anodizing

Material selection is a critical engineering decision that directly determines the performance, cost, and manufacturability of precision components. At Wuxi Lead Precision Machinery, our horizontal CNC machining centers excel with challenging materials due to their superior rigidity, thermal stability, and multi-axis capabilities. Understanding the unique properties and machining characteristics of Aluminum, Steel, and Titanium ensures optimal part functionality and production efficiency. The choice must align with the component’s mechanical requirements, environmental exposure, and post-processing needs like anodizing.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are industry standards for lightweight, high-strength applications requiring excellent machinability and thermal conductivity. Their low density reduces inertia in moving parts, while natural corrosion resistance suits aerospace and automotive housings. Horizontal machining leverages aluminum’s softness for high-speed cutting and complex geometries, though proper chip evacuation is essential to prevent built-up edge. Steel variants like 4140 alloy steel and 304/316 stainless offer superior strength, wear resistance, and structural integrity for tooling, shafts, and high-load components. Machining steel demands robust tooling and precise coolant management to handle higher cutting forces and heat generation. Stainless grades require attention to work hardening but deliver exceptional corrosion resistance for medical or marine environments.

Titanium alloys, notably Grade 5 (Ti-6Al-4V), present the ultimate challenge with exceptional strength-to-weight ratio, biocompatibility, and extreme corrosion resistance. However, titanium’s low thermal conductivity causes heat concentration at the cutting edge, demanding slower speeds, rigid setups, and specialized tool geometries to avoid work hardening or tool failure. Our horizontal CNC platforms mitigate these issues through consistent thermal control and vibration damping, making titanium viable for critical aerospace and medical implants.

Anodizing is the premier surface finish for aluminum components, enhancing corrosion resistance, wear properties, and aesthetic appeal. Type II (sulfuric acid) anodizing provides standard decorative and protective layers, while Type III (hard coat) delivers thicker, harder surfaces for severe wear applications. Achieving uniform anodizing requires meticulous pre-machining surface preparation and tight dimensional control during CNC processing to account for the oxide layer’s growth.

Key material properties for horizontal CNC machining are summarized below:

| Material | Common Grades | Tensile Strength (MPa) | Machinability Index | Key Horizontal Machining Advantages |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310-570 | 150-200 | High-speed cutting, excellent chip flow, thermal stability for thin walls |

| Carbon/Alloy Steel | 4140, A36 | 415-1000 | 50-70 | Rigidity handles high cutting forces, precision for tight-tolerance shafts |

| Stainless Steel | 304, 316 | 515-690 | 40-45 | Vibration damping counters work hardening, consistent coolant delivery |

| Titanium | Ti-6Al-4V (Gr5) | 880-950 | 22-30 | Thermal stability prevents heat buildup, rigid setup minimizes deflection |

Selecting the right material and finish is inseparable from the machining process itself. Wuxi Lead Precision Machinery combines advanced horizontal CNC technology with deep metallurgical expertise to transform challenging materials into mission-critical components. Consult our engineering team early in the design phase to optimize material choice, machining strategy, and surface treatment for your specific application, ensuring performance, durability, and cost-effectiveness.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful horizontal CNC machining project begins with meticulous design evaluation and optimization. Our engineering team collaborates closely with clients to review CAD models, ensuring geometric accuracy, material suitability, and manufacturability. We perform comprehensive Design for Manufacturability (DFM) analysis to identify potential challenges early, minimizing risks and reducing lead times. This phase includes tolerance validation, feature complexity assessment, and fixture planning tailored to horizontal machining centers. By leveraging advanced simulation software, we verify tool paths and detect collisions virtually, ensuring the design is not only functional but also optimized for high-efficiency, high-accuracy production.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to precision prototyping using the same horizontal CNC machining centers employed in full-scale production. This ensures complete process consistency and eliminates variables when transitioning to mass production. Prototypes are machined from the specified production-grade materials, allowing for accurate functional testing, fit checks, and client validation. Each prototype undergoes rigorous first-article inspection (FAI), with full dimensional reporting and material certification. Any required design or process refinements are implemented at this stage, supported by iterative feedback loops. Our prototyping phase is not a mere sample run—it is a full-scale rehearsal of the production process, engineered to confirm zero-defect capability before volume manufacturing begins.

Mass Production: Consistency, Control, and Zero Defects

With design and prototype approval, we initiate high-volume horizontal CNC machining under a fully documented and controlled production plan. Our facility utilizes state-of-the-art horizontal machining centers with multi-pallet systems, enabling continuous, lights-out operation while maintaining micron-level precision. Each production batch is managed through a structured workflow that includes automated tool wear monitoring, in-process gauging, and real-time quality data collection. We enforce strict adherence to ISO 9001-certified quality management protocols, ensuring every component meets the specified tolerances and surface finish requirements.

To guarantee zero defects, we implement a multi-tiered inspection strategy: 100% critical dimension checks on initial runs, statistical process control (SPC) for ongoing monitoring, and final batch certification with traceable inspection reports. Our closed-loop corrective action system ensures immediate response to any deviation, maintaining process stability across long production runs.

Typical Production Specifications

| Parameter | Specification |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm (adjustable per requirement) |

| Maximum Work Envelope | 1200 x 800 x 800 mm |

| Spindle Speed Range | 8,000 – 20,000 rpm |

| Tool Changer Capacity | 30 – 60 tools (depending on model) |

| Repeatability | ±0.003 mm |

| Materials Supported | Aluminum Alloys, Stainless Steel, Titanium, Tool Steels, Engineering Plastics |

Through disciplined process control, advanced technology, and a zero-defect mindset, Wuxi Lead Precision Machinery delivers consistent, high-quality components for aerospace, medical, and industrial automation applications worldwide.

Why Choose Wuxi Lead Precision

Engineering-Driven Partnership for Complex Horizontal Machining

Achieving uncompromised precision and efficiency in high-mix, low-volume production demands more than just advanced machinery; it requires a strategic partner with deep engineering insight and unwavering commitment to your project’s success. At Wuxi Lead Precision Machinery, we specialize in transforming intricate horizontal CNC machining challenges into tangible competitive advantages for global aerospace, energy, and medical device manufacturers. Our dedicated engineering team collaborates from the initial design review phase, identifying manufacturability optimizations and potential cost savings long before the first chip is cut. This proactive approach minimizes costly iterations and accelerates time-to-market, ensuring your complex components meet the most stringent geometric and surface finish requirements consistently. We understand that your reputation hinges on part integrity, and our ISO 9001:2015 certified processes provide the rigorous quality assurance framework you require.

Our horizontal machining capabilities are built upon a foundation of cutting-edge technology and meticulous process control. We operate a modern fleet of multi-pallet horizontal machining centers, including advanced 5-axis simultaneous interpolation models, specifically configured for demanding applications requiring minimal setups and maximum thermal stability. The table below outlines our core horizontal machining specifications, demonstrating our capacity to handle your most challenging projects with precision and reliability.

| Parameter | Wuxi Lead Capability | Industry Standard Benchmark |

|---|---|---|

| Max Table Size | 1000 x 630 mm | 800 x 500 mm |

| X/Y/Z Travel | 1000 / 762 / 762 mm | 800 / 600 / 600 mm |

| Spindle Power (40/50) | 37 kW / 56 kW | 22 kW / 40 kW |

| Max Spindle Speed | 12,000 rpm | 8,000 rpm |

| Positioning Accuracy | ± 0.003 mm | ± 0.005 mm |

| Repeatability | ± 0.002 mm | ± 0.003 mm |

| Pallet System Capacity | Up to 12 pallets | Typically 6 pallets |

| Typical Tolerance Range | ± 0.005 mm | ± 0.010 mm |

Beyond raw machine specifications, our value lies in the integrated engineering support and transparent communication throughout your project lifecycle. Our CNC programmers and process engineers utilize the latest CAM software to develop optimized, collision-free toolpaths, while our dedicated quality lab employs CMMs, optical comparators, and surface roughness testers to validate every critical dimension against your print. We proactively share detailed inspection reports and real-time production updates, fostering true collaboration and eliminating uncertainty. This level of technical partnership ensures not only that your parts are manufactured correctly, but that the entire process is efficient, predictable, and scalable to your evolving needs.

Initiate a conversation that elevates your manufacturing outcomes. Share your most complex horizontal machining project specifications or CAD files with our engineering team. Contact us directly at [email protected] to discuss your requirements, request a detailed technical capability review, or schedule a virtual tour of our Wuxi facility. Let Wuxi Lead Precision Machinery become your trusted extension, delivering the precision, reliability, and engineering partnership essential for success in today’s demanding industrial landscape. We are ready to engineer your solution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.