Technical Contents

Engineering Guide: High Resolution 3D Printing Service

Engineering Insight: High Resolution 3D Printing Service

In the realm of advanced custom metal manufacturing, high resolution 3D printing services have emerged as a transformative force, enabling unprecedented levels of design complexity and dimensional accuracy. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric—it is the foundation of functional integrity, reliability, and long-term value in mission-critical applications. Our expertise in high resolution 3D printing is built on years of engineering refinement and direct involvement in projects demanding the highest standards, including components developed for Olympic-grade equipment and defense-industry systems.

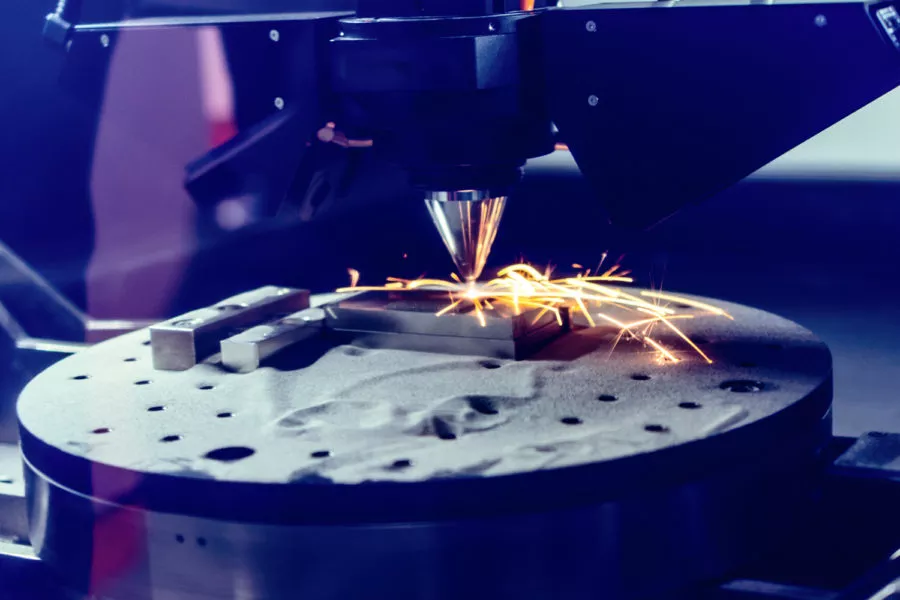

High resolution 3D printing, particularly in metal, allows for the production of parts with fine feature details, smooth surface finishes, and tight tolerances that rival or exceed those of traditional subtractive methods. This capability is essential in sectors such as aerospace, medical devices, and high-performance automotive engineering, where even micrometer-level deviations can compromise system performance. Our metal additive manufacturing platforms utilize selective laser melting (SLM) technology with ultra-fine focus lasers and optimized scanning strategies to achieve layer resolutions as low as 20 microns, ensuring exceptional geometric fidelity.

Precision in 3D printing extends beyond resolution alone. It encompasses material consistency, thermal management during build, post-processing control, and rigorous quality assurance. At Lead Precision, we maintain full in-house oversight of the production chain—from CAD optimization and support structure design to heat treatment, precision machining, and metrology-grade inspection. This vertical integration ensures that every component meets exacting specifications, with traceability and repeatability across production batches.

Our experience in delivering components for Olympic applications—where performance margins are razor-thin—has honed our ability to balance lightweight design with structural resilience. Similarly, our work with military-grade systems has reinforced the necessity of environmental durability, including resistance to thermal cycling, vibration, and corrosion. These real-world challenges inform our approach to high resolution 3D printing, ensuring that every part is not only dimensionally accurate but functionally superior.

The following table outlines key technical specifications of our high resolution metal 3D printing service:

| Parameter | Specification |

|---|---|

| Technology | Selective Laser Melting (SLM) |

| Layer Thickness Range | 20 – 50 µm |

| Build Volume | Up to 250 × 250 × 300 mm |

| Minimum Feature Size | 50 µm |

| Positional Accuracy | ±10 µm over 100 mm |

| Surface Roughness (as-built) | Ra 8 – 12 µm |

| Post-Processing Options | Stress relief, HIP, CNC finishing, polishing |

| Supported Materials | Ti-6Al-4V, Inconel 718, 17-4 PH, AlSi10Mg |

At Wuxi Lead Precision Machinery, we combine cutting-edge technology with deep engineering insight to deliver high resolution 3D printed metal components that meet the most demanding requirements. Precision is not an option—it is our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration for Mission-Critical Metal Components

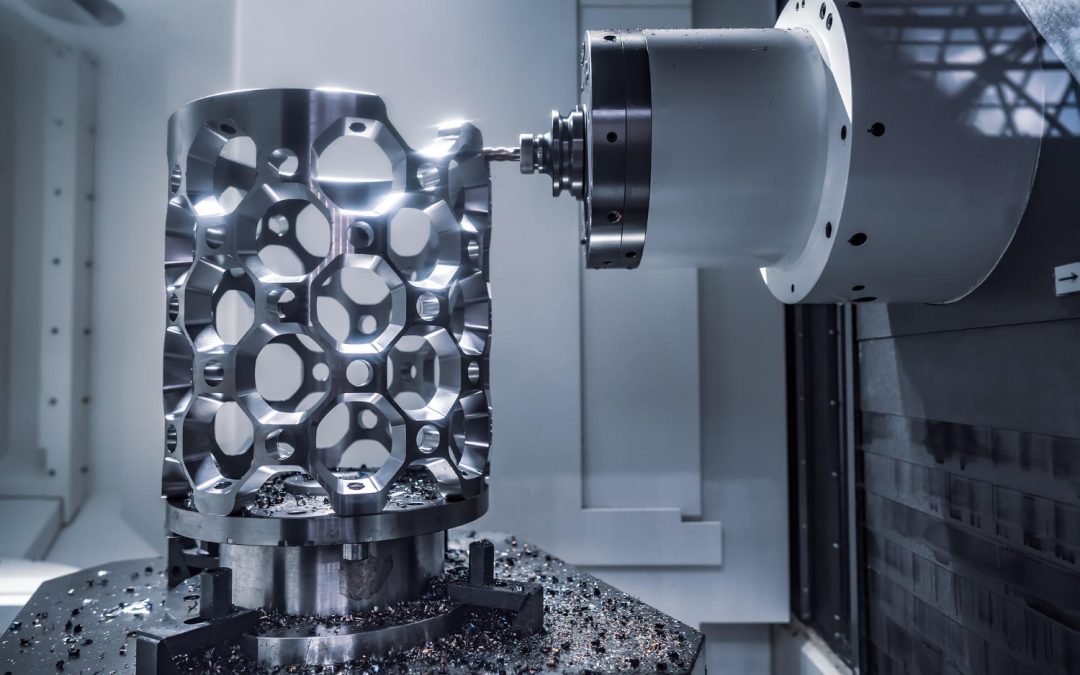

Wuxi Lead Precision Machinery delivers unparalleled value in high-resolution metal 3D printing by integrating additive manufacturing with precision subtractive and inspection technologies. Our end-to-end process ensures printed metal components meet aerospace, medical, and energy sector demands where tolerances directly impact performance and safety. We specialize in post-processing additively manufactured parts using industry-leading 5-axis CNC systems, transforming near-net shapes into fully functional, dimensionally exact components. This hybrid approach overcomes inherent limitations of standalone 3D printing, enabling complex geometries with surface finishes and accuracies unattainable through additive methods alone.

Our DMG MORI CTX beta 1250 5-axis CNC machining centers provide simultaneous multi-axis interpolation for intricate features, undercuts, and tight-tolerance critical surfaces. These systems eliminate secondary setups, minimizing cumulative error while achieving micron-level positional accuracy across complex contours. All machining operations utilize high-stability tooling, thermal compensation systems, and in-process probing to maintain consistency from prototype to production volumes. Crucially, every component undergoes rigorous validation via our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), featuring a sub-5µm probing uncertainty and automated scanning capabilities. This metrology-grade inspection validates geometric dimensioning and tolerancing (GD&T) compliance against CAD models, ensuring full traceability and conformance to AS9100 and ISO 13485 standards.

The table below defines our certified capability envelope for integrated 3D printing and finishing services. These specifications reflect real-world production outcomes under controlled environmental conditions, not theoretical machine limits.

| Parameter | 3D Printing Capability (as-built) | CNC Finishing Capability | Measurement Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.1 mm / 100 mm | ±0.005 mm | ISO 2768-mK |

| Geometric Accuracy (GD&T) | ±0.2 mm | ±0.01 mm (True Position) | ASME Y14.5-2018 |

| Surface Roughness (Ra) | 12–25 µm | 0.4–1.6 µm | ISO 4287 |

| Feature Resolution | 50 µm (minimum wall) | 25 µm (micro-machining) | ISO 11952 |

This precision ecosystem enables Wuxi Lead to produce components such as turbine blades with aerodynamic surfaces, implant threads requiring biocompatible smoothness, and fluidic manifolds with internal channels meeting strict flow dynamics criteria. Our engineers collaborate with clients during design for manufacturability (DFM) reviews to optimize part orientation, support structures, and finishing sequences—maximizing yield while meeting target tolerances. All inspection data is delivered in standardized DMIS reports with graphical deviation mapping, providing actionable insights for continuous improvement. By controlling the entire workflow from powder to polished component, we guarantee zero-defect delivery for applications where failure is not an option. Partner with Wuxi Lead to transform high-resolution metal 3D printing from a prototyping tool into a certified production solution.

Material & Finish Options

Material selection is a critical factor in high-resolution 3D printing for custom metal manufacturing, directly influencing part performance, durability, and application suitability. At Wuxi Lead Precision Machinery, we specialize in precision additive manufacturing using advanced metal alloys, with a focus on aluminum, steel, and titanium. Each material offers distinct mechanical properties and thermal characteristics, making them ideal for specific industrial applications ranging from aerospace and automotive to medical and energy sectors.

Aluminum alloys, particularly AlSi10Mg, are widely used for their excellent strength-to-weight ratio and good thermal conductivity. This makes them ideal for lightweight structural components, heat exchangers, and complex geometries where weight reduction is essential. Aluminum also demonstrates strong corrosion resistance and is well-suited for post-processing techniques such as anodizing, which enhances surface hardness and wear resistance. In high-resolution 3D printing, aluminum parts achieve fine detail and smooth surface finishes, enabling intricate designs that are difficult to produce with traditional machining.

Stainless steel, especially grades like 316L and 17-4 PH, delivers high tensile strength, excellent corrosion resistance, and superior performance in extreme environments. These properties make steel a preferred choice for industrial tooling, fluid systems, and components exposed to high pressure or chemical exposure. The fine layer resolution of our metal 3D printing systems ensures dense, fully fused steel parts with minimal porosity, meeting stringent quality standards for mission-critical applications. Post-build heat treatments can further enhance mechanical properties, tailoring performance to specific operational demands.

Titanium, primarily Ti6Al4V (Grade 5), stands out for its exceptional strength-to-density ratio and biocompatibility. It is the material of choice in aerospace, defense, and medical implant manufacturing. Titanium’s ability to withstand high temperatures and resist corrosion in aggressive environments—such as saltwater or chemical exposure—makes it invaluable for demanding applications. Our high-resolution printing process ensures precise control over microstructure, resulting in parts with excellent fatigue resistance and mechanical integrity.

Surface finishing, particularly anodizing, plays a key role in enhancing functional performance. Anodizing aluminum increases surface hardness, improves wear resistance, and allows for color coding for part identification. While anodizing is specific to aluminum and certain titanium alloys, other surface treatments such as polishing, sandblasting, and coating are available for steel and titanium to meet aesthetic or functional requirements.

The following table summarizes key material properties and processing characteristics:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications | Suitable for Anodizing |

|---|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–450 | 250–280 | 8–12 | Aerospace, automotive, heat sinks | Yes |

| 316L Steel | 8.0 | 550–600 | 290–320 | 35–40 | Marine, chemical processing | No |

| 17-4 PH Steel | 7.8 | 1000–1200 | 850–1000 | 12–15 | Tooling, aerospace components | No |

| Ti6Al4V | 4.43 | 900–950 | 830–880 | 10–12 | Medical implants, aerospace | Limited (Type II/III) |

Selecting the right material and finish ensures optimal performance, longevity, and cost-efficiency in high-resolution metal 3D printed components. Wuxi Lead Precision Machinery supports clients in making informed decisions based on application requirements, environmental conditions, and functional goals.

Manufacturing Process & QC

Production Process: From Design to Zero-Defect Mass Production

Our high-resolution metal 3D printing service delivers precision-engineered components through a rigorously controlled, end-to-end workflow. This integrated process ensures seamless transition from concept to certified production, eliminating defects before they occur. We begin with collaborative design validation, where our engineering team reviews CAD files for manufacturability, optimizing support structures and orientation to minimize thermal stress and achieve micron-level accuracy. Critical features undergo finite element analysis to predict and mitigate potential distortion, ensuring the digital model translates flawlessly to physical form. This phase establishes the foundation for Zero Defects by resolving issues at the source.

Prototyping is not a separate phase but an integral validation step within our production system. Using identical machines, materials, and parameters planned for final production, we manufacture functional prototypes for dimensional verification and performance testing. Every prototype undergoes comprehensive metrology, including CT scanning for internal integrity and CMM validation against the original CAD model. This strict adherence to production-equivalent conditions guarantees that the prototype accurately reflects mass production output, eliminating costly requalification cycles and ensuring design intent is preserved.

Mass production leverages our certified industrial additive manufacturing cells, operating under strict ISO 13485 and AS9100 quality management systems. Real-time melt pool monitoring and inert gas atmosphere control ensure consistent material properties and surface finish. Each build undergoes in-process inspections at predefined intervals, with automated dimensional checks against the validated prototype data. Post-processing, including precision heat treatment, HIP, and CNC machining, follows documented procedures with full material traceability. Final inspection employs multi-sensor metrology, verifying all critical dimensions and surface characteristics meet the exacting tolerances required for aerospace, medical, and energy applications. This closed-loop system, where design, prototyping, and production share identical parameters and controls, is the cornerstone of our Zero Defects commitment. Variability is engineered out, not inspected in.

Critical Process Specifications

| Parameter | Capability | Tolerance/Resolution | Certification Standard |

|---|---|---|---|

| Material Options | Ti6Al4V ELI, Inconel 718, 316L, AlSi10Mg | ASTM F136, AMS 5662, etc. | Material Certificates |

| Build Volume | 250 x 250 x 325 mm | – | Machine Calibration |

| Layer Resolution | Down to 30 μm | ± 5 μm | In-Process Monitoring |

| Dimensional Accuracy | Complex Geometries | ± 0.02 mm per 100 mm | CMM, CT Scan Verified |

| Surface Roughness (As-Built) | Typical | Ra 8 – 12 μm | ISO 4287 |

| Post-Processing | HIP, Stress Relief, Precision Machining | Feature Tolerance ≤ ±0.01 mm | AS9100D, ISO 13485 |

This disciplined approach ensures every component shipped meets the highest standards of performance and reliability, transforming complex metal 3D printing from a prototyping tool into a dependable, zero-defect manufacturing solution.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched High-Resolution 3D Printing in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation define the future of advanced manufacturing. As a leader in custom metal solutions, we offer high-resolution 3D printing services engineered to meet the most demanding industrial requirements. Whether you are developing complex aerospace components, medical devices, or high-performance automotive systems, partnering with Lead Precision ensures your designs are translated into reality with micron-level accuracy and superior material integrity.

Our state-of-the-art metal additive manufacturing systems leverage selective laser melting (SLM) technology to produce fully dense, functional metal parts with intricate geometries that traditional machining cannot achieve. We support a wide range of high-performance alloys, including titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel (718, 625), and aluminum (AlSi10Mg), ensuring compatibility with extreme environments and critical applications. Every build is monitored in real time using advanced in-situ monitoring and quality assurance protocols to guarantee repeatability, consistency, and compliance with international standards.

What sets us apart is our integrated approach to precision engineering. We don’t just print parts—we engineer solutions. From design optimization and topology simulation to post-processing, heat treatment, and precision CNC finishing, our end-to-end workflow ensures maximum performance and dimensional stability. Our ISO 9001-certified facility in Wuxi, China, operates under strict quality control, making us a trusted partner for global OEMs, R&D institutions, and high-tech enterprises.

When you collaborate with Lead Precision, you gain access to a team of expert engineers and metallurgists who work closely with your design and production teams to refine your components for additive manufacturing, reduce lead times, and lower total production costs. We specialize in low-volume, high-mix production and rapid prototyping, enabling faster time-to-market without compromising on quality.

Explore the full potential of high-resolution 3D printing with a partner committed to technical excellence and customer success.

| Specification | Detail |

|---|---|

| Build Volume | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 μm |

| Positioning Accuracy | ±0.02 mm |

| Supported Materials | Ti6Al4V, 316L, 17-4 PH, Inconel 718 & 625, AlSi10Mg |

| Surface Roughness (as-built) | Ra 8–12 μm (can be polished to Ra <1 μm) |

| Post-Processing Options | Stress relieving, HIP, CNC machining, polishing, coating |

| Quality Standards | ISO 9001, Full traceability, First Article Inspection (FAI) reports |

Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery become your strategic partner in advanced metal 3D printing—where precision meets innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.