Technical Contents

Engineering Guide: High Quality 3D Printing Service

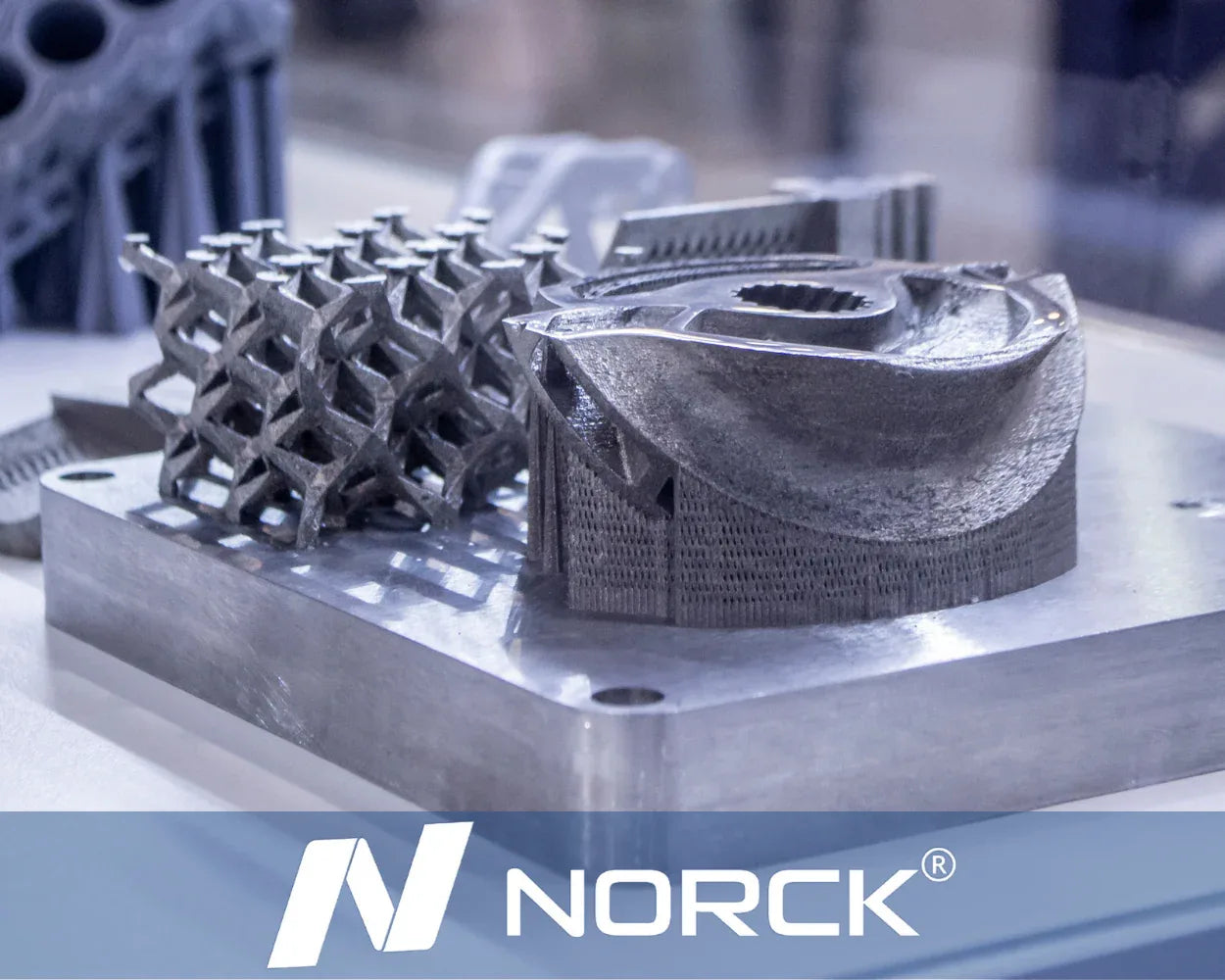

Engineering Insight Precision as the Non-Negotiable Foundation of High-Quality Metal 3D Printing

In the demanding realm of custom metal manufacturing, particularly for mission-critical applications, the term “high quality” in 3D printing transcends mere surface finish or basic dimensional conformity. True high quality is fundamentally rooted in micron-level precision and unwavering process consistency. This precision is not an optional luxury; it is the absolute prerequisite for functional integrity, assembly compatibility, and long-term performance under extreme operational stresses. Variations beyond tight tolerances directly compromise structural soundness, fatigue life, and the intricate fit required in complex assemblies. For industries like aerospace, defense, and high-performance motorsport, where components face immense thermal cycles, vibration, and load, even minute deviations can cascade into catastrophic failure. Achieving this level of precision demands far more than advanced hardware; it requires deep metallurgical understanding, rigorous process control protocols, and extensive validation experience under the most unforgiving conditions.

Wuxi Lead Precision Machinery embodies this precision imperative. Our engineering team possesses over 15 years of specialized expertise in metal additive manufacturing, forged through direct collaboration on projects where failure is not an option. This includes supplying critical titanium and nickel-alloy components validated under the intense scrutiny of Olympic-level sporting equipment and meeting the exacting, classified specifications of advanced military systems. These engagements were not merely production runs; they were rigorous validations of our ability to consistently achieve and certify dimensional accuracy, material properties, and geometric complexity demanded by the world’s highest-performance applications. The lessons learned from ensuring components perform flawlessly at 10,000 meters altitude or within milliseconds of critical operation are directly applied to every client project, regardless of scale.

Our commitment to precision is quantifiable and systematically controlled. We leverage advanced in-situ monitoring, post-build metrology traceable to national standards, and proprietary parameter optimization honed through thousands of production hours. This ensures the final part meets not just the nominal CAD geometry, but the stringent functional requirements of the application. The following table outlines the core precision capabilities underpinning our high-quality service:

| Parameter | Capability | Application Impact |

|---|---|---|

| Dimensional Accuracy | ±0.02 mm to ±0.05 mm | Ensures perfect fit in complex assemblies, eliminates post-machining scrap |

| Feature Resolution | Down to 0.1 mm details | Enables functional micro-features, lattice structures, cooling channels |

| Surface Roughness (As-Built) | Ra 6.3 µm to 12.5 µm | Reduces need for extensive finishing, maintains integrity of thin walls |

| Material Density | >99.95% (Ti6Al4V, Inconel 718) | Guarantees mechanical properties match forged equivalents |

| Repeatability (CpK) | ≥1.67 across build volume | Eliminates batch variation, ensures consistent performance |

This precision translates directly into tangible client value: reduced total cost of ownership through minimized waste and rework, accelerated time-to-market via first-time-right production, and significantly de-risked deployment of innovative metal AM components. At Wuxi Lead Precision Machinery, we understand that high-quality 3D printing is defined by the relentless pursuit of dimensional and material perfection, proven where it matters most. Your critical components deserve nothing less than engineered precision validated by the highest global standards.

Precision Specs & Tolerances

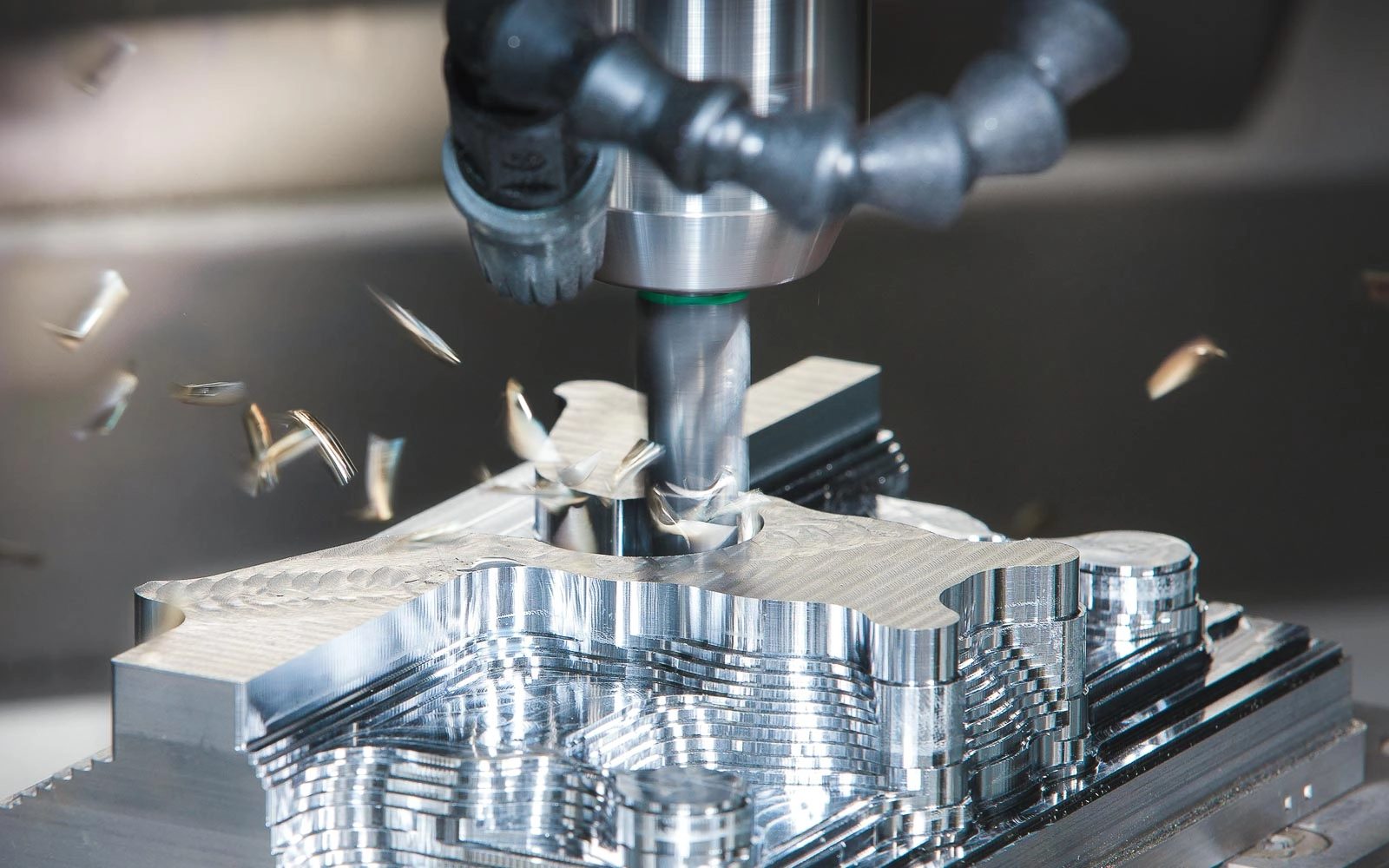

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, centered around precision engineering and high-integrity production processes. At the core of our operations is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility for machining intricate components from solid metal stock. This capability is particularly critical for industries such as aerospace, medical device manufacturing, and high-performance automotive, where part complexity and reliability are non-negotiable.

Our 5-axis CNC platforms are integrated with high-resolution control systems and automated tool changers, ensuring continuous operation with minimal human intervention. This results in reduced cycle times, tighter process control, and consistent repeatability across production runs. We work with a wide range of engineering-grade metals, including titanium alloys, Inconel, stainless steel, aluminum, and tool steels, supporting both prototyping and volume production. Each machining program is optimized using advanced CAM software, ensuring efficient toolpaths, minimized thermal distortion, and maximum material removal rates without compromising dimensional accuracy.

To guarantee the highest level of quality, every critical component undergoes comprehensive inspection using a Zeiss industrial-grade Coordinate Measuring Machine (CMM). This metrology system provides full 3D verification of part geometry, ensuring compliance with design specifications down to the micron level. Our CMM inspection process includes first-article inspection (FAI), in-process checks, and final batch validation, all documented with detailed inspection reports traceable to international standards. This rigorous quality control protocol ensures that every component meets or exceeds customer-defined tolerances and regulatory requirements.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC and inspection processes:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and material |

| Angular Tolerances | ±0.1° | ±0.05° | Measured via CMM |

| Positional Accuracy | ±0.02 mm | ±0.01 mm | For hole patterns and critical features |

| Surface Roughness | Ra 3.2 μm | Ra 0.8 μm | Achievable with fine finishing passes |

| Geometric Tolerances (GD&T) | Per ISO 2768-mK | Custom to drawing | Full GD&T inspection supported |

| Feature Size (Minimum) | 0.5 mm diameter | 0.2 mm diameter | For milled features and holes |

All manufacturing and inspection data is maintained in a secure digital environment, enabling full traceability and audit readiness. Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous quality assurance, and engineering expertise to deliver high quality 3D printing service alternatives through precision subtractive manufacturing, ensuring clients receive components that meet the most demanding technical and performance criteria.

Material & Finish Options

Material Selection for High-Performance Metal Additive Manufacturing

Selecting the optimal material for metal additive manufacturing (AM) is critical for achieving functional performance, cost efficiency, and regulatory compliance in demanding industrial applications. At Wuxi Lead Precision Machinery, our expertise in high-quality 3D printing services ensures precise material execution aligned with your engineering requirements. Material choice directly impacts mechanical properties, thermal behavior, corrosion resistance, and post-processing pathways. We prioritize certified, aerospace-grade alloys processed under stringent ISO 9001 and AS9100 quality systems to guarantee repeatability and part integrity.

Aluminum Alloys dominate lightweight structural applications requiring thermal conductivity and moderate strength. AlSi10Mg is the industry standard for AM, offering excellent castability, good fatigue resistance, and a favorable strength-to-weight ratio. It is ideal for complex aerospace ducting, heat sinks, and automotive prototypes where weight reduction is paramount. Its relatively low melting point enhances process stability but requires careful thermal management during build.

Stainless Steel Alloys provide superior strength, hardness, and corrosion resistance for harsh environments. 17-4 PH stainless steel is widely specified for its high yield strength (achievable via precipitation hardening), excellent machinability post-print, and biocompatibility. Applications include hydraulic manifolds, medical instruments, and marine components. 316L stainless steel offers enhanced corrosion resistance in chemical or saline environments, suitable for fluid handling systems and surgical implants, though with lower ultimate strength than 17-4 PH.

Titanium Alloys deliver the highest strength-to-weight ratio and exceptional biocompatibility and corrosion resistance. Ti6Al4V (Grade 5) is the predominant AM titanium alloy, withstanding extreme temperatures and aggressive media. It is indispensable for critical aerospace brackets, biomedical implants, and high-performance motorsport components where failure is not an option. Its high reactivity necessitates inert build chamber environments, which our certified systems strictly maintain.

Anodizing: Essential Surface Enhancement for Aluminum AM Parts

While anodizing is not applicable to steel or titanium AM parts, it is a vital post-processing step for aluminum components. This electrochemical process grows a dense, wear-resistant oxide layer on the aluminum surface, significantly improving corrosion resistance, abrasion tolerance, and adhesion for paints or adhesives. Decorative coloring is achievable, but industrial applications prioritize functional Type II (sulfuric acid) or hardcoat Type III anodizing for maximum durability. Crucially, anodizing seals surface porosity inherent in as-built AM aluminum parts, enhancing pressure tightness and longevity in service. Our integrated finishing capabilities ensure consistent anodized layers meeting MIL-A-8625 specifications.

Material performance specifications are summarized below for rapid comparison:

| Material | Key Alloys | Density (g/cm³) | Yield Strength (MPa) | Typical Applications |

|---|---|---|---|---|

| Aluminum | AlSi10Mg | 2.67 | 190-250 | Aerospace ducts, heat exchangers, enclosures |

| Stainless Steel | 17-4 PH, 316L | 7.8-8.0 | 800-1000 (17-4 PH) | Hydraulic manifolds, medical tools, marine fittings |

| Titanium | Ti6Al4V | 4.43 | 880-950 | Aircraft brackets, surgical implants, motorsport components |

Partnering with Wuxi Lead ensures your material selection leverages our deep process knowledge and certified production environment. We provide comprehensive material traceability and mechanical property validation to de-risk your high-value projects. Contact our engineering team for application-specific material qualification support.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of every successful metal 3D printing project begins with meticulous design engineering. Our team of certified mechanical and materials engineers collaborates directly with clients to transform conceptual sketches or functional requirements into optimized 3D CAD models. We employ advanced simulation software to conduct finite element analysis (FEA), thermal stress modeling, and topology optimization, ensuring that each design is not only manufacturable but also structurally efficient and material-conservative. This phase includes material selection based on operational demands—such as high-temperature resistance, corrosion performance, or mechanical load—using premium alloys like Inconel 718, Ti-6Al-4V, 316L stainless steel, or AlSi10Mg. Design for Additive Manufacturing (DfAM) principles are rigorously applied to minimize support structures, reduce post-processing effort, and enhance part performance, setting the stage for zero-defect production.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using our state-of-the-art metal laser powder bed fusion (LPBF) systems. Each prototype is manufactured under strict environmental controls to ensure dimensional stability and metallurgical integrity. In-house metrology tools, including coordinate measuring machines (CMM) and industrial computed tomography (CT) scanning, verify internal and external geometries against original CAD data with micron-level accuracy. Mechanical testing—tensile, hardness, and fatigue—is conducted on sample coupons built alongside each prototype to validate material properties. Clients receive a comprehensive test report, including density analysis (typically >99.95%) and surface roughness data, enabling informed approval before mass production. This iterative validation loop ensures functional performance, regulatory compliance, and design robustness, eliminating costly errors downstream.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, Wuxi Lead transitions seamlessly into high-volume manufacturing using a synchronized fleet of industrial-grade metal 3D printers. Our production floor operates under ISO 9001 and IATF 16949 quality management systems, with real-time monitoring of laser power, layer thickness, oxygen levels, and thermal gradients. Each build undergoes in-process inspection via integrated cameras and melt pool monitoring, allowing immediate detection of anomalies. Post-processing—including stress relief, support removal, heat treatment, CNC machining, and surface finishing—is executed in-house to maintain full traceability and process control. Final inspection includes first-article inspection (FAI) reporting and batch-level quality certification. This closed-loop production system, combined with rigorous operator training and automated data logging, enables us to achieve a Six Sigma defect rate of less than 3.4 defects per million opportunities.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–60 µm |

| Build Envelope (Max) | 500 x 500 x 500 mm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 10–15 µm (can be polished to Ra <1 µm) |

| Material Density | >99.95% |

| Common Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, Tool Steel |

| Post-Processing Options | HIP, CNC Machining, Polishing, Passivation |

Every stage of our process is engineered for repeatability, quality, and full compliance with aerospace, medical, and industrial standards.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Additive Excellence

When your project demands engineering-grade metal 3D printing with zero tolerance for error, Wuxi Lead Precision Machinery delivers the convergence of advanced technology and meticulous craftsmanship. As your strategic manufacturing partner, we transcend conventional service providers by embedding our decades of CNC engineering expertise directly into every additive build. Our ISO 9001-certified facility in Wuxi operates under stringent aerospace and medical quality protocols, ensuring your critical components meet global regulatory standards without compromise. We understand that high-value prototypes and end-use parts require more than layer deposition—they demand metallurgical integrity, geometric precision, and unwavering repeatability. That is why our engineers collaborate with you from initial design validation through post-processing, applying finite element analysis to optimize build orientation and support structures for minimal distortion and maximum mechanical performance.

Our industrial-grade metal additive systems are calibrated and maintained to micron-level accuracy, supported by in-house metrology labs featuring 5-axis CMMs and CT scanners. This integrated capability allows us to guarantee specifications that align with the most demanding applications in aerospace, energy, and high-performance automation. Below are key technical parameters defining our production readiness:

| Capability | Specification Detail |

|---|---|

| Supported Materials | Ti-6Al-4V, Inconel 718, 17-4 PH, 316L, AlSi10Mg, Custom Alloys |

| Build Volume | Up to Ø350 x 400 mm (EOS M 400-4 Platform) |

| Layer Thickness | 20–60 μm (adjustable per application) |

| Dimensional Accuracy | ±25 μm per 100 mm (post-machining) |

| Surface Finish | As-built: Ra 8–12 μm; Machined: Ra 0.8 μm |

| Post-Processing | HIP, Stress Relief, CNC Machining, Polishing, CMM Validation |

Choosing Lead Precision means gaining a partner invested in your success beyond the print cycle. We mitigate supply chain vulnerabilities through dual-source material qualification and maintain 95%+ first-pass yield rates via real-time melt pool monitoring and AI-driven anomaly detection. Our technical team speaks your engineering language—providing actionable feedback on DfAM improvements, cost-reduction opportunities, and certification documentation tailored to your industry’s compliance framework. For projects where failure is not an option, our closed-loop quality management system ensures traceability from powder lot to finished component, with full material test reports and 3D deviation maps included in every shipment.

Initiate your precision metal additive project with confidence. Contact our engineering sales team directly at [email protected] to receive a technical consultation and project-specific capability assessment within 24 business hours. Specify your component’s critical features, material requirements, and target volume to expedite our feasibility analysis. For urgent RFQs, call +86 510 8533 8888 or visit leadmachinery.net/engineering-services. Let Lead Precision transform your most complex metal 3D printing challenges into certified, production-ready solutions—engineered in China, trusted globally. Your next breakthrough component begins with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.