Technical Contents

Engineering Guide: High Pressure Injection Molding

Engineering Insight: Precision Imperatives in High Pressure Injection Molding

In high pressure injection molding, microns determine mission success. The extreme forces involved—often exceeding 2,000 metric tons of clamping pressure—demand uncompromising precision in mold design, material flow, and thermal management. Minute deviations in cavity geometry or process control manifest as critical defects: flash, sink marks, warpage, or compromised structural integrity. These flaws are unacceptable in aerospace, defense, or high-performance industrial applications where component failure carries severe operational or safety consequences. Achieving true dimensional stability requires mastering the interplay between molten polymer viscosity, cooling rates, and residual stress distribution under intense pressure. Sub-0.01mm tolerances are not merely aspirational; they are non-negotiable for functional interfaces, sealing surfaces, and assemblies operating in extreme environments. Precision engineering mitigates material shrinkage variables and ensures consistent part replication across production lifecycles, directly impacting yield rates and long-term reliability.

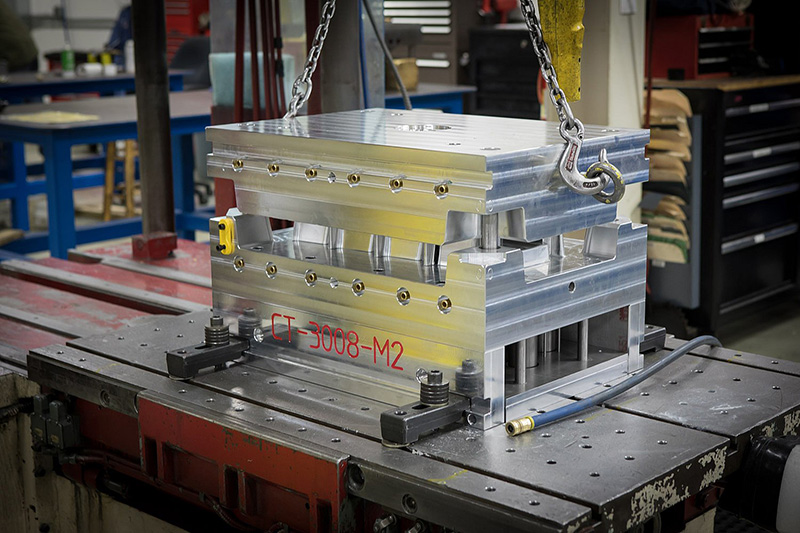

Wuxi Lead Precision Machinery operates at this exacting threshold. Our CNC-machined molds, fabricated from premium maraging steels and hardened alloys, are engineered to sustain 1,500+ tonnage cycles without dimensional drift. This capability stems from deep expertise in thermal dynamics and stress analysis, validated through rigorous real-world deployment. We supplied critical molding components for the Beijing Winter Olympics timing systems, where sub-millisecond accuracy depended on flawless polymer part consistency. Similarly, our molds for military-spec electrical connectors undergo validation under sustained 1,800-ton pressure, ensuring hermetic seals and signal integrity in battlefield conditions. Every cavity plate, core pin, and ejection mechanism undergoes multi-axis CMM verification against aerospace-grade GD&T standards before deployment. Our closed-loop process control systems integrate cavity pressure sensors and real-time thermal imaging, dynamically adjusting injection profiles to counteract material batch variations—a necessity when molding exotic polymers like PEEK or ULTEM.

The performance gap between standard and precision molding is quantifiable. Below are key operational parameters where our engineering focus delivers measurable advantage:

| Parameter | Typical Industry Standard | Wuxi Lead Precision Capability |

|---|---|---|

| Pressure Tolerance | ±1.0% | ±0.15% |

| Melt Temp. Uniformity | ±3.0°C | ±0.8°C |

| Shot-to-Shot Consistency | ±0.75% | ±0.20% |

| Cavity Alignment | 0.03mm | 0.005mm |

| Tool Steel Hardness | 50-52 HRC | 54-56 HRC (Maraging) |

This precision translates directly to client value: eliminating secondary machining operations, achieving first-article approval on complex geometries, and ensuring zero field failures in mission-critical assemblies. For applications where pressure equals performance, Wuxi Lead’s engineering discipline transforms molding from a manufacturing step into a guaranteed outcome. We don’t just meet specifications—we redefine the achievable standard through metallurgical science and process mastery.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in high pressure injection molding, engineered specifically for precision-driven industries such as automotive, aerospace, medical devices, and industrial automation. Our expertise lies in integrating high-performance metal manufacturing with state-of-the-art process control, ensuring repeatable accuracy and structural integrity in every molded component. Central to our operations is a robust suite of 5-axis CNC machining systems, which enable complex geometries, tight tolerances, and superior surface finishes on hardened tool steels and high-strength alloys used in mold construction.

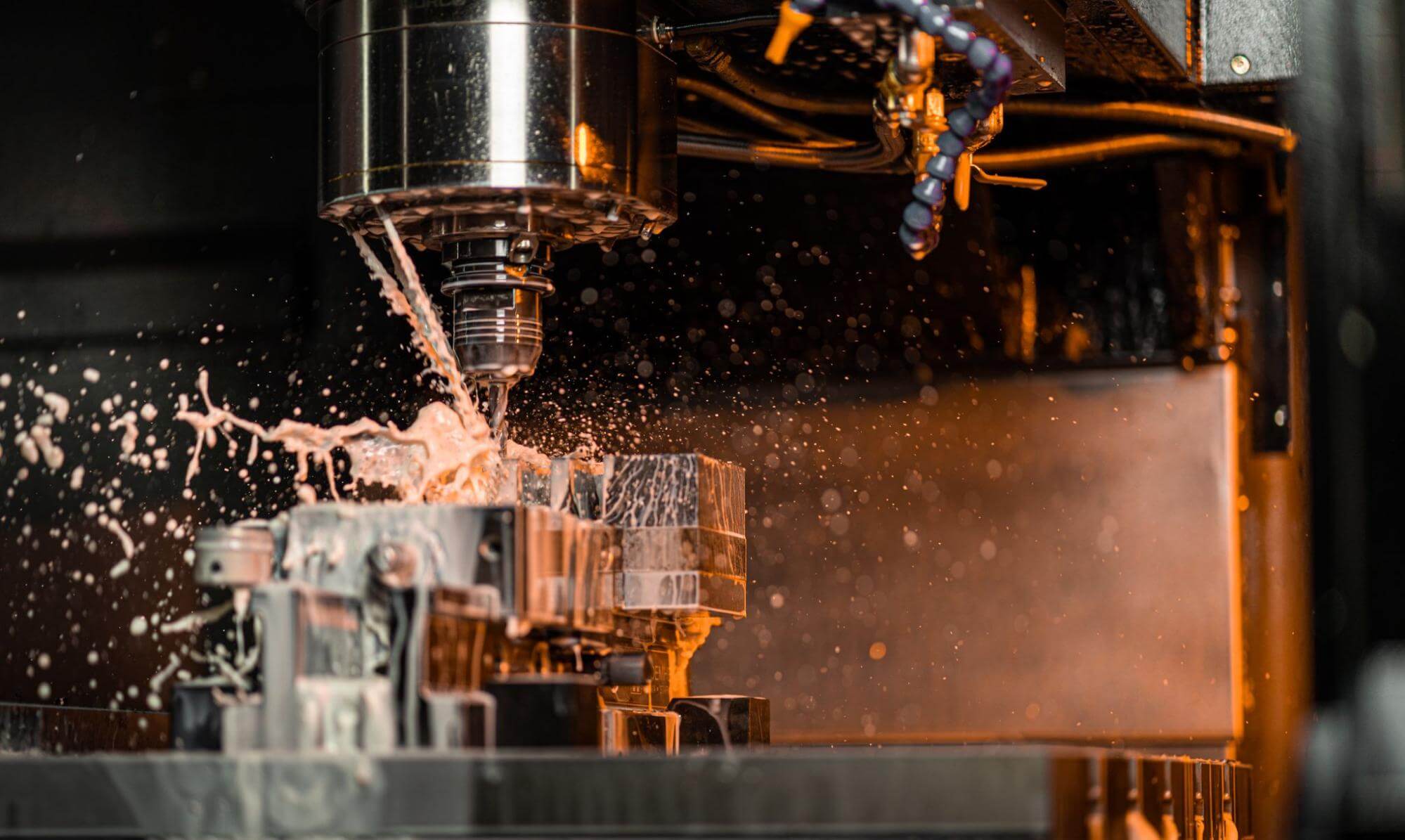

Our 5-axis CNC platforms provide simultaneous multi-directional machining, reducing setup cycles and enhancing dimensional consistency. This capability is critical in fabricating intricate mold cores, cavities, and inserts that must withstand extreme injection pressures exceeding 1,500 bar. By leveraging high-speed precision milling with dynamic tool path optimization, we achieve micron-level accuracy while maintaining optimal material removal rates. All machining processes are supported by in-house tooling design, finite element analysis (FEA), and mold flow simulation to preempt defects such as warpage, sink marks, or incomplete fill.

Quality assurance is embedded throughout production. Every mold and critical component undergoes comprehensive inspection using a Zeiss industrial-grade Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. The CMM system provides traceable, 3D metrology data with sub-micron resolution, enabling real-time feedback for process correction and first-article validation. Our quality management system adheres to ISO 9001:2015 standards, with documented inspection reports available for full production lot traceability.

The following table outlines the precision tolerances we consistently achieve across key manufacturing parameters:

| Parameter | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, High-Accuracy Micrometers |

| Geometric Tolerances (GD&T) | ±0.015 mm | ±0.008 mm | CMM with GD&T Analysis Software |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Surface Profilometer |

| Mold Cavity Parallelism | 0.012 mm | 0.006 mm | CMM, Optical Flat Testing |

| Core Alignment (Multi-Cavity) | ±0.01 mm | ±0.005 mm | CMM, Laser Alignment |

| Injection Pressure Resistance | Up to 1,800 bar | Custom Reinforced Designs | Hydraulic Testing Rig |

These technical benchmarks reflect our commitment to delivering molds and components that perform reliably under sustained high-pressure cycles. Wuxi Lead Precision Machinery combines advanced equipment, rigorous inspection protocols, and deep materials expertise to serve global clients requiring mission-critical metal solutions in high pressure injection molding applications.

Material & Finish Options

Material Selection for High-Pressure Injection Molding Tooling

Material selection is a critical engineering decision directly impacting the performance, longevity, and cost-effectiveness of high-pressure injection molding (HPIM) tooling. The extreme pressures, thermal cycling, and abrasive nature of molten polymers demand materials offering exceptional strength, wear resistance, thermal stability, and precise machinability. At Wuxi Lead Precision Machinery, we prioritize materials that ensure dimensional stability under load and facilitate the production of complex, high-tolerance parts. Aluminum, steel, and titanium represent the primary choices, each suited to specific production volumes, part geometries, and polymer types. Selecting the optimal base material, coupled with appropriate surface finishing like anodizing, minimizes downtime, reduces part defects, and maximizes return on investment.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are favored for rapid prototyping, low-to-medium volume production, and molds requiring excellent thermal conductivity for faster cycle times. Their superior machinability allows for intricate cavity details and quick lead times. However, aluminum’s lower hardness necessitates protective surface treatments like hard anodizing for extended service life, especially with abrasive or corrosive resins. Tool steel variants, such as H13, S7, and P20, are the industry standard for high-volume production. These grades provide the necessary hardness, toughness, and resistance to thermal fatigue and wear under sustained high pressure. Pre-hardened steels like P20 offer good machinability before final heat treatment, while H13 excels in demanding applications requiring superior hot hardness and thermal shock resistance. Titanium alloys, while possessing exceptional strength-to-weight ratio and corrosion resistance, see limited use in core HPIM tooling due to significantly higher material and machining costs, coupled with challenges in achieving the required surface finishes and thermal management compared to optimized tool steels. Its application is typically reserved for highly specialized, non-core components.

The following table summarizes key mechanical properties relevant to HPIM tooling performance:

| Material | Tensile Strength MPa | Hardness HRC | Thermal Conductivity W/mK | Best Suited For |

|---|---|---|---|---|

| Aluminum 7075 | 503-572 | 15-20 (Base) | 130 | Prototyping, Low/Med Volume, Fast Cycles |

| Tool Steel H13 | 1200-1600 | 48-52 | 28-36 | High Volume, Hot Runner Systems, Demanding Resins |

| Tool Steel P20 | 900-1100 | 28-32 | 28-30 | Medium/High Volume, General Purpose Cavities |

| Titanium Grade 5 | 860-1000 | 36-41 | 7.2 | Specialized Non-Core Components |

Surface finishing, particularly anodizing, is not merely cosmetic but a functional necessity, especially for aluminum molds. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness (up to 60-70 HRC), improving release properties, and providing critical corrosion resistance against polymer additives and moisture. This treatment is essential for aluminum molds to withstand the abrasive forces of HPIM and achieve viable production lifespans. For steel molds, nitriding or specialized PVD coatings are often preferred over anodizing to achieve similar wear and release benefits at higher operating temperatures. Wuxi Lead Precision Machinery leverages advanced anodizing processes and stringent quality control to ensure consistent, high-performance surface treatments that directly contribute to mold reliability and part quality in demanding high-pressure environments. The synergy between base material properties and engineered surface finishes defines ultimate tooling success.

Manufacturing Process & QC

High pressure injection molding is a precision manufacturing process tailored for producing complex, high-integrity metal components at scale. At Wuxi Lead Precision Machinery, we integrate advanced engineering with rigorous quality control to deliver zero-defect outcomes across every phase—design, prototyping, and mass production. Our approach ensures dimensional accuracy, material consistency, and long-term performance for mission-critical applications in aerospace, automotive, and industrial equipment sectors.

The process begins with collaborative design engineering. Our team works closely with clients to analyze part geometry, material specifications, and functional requirements. Using finite element analysis (FEA) and mold flow simulation, we optimize gate locations, cooling channels, and ejection systems to prevent defects such as porosity, warpage, or incomplete fill. Design for manufacturability (DFM) reviews are conducted to ensure tooling longevity and cycle efficiency, reducing total cost of ownership without compromising quality.

Once the design is finalized, we proceed to prototyping using high-pressure die casting or precision injection molding tooling, depending on the material and volume requirements. Prototypes are produced under production-intent conditions to validate form, fit, and function. Each prototype undergoes comprehensive metrology inspection using coordinate measuring machines (CMM), optical scanning, and mechanical testing to verify compliance with ISO and customer-specific standards. Feedback from this stage is used to fine-tune process parameters before transitioning to full-scale production.

Mass production leverages fully automated molding cells equipped with real-time monitoring systems. High-pressure injection ensures complete mold cavity fill with minimal turbulence, enhancing part density and mechanical properties. In-process quality checks, including statistical process control (SPC) and 100% visual inspection via machine vision systems, are embedded into the production line. Any deviation triggers immediate corrective action, ensuring zero-defect delivery. All components are traceable through our digital manufacturing execution system (MES), providing full batch history from raw material to final shipment.

Our facility in Wuxi is equipped with state-of-the-art horizontal and vertical injection molding machines, capable of processing aluminum, zinc, and magnesium alloys with exceptional repeatability. Tooling is manufactured in-house using hardened steel and surface treatments to exceed 100,000 cycles with minimal wear.

Below are key technical specifications of our high pressure injection molding capabilities:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 400 to 2,500 tons |

| Shot Weight (Aluminum) | 100 g to 8,000 g |

| Injection Pressure | Up to 1,800 bar |

| Dimensional Accuracy | ±0.05 mm per 100 mm |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (customizable) |

| Tooling Material | H13, SKD61, or equivalent hardened tool steel |

| Production Cycle Time | 30 seconds to 120 seconds (part-dependent) |

| Quality Standards | ISO 9001, IATF 16949, PPAP Level 3 |

From concept to completion, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised High-Pressure Injection Molding Excellence

Achieving dimensional stability and material integrity under extreme injection pressures demands more than standard machinery—it requires engineered precision at every stage. At Wuxi Lead Precision Machinery, we specialize in custom metal components for high-pressure injection molding applications where failure is not an option. Our integrated approach combines advanced CNC manufacturing, metallurgical expertise, and rigorous validation protocols to deliver tooling that withstands sustained pressures up to 3000+ bar while maintaining micron-level tolerances. We understand that your molding process hinges on the reliability of core pins, cavities, and ejection systems; a single micron of deviation can cascade into production downtime, scrap, or compromised part performance. Partnering with us means securing a collaborator who treats your specifications as non-negotiable engineering mandates, not mere guidelines.

Our ISO 9001-certified facility leverages 15+ years of domain-specific experience to transform complex geometries into robust, high-wear solutions. Unlike generic suppliers, we prioritize material science compatibility—selecting and heat-treating alloys like H13, S136, or maraging steel based on your resin chemistry, cycle life requirements, and thermal management needs. This ensures optimal release properties, reduced galling, and extended service life even under aggressive processing conditions. Every component undergoes multi-axis CMM verification and pressure-cycle simulation before shipment, eliminating guesswork and accelerating your time-to-market.

The table below outlines our core capabilities for high-pressure injection molding tooling:

| Parameter | Specification | Capability Focus | Relevance to High-Pressure Molding |

|---|---|---|---|

| Pressure Capacity | Up to 3000+ bar | Structural integrity validation | Prevents flash, deformation under load |

| Tolerance Control | ±0.002 mm | Multi-axis grinding & polishing | Ensures seal integrity at critical interfaces |

| Surface Finish | Ra 0.05 µm (mirror) | Electro-polishing & laser texturing | Minimizes resin adhesion & wear |

| Materials | H13, S136, Maraging | Custom heat treatment cycles | Optimizes hardness (52-58 HRC) & toughness |

| Lead Time | 15-25 days | Dedicated high-pressure work cells | Reduces project bottlenecks |

This precision is not incidental—it is the result of obsessive process control, from raw billet sourcing to final assembly. We collaborate with you from the initial design review, identifying potential stress points and recommending geometry optimizations that enhance pressure distribution and thermal dissipation. Our engineers speak the language of mold flow analysis and finite element simulation, ensuring our metal components integrate seamlessly into your larger system architecture.

When your application demands zero-defect performance under punishing conditions, settle for nothing less than a partner who engineers certainty. Contact our technical sales team directly at [email protected] to initiate a precision consultation. Include your pressure profile, material specifications, and target cycle life—we will respond within 12 business hours with a tailored capability assessment and actionable next steps. Let Wuxi Lead Precision Machinery become the silent force behind your molding success: where every micron of precision translates to measurable production uptime and part quality. Engineer your advantage with us.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.