Technical Contents

Engineering Guide: High Precision Injection Moulding

Engineering Insight: High Precision Injection Moulding

In the realm of advanced manufacturing, high precision injection moulding stands as a critical process for producing complex, dimensionally accurate components at scale. This technology is not merely about shaping molten material into form—it is about achieving micron-level consistency, repeatability, and structural integrity across thousands or even millions of cycles. For industries such as aerospace, medical devices, automotive, and defense, where performance under extreme conditions is non-negotiable, the margin for error is effectively zero. At Wuxi Lead Precision Machinery, we understand that precision is not an outcome—it is engineered into every stage of the process.

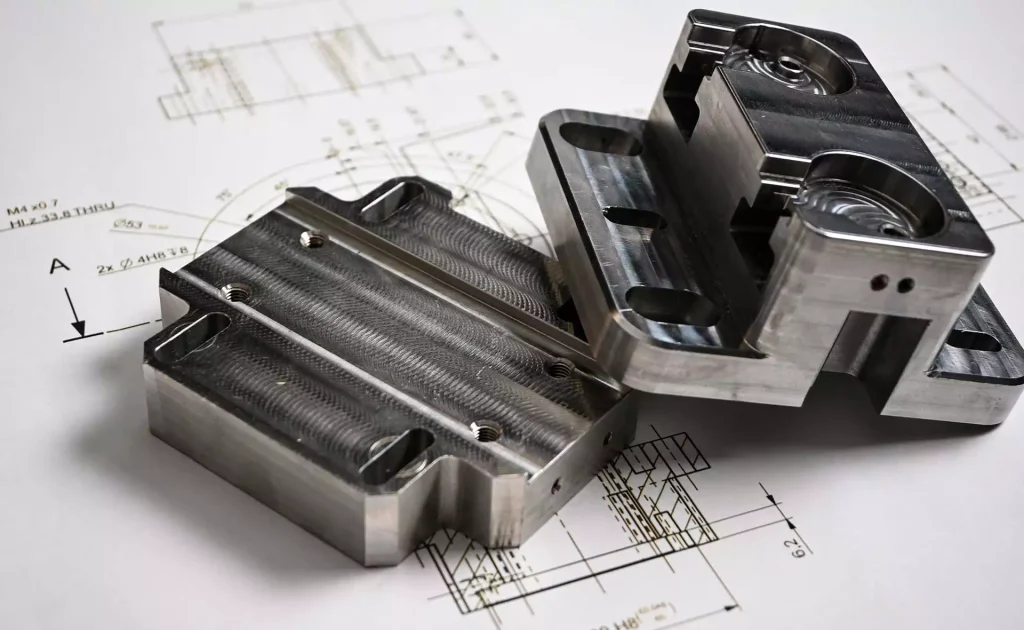

High precision injection moulding demands more than advanced machinery; it requires a holistic integration of design expertise, material science, thermal management, and real-time process control. The mould itself must be manufactured to exacting tolerances, often within ±0.002 mm, using high-grade tool steels and CNC machining techniques that ensure longevity and stability. Even minor deviations in cavity geometry, cooling channel placement, or surface finish can result in warpage, sink marks, or inconsistent part dimensions—defects that are unacceptable in mission-critical applications.

Our engineering team at Wuxi Lead Precision Machinery has spent over a decade refining this balance of art and science. With direct involvement in projects for Olympic-standard equipment and military-grade systems, we have delivered moulds that operate under the most rigorous quality audits and performance benchmarks. These applications demand not only precision but also traceability, durability, and compliance with international standards such as ISO 9001 and AS9100. Our experience in these elite sectors informs every custom solution we build, ensuring that clients receive not just a product, but a guaranteed performance platform.

Precision is also sustained through intelligent process integration. We employ closed-loop monitoring systems that track injection pressure, melt temperature, and clamp force in real time, allowing for immediate corrections and full batch consistency. Coupled with advanced simulation software, we predict and optimize flow dynamics before the first shot is ever made, minimizing trial runs and accelerating time to market.

The following table outlines key specifications that define our high precision injection moulding capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05–0.2 µm |

| Mould Life Expectancy | 1,000,000+ cycles |

| Material Compatibility | Engineering plastics, liquid silicone, PEEK, PPS |

| Machine Clamping Force Range | 50–2000 Tons |

| Process Control | Real-time monitoring with SPC integration |

| Cooling Efficiency | Optimized conformal cooling channels |

At Wuxi Lead Precision Machinery, we do not simply meet precision standards—we set them. Our commitment to excellence is forged in the challenges of elite industrial applications and delivered in every custom metal solution we engineer.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Injection Moulding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision for high-end injection moulding components, serving global leaders in medical, aerospace, and advanced consumer electronics. Our technical foundation centers on advanced multi-axis machining and rigorous metrology, ensuring every part meets the most stringent geometric and dimensional requirements inherent in complex mould fabrication and critical component production. We understand that success in high precision injection moulding hinges on the absolute accuracy of the tooling and core components; our capabilities are engineered specifically to eliminate variability at the source.

Our core manufacturing capability is anchored by a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems, featuring thermal compensation, high-resolution feedback, and rigid construction, enable the efficient production of mould cores, cavities, inserts, and electrodes with exceptional geometric complexity. The simultaneous 5-axis motion allows for single-setup machining of intricate 3D contours, undercuts, and micro-features common in precision moulds, significantly reducing cumulative error from multiple fixtures. Advanced toolpath strategies and in-process probing ensure micron-level accuracy is maintained throughout the machining cycle, directly translating to superior part consistency and surface finish in the final moulded product. Material versatility spans hardened tool steels (H13, S7, stainless grades), aluminum alloys, and specialty metals, all processed under strict environmental controls.

Quality assurance is not a final step but an integrated process, beginning with material certification and continuing through every machining phase. The cornerstone of our dimensional verification is a comprehensive Coordinate Measuring Machine (CMM) laboratory. Equipped with high-accuracy, multi-sensor CMMs (including optical and tactile probes), we perform full 3D geometric dimensioning and tolerancing (GD&T) analysis on critical features. Our inspection protocols exceed standard industry practices, utilizing advanced metrology software for comprehensive deviation mapping, surface texture analysis, and first-article inspection reports traceable to international standards (ISO 17025 accredited processes where applicable). This metrology-grade validation provides clients with absolute confidence in part conformity before mould assembly or component integration.

The following table details our standard achievable tolerance capabilities for machined components, reflecting the performance envelope consistently delivered across our production floor for high precision injection moulding applications. These specifications represent our routine production capability under controlled conditions for features within typical size ranges for mould components.

| Specification Category | Standard Capability | Notes |

|---|---|---|

| Linear Dimensions (up to 300mm) | ±0.002 mm | Verified via CMM; sub-micron repeatability |

| Angular Tolerances | ±0.001° | Critical for alignment surfaces & angles |

| Surface Roughness (Ra) | 0.05 µm (0.2 µin) | Achieved with fine finishing strategies |

| Positional Tolerance (Holes) | ±0.003 mm | Relative to datum; verified in 3D |

| Flatness (up to 100x100mm) | 0.0015 mm | Critical for sealing surfaces & parting lines |

This combination of advanced 5-axis CNC technology, integrated CMM inspection, and disciplined process control forms the bedrock of Wuxi Lead’s ability to produce injection moulding components where tolerances are non-negotiable. We partner with clients from initial design for manufacturability through final validation, ensuring the precision engineered into the tool is faithfully replicated in every moulded part.

Material & Finish Options

Material Selection for High Precision Injection Moulding

Selecting the appropriate material for injection moulding components is critical to ensuring performance, durability, and cost-efficiency in high-precision manufacturing. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions using premium-grade Aluminum, Steel, and Titanium—each offering distinct mechanical and thermal properties suitable for demanding industrial applications. The choice of material directly affects mould life, dimensional stability, thermal conductivity, and resistance to wear and corrosion.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume production moulds due to their excellent machinability and high thermal conductivity. These properties allow for faster cooling cycles, improving production efficiency. While not as hard as steel, aluminum offers sufficient strength for many applications and significantly reduces machining time and tool wear. It is ideal for applications where lead time and cost are critical factors.

Steel, especially tool steels such as P20, H13, and S136, remains the standard for high-volume injection moulding. These steels offer superior hardness, wear resistance, and longevity under repeated thermal cycling. P20 is commonly used for general-purpose moulds, while H13 provides excellent toughness and resistance to thermal fatigue—making it suitable for hot-runner systems. S136 stainless steel is preferred in corrosive environments or when optical clarity and surface finish are paramount, such as in medical or optical components.

Titanium alloys, particularly Ti-6Al-4V, are employed in highly specialized applications where extreme strength-to-density ratio, corrosion resistance, and performance at elevated temperatures are required. While significantly more expensive and challenging to machine, titanium’s inertness and durability make it suitable for aerospace, defense, and high-performance automotive components. Its use in moulding is typically limited to critical inserts or cores exposed to aggressive conditions.

Surface finishing plays a pivotal role in mould performance and part quality. Anodizing is a widely adopted electrochemical process for aluminum moulds, enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat anodizing) delivers a thick, wear-resistant ceramic-like surface capable of withstanding prolonged use. Anodized layers also provide electrical insulation and can be dyed for identification purposes. For steel and titanium, alternative treatments such as nitriding, chrome plating, or PVD coatings are typically recommended.

Below is a comparative overview of key material properties relevant to high precision injection moulding:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 570 | 15–20 (HB) | 130 | Prototypes, low-volume production |

| P20 Steel | 900–1100 | 28–32 | 30 | General-purpose moulds, medium volume |

| H13 Steel | 1300–1600 | 45–52 | 25 | High-temperature, high-wear environments |

| S136 Steel | 1400–1700 | 48–54 | 22 | Corrosion-resistant, optical components |

| Titanium Ti-6Al-4V | 900–1000 | 36–42 | 7 | Aerospace, defense, specialized inserts |

Material and finish selection must be aligned with production volume, part geometry, environmental exposure, and surface finish requirements. Wuxi Lead Precision Machinery provides expert consultation to match your project specifications with the optimal material and treatment process, ensuring reliability and precision in every component.

Manufacturing Process & QC

Precision Injection Moulding: The Zero Defects Production Pathway

At Wuxi Lead Precision Machinery, our high-precision metal injection moulding process is engineered from inception to eliminate defects, ensuring components meet the most stringent aerospace, medical, and automotive standards. This rigorous methodology spans three integrated phases: Design, Prototyping, and Mass Production, each governed by closed-loop quality systems.

The foundation is meticulous Design Engineering. Our team collaborates with clients to analyze part geometry, material properties, and functional requirements using advanced simulation software. Finite Element Analysis (FEA) predicts flow behavior, thermal gradients, and potential stress points before tooling begins. This virtual validation identifies and resolves risks like warpage, sink marks, or incomplete fills, establishing precise gating strategies and cooling channel layouts. Critical tolerances are defined against international standards, ensuring dimensional stability is achievable within the process window. This phase prevents 90% of potential defects at the conceptual stage.

Prototyping transitions validated designs into tangible reality under production-intent conditions. We utilize hardened steel prototype tools machined to final specifications on our Swiss CNC systems, not soft aluminum molds. Each prototype run undergoes comprehensive metrology: CMM scans, optical contour checks, and material composition verification against client blueprints. Process parameters are fine-tuned using cavity pressure monitoring and real-time melt viscosity tracking. Any deviation triggers immediate root-cause analysis and process adjustment. This stage confirms manufacturability and secures client sign-off on both part quality and the repeatable process window, eliminating surprises before scale-up.

Mass Production executes the perfected process with uncompromising control. Our automated cells feature integrated in-mold sensors monitoring temperature, pressure, and fill time at 1,000 Hz. Every cycle is compared against the golden prototype dataset; deviations exceeding 0.5% tolerance trigger automatic part rejection and machine lockdown. Statistical Process Control (SPC) charts run continuously, with data fed into our central quality management system for predictive maintenance and trend analysis. Material batches undergo strict pre-production drying and viscosity checks. The result is sustained production of components where critical features consistently achieve ±0.005 mm tolerances, surface finishes to Ra 0.2 µm, and zero functional defects. This closed-loop execution guarantees batch-to-batch uniformity demanded by Tier-1 suppliers.

Critical Process Control Parameters for Zero Defects

| Parameter | Specification | Control Method |

|---|---|---|

| Melt Temperature | ±2°C stability | Dual-zone heaters with PID feedback |

| Injection Pressure | ±1.5 MPa repeatability | Real-time cavity pressure sensors |

| Cycle Time | ±0.3 seconds | Automated clamp stroke monitoring |

| Dimensional Tolerance | Critical features ±0.005 mm | In-line CMM verification per 50 parts |

| Material Moisture | <0.02% | Pre-drying verification sensors |

This seamless integration of predictive design, rigorously validated prototyping, and sensor-driven mass production forms the core of Wuxi Lead’s Zero Defects commitment. Your component’s performance is non-negotiable; our process ensures it is delivered consistently, verified through data, and validated through every part.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for High Precision Injection Moulding Excellence

When your manufacturing operations demand uncompromising accuracy, repeatable performance, and long-term reliability, partnering with a proven leader in custom metal manufacturing is essential. At Wuxi Lead Precision Machinery, we specialize in high precision injection moulding solutions engineered to meet the exacting standards of industries such as automotive, medical devices, aerospace, and advanced electronics. Our expertise lies not only in producing precision-critical components but in delivering fully integrated manufacturing systems tailored to your production goals.

Our approach begins with a deep understanding of your application requirements. From material selection and part geometry to cycle time optimization and tooling longevity, we apply advanced simulation, metrology, and process control methodologies to ensure every injection moulding solution we deliver exceeds expectations. Our in-house capabilities span CNC machining, EDM, surface grinding, and automated assembly, enabling seamless transition from prototype to high-volume production—all under one roof in our ISO 9001-certified facility in Wuxi, China.

What sets us apart is our commitment to precision as a system, not just a specification. We combine German-influenced engineering principles with cutting-edge manufacturing technology to achieve tolerances as tight as ±0.002 mm, surface finishes down to Ra 0.05 µm, and mould lifespans exceeding 1 million cycles. Our engineering team works collaboratively with clients from design validation through production ramp-up, ensuring technical alignment and risk mitigation at every stage.

We understand that in high-stakes manufacturing environments, downtime is not an option. That’s why every system we deliver is built for durability, serviceability, and integration with Industry 4.0 monitoring platforms. Whether you require hot runner systems, multi-cavity precision moulds, or overmoulding solutions for complex assemblies, we provide turnkey support backed by rigorous quality assurance protocols and responsive after-sales service.

Below are key technical capabilities that define our high precision injection moulding solutions:

| Specification | Performance Level |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 – 0.4 µm (polished) |

| Mould Lifetime | Up to 1,000,000+ cycles |

| Maximum Mould Size | 1200 × 800 × 700 mm |

| Clamping Force Range | 50 – 2000 Tons |

| Materials Supported | PEEK, PPS, PC, PBT, PA, LCP, and medical-grade resins |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical) |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally with proven expertise in solving the most complex precision challenges. We don’t just build moulds—we engineer performance, reliability, and value into every component we produce.

For technical consultations, project inquiries, or to request a design for manufacturability (DFM) review, contact us today at [email protected]. Let us help you achieve precision that performs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.