Technical Contents

Engineering Guide: High Precision Injection Molding

Engineering Insight: The Non-Negotiable Imperative of Precision in Injection Molding

In high-end custom metal manufacturing, particularly for complex injection molding applications, precision transcends mere specification—it is the foundational element determining functional integrity, assembly success, and ultimately, product lifecycle. Standard tolerances often fail under the demands of aerospace, medical, and advanced electronics sectors, where micron-level deviations trigger catastrophic cascade failures. Material behavior during injection—viscosity shifts, thermal contraction, and gate dynamics—demands engineering control far beyond conventional capabilities. At Wuxi Lead Precision Machinery, we treat precision as a systemic outcome, not a target. It originates in mold design integrity, extends through thermal management of the molding process, and culminates in metrology-grade verification. Without this holistic approach, even nominally compliant parts exhibit warpage, sink marks, or dimensional drift under operational stress, leading to field failures and costly recalls.

Our engineering philosophy integrates decades of empirical validation from projects where failure was inconceivable. We engineered critical components for Olympic timing systems requiring sub-10-micron repeatability across 10,000+ cycles—a tolerance stricter than most aerospace actuators. Similarly, military-grade communication housings we produced demanded hermetic seals under extreme vibration, necessitating cavity pressure control within ±0.5% and flatness tolerances of 0.005mm per square inch. These projects forged our methodology: predictive flow simulation calibrated to actual machine response, mold steel selection matched to abrasive fillers, and in-process SPC monitoring at 100Hz sampling rates. This eliminates post-mold correction, ensuring first-article compliance.

Precision is quantifiable through process stability and output consistency. The table below contrasts industry benchmarks with Wuxi Lead’s engineered capabilities for critical parameters:

| Parameter | Standard Industry Tolerance | High-Precision Requirement | Wuxi Lead Precision Capability |

|---|---|---|---|

| Dimensional Tolerance | ±0.10 mm | ±0.025 mm | ±0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | 0.05 µm |

| Parting Line Flash | ≤ 0.15 mm | ≤ 0.03 mm | ≤ 0.008 mm |

| Cavity Pressure Control | ±2.0% | ±0.8% | ±0.3% |

| Warpage (100mm span) | ≤ 0.50 mm | ≤ 0.10 mm | ≤ 0.02 mm |

Achieving this requires more than advanced machinery—it demands an engineering culture where every thermal gradient and servo response is interrogated. Our Shanghai facility employs dual-column molding presses with closed-loop viscosity control, coupled with in-mold strain gauges feeding real-time data to our proprietary AI process optimizer. Crucially, we reject the notion of “acceptable deviation bands.” Every component undergoes full CMM inspection against 3D CAD nominal geometry, with traceable calibration to NIM standards. For clients in regulated industries, this translates to zero non-conformance rates in serial production. When your application demands that every micron matters, Wuxi Lead Precision Machinery delivers engineered certainty—not just precision, but provable, repeatable precision validated under the most exacting global standards.

Precision Specs & Tolerances

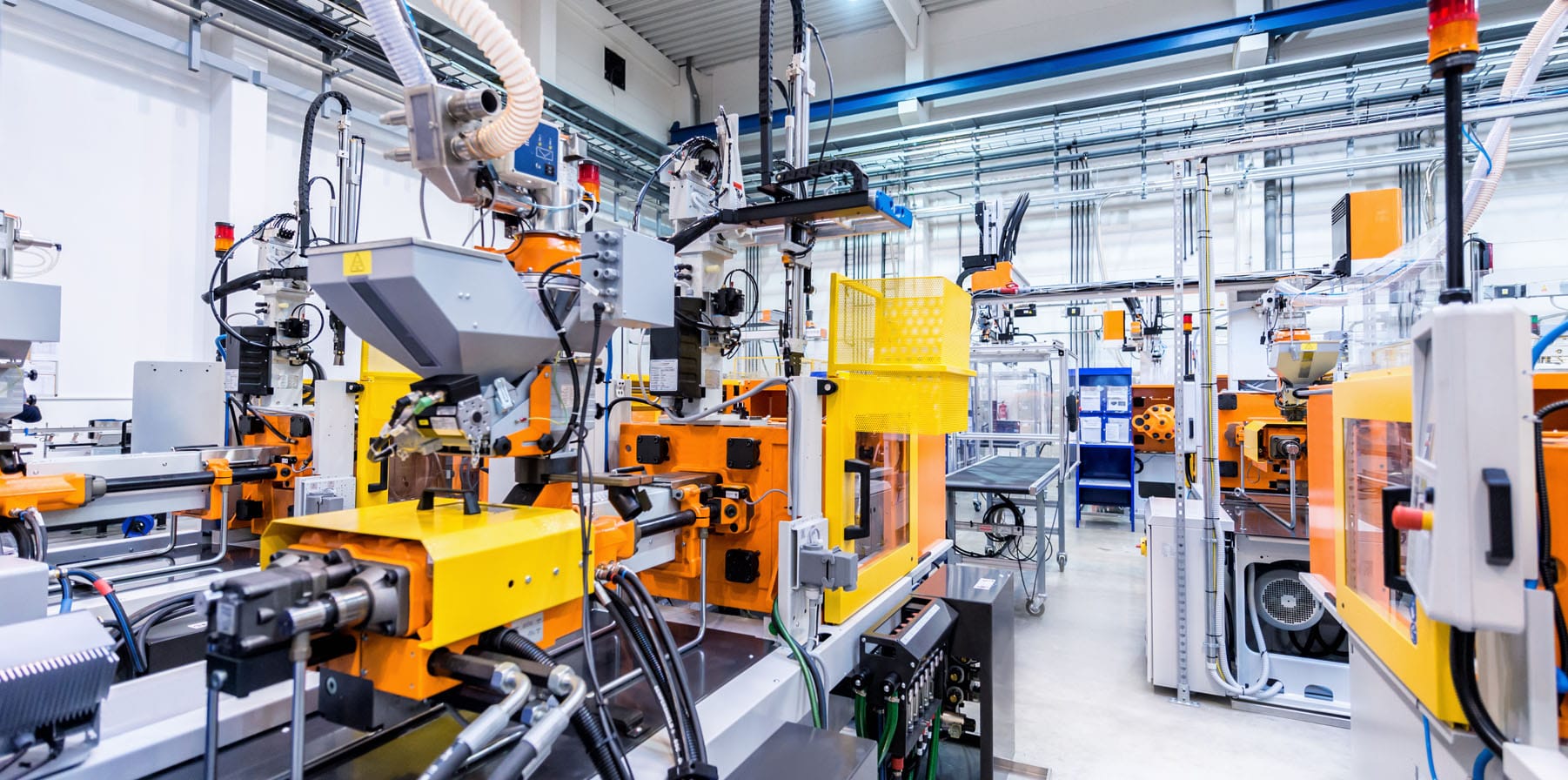

Wuxi Lead Precision Machinery delivers advanced technical capabilities in high precision injection molding, engineered to meet the exacting demands of industries such as aerospace, medical devices, automotive, and industrial automation. Our expertise lies in the integration of precision metal manufacturing with advanced molding technologies, ensuring that every component meets stringent performance and reliability standards. At the core of our production infrastructure is a suite of 5-axis CNC machining centers, which enable us to produce complex, high-tolerance mold components with exceptional surface finish and geometric accuracy.

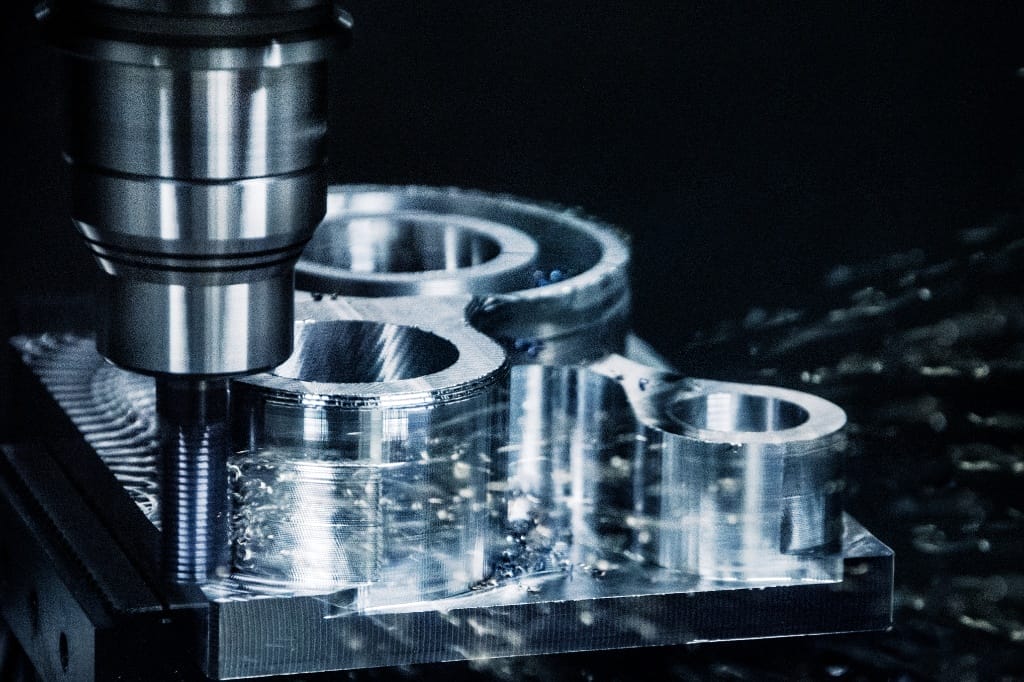

Our 5-axis CNC systems provide simultaneous multi-directional cutting, allowing for intricate cavity and core geometries that are difficult or impossible to achieve with conventional 3-axis equipment. This level of machining precision ensures optimal mold performance, reduced cycle times, and extended tool life. By leveraging high-speed machining and adaptive toolpath strategies, we minimize human intervention and maintain consistency across production runs, whether for prototyping or large-scale manufacturing.

Quality control is embedded at every stage of our process. All critical mold components undergo comprehensive inspection using a state-of-the-art Coordinate Measuring Machine (CMM), ensuring dimensional compliance with design specifications. Our CMM system supports full 3D measurement with micron-level accuracy, enabling detailed analysis of form, position, and surface geometry. This metrology capability is ISO-compliant and integrated into our quality management system, providing full traceability and certification for every project.

We specialize in molds requiring tight tolerances and superior repeatability, particularly for micro-molding and thin-wall applications. Material selection, thermal management, and gate design are optimized through advanced simulation software, reducing defects such as warpage, sink marks, and flow imbalance. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to ensure moldability, cost efficiency, and long-term performance.

The following table outlines the typical precision capabilities we achieve across our high-end injection molding and mold manufacturing processes:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Tolerance (mm) | ±0.01 mm | ±0.005 mm |

| Geometric Tolerance (GD&T) | ±0.015 mm (Position) | ±0.008 mm (Position) |

| Surface Roughness (Ra) | 0.4 µm | 0.2 µm |

| Mold Cavity Accuracy | ±0.01 mm | ±0.005 mm |

| Part Weight Repeatability | ±0.1% | ±0.05% |

| Dimensional Stability (over 10k cycles) | Within ±0.02 mm | Within ±0.01 mm |

These specifications reflect our commitment to delivering molds and molded components that perform reliably in mission-critical applications. Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous quality assurance, and deep technical expertise to provide solutions that exceed industry benchmarks in precision and durability.

Material & Finish Options

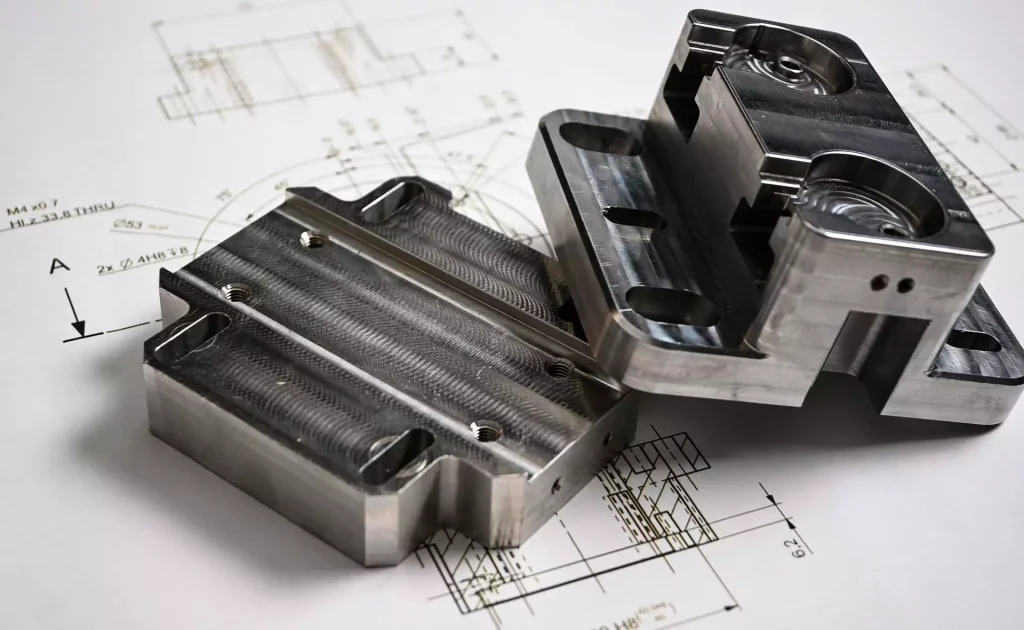

Material Selection for High-Precision Injection Molding Tooling

Selecting the optimal material for injection molding tooling is a critical engineering decision directly impacting part quality, production longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific application demands, production volume, and part geometry. Misalignment here leads to premature wear, dimensional instability, surface defects, and costly downtime. Aluminum, steel, and titanium each offer distinct advantages and constraints requiring careful evaluation against your project parameters.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their high thermal conductivity accelerates cycle times significantly, while machinability reduces lead times and initial tooling costs. However, aluminum’s lower hardness and wear resistance limit its use for abrasive materials or extended high-volume runs. It is ideal for initial design validation, short production cycles, and applications where thermal management is paramount.

Tool steels, including P20, H13, and S136, form the backbone of high-volume, production-critical molding. Offering superior hardness, wear resistance, and dimensional stability under thermal cycling, steels withstand abrasive fillers and demanding polymers. P20 suits general-purpose molding, H13 handles high-heat applications like engineering plastics, and corrosion-resistant grades like S136 are essential for PVC or medical-grade resins. The higher initial cost is justified by extended tool life measured in millions of cycles for demanding applications.

Titanium alloys, while significantly more expensive, provide an exceptional strength-to-weight ratio and outstanding corrosion resistance. Their primary niche is specialized applications requiring extreme weight reduction in the mold assembly itself or exposure to highly corrosive environments where even premium tool steels degrade. Usage is typically confined to specific, high-value components within the mold rather than the entire tool structure due to cost and machining complexity.

The following table summarizes key comparative properties for common tooling materials:

| Material | Typical Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Primary Application Focus |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 503-572 | 130 | Low | Prototyping, Low/Med Volume |

| P20 Tool Steel | 28-32 | 950-1100 | 30 | Moderate | General High-Volume Production |

| H13 Tool Steel | 44-48 | 1300-1600 | 25 | Moderate | High-Temp Plastics, Hot Runner |

| S136 Stainless | 48-52 | 1400-1650 | 20 | High | Corrosive Resins, Medical |

| Titanium Grade 5 | 35-40 | 895-1000 | 7.2 | Very High | Specialized Corrosive/Weight-Critical |

Surface finishing, particularly anodizing for aluminum tools, is integral to performance. Type II (Sulfuric Acid Anodizing) provides a standard wear and corrosion-resistant oxide layer, typically 8-25 µm thick. For maximum durability in abrasive molding or extended production, Type III (Hard Anodizing) creates a much denser, thicker (25-100+ µm), and harder surface (500-900 HV), significantly enhancing wear life. Proper sealing of the anodized layer is crucial for optimal corrosion resistance in humid or chemical-exposed environments.

Material selection transcends basic cost analysis; it is an investment in process stability and part conformance. Wuxi Lead’s material science team collaborates closely with clients to analyze resin characteristics, part geometry, volume requirements, and environmental factors, ensuring the optimal material and finish specification for your precision molding success. Consult our engineering department early in the design phase to maximize tool performance and ROI.

Manufacturing Process & QC

High Precision Injection Molding: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, high precision injection molding is executed as a tightly integrated, phase-gated manufacturing process that ensures dimensional accuracy, material consistency, and zero-defect output. Our methodology spans three core stages: Design, Prototyping, and Mass Production, each governed by advanced engineering protocols and real-time quality assurance.

The process begins with Design, where our engineering team collaborates closely with clients to translate product requirements into manufacturable solutions. Utilizing 3D CAD modeling and mold flow simulation software, we analyze part geometry, gate placement, cooling channels, and material behavior under injection conditions. This predictive analysis mitigates risks such as warpage, sink marks, or incomplete filling. Design for Manufacturability (DFM) reviews are conducted to optimize wall thickness, draft angles, and parting lines, ensuring long-term repeatability and minimal cycle time. All designs adhere to ISO 13485 and IATF 16949 standards, particularly critical for medical and automotive clients.

Next, the Prototyping phase validates the design using high-precision CNC-machined or EDM-finished mold inserts. These pre-series molds produce functional prototypes within ±0.005 mm tolerance, allowing for form, fit, and function testing. We conduct rigorous first-article inspections using coordinate measuring machines (CMM) and optical comparators. Material qualification is performed under actual processing conditions to confirm mechanical performance and surface finish compliance. Feedback from this stage is looped back into mold adjustments or design refinements, ensuring the final tooling meets all performance criteria before scale-up.

The transition to Mass Production is governed by a formal Production Part Approval Process (PPAP). Our state-of-the-art electric and hybrid injection molding machines, equipped with closed-loop control systems, maintain shot-to-shot consistency. Each production run is monitored through real-time data acquisition systems that track pressure, temperature, cycle time, and clamp tonnage. Automated vision inspection systems and statistical process control (SPC) charts are deployed inline to detect deviations instantly. Any out-of-spec condition triggers immediate process correction, preventing defect escape.

Wuxi Lead Precision Machinery’s commitment to zero defects is reinforced through full traceability—each component is serialized and linked to its production batch, machine parameters, and inspection records. Preventive maintenance schedules and ISO 9001-certified cleanroom environments further ensure process stability.

| Specification | Value |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | 0.05 – 0.8 µm |

| Mold Material | H13, S136, 2344, or client-specified |

| Clamping Force Range | 50 – 2000 tons |

| Injection Pressure | Up to 200 MPa |

| Process Control | Closed-loop, real-time SPC |

| Quality Standards | ISO 9001, IATF 16949, ISO 13485 |

This disciplined, data-driven approach enables Wuxi Lead Precision Machinery to deliver high precision injection molded components with unmatched consistency and reliability, meeting the most demanding requirements in aerospace, medical, and advanced electronics industries.

Why Choose Wuxi Lead Precision

Elevate Your Precision Injection Molding with Lead Precision Engineering

In the demanding realm of high-precision injection molding, component failure is not an option. Sub-micron deviations compromise performance, safety, and regulatory compliance across aerospace, medical, and semiconductor applications. Wuxi Lead Precision Machinery delivers more than machinery—we engineer certainty. For over 15 years, our ISO 9001 and IATF 16949 certified facility in Wuxi has partnered with global leaders to transform complex metal fabrication challenges into flawless production realities. Our integrated approach merges advanced CNC machining with proprietary mold-making expertise, ensuring every cavity, core, and ejector pin meets the most stringent geometric and surface finish requirements.

We understand that precision begins with material integrity and process control. Our dedicated team of veteran CNC engineers collaborates with your R&D department from initial design review through final validation, leveraging 5-axis grinding, wire EDM, and multi-spindle milling to achieve tolerances unattainable with conventional methods. This eliminates costly iterations and accelerates time-to-market for mission-critical components. Below are key capabilities defining our partnership value:

| Specification Category | Lead Precision Capability | Industry Standard Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | ±0.005 mm (±0.0002″) |

| Surface Roughness (Ra) | 0.05 µm (2 µin) | 0.8 µm (32 µin) |

| Material Compatibility | Inconel 718, Titanium Gr5, PEEK, Tool Steels (H13, S136) | Limited high-temp alloys |

| Machine Fleet | 32 CNC Centers (Makino, DMG MORI), 8 Wire EDM Units | 10–15 standard CNC units |

| Lead Time Reduction | 22% average vs. competitors | Baseline |

This technical superiority translates to tangible outcomes: reduced scrap rates, extended mold life exceeding 1 million cycles, and seamless scalability from prototyping to high-volume production. Our facility’s strategic location within China’s Yangtze River Delta industrial corridor ensures agile logistics while maintaining rigorous quality oversight—no offshore surprises. When your project demands zero-defect execution, our engineers become an extension of your team, providing real-time process data and proactive optimization.

The cost of precision miscalculation extends far beyond rework—it risks brand reputation and market position. Partner with a manufacturer where engineering rigor is non-negotiable. Contact our technical sales team today to receive a project-specific capability assessment. Send your component drawings and requirements to [email protected] for a confidential review. Our engineers respond within 4 business hours (Wuxi time, UTC+8) with actionable insights on feasibility, timeline, and cost optimization. Do not compromise on the foundation of your injection molding success. Trust Lead Precision to deliver micron-perfect results—on spec, on schedule, every cycle.

Wuxi Lead Precision Machinery: Where Engineering Excellence Meets Manufacturing Certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.