Technical Contents

Engineering Guide: High Density Polyethylene Molding

Engineering Insight: High Density Polyethylene Molding and the Critical Role of Precision

High density polyethylene (HDPE) is a thermoplastic polymer widely utilized across industries due to its excellent strength-to-density ratio, chemical resistance, and durability. While HDPE is inherently a robust material, achieving optimal performance in final components hinges on the precision of the molding process. In high-stakes applications such as military equipment, infrastructure systems, and Olympic-grade installations, dimensional accuracy, consistency, and repeatability are not merely desirable—they are mandatory. At Wuxi Lead Precision Machinery, we understand that precision in HDPE molding begins long before the material meets the mold; it starts with engineering excellence and rigorous process control.

HDPE molding demands exact temperature regulation, uniform cooling rates, and highly accurate mold tooling to prevent warping, sink marks, or internal stresses. Even minor deviations in cavity dimensions or cooling channel placement can result in part failure under operational stress. This is especially critical in custom metal-manufactured molds, where the interface between steel integrity and polymer behavior must be perfectly balanced. Our engineering team leverages advanced simulation software and CNC-machined tooling to ensure mold geometries are optimized for material flow and shrinkage characteristics unique to HDPE.

At Wuxi Lead, our experience in delivering mission-critical components for Olympic infrastructure projects and defense-grade applications has refined our approach to precision molding. These projects required zero-defect output, full traceability, and adherence to international standards such as ISO 9001 and MIL-STD-810. The molds we produce are not only dimensionally stable but also engineered for extended service life under high-cycle production environments. Our in-house quality control systems, including CMM (Coordinate Measuring Machine) inspection and thermal imaging during trials, ensure every mold meets exact client specifications before deployment.

We specialize in custom mold fabrication using high-grade tool steels such as H13 and P20, treated to resist wear and corrosion from prolonged HDPE processing. Surface finishes are controlled to ±0.1 µm, ensuring clean release and aesthetic consistency. Our integration of real-time monitoring systems allows for adaptive control during molding, minimizing variability and maximizing yield.

The following table outlines key specifications and capabilities for HDPE molding tooling at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Compatibility | HDPE, UHMW-PE, PP, ABS, and other engineering thermoplastics |

| Mold Base Materials | H13, P20, 718H, S136 (stainless) |

| Tolerance Range | ±0.005 mm – ±0.02 mm (depending on part size) |

| Surface Finish | Ra 0.1 µm to Ra 1.6 µm (polished, textured, or as-machined) |

| Cooling System Design | Conformal cooling channels via CNC and 3D simulation |

| Production Cycle Life | Up to 1 million cycles (depending on design and maintenance) |

| Quality Standards | ISO 9001, ISO 13485, MIL-STD-810 (upon request) |

| Lead Time (Average) | 4–8 weeks (based on complexity) |

Precision in HDPE molding is not an incremental advantage—it is the foundation of reliability. Wuxi Lead Precision Machinery combines advanced manufacturing technology with proven experience in high-demand sectors to deliver molds that perform consistently under real-world conditions. For industries where failure is not an option, precision is non-negotiable.

Precision Specs & Tolerances

Technical Capabilities: Precision Enabling HDPE Molding Excellence

Wuxi Lead Precision Machinery delivers the foundational metal manufacturing expertise essential for high-performance high density polyethylene (HDPE) molding applications. Our core strength lies in producing ultra-precise, durable mold tooling and critical components from advanced alloys, directly impacting the dimensional stability, surface finish, and cycle efficiency of HDPE parts. This precision originates from our integrated suite of advanced metalworking technologies, specifically engineered to meet the stringent thermal and mechanical demands of HDPE processing.

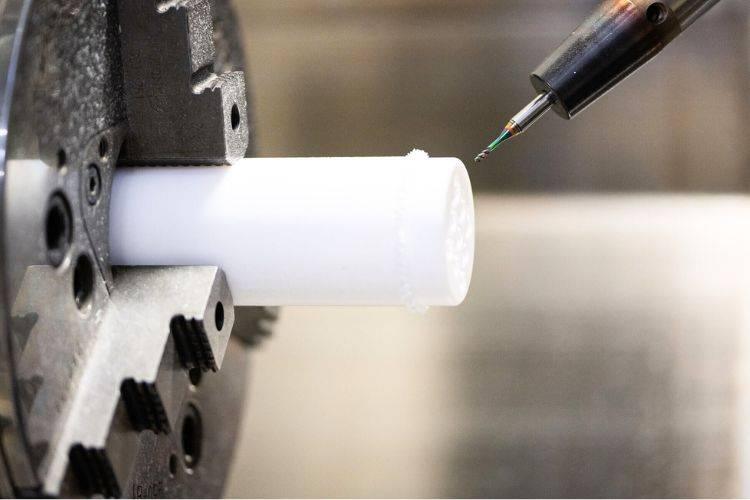

Central to our capability is the deployment of state-of-the-art 5-axis CNC machining centers. These systems enable the fabrication of complex mold cavities, cores, and intricate cooling channels with exceptional geometric accuracy. The simultaneous multi-axis movement eliminates the need for multiple setups, drastically reducing cumulative error and ensuring critical features—such as undercuts, fine textures, and conformal cooling paths—are machined to exact specification in a single operation. This capability is non-negotiable for HDPE molds, where thermal management directly influences part warpage, sink marks, and overall structural integrity. Our machining processes utilize specialized toolpaths and high-stability fixtures to maintain micron-level control across large work envelopes, accommodating molds for everything from small medical components to large industrial containers.

Rigorous quality control is embedded at every stage, anchored by comprehensive Coordinate Measuring Machine (CMM) inspection. Every critical mold component undergoes full 3D scanning against the original CAD model, verifying conformity across all dimensions, form tolerances, and positional relationships. This data-driven approach provides objective evidence of quality, not just for dimensional accuracy but also for surface continuity and feature alignment—factors paramount in preventing flash, ensuring proper ejection, and achieving consistent part replication in HDPE molding. Our CMM protocols exceed standard industry practices, incorporating thermal compensation routines to account for ambient fluctuations during measurement, guaranteeing results reflect real-world performance conditions.

The following table details the typical tolerance capabilities achievable for mold tooling components, reflecting our commitment to enabling superior HDPE part production:

| Feature Category | Typical Tolerance Range | Critical Application Impact for HDPE Molding |

|---|---|---|

| Cavity/Core Dimensions | ±0.005 mm to ±0.012 mm | Minimizes part shrinkage variation and dimensional drift |

| Flatness (Large Surfaces) | 0.008 mm per 100 mm | Ensures uniform clamping pressure, prevents flash |

| Hole Position & Diameter | ±0.005 mm | Guarantees precise alignment of pins, lifters, inserts |

| Surface Finish (Ra) | 0.2 µm to 0.8 µm | Controls part release, reduces cycle time, enhances surface quality |

| Conformal Cooling Path | ±0.02 mm positional | Optimizes thermal uniformity, reduces warpage in thick sections |

This level of precision in the metal tooling stage directly translates to reduced scrap rates, extended mold life, and consistent part quality in HDPE production. Wuxi Lead’s integrated approach—combining advanced 5-axis CNC fabrication with uncompromising CMM validation—provides the reliable, high-fidelity foundation necessary for demanding HDPE molding operations. We partner with clients to transform complex design requirements into robust, high-yield manufacturing solutions, ensuring your HDPE components meet the most exacting performance standards.

Material & Finish Options

When selecting materials for high density polyethylene (HDPE) molding tooling, the choice of metal significantly impacts mold longevity, surface finish, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision molds, leveraging advanced engineering to match material properties with application demands. The most commonly used metals in HDPE molding tooling are aluminum, steel, and titanium, each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is often selected for prototyping and low-to-medium volume production due to its excellent machinability and thermal conductivity. Its lightweight nature allows for faster mold cycling, reducing energy consumption during molding. However, aluminum’s lower hardness makes it more susceptible to wear in high-volume applications. For enhanced durability, aluminum molds are frequently anodized—a surface treatment that increases hardness, improves corrosion resistance, and reduces friction between the mold and HDPE resin.

Steel, particularly tool steels like P20 or H13, is the preferred choice for high-volume HDPE molding. Its high hardness and wear resistance ensure long service life even under repeated thermal cycling and mechanical stress. Steel molds maintain dimensional stability over thousands of cycles, making them ideal for complex geometries and tight tolerance requirements. While steel is slower to machine and heavier than aluminum, its durability justifies the investment for mass production. Surface treatments such as nitriding or chrome plating can further enhance performance, though anodizing is not applicable to steel.

Titanium is used selectively in specialized applications where extreme corrosion resistance and high strength-to-density ratio are critical. While not common for full mold construction due to cost and machining challenges, titanium alloys are sometimes employed in mold inserts or cores exposed to aggressive environments. Titanium’s biocompatibility and resistance to chlorinated HDPE additives make it suitable for medical or chemical processing applications. Like aluminum, titanium can be anodized to tailor surface properties, including color and wear resistance, offering both functional and aesthetic benefits.

The choice of finish is as critical as the base material. Anodizing, particularly hard anodizing, forms a durable oxide layer that improves surface hardness up to 600 HV and enhances release properties—key for non-stick HDPE molding. This finish also resists chemical degradation from residual resins and cleaning agents, extending mold maintenance intervals.

Below is a comparative overview of key material properties relevant to HDPE molding applications.

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum (7075) | 150 | 130 | Moderate | Prototyping, low-volume | Yes |

| Steel (P20) | 290 | 30 | Low to Moderate | High-volume production | No |

| Titanium (Grade 5) | 360 | 7 | Excellent | Specialized inserts | Yes |

Selecting the optimal material and finish requires balancing performance, cost, and production goals. At Wuxi Lead Precision Machinery, we collaborate closely with clients to engineer molds that maximize efficiency and lifespan in HDPE molding operations.

Manufacturing Process & QC

HDPE Molding Production Process: Precision Engineering for Zero Defects

At Wuxi Lead Precision Machinery, our HDPE molding process integrates advanced metal manufacturing expertise with stringent quality protocols to achieve flawless production outcomes. We execute a rigorously controlled sequence from initial concept to high-volume output, ensuring every component meets exacting dimensional and performance specifications demanded by critical industries. This structured workflow eliminates defects at their source through proactive engineering and validation.

The process begins with collaborative Design Engineering where our team translates client requirements into optimized mold architecture. Utilizing 3D CAD/CAM systems and mold flow simulation software, we analyze material behavior under HDPE’s specific thermal and pressure profiles. This phase focuses on gate placement, cooling channel layout, and ejection dynamics to prevent warpage, sink marks, or internal stresses. Finite element analysis validates structural integrity under operational loads, while thermal modeling ensures uniform solidification. Client feedback is incorporated iteratively, with tolerance stacks verified against ASME Y14.5 standards before finalizing the metal tool design.

Prototyping & Validation follows with the fabrication of a single-cavity pre-production mold using hardened P20 or H13 tool steel. This stage employs our CNC milling and EDM capabilities to achieve micron-level accuracy in critical surfaces. Initial trial runs under controlled conditions generate physical samples for comprehensive metrology. We conduct CT scanning, CMM inspection against 3D models, and material property testing including tensile strength and impact resistance per ASTM D638/D256. Statistical Process Control (SPC) charts track cavity pressure, cycle time, and part weight variability. Only when dimensional conformity exceeds 99.95% and functional tests pass without deviation do we approve the design for scale-up.

Zero-Defect Mass Production leverages our validated mold design in multi-cavity production tools. Real-time monitoring systems track 20+ parameters per cycle, including melt temperature gradients within ±2°C and clamp force consistency at 99.8% repeatability. Automated vision systems inspect every part for surface defects, while in-line cavity pressure sensors detect micro-voids invisible to the eye. Our closed-loop process adjusts injection speed and packing pressure dynamically to compensate for material batch variations. Each production run undergoes first-article inspection, hourly SPC audits, and final batch validation against the initial prototype’s certified data package. This systematic approach ensures consistent output where critical dimensions maintain ±0.05mm tolerances across millions of cycles.

Key mold specifications enabling this precision are detailed below:

| Parameter | Specification | Quality Impact |

|---|---|---|

| Tool Steel Grade | H13 (HRC 50-52) or S136 | Resists thermal fatigue; maintains polish for optical surfaces |

| Cooling Channels | Conformal, ±0.1mm positional | Eliminates differential shrinkage; reduces cycle time 15% |

| Surface Finish | SPI A2 (0.1µm Ra) or custom | Prevents part adhesion; ensures cosmetic integrity |

| Tolerance Control | ±0.005mm on critical cores | Guarantees assembly fit; minimizes weld lines |

| Sensor Integration | 8-12 cavity pressure points | Enables real-time defect detection and correction |

Wuxi Lead’s end-to-end ownership of the metal tooling process—from steel selection through production support—creates an unbroken chain of quality accountability. By embedding defect prevention into every phase rather than relying on end-of-line checks, we deliver HDPE components that perform reliably in demanding applications, from medical fluidics to automotive fuel systems. This is precision manufacturing engineered for zero compromise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced High-Density Polyethylene Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom-engineered metal manufacturing systems tailored to the evolving demands of high-density polyethylene (HDPE) molding applications. As a trusted leader in precision industrial machinery, we combine decades of engineering expertise with cutting-edge technology to provide turnkey solutions that enhance productivity, reduce cycle times, and ensure superior part consistency.

HDPE molding presents unique challenges due to the material’s high shrinkage rate, thermal sensitivity, and processing requirements. Our custom-designed molding systems are engineered to address these complexities with precision-engineered molds, optimized cooling channels, and robust clamping mechanisms that maintain integrity under high-pressure conditions. Whether your operation involves blow molding, injection molding, or rotational molding of HDPE components, our team delivers solutions calibrated to your exact specifications.

We understand that in high-volume industrial manufacturing, downtime is not an option. That’s why every system we produce undergoes rigorous quality validation and performance testing before deployment. Our in-house R&D facility enables rapid prototyping and iterative design improvements, ensuring that your final equipment not only meets but exceeds industry standards for durability and efficiency.

Our engineering team works closely with clients from concept development through to installation and commissioning. We offer full lifecycle support, including operator training, preventive maintenance programs, and remote diagnostics to ensure maximum uptime and long-term reliability. With a global footprint and a commitment to localized service, Wuxi Lead Precision Machinery ensures responsive, on-time support wherever your operations are based.

Below are key technical specifications of our HDPE molding machinery platforms:

| Specification | Details |

|---|---|

| Clamping Force Range | 800 kN – 6,500 kN |

| Shot Weight Capacity (HDPE) | 500 g – 12,000 g |

| Screw Diameter | 50 mm – 150 mm |

| Injection Pressure | Up to 220 MPa |

| Mold Mounting Dimensions | Customizable, up to 1,800 mm × 2,200 mm |

| Control System | Siemens S7-1500 with HMI interface |

| Cooling Efficiency | Dual-circuit, closed-loop system with PID control |

| Energy Recovery | Optional servo-hybrid drive system (up to 40% energy savings) |

All systems are built to comply with CE and ISO 9001 standards, with optional integration for Industry 4.0 connectivity, enabling real-time process monitoring and data logging.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a long-term engineering ally committed to your operational success. Our mission is to deliver precision, reliability, and innovation in every machine we build.

Contact us today to discuss your HDPE molding requirements. Email us at [email protected] and let our engineers help you design the optimal solution for your production goals.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.