Technical Contents

Engineering Guide: High-Capacity Cnc Milling Services

Engineering Insight: High-Capacity CNC Milling Services

In the realm of advanced manufacturing, high-capacity CNC milling services are not merely about volume—they are a convergence of precision, repeatability, and engineering excellence. At Wuxi Lead Precision Machinery, we understand that scaling production without compromising accuracy is the cornerstone of modern industrial success. High-capacity does not imply compromise; rather, it demands tighter tolerances, superior process control, and a deep-rooted commitment to quality assurance.

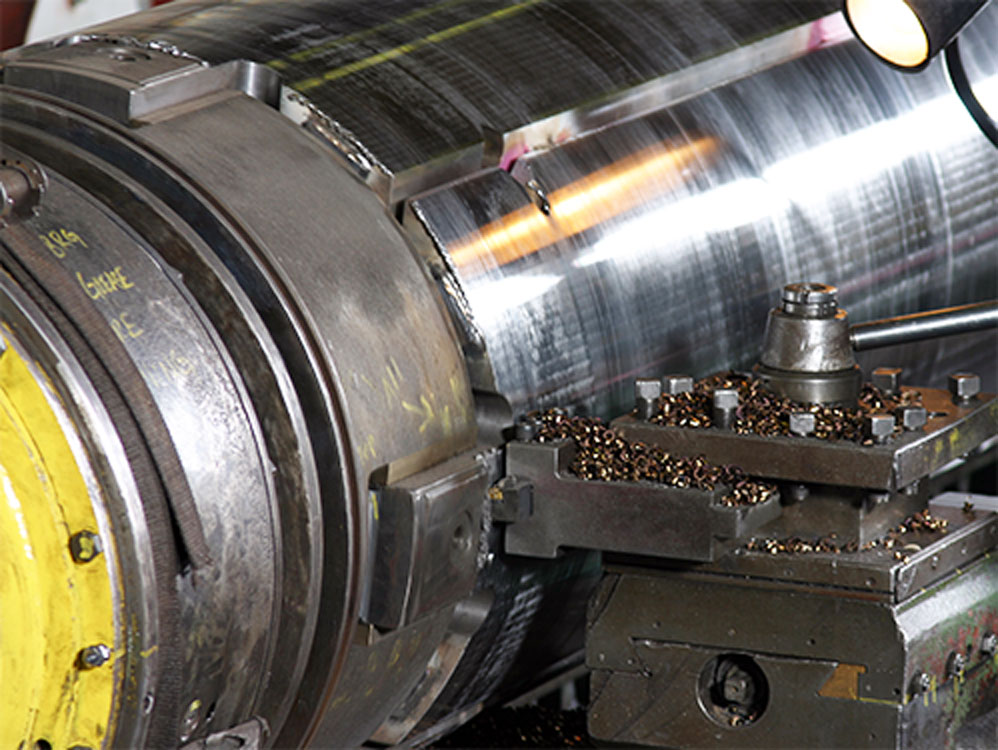

Precision in CNC milling is defined by the ability to consistently produce components within micrometer-level tolerances, across thousands of units. This level of accuracy is non-negotiable in sectors such as aerospace, defense, and high-performance automotive, where part failure can have catastrophic consequences. Our engineering team leverages state-of-the-art 3-, 4-, and 5-axis CNC milling centers equipped with high-resolution probing systems, thermal compensation, and real-time tool wear monitoring to maintain dimensional stability throughout extended production runs.

Our track record in mission-critical applications speaks to our capability. Wuxi Lead has delivered precision-machined components for Olympic-grade sporting equipment, where material integrity and geometric perfection directly influence athletic performance. Additionally, we have supported defense programs requiring MIL-STD compliance, demonstrating our ability to meet the most stringent quality and documentation standards. These projects underscore our mastery in balancing high-volume output with uncompromising precision.

Material selection, fixturing strategy, and toolpath optimization are rigorously analyzed during our process planning phase. We employ advanced simulation software to predict and eliminate potential sources of error, including vibration, thermal expansion, and tool deflection. Our quality control infrastructure includes CMMs, optical comparators, and surface finish testers, ensuring every component conforms to print specifications.

Below are key technical specifications that define our high-capacity CNC milling capabilities:

| Specification | Detail |

|---|---|

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 RPM |

| Tolerance Range | ±0.01 mm to ±0.002 mm (depending on geometry and material) |

| Materials Processed | Aluminum alloys, stainless steel, titanium, Inconel, brass, engineering plastics |

| Production Capacity | Up to 10,000 units per month (depending on complexity) |

| Quality Standards | ISO 9001:2015, MIL-STD-1312, GD&T compliant |

At Wuxi Lead Precision Machinery, high-capacity CNC milling is not a function of machine count alone—it is the result of disciplined engineering, continuous process refinement, and a culture of precision. We partner with clients who demand more than volume; they demand perfection, at scale.

Precision Specs & Tolerances

Technical Capabilities: High-Capacity 5-Axis CNC Milling Excellence

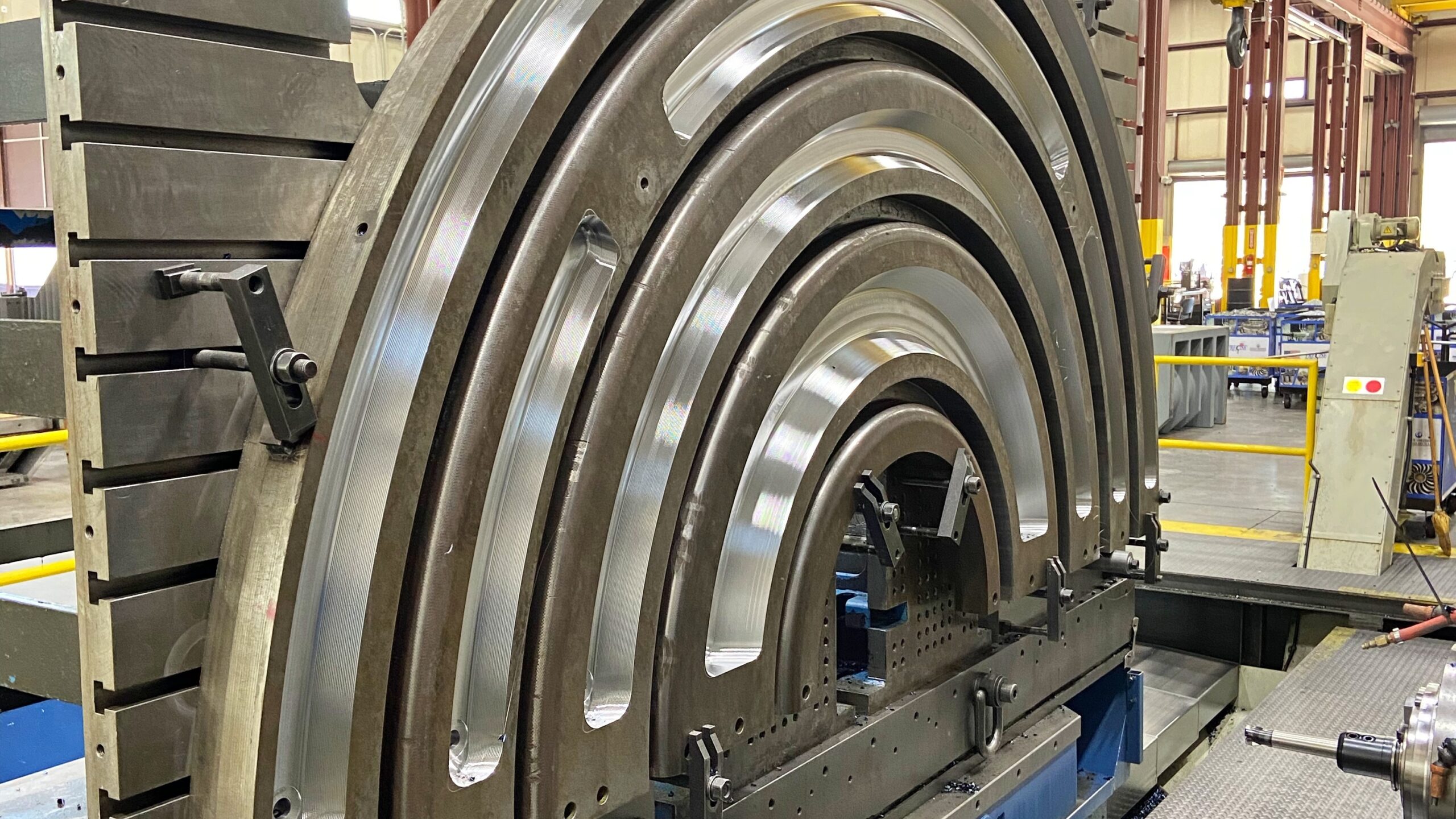

Wuxi Lead Precision Machinery delivers mission-critical high-capacity CNC milling services engineered for complex, large-volume production runs. Our core capability centers on advanced 5-axis simultaneous machining, eliminating repositioning errors and enabling single-setup fabrication of intricate geometries. We deploy a dedicated fleet of DMG MORI CTX beta 1250 5-axis mills and Makino D200Z 5-axis vertical machining centers, each featuring high-torque spindles (15,000 RPM), 30-tool ATCs, and FANUC 31i-B5 controls. This infrastructure supports continuous 24/7 production of monolithic aerospace structural components, medical implants, and energy sector housings up to Ø1,250 mm × 1,000 mm, with proven production stability exceeding 98.5% uptime. Our process integrates near-net-shape roughing and micron-level finishing within unified workflows, reducing lead times by 40% versus traditional multi-machine approaches while maintaining strict adherence to ITAR and NADCAP standards.

Throughput scalability is achieved via synchronized cell management across 18 production bays, each monitored by our proprietary MES platform for real-time tool wear compensation and adaptive feed rate control. This system ensures consistent output of 500+ complex parts per week across diverse materials—from 7075-T6 aluminum to Inconel 718 and Ti-6Al-4V—without compromising dimensional integrity. All operations leverage high-pressure coolant systems (70 bar) for chip evacuation in deep cavities and thermal stability management, critical for maintaining tolerances during extended production cycles.

Rigorous quality assurance is non-negotiable. Every component undergoes 100% first-article inspection and batch sampling via our Zeiss CONTURA G3 CMMs with VAST XT gold probes, delivering NIST-traceable measurements to ±1.5 µm. Statistical process control (SPC) data is automatically fed into our quality management system, generating AS9100-compliant inspection reports with full GD&T validation. This closed-loop methodology ensures defect rates remain below 50 PPM across high-mix, high-volume programs.

Standard Machining Tolerances

| Feature Type | Material Group | Typical Tolerance | Max Achievable Tolerance | Surface Finish (Ra) |

|---|---|---|---|---|

| Linear Dimensions | Aluminum Alloys | ±0.010 mm | ±0.005 mm | 0.8 µm |

| Linear Dimensions | Steel Alloys | ±0.012 mm | ±0.008 mm | 1.6 µm |

| Linear Dimensions | Titanium/Exotics | ±0.015 mm | ±0.010 mm | 1.6 µm |

| Geometric (GD&T) | All Materials | ±0.025 mm | ±0.012 mm | N/A |

| Critical Features | Aerospace Grade | ±0.005 mm | ±0.002 mm | 0.4 µm |

These capabilities translate into guaranteed repeatability for clients requiring certified precision at volume. We partner with tier-1 aerospace integrators and medical OEMs to transform demanding specifications into defect-free production outcomes, backed by our zero-concession quality policy and dedicated engineering support from prototype to serial production.

Material & Finish Options

Material selection is a critical decision in high-capacity CNC milling services, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision machining of engineering-grade metals tailored for aerospace, automotive, medical, and industrial applications. Our expertise ensures optimal material pairing with design intent and operational environment. Among the most widely used materials in high-volume production are aluminum, steel, and titanium—each offering distinct mechanical properties and compatibility with advanced surface treatments such as anodizing.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is frequently selected for structural components, enclosures, and heat sinks due to its weldability and post-machining stability. For more demanding applications, 7075-T6 provides superior strength, often used in aerospace systems. Aluminum’s natural oxide layer enhances durability, but when enhanced surface hardness and wear resistance are required, anodizing becomes essential. Our Type II and Type III anodizing processes deliver controlled coating thicknesses, improved corrosion protection, and aesthetic consistency across large production batches.

Steel remains the backbone of high-stress mechanical systems. We routinely machine medium-carbon steels like 4140 and 4340, known for their toughness, fatigue resistance, and response to heat treatment. These alloys are ideal for shafts, gears, and tooling fixtures subjected to dynamic loading. For applications requiring elevated corrosion resistance, we utilize stainless steel grades such as 304, 316, and 17-4 PH. These materials maintain integrity in harsh environments while supporting tight tolerances during high-speed milling operations.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance demands. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high-temperature degradation make it indispensable in aerospace and medical implant manufacturing. While more challenging to machine due to low thermal conductivity and work hardening tendencies, our optimized toolpaths, cooling strategies, and rigid setups ensure consistent quality and dimensional accuracy at scale.

Surface finishing plays a pivotal role in functional performance. Anodizing, especially for aluminum, not only improves wear resistance but also enables electrical insulation and color coding for part identification. Our in-house finishing capabilities support batch uniformity, critical for OEMs managing large-scale assembly lines.

The following table summarizes key material properties and machining characteristics:

| Material | Common Grades | Tensile Strength (MPa) | Hardness (HB) | Machinability Rating | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 95–150 | Excellent | Yes (Type II/III) |

| Steel | 4140, 17-4 PH | 655–1300 | 180–350 | Good | No |

| Stainless Steel | 304, 316 | 515–620 | 150–180 | Moderate | No |

| Titanium | Ti-6Al-4V (Gr 5) | 900–950 | 360–380 | Fair | No |

At Wuxi Lead Precision Machinery, we combine material science insight with advanced CNC infrastructure to deliver high-capacity milling solutions that meet the exacting standards of global industries.

Manufacturing Process & QC

Production Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our high-capacity CNC milling services deliver uncompromising precision through a rigorously controlled, integrated production process. We eliminate defects at the source by embedding quality assurance into every phase, ensuring seamless transition from concept to high-volume output. This systematic approach guarantees dimensional accuracy, material integrity, and functional reliability for mission-critical components.

Design Phase: Engineering Precision from Inception

The foundation for zero defects begins with collaborative design for manufacturability (DFM) analysis. Our engineering team partners with clients to optimize part geometry, material selection, and tolerance specifications before machining commences. Advanced CAD/CAM simulation software rigorously validates toolpaths, identifies potential collision risks, and predicts thermal behavior. This virtual prototyping phase proactively resolves 95% of potential production issues, significantly reducing physical iteration cycles and ensuring the design is inherently manufacturable to micron-level tolerances under high-volume conditions. Material suitability and stress point analysis are integral to this stage, preventing latent failures.

Prototyping Phase: Validating Performance Under Real Conditions

Physical prototyping serves as the critical validation step, not merely a form check. Utilizing the exact production-grade CNC milling centers intended for volume runs, we produce functional prototypes under controlled process parameters. Each prototype undergoes comprehensive metrology-grade verification against the validated CAD model using CMMs, optical comparators, and surface roughness testers. This phase confirms dimensional stability, surface finish compliance, and assembly functionality. Crucially, we conduct rigorous process capability studies (Cp/Cpk) during prototyping, establishing statistically valid control limits and refining feed/speed parameters. Only when prototypes consistently meet all specifications and the process demonstrates proven capability does the project advance.

Mass Production Phase: Sustained Excellence at Scale

High-capacity production leverages the validated process and parameters established in prototyping. Our automated cell lines, featuring state-of-the-art multi-axis CNC milling centers, operate under stringent statistical process control (SPC). Real-time in-process monitoring tracks critical dimensions, tool wear, and environmental factors. Every component undergoes 100% critical feature inspection via automated vision systems or touch probes integrated within the machining cycle, coupled with rigorous first-article and periodic lot sampling verified on calibrated CMMs. Full traceability, from raw material batch to final inspection report, is maintained. This closed-loop system, combined with our ISO 9001-certified quality management processes, ensures sustained zero-defect output across production runs exceeding 10,000+ units, minimizing scrap and guaranteeing on-time delivery of flawless parts.

Wuxi Lead Precision Machinery High-Capacity Milling Capabilities

| Parameter | Specification Detail |

|---|---|

| Machine Types | DMG MORI, Makino, HAAS 3-5 Axis Vertical/Horizontal Machining Centers |

| Max Work Envelope | 2000 x 1000 x 800 mm (X, Y, Z) |

| Positioning Accuracy | ≤ ± 0.005 mm |

| Repeatability | ≤ ± 0.002 mm |

| Materials Processed | Aluminum Alloys, Stainless Steels (303, 304, 316, 17-4PH), Titanium, Inconel, Brass, Engineering Plastics |

| Typical Tolerances | ± 0.01 mm (Standard), ± 0.005 mm (Tight) |

| Max Production Rate | 50,000+ parts/month (depending on complexity) |

| Key Quality Systems | ISO 9001, Full SPC Implementation, 100% Critical Feature In-Process Gauging, CMM Final Inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for High-Capacity CNC Milling Services

When your manufacturing demands require precision, scalability, and unwavering consistency, partnering with Wuxi Lead Precision Machinery ensures your production goals are not just met—but exceeded. As a leading provider of high-capacity CNC milling services in China, we specialize in delivering complex, high-tolerance components across aerospace, medical, energy, and industrial automation sectors. Our advanced manufacturing infrastructure, combined with decades of engineering expertise, positions us as a strategic partner for global OEMs and tier-one suppliers.

At Lead Precision, we understand that high-capacity production is not solely about volume—it’s about maintaining precision under scale. Our facility is equipped with a comprehensive array of multi-axis CNC milling centers, including 5-axis simultaneous machining systems, horizontal and vertical machining centers, and automated pallet systems that enable 24/7 continuous operation. This allows us to support batch runs from prototypes to full-scale production, all within tightly controlled quality parameters.

Our commitment begins with engineering collaboration. We work closely with your design and manufacturing teams to optimize part geometry, material selection, and tooling strategies, ensuring manufacturability without compromising performance. This proactive approach reduces lead times, lowers total cost of ownership, and accelerates time-to-market—critical advantages in competitive industries.

Quality is embedded in every process. Our ISO 9001:2015 and IATF 16949-certified systems govern every stage of production, from raw material inspection to final dimensional validation. We utilize state-of-the-art CMMs, optical comparators, and surface finish testers to verify compliance with tolerances as tight as ±0.002 mm. Real-time process monitoring and SPC ensure consistency across large production runs.

Below are key specifications that define our high-capacity CNC milling capabilities:

| Capability | Specification |

|---|---|

| Maximum Work Envelope | 2,200 mm × 1,200 mm × 1,000 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Processed | Aluminum alloys, stainless steel, titanium, Inconel, brass, engineering plastics |

| Tolerances | Standard: ±0.01 mm, Precision: ±0.002 mm |

| Production Capacity | Up to 50,000 parts/month |

| Automation | Robotic loading, pallet changers, FMS integration |

We are not just a service provider—we are an extension of your manufacturing team. Our project management structure ensures transparent communication, on-time delivery, and full traceability for every component produced.

For high-capacity CNC milling that combines precision, speed, and reliability, contact us today. Reach out to our engineering team at [email protected] to discuss your next production challenge. Let Wuxi Lead Precision Machinery power your precision manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.