Technical Contents

Engineering Guide: Heavy Duty Sheet Metal Joining

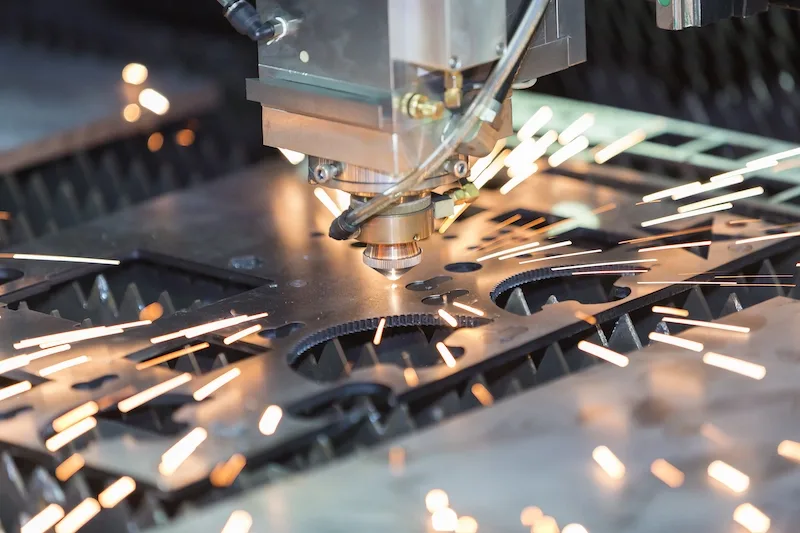

Engineering Insight: Precision as the Non-Negotiable Foundation in Heavy Duty Sheet Metal Joining

In heavy duty sheet metal fabrication, the integrity of the final structure hinges entirely on the precision achieved during the joining phase. Unlike lighter applications, heavy duty components—such as those used in大型 infrastructure, defense platforms, or industrial machinery—face extreme operational stresses, cyclic loading, thermal fluctuations, and environmental exposure. Imperfections in weld geometry, misalignment, or dimensional variance exceeding tight tolerances are not merely cosmetic flaws; they become critical stress concentration points. These microscopic weaknesses propagate under load, accelerating fatigue failure and potentially leading to catastrophic structural compromise. Precision in joining ensures uniform load distribution, optimal material performance, and the long-term reliability demanded by mission-critical applications. It transcends mere adherence to drawings; it is the engineering discipline that guarantees the theoretical strength calculations translate into real-world performance and safety.

At Wuxi Lead Precision Machinery, we engineer this precision into every heavy duty joining operation. Our approach integrates advanced CNC-controlled welding systems with rigorous in-process metrology, ensuring dimensional stability from initial fit-up through final weld completion. We understand that thermal distortion management is paramount; our processes incorporate predictive compensation algorithms and controlled heat-input techniques specifically calibrated for thick-section materials common in heavy duty work. This deep technical capability has been rigorously proven in projects where failure is not an option. We have supplied precision-joined structural components for major Olympic venue construction, meeting the exacting seismic and load-bearing specifications required for large-scale public infrastructure. Similarly, our work for defense sector partners involves classified components where dimensional accuracy, material integrity, and repeatability under stringent mil-spec requirements are non-negotiable. These experiences define our standard operating procedure, not exceptional cases.

Our commitment to precision is quantifiable through our process capabilities and certifications. The table below outlines key parameters for our heavy duty sheet metal joining services:

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Material Thickness | 3mm to 50mm | ASTM A36, A572, SS316L |

| Dimensional Tolerance | ±0.1mm (up to 3m length) | ISO 2768-mK, ISO 13920 |

| Weld Geometry Tolerance | ±0.5mm (profile & penetration) | AWS D1.1, EN 1090-2 EXC3 |

| Process Control | Real-time thermal monitoring | ISO 9001, AS9100D |

| Post-Weld Verification | CMM, Ultrasonic Testing (UT) | MIL-STD-883, ASTM E165 |

Achieving this level of consistency requires more than advanced machinery; it demands an engineering culture obsessed with process control. Every weld procedure is qualified, every operator certified to the highest applicable standards, and every critical joint subjected to multi-stage inspection. For the buyer specifying heavy duty sheet metal components, prioritizing a partner with demonstrable precision engineering expertise—proven in the most demanding real-world applications—is not a cost premium; it is the fundamental investment securing structural longevity, operational safety, and total cost of ownership. Wuxi Lead Precision Machinery delivers this assurance as standard.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in heavy-duty sheet metal joining, engineered to meet the exacting demands of high-performance industrial applications. Our integrated manufacturing platform combines precision fabrication, high-strength joining techniques, and rigorous quality assurance to produce components that perform reliably under extreme mechanical and thermal stress. Central to our operations is a suite of 5-axis CNC machining centers, enabling complex geometry processing with exceptional accuracy and repeatability. These systems allow us to machine and prepare sheet metal components with intricate contours, tight fit-up requirements, and superior surface integrity—critical for achieving optimal joint strength in downstream assembly.

Our expertise in heavy-duty joining encompasses MIG, TIG, and robotic welding processes, tailored to materials such as carbon steel, stainless steel, and aluminum alloys. Each weld procedure is developed in compliance with international standards, including ISO 3834 and AWS D1.1, ensuring structural integrity and long-term durability. Pre-weld machining and post-weld stress relieving are performed in-house, minimizing distortion and maintaining dimensional consistency across large assemblies. This holistic approach to fabrication ensures that every joint meets the mechanical, metallurgical, and geometric requirements of mission-critical applications in energy, transportation, and industrial equipment sectors.

Quality control is embedded throughout our production workflow. All components undergo comprehensive inspection using a coordinate measuring machine (CMM), providing full 3D verification of critical dimensions and geometric tolerances. Our CMM system is calibrated to ISO 17025 standards and operated by certified metrology technicians, ensuring traceable and repeatable measurement results. Real-time data analysis allows for immediate process correction, reducing variability and enhancing first-pass yield. In addition to dimensional inspection, we perform non-destructive testing (NDT), including dye penetrant and ultrasonic testing, to validate weld integrity.

The following table outlines the key technical specifications and achievable tolerances across our heavy-duty sheet metal joining processes:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 3 mm – 50 mm |

| Minimum Feature Size | ±0.1 mm (machined) |

| Positional Tolerance | ±0.05 mm (CNC machined features) |

| Angular Tolerance | ±0.2° |

| Flatness Tolerance | 0.1 mm per 100 mm |

| Weld Profile Consistency | ±0.5 mm (reinforcement height) |

| Dimensional Repeatability | ±0.03 mm (CMM-verified) |

| Surface Roughness (Ra) | As low as 0.8 µm (machined surfaces) |

| Maximum Work Envelope | 2000 mm × 1500 mm × 800 mm |

| Inspection Accuracy (CMM) | ±(2.5 + L/300) µm, L in mm |

Wuxi Lead Precision Machinery maintains full process control from raw material preparation to final inspection, ensuring every fabricated assembly meets the highest standards of precision and reliability. Our technical capabilities are designed to support complex, low-to-medium volume production runs where quality, repeatability, and structural performance are non-negotiable.

Material & Finish Options

Material Selection for Heavy-Duty Sheet Metal Joining: Engineering Performance First

Selecting the optimal material for heavy-duty sheet metal joining is a critical engineering decision directly impacting structural integrity, service life, and operational safety. In applications subjected to high loads, vibration, extreme temperatures, or corrosive environments, generic material choices are insufficient. Performance must be prioritized over initial cost. Aluminum alloys, carbon and alloy steels, and titanium each offer distinct advantages and limitations under severe duty cycles. Understanding their core mechanical behavior and compatibility with robust joining processes like precision MIG, TIG, or friction stir welding is paramount. Partnering with a fabricator possessing deep metallurgical expertise ensures the selected material performs reliably within your specific operational envelope, minimizing lifecycle costs through extended component longevity.

Aluminum alloys, particularly 5052-H32 and 6061-T6, provide an excellent strength-to-weight ratio essential for mobile or weight-sensitive heavy equipment. They exhibit good corrosion resistance naturally but require specific anodizing for enhanced surface hardness and protection in abrasive or highly corrosive settings. While weldable, aluminum demands stringent process control due to thermal conductivity and oxide layer challenges. Carbon steels like A36 and A572-Grade 50 remain the backbone for static structural applications demanding maximum strength and impact resistance at economical cost. Their weldability is generally excellent with common techniques, though mandatory protective finishes like powder coating or galvanizing are non-negotiable for outdoor or harsh environment exposure to prevent rapid corrosion. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), offer unparalleled strength-to-weight, exceptional corrosion resistance across extreme environments including seawater and chemicals, and outstanding fatigue performance. However, their high cost and demanding welding requirements (requiring inert gas shielding purity exceeding 99.995%) limit use to mission-critical aerospace, defense, or chemical processing components where failure is unacceptable.

Key mechanical properties guide this critical selection. The following table summarizes essential characteristics for common heavy-duty sheet materials:

| Material | Key Mechanical Properties | Primary Heavy-Duty Applications |

|---|---|---|

| Aluminum 6061-T6 | Yield Strength: 276 MPa, Density: 2.7 g/cm³, Good corrosion resistance (enhanced by anodizing) | Mobile cranes, truck frames, marine components, structural supports where weight savings are critical |

| Steel A36 | Yield Strength: 250 MPa, Density: 7.85 g/cm³, Moderate corrosion resistance (requires finish) | Building frameworks, heavy machinery bases, structural platforms, mining equipment |

| Titanium Ti-6Al-4V | Yield Strength: 880 MPa, Density: 4.43 g/cm³, Exceptional corrosion resistance, High fatigue strength | Aerospace landing gear, chemical reactor vessels, offshore oil & gas components, high-performance defense systems |

Anodizing is not merely a cosmetic finish for aluminum in heavy-duty contexts; it is a functional surface engineering process. Hard anodizing (per MIL-A-8625 Type III) creates a thick, dense, wear-resistant oxide layer significantly improving surface hardness (up to 600 HV), abrasion resistance, and corrosion protection beyond the base alloy’s capability. This is vital for components exposed to grit, constant friction, or salt-laden atmospheres. Wuxi Lead Precision Machinery integrates material science expertise with advanced fabrication. We rigorously evaluate your operational demands – load profiles, environmental exposure, lifecycle expectations – to recommend and precisely process the optimal material and finish combination, ensuring joined assemblies deliver uncompromised performance and safety under the most demanding industrial conditions. Our engineering team collaborates from specification through final inspection to guarantee material integrity is maintained throughout the joining process.

Manufacturing Process & QC

Design: The Foundation of Flawless Sheet Metal Joining

At Wuxi Lead Precision Machinery, the journey toward zero-defect heavy duty sheet metal joining begins with precision engineering at the design stage. Our design engineers utilize advanced CAD/CAM software to develop 3D models that account for material behavior, thermal expansion, load distribution, and joint integrity under operational stress. Finite element analysis (FEA) is applied to simulate real-world conditions, ensuring that every joint design meets or exceeds structural and durability requirements. Design for manufacturability (DFM) principles are rigorously followed to eliminate potential production bottlenecks and ensure seamless transition into prototyping. Material compatibility, weld penetration depth, and edge preparation are optimized during this phase to reduce residual stresses and distortion during joining.

Prototyping: Validating Performance Before Scale

Once the design is finalized, a functional prototype is produced using the same heavy duty joining techniques intended for mass production—primarily MIG, TIG, and robotic pulsed arc welding, depending on material thickness and application. Prototyping allows us to conduct comprehensive metallurgical and mechanical testing, including tensile strength, bend tests, and non-destructive inspections (NDT) such as ultrasonic and X-ray evaluation. Dimensional accuracy is verified using coordinate measuring machines (CMM), ensuring geometric conformity within ±0.1 mm. Any deviations are traced back to the design or process parameters and corrected before proceeding. This iterative validation ensures that the final production process is both reliable and repeatable, forming the cornerstone of our zero-defect philosophy.

Mass Production: Precision, Consistency, Zero Defects

With design and prototype approval, production transitions to high-volume manufacturing under a fully controlled environment. Our automated welding cells, equipped with real-time monitoring systems, maintain consistent arc stability, travel speed, and filler deposition. Each weld pass is tracked through a digital quality management system that logs process parameters for full traceability. In-process inspections occur at defined intervals, supported by statistical process control (SPC) to detect trends before defects arise. Final assemblies undergo full dimensional inspection and functional testing, with all data archived for audit compliance. Employee training, preventive maintenance, and strict adherence to ISO 9001 protocols ensure that every unit meets the same standard as the approved prototype.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 3 mm – 50 mm |

| Joining Methods | MIG, TIG, Robotic Pulsed Arc, Spot Welding |

| Positional Accuracy | ±0.1 mm |

| Weld Penetration Depth | 95–100% of base material thickness |

| NDT Inspection Rate | 100% critical joints, 20% batch sampling |

| Production Capacity | Up to 500 units per day (depending on complexity) |

| Quality Standard | ISO 3834, ISO 9001, AWS D1.1 compliance |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers heavy duty sheet metal assemblies with uncompromised integrity and zero-defect reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Heavy-Duty Sheet Metal Joining

When your fabrication demands exceed standard capabilities, partnering with Wuxi Lead Precision Machinery delivers engineered certainty. We specialize in mission-critical sheet metal joining for aerospace, defense, energy, and industrial infrastructure—where failure is not an option. Our ISO 9001:2015 and CE-certified facility in Wuxi integrates German-engineered CNC technology with 18 years of metallurgical expertise to solve your most complex joining challenges. Forget generic fabrication houses; we deploy precision-welded assemblies with documented traceability, zero-defect validation, and full compliance with ASME Section IX, AWS D1.1, and EN 1090 standards.

Heavy-duty applications demand more than brute-force machinery. Our process begins with material integrity analysis—preventing thermal distortion in 6mm–100mm steel, aluminum, and exotic alloys through controlled heat-input welding and robotic seam tracking. We eliminate post-weld rework via in-process CMM verification and real-time weld parameter monitoring. For structural assemblies requiring micron-level alignment, our 5-axis laser welding cells achieve 0.02mm positional accuracy across 10-meter spans. This isn’t just joining; it’s permanent metallurgical integrity.

Critical Specifications for Demanding Applications

| Parameter | Capability | Industry Standard |

|---|---|---|

| Material Thickness Range | 6mm – 100mm (Mild Steel/SS/Al) | Exceeds AWS D1.4 |

| Max. Weld Length | 12,000mm continuous | N/A |

| Positional Accuracy | ±0.02mm over 10m | AS9100 Rev D |

| Load Capacity | 500-ton hydraulic press brakes | ISO 2768-mK |

Why partner with Lead Precision? We own the entire value chain—from precision laser cutting and bending to certified welding and finishing—ensuring seamless process control. Our engineers collaborate at the design phase to optimize weld accessibility, minimize residual stress, and certify joint performance under extreme cyclic loads. Every component ships with full material test reports (MTRs), weld procedure specifications (WPS), and 3D inspection data. For projects where dimensional stability impacts system safety, our closed-loop feedback systems deliver repeatability no manual process can match.

Do not compromise on structural integrity. Contact our engineering team today to discuss your heavy-duty joining requirements. Submit your RFQ with material specifications, geometric tolerances, and load conditions to [email protected]. We respond within 4 business hours with a feasibility assessment and process validation plan. Let Lead Precision become your certified partner for assemblies that perform under pressure—where precision isn’t optional, it’s physics.

Wuxi Lead Precision Machinery Co., Ltd.

No. 18, Hengtang Road, Xinwu District, Wuxi, Jiangsu 214028, China

[email protected] | +86 510 8877 6188

Engineered Certainty. Delivered Globally.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.