Technical Contents

Engineering Guide: Heat Molded Plastic Sheet

Engineering Insight Precision in Heat Molded Plastic Sheet Fabrication

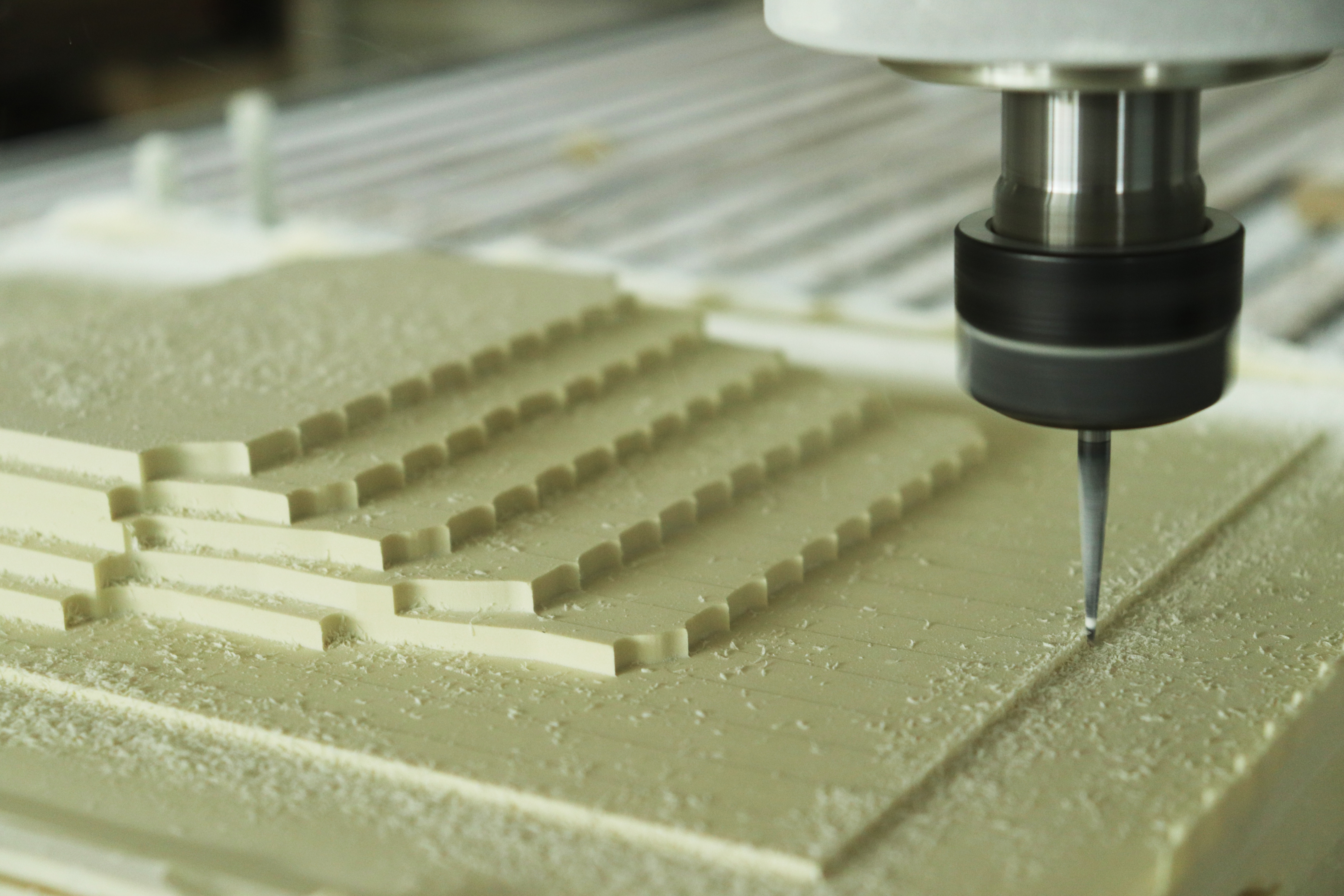

Precision engineering is not merely advantageous in heat molded plastic sheet production—it is the absolute foundation of functional integrity and performance. While the final component appears as a singular thermoplastic form, its success is entirely dictated by the accuracy and stability of the underlying metal tooling system. Minute deviations in mold geometry, thermal distribution, or clamping force during the heating and forming cycle translate directly into critical failures: warpage compromising assembly, inconsistent wall thickness affecting structural load paths, or surface defects violating optical or sealing requirements. For applications demanding hermetic seals in medical devices, aerodynamic contours in aerospace components, or exact optical clarity in instrumentation, tolerances measured in thousandths of an inch are non-negotiable. The metal tooling—typically crafted from high-grade aluminum or steel alloys—must maintain dimensional stability under repeated thermal cycling and mechanical stress. This requires CNC machining capabilities capable of holding tight tolerances on complex 3D surfaces, ensuring uniform heat transfer across the mold face, and guaranteeing perfect alignment during the pressing phase. Without this foundational precision in the tool, the plastic sheet’s inherent properties cannot be reliably harnessed, leading to scrap, rework, and ultimately, project failure.

Wuxi Lead Precision Machinery brings proven expertise in developing and manufacturing the ultra-precise metal tooling essential for critical heat molded plastic applications. Our CNC engineering team possesses deep experience in materials science and thermal dynamics specific to molding processes. We understand that the mold is not just a shape—it is a thermal management system requiring meticulous channel design and surface finish control. This precision capability has been rigorously validated through demanding projects, including components for Beijing Winter Olympics infrastructure requiring exact environmental sealing under extreme cold, and mission-critical housings for military avionics where dimensional stability across wide temperature ranges is paramount for system reliability. Our facility consistently achieves the tight tolerances and surface finishes demanded by these sectors, directly enabling the production of high-integrity plastic parts.

The following specifications represent the baseline precision achievable with our advanced CNC machining and finishing processes for heat molding tooling:

| Material Grade | Dimensional Tolerance | Surface Finish (Ra) | Critical Application Example |

|---|---|---|---|

| Aluminum 7075-T6 | ±0.005 mm | 0.4 µm | Aerospace interior components |

| P20 Tool Steel | ±0.008 mm | 0.2 µm | Medical device fluidic manifolds |

| H13 Tool Steel | ±0.010 mm | 0.8 µm | High-volume automotive lighting |

Achieving consistent results in heat molded plastic sheet production hinges on the uncompromising quality of the metal forming tool. Wuxi Lead Precision Machinery leverages its extensive CNC engineering heritage and rigorous quality systems, forged through Olympic and military-grade projects, to deliver tooling that ensures dimensional repeatability, optimal thermal response, and superior surface replication. This commitment to precision engineering translates directly into reduced scrap rates, extended tool life, and components that meet the most stringent functional requirements. Partner with us to transform your heat molded plastic sheet designs from concept to certified reality, where every micron matters for your production economics and end-product performance. Contact our engineering team for a detailed assessment of your specific molding challenge.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored to the rigorous demands of high-performance industries, including aerospace, medical, and precision automation. While our core expertise lies in custom metal manufacturing, our capabilities extend to supporting processes involving heat molded plastic sheets—particularly when integrated into hybrid metal-plastic assemblies or precision tooling applications. Our technical infrastructure ensures that every component, whether metallic or polymer-based, meets exacting dimensional and functional standards.

Central to our precision manufacturing workflow is our fleet of 5 Axis CNC machining centers. These systems enable complex, multi-faceted operations with exceptional accuracy, allowing us to produce intricate molds, forming tools, and support fixtures used in heat molding processes. The simultaneous movement across five axes ensures smooth surface finishes and tight geometric control, critical when fabricating tooling for heat formed plastic sheets. Materials such as polycarbonate, acrylic (PMMA), and engineering-grade thermoplastics are routinely handled through our supported processes, where thermal stability and dimensional repeatability are paramount.

All components and tooling produced at Wuxi Lead undergo rigorous quality control protocols. Every part is subject to post-process inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with design specifications down to the micron level. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, providing full traceability and inspection reporting with every production batch. This level of scrutiny guarantees that molds and forming surfaces maintain precise contours, directly influencing the fidelity of heat molded plastic components.

Our commitment to precision is reflected in the tolerances we consistently achieve across both metallic tooling and associated plastic-formed parts. Below is a summary of our standard and precision capability ranges.

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (Metal) | ±0.05 mm | ±0.01 mm | Measured via CMM |

| Linear Dimensions (Plastic Tooling) | ±0.05 mm | ±0.02 mm | Molded part dependent |

| Geometric Tolerance (GD&T) | ±0.03 mm | ±0.01 mm | Full GD&T compliant |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Machined surfaces |

| Angular Tolerance | ±0.1° | ±0.05° | 5 Axis alignment |

| Mold Cavity Matching | ±0.03 mm | ±0.015 mm | For multi-part tooling |

Wuxi Lead Precision Machinery combines advanced CNC technology with systematic quality assurance to support high-integrity applications involving heat molded plastic sheets. Our focus remains on delivering precision-engineered solutions where consistency, repeatability, and performance are non-negotiable.

Material & Finish Options

Material Selection Guidance for Precision Metal Components

Clarification is essential at the outset: Wuxi Lead Precision Machinery specializes in custom metal manufacturing, not plastic fabrication. While heat-molded plastics serve niche applications, structural and high-performance industrial components demand the superior strength, thermal stability, and longevity of metals. For critical applications requiring precision engineering—such as aerospace brackets, medical device housings, or semiconductor tooling—aluminum, steel, and titanium remain the unequivocal standards. Below, we detail material properties and finish considerations to optimize your component’s performance, cost-efficiency, and lifecycle.

Material selection hinges on application-specific requirements. Aluminum alloys (e.g., 6061-T6, 7075-T6) offer an exceptional strength-to-weight ratio and corrosion resistance, ideal for weight-sensitive applications like drone frames or automotive heat shields. Steel variants (e.g., 304/316 stainless, 4140 alloy) provide unmatched durability and load-bearing capacity for hydraulic manifolds or industrial machinery bases. Titanium (Grade 5 Ti-6Al-4V) delivers aerospace-grade strength at half steel’s weight with extreme corrosion resistance, critical for marine or biomedical implants. Each material’s machinability, thermal expansion, and fatigue limits directly impact CNC processing precision and final part integrity.

Anodizing is the premier finish for aluminum components, enhancing surface hardness, wear resistance, and adhesion for secondary coatings. Type II (sulfuric acid) anodizing suits general industrial use, while Type III (hardcoat) achieves 50–70 µm thickness for abrasive environments. For steel, passivation or electropolishing prevents rust in stainless grades, whereas zinc-nickel plating protects carbon steel in corrosive settings. Titanium typically requires no plating but benefits from abrasive blasting for biocompatibility in medical devices. Always specify finish requirements early—surface treatments influence tolerances during CNC milling and turning.

Below is a comparative specification table for core materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | High (anodized) | Aerospace brackets, heat sinks |

| Stainless 316 | 620 | 8.0 | Very High | Marine fittings, chemical valves |

| Titanium Ti-6Al-4V | 900 | 4.4 | Extreme | Surgical implants, jet engine parts |

Choosing the correct material and finish prevents costly field failures. Aluminum’s thermal conductivity mitigates heat distortion in electronics housings; steel’s rigidity ensures dimensional stability in high-torque assemblies; titanium’s biocompatibility eliminates rejection risks in surgical tools. At Wuxi Lead, our CNC engineers analyze your operational environment—temperature extremes, load cycles, regulatory standards—to validate material suitability before quoting. We reject one-size-fits-all approaches, instead leveraging ASTM and ISO testing protocols to certify every batch.

Partner with us to transform material science into manufacturing advantage. Contact our engineering team with your application parameters for a tailored material recommendation and DFM analysis. Precision begins with the right foundation.

Manufacturing Process & QC

The production process for high-precision heat molded plastic sheet components at Wuxi Lead Precision Machinery follows a disciplined, engineering-driven pathway from initial design through prototyping to full-scale mass production. Our methodology ensures zero-defect output by integrating advanced simulation, metrology, and process validation at every stage. This structured approach is tailored for demanding industrial applications where dimensional accuracy, material consistency, and repeatability are non-negotiable.

Design begins with a collaborative engineering review between our technical team and the client. Using CAD and finite element analysis (FEA), we simulate thermal behavior, stress distribution, and mold flow dynamics to optimize part geometry and material selection. This phase includes tolerance stack-up analysis and moldability assessment to preempt potential defects such as warpage, sink marks, or incomplete molding. All design data is validated against international standards and customer-specific requirements before release.

Prototyping is executed using precision-controlled thermoforming or vacuum-assisted molding systems, replicating production conditions at a small scale. Each prototype is subjected to full dimensional inspection via coordinate measuring machines (CMM) and 3D scanning, ensuring conformity to GD&T specifications. Functional testing, including thermal cycling and mechanical load evaluation, verifies performance under real-world conditions. Feedback from this stage is used to refine tooling and process parameters, ensuring a seamless transition to volume manufacturing.

Mass production leverages automated molding cells with closed-loop temperature, pressure, and cycle-time controls. Each heat molded plastic sheet is formed under tightly regulated conditions, with real-time monitoring of critical parameters. In-line vision systems and automated defect detection eliminate non-conforming parts before they proceed downstream. Every batch undergoes statistical process control (SPC) analysis to maintain CpK values above 1.67, guaranteeing long-term process stability and zero-defect performance.

Our quality assurance framework is anchored in ISO 9001 and IATF 16949 standards, with full traceability from raw material lot to finished component. This end-to-end rigor ensures that every heat molded plastic sheet meets the highest benchmarks for precision, durability, and consistency.

Below are the key technical specifications supported in our production process:

| Parameter | Specification |

|---|---|

| Material Compatibility | ABS, PC, PMMA, PVC, PS, PETG, and engineered composites |

| Sheet Thickness Range | 0.5 mm to 6.0 mm |

| Maximum Forming Area | 1200 mm × 2400 mm |

| Temperature Control Range | 80°C to 300°C (±2°C accuracy) |

| Cycle Time Range | 30–180 seconds (depending on complexity) |

| Dimensional Tolerance | ±0.15 mm over 1000 mm |

| Surface Finish Options | Gloss, matte, textured, or custom embossing |

| Production Capacity | Up to 50,000 units per month |

This integrated approach enables Wuxi Lead Precision Machinery to deliver high-end heat molded plastic sheet solutions with unmatched reliability, supporting global clients in automotive, medical, and industrial equipment sectors.

Why Choose Wuxi Lead Precision

Precision Metal Solutions for Advanced Heat Forming Applications

Wuxi Lead Precision Machinery operates at the intersection of metal fabrication expertise and advanced manufacturing processes. While our core specialization is custom metal component production—not plastic molding—we provide critical enabling technology for heat-formed plastic sheet applications. High-performance molds, dies, and support tooling require micron-level metal precision to achieve consistent plastic part quality. Our engineering team designs and manufactures the metal infrastructure that ensures thermal stability, dimensional accuracy, and longevity in demanding heat forming operations.

Partnering with Lead Precision means accessing China’s leading capabilities in precision metal manufacturing for industrial tooling systems. We engineer hardened steel and aluminum components that withstand repeated thermal cycling, maintaining tight tolerances under extreme conditions. Our CNC-machined bases, cavity inserts, and alignment systems directly impact plastic sheet forming repeatability, reducing scrap rates and extending mold service life. Every component undergoes rigorous metrology validation to ISO 2768-mK standards, ensuring seamless integration into your heat forming production lines.

Critical Metal Component Specifications for Heat Forming Tooling

| Component Type | Standard Tolerance | Material Options | Surface Finish (Ra) | Max Working Temp |

|---|---|---|---|---|

| Mold Bases | ±0.005 mm | P20, H13, 420SS | 0.8 µm | 600°C |

| Cavity Inserts | ±0.002 mm | S136, NAK80, Aluminum 7075 | 0.4 µm | 450°C |

| Alignment Pins/Sleeves | ±0.001 mm | Tool Steel, Tungsten Carbide | 0.2 µm | 800°C |

| Ejection Systems | ±0.003 mm | 17-4PH, A2 | 0.6 µm | 550°C |

These specifications reflect our commitment to eliminating thermal distortion and mechanical drift in plastic sheet forming environments. Our vacuum-hardened components resist deformation at elevated temperatures, while precision-ground surfaces prevent material adhesion and ensure clean part release. Unlike generic suppliers, we optimize metal grain structure and heat treatment protocols specifically for cyclic thermal loads—critical for maintaining plastic part geometry across 500,000+ cycles.

Your heat forming process demands metal reliability you can measure. Wuxi Lead Precision Machinery delivers documented process control from raw material certification to final inspection. We provide full material traceability, 3D inspection reports, and thermal stress analysis for every tooling system. This engineering rigor minimizes unplanned downtime and guarantees your plastic sheet molding operations achieve maximum throughput and part consistency.

Initiate a collaborative engineering review with our technical team to optimize your metal tooling infrastructure. Contact [email protected] with your application parameters—including plastic material type, cycle frequency, and critical dimensions—for a precision metal solution assessment. Our engineers will respond within 24 hours with a feasibility analysis and tolerance validation plan. Partner with China’s certified ISO 9001:2015 metal manufacturing specialist where micron-level accuracy directly enables your plastic forming success. Let us prove how precision metal engineering elevates your entire production ecosystem.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.