Technical Contents

Engineering Guide: Heat Molded Inserts

Engineering Insight: Precision Imperatives in Heat Molded Insert Manufacturing

Achieving flawless integration of heat molded inserts demands uncompromising precision at every stage. These components, embedded within polymer matrices during molding cycles, serve critical structural or functional roles in aerospace, medical devices, and high-performance automotive systems. Minor deviations in insert geometry, thermal properties, or surface preparation directly compromise interfacial integrity, leading to catastrophic failures under operational stress. The core challenge lies in managing complex thermal expansion differentials between dissimilar materials—metal inserts and thermoplastics—during rapid heating and cooling phases. Tolerance stack-ups exceeding ±0.025mm induce internal stresses that initiate micro-cracking, delamination, or premature fatigue. Material selection must align precisely with the polymer’s glass transition temperature and coefficient of thermal expansion; mismatched properties guarantee bond failure. Surface treatments like plasma activation or micro-etching require micron-level control to maximize adhesion without compromising base material integrity. Even minute particulate contamination during insertion creates weak points prone to moisture ingress and corrosion.

Wuxi Lead Precision Machinery operates at the pinnacle of this exacting discipline. Our CNC manufacturing protocols, refined through decades of supplying mission-critical components, enforce tolerances down to ±0.005mm. This capability is not theoretical—it is proven in applications where failure is unacceptable. We engineered titanium inserts for Olympic-caliber composite sporting equipment subjected to extreme cyclic loads, ensuring zero delamination during world-record performances. Similarly, our military-grade aluminum alloy inserts for armored vehicle electronics housings withstand repeated thermal shock from desert to arctic environments while maintaining hermetic seals. Such projects demand more than machinery; they require predictive modeling of thermal-structural behavior and real-time process validation that only deep experiential knowledge provides.

The following specifications represent the baseline precision standards we enforce for all heat molded insert programs. These parameters are non-negotiable for high-reliability applications and form the foundation of our quality management system.

| Critical Parameter | Standard Tolerance | Measurement Method | Industry Benchmark |

|---|---|---|---|

| Dimensional Accuracy | ±0.005mm | CMM with thermal compensation | ±0.025mm |

| Concentricity | ≤0.010mm | Optical comparator | ≤0.050mm |

| Surface Roughness (Ra) | 0.2–0.8µm | Profilometer | 1.6–3.2µm |

| Thermal Expansion Match | Δα ≤ 2.5 ppm/°C | Dilatometry | Δα ≤ 10 ppm/°C |

| Insertion Force Consistency | ±2% | In-process load cells | ±10% |

Precision in heat molded inserts transcends dimensional correctness—it is a holistic systems engineering achievement. At Lead Precision, we integrate material science, thermal dynamics, and micron-level manufacturing into a single validated process. This approach eliminates the scrap and rework costs inherent in less rigorous operations, delivering inserts that perform reliably across 10,000+ thermal cycles. When your application demands absolute certainty in material fusion, our Olympic and military-proven expertise ensures the bond survives where others fail. Contact our engineering team to implement precision protocols calibrated for your specific polymer-metal interface challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance applications requiring heat molded inserts, serving industries such as aerospace, medical devices, automotive, and industrial automation. Our technical capabilities are built around precision engineering, advanced material processing, and rigorous quality assurance, ensuring that every component meets the exact functional and environmental demands of its application.

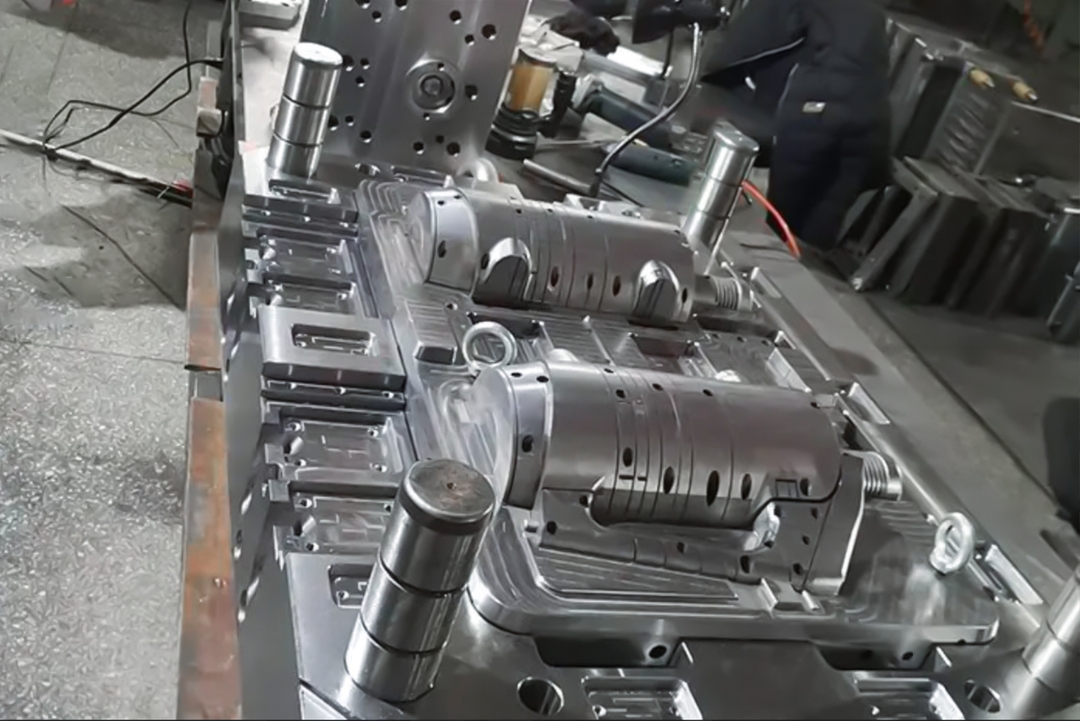

At the core of our production process is our 5-axis CNC machining technology, which enables the creation of complex geometries with exceptional accuracy and surface integrity. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across multiple planes, reducing setup time, minimizing human error, and ensuring tight alignment across intricate features. This capability is particularly critical when machining heat molded inserts, where precise dimensional control and angular tolerances directly affect performance during thermal expansion cycles and long-term operational stress.

We specialize in working with high-grade alloys, including stainless steels, titanium, Inconel, and specialized tooling materials that maintain structural stability under extreme temperatures. Our machining protocols are optimized for thermal compatibility, ensuring that inserts perform reliably when integrated into molding tools or composite structures subjected to repeated heating and cooling. Each insert is machined with controlled tool paths to minimize residual stress and prevent microstructural deformation, preserving material properties essential for durability.

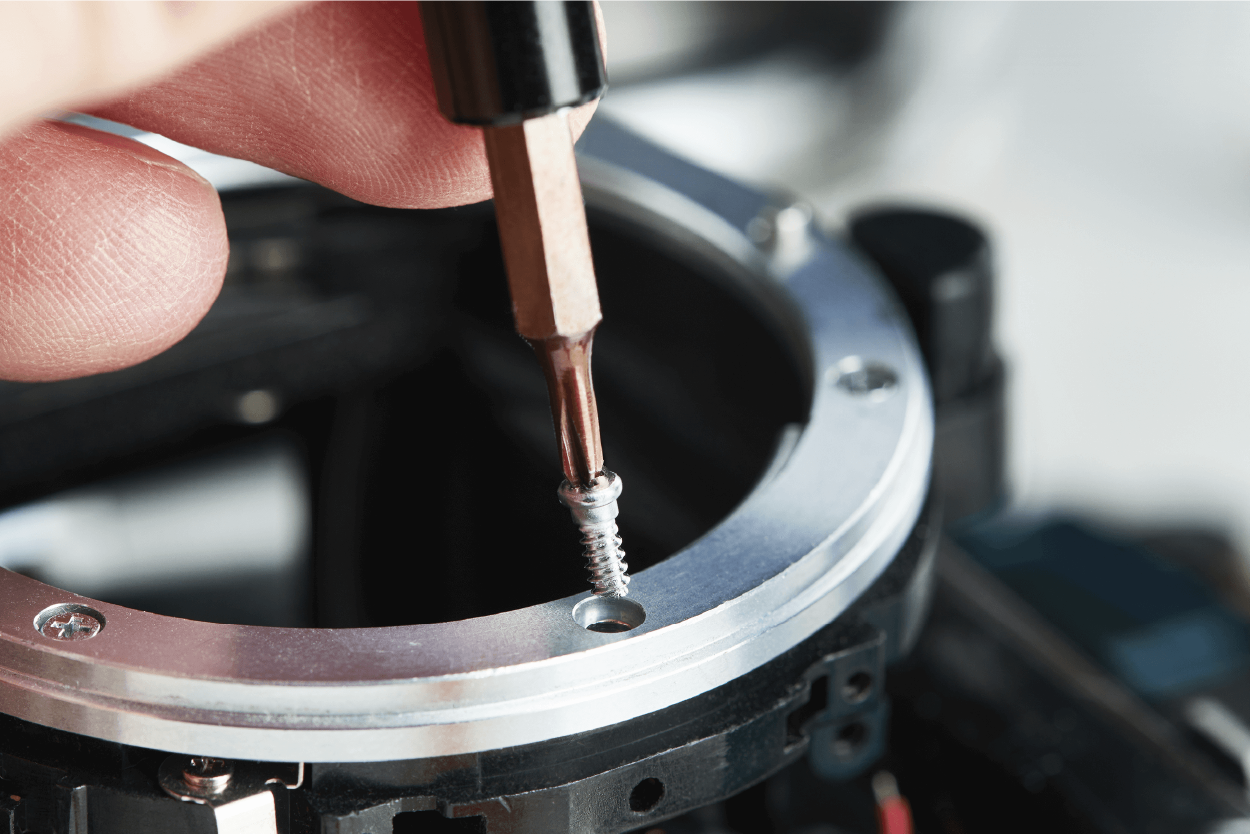

Quality control is integrated at every stage of production. All heat molded inserts undergo comprehensive inspection using our Coordinate Measuring Machine (CMM) system, which provides micron-level verification of critical dimensions, positional accuracy, and geometric tolerances. The CMM data is analyzed against CAD models to ensure full compliance with design specifications, and detailed inspection reports are provided with each delivery. This metrology-backed validation process ensures traceability and consistency, meeting the certification requirements of ISO 13485, AS9100, and other industrial standards.

Our end-to-end manufacturing approach combines engineering consultation, rapid prototyping, and scalable production, allowing clients to transition seamlessly from concept to volume output. Whether producing single prototype inserts for validation or high-volume batches for integration into automated assembly lines, we maintain uniform precision and repeatability.

The table below outlines the standard technical specifications we achieve for heat molded inserts under controlled production conditions.

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Positional Tolerance | ±0.01 mm |

| Surface Roughness (Ra) | 0.4 – 1.6 µm (adjustable) |

| Maximum Part Size | 800 mm x 600 mm x 500 mm |

| Minimum Feature Size | 0.5 mm |

| Angular Tolerance | ±0.05° |

| Materials Supported | Stainless Steel (303, 304, 316), Titanium (Gr 2, Gr 5), Inconel 718, Tool Steel (H13, S7), Aluminum Alloys |

| Inspection Method | CMM, Optical Comparator, Surface Profilometer |

Wuxi Lead Precision Machinery maintains a zero-defect mindset, supported by a cleanroom-grade machining environment and real-time process monitoring. Our technical team collaborates closely with clients to optimize insert designs for manufacturability, thermal performance, and integration efficiency.

Material & Finish Options

Material Selection for Precision Heat Molded Inserts: Engineering for Thermal Performance

Selecting the optimal material for heat molded inserts is critical to ensuring thermal stability, dimensional accuracy, and longevity in high-cycle manufacturing processes. At Wuxi Lead Precision Machinery, we prioritize materials that balance thermal conductivity, coefficient of thermal expansion (CTE), and mechanical strength to prevent warpage, seal failure, or premature wear during molding operations. Aluminum alloys excel in applications demanding rapid heat transfer, such as plastic injection molds, due to their high thermal conductivity and low density. Steel variants offer superior hardness and wear resistance for high-pressure environments, while titanium provides an exceptional strength-to-weight ratio and corrosion resistance for aerospace or medical applications where weight savings and biocompatibility are paramount. Each material’s CTE must closely align with the molded substrate to minimize stress during thermal cycling.

Below is a comparative specification table for common insert materials, reflecting industry-standard grades we machine to ±0.005mm tolerance:

| Material | Thermal Conductivity (W/m·K) | CTE (μm/m·°C) | Tensile Strength (MPa) | Density (g/cm³) | Primary Application Context |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 167 | 23.6 | 310 | 2.7 | High-speed plastic molding, lightweight tooling |

| Stainless Steel 304 | 16.2 | 17.3 | 515 | 8.0 | Corrosive environments, high-pressure inserts |

| Titanium Ti-6Al-4V | 7.2 | 8.6 | 900 | 4.4 | Aerospace, medical implants, extreme temp stability |

Anodizing remains the preferred finish for aluminum inserts, enhancing surface hardness and thermal resilience. Type II (sulfuric acid) anodizing provides moderate corrosion resistance with a typical thickness of 5–25μm, suitable for general-purpose molds. For inserts subjected to abrasive polymers or extended cycles, Type III (hardcoat) anodizing delivers 50–75μm thickness and 600+ HV hardness, significantly extending service life. Crucially, anodizing must be applied post-machining to avoid dimensional shifts; we maintain strict process controls to ensure coating uniformity within ±5μm. Steel inserts typically require nitriding or PVD coatings for equivalent wear protection, while titanium benefits from plasma electrolytic oxidation (PEO) for enhanced surface durability.

Material and finish selection must align with your specific thermal profile, cycle count, and substrate material. For instance, pairing aluminum 6061-T6 with Type III anodizing optimizes thermal dissipation in LED lens molding, whereas titanium with PEO suits biocompatible medical component production. Wuxi Lead Precision Machinery conducts thermal simulation testing during prototyping to validate material performance under your operational parameters. Partner with our engineering team to specify the precise alloy, temper, and surface treatment that eliminates thermal distortion risks in your heat molded insert application.

Manufacturing Process & QC

Design Phase: Precision Engineering at the Core

The foundation of any successful heat molded insert production lies in the design phase. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to translate functional requirements into manufacturable designs. Utilizing advanced CAD/CAM software, we conduct detailed thermal and structural simulations to predict material behavior during the heating and molding process. This ensures dimensional stability, optimal material flow, and long-term performance under operational stress. Design for manufacturability (DFM) principles are applied rigorously, minimizing complexity while maximizing strength and consistency. Each design is validated through finite element analysis (FEA) to anticipate stress concentrations and thermal expansion effects, ensuring the insert will perform reliably in its intended application—whether in automotive powertrains, aerospace components, or industrial machinery.

Prototyping: Bridging Concept and Reality

Once the design is finalized, we proceed to prototype development using precision CNC machining and controlled heat treatment processes. Prototypes are produced in small batches using the same materials and process parameters intended for mass production. This allows us to verify fit, form, and function under real-world conditions. Every prototype undergoes stringent inspection using coordinate measuring machines (CMM) and optical profilometry to confirm compliance with geometric dimensioning and tolerancing (GD&T) specifications. Thermal cycling tests are performed to simulate operational environments, ensuring the insert maintains integrity across temperature extremes. Client feedback is integrated at this stage, enabling rapid iteration without compromising timeline or quality. This phase is critical for risk mitigation, reducing the likelihood of defects during full-scale production.

Mass Production: Zero Defects Through Process Control

With prototype approval, we transition to mass production under a fully documented quality management system compliant with ISO 9001:2015 standards. Our automated production lines integrate real-time monitoring of temperature, pressure, and cycle time to maintain consistency across thousands of units. Each insert is formed using high-precision dies and controlled induction heating, ensuring uniform material properties and minimal variance. In-line inspection systems, including automated vision checks and laser measurement, detect deviations at sub-micron levels. Non-conforming parts are immediately quarantined, and root cause analysis is conducted to prevent recurrence. All batches are traceable through serialized lot numbering, enabling full material and process history tracking.

Typical Production Specifications

| Parameter | Specification Range |

|---|---|

| Material Options | Stainless Steel (304, 316), Inconel 718, Titanium Grade 5, Tool Steel |

| Tolerance (±) | 0.01 mm – 0.05 mm |

| Surface Roughness (Ra) | 0.4 µm – 1.6 µm |

| Insert Diameter Range | 3 mm – 50 mm |

| Operating Temperature | Up to 800°C (material dependent) |

| Production Capacity | 5,000 – 50,000 units/month |

| Lead Time (Mass Production) | 15 – 25 days after sample approval |

Through disciplined execution across design, prototyping, and production, Wuxi Lead Precision Machinery delivers heat molded inserts with zero defects—ensuring reliability, repeatability, and performance in the most demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Heat Molded Insert Solutions

Elevate your precision manufacturing capabilities by partnering with Wuxi Lead Precision Machinery. As your dedicated engineering and production partner for critical heat molded inserts, we transcend standard component supply. We integrate deeply with your design and production teams to solve complex thermal and mechanical challenges inherent in demanding applications across aerospace, medical device, and high-performance automotive sectors. Our commitment begins at the conceptual stage, where our senior CNC engineers collaborate to optimize insert geometry, material selection, and thermal management strategies, ensuring seamless integration into your final assembly process. This proactive engineering partnership minimizes prototyping iterations and accelerates time-to-market for your most sophisticated products.

Our advanced manufacturing ecosystem, centered around state-of-the-art CNC milling, grinding, and EDM technologies, is specifically calibrated for the stringent requirements of heat molded inserts. We achieve exceptional dimensional stability and surface integrity under extreme thermal cycling, critical for maintaining seal integrity and structural performance. Every insert undergoes rigorous in-process and final inspection using calibrated CMMs and optical comparators, verifying conformance to sub-micron tolerances and surface finishes down to Ra 0.2 µm. Our AS9100-certified quality management system guarantees traceability from raw material certification through final shipment, providing the audit trail essential for regulated industries.

The table below summarizes our core technical capabilities for heat molded insert production, reflecting the precision and material science expertise you require:

| Parameter | Capability Range | Standard Tolerance | Key Materials Supported |

|---|---|---|---|

| Insert Diameter | Ø0.5 mm to Ø150 mm | ±0.002 mm | 316L/304L Stainless Steel |

| Length | 1.0 mm to 200 mm | ±0.005 mm | Titanium Alloys (Gr5, Gr2) |

| Wall Thickness | 0.1 mm to 10.0 mm | ±0.0015 mm | Inconel 718, 625 |

| Temperature Range | -196°C to +800°C (Material Dependent) | N/A | Aluminum Alloys (7075, 6061-T6) |

| Surface Finish (Ra) | 0.05 µm to 1.6 µm | ±0.1 µm | Custom High-Temp Alloys |

| Critical Feature Tol. | Down to ±2 µm (Sub-Micron Capability) | N/A | Copper Alloys (C18150, C10100) |

Partnering with Lead Precision means gaining a strategic asset, not just a vendor. We invest in understanding your unique thermal dynamics and assembly processes to deliver inserts that perform flawlessly within your specific heat molding parameters, eliminating costly field failures and enhancing end-product reliability. Our engineering team is prepared to review your CAD models, material specifications, and thermal requirements immediately. Contact us today to initiate a technical consultation and receive a detailed feasibility assessment for your next heat molded insert project. Send your specifications and requirements to [email protected]. Our senior application engineers will respond within 24 business hours to discuss how our precision manufacturing solutions can directly support your production goals and quality standards. Let us prove why global innovators trust Lead Precision for their most demanding thermal insert applications.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.