Technical Contents

Engineering Guide: Hdpe Mold

Engineering Insight: Precision Imperatives in HDPE Mold Manufacturing

Achieving flawless HDPE molded components demands uncompromising precision in mold construction. HDPE’s unique thermal behavior and flow characteristics magnify the consequences of even microscopic deviations in cavity geometry, surface finish, or thermal management. Inconsistent wall thickness control directly translates to part warpage and sink marks, while inadequate venting or ejection precision causes surface defects like drag marks or vacuum lock. Crucially, the thermal expansion coefficient mismatch between the mold steel and molten HDPE necessitates exacting compensation in cavity dimensions. A tolerance deviation exceeding 0.01mm can cascade into significant dimensional instability in the final part, especially across large or complex geometries, leading to assembly failures and scrap rates that devastate production economics. Surface replication is equally critical; optical-grade finishes require mirror-like cavity surfaces held within nanometer tolerances, as any irregularity is directly transferred to the HDPE part.

At Wuxi Lead Precision Machinery, we engineer HDPE molds to exceed standard industry tolerances, treating every cavity and core as a high-precision metrology component. Our process begins with advanced thermal simulation to predict and counteract HDPE-specific shrinkage and warpage, ensuring cavity dimensions are precisely offset before steel cutting. We utilize hardened, pre-hardened, or stainless tool steels selected for optimal thermal conductivity and wear resistance under HDPE’s processing demands. CNC machining achieves critical feature tolerances consistently within ±0.005mm, verified through CMM and optical measurement systems calibrated to ISO 17025 standards. This granular control extends to surface texturing and polishing, where Ra values are maintained within specified ranges to ensure consistent part release and aesthetic quality.

Our commitment to precision is proven in the most demanding applications. We have manufactured molds for Olympic-standard equipment components requiring zero-defect surface integrity and dimensional stability under rigorous international competition scrutiny. Similarly, our molds for critical defense sector applications undergo stringent validation to meet MIL-spec requirements for durability and performance under extreme environmental conditions, where failure is not an option. This heritage directly benefits every HDPE mold project we undertake.

The following table outlines key precision parameters essential for high-performance HDPE molds:

| Parameter | Target Tolerance | Measurement Method | Critical Impact on HDPE Part |

|---|---|---|---|

| Cavity Dimension | ±0.005 mm | CMM (Calibrated to ISO) | Dimensional stability, assembly fit |

| Core Pin Alignment | ≤ 0.003 mm | Optical Comparator | Wall thickness uniformity, warpage prevention |

| Surface Finish (Ra) | ±0.05 µm | Profilometer | Part release, surface aesthetics, defect control |

| Thermal Expansion Comp. | Material Specific | FEA Simulation + CMM | Net-shape accuracy, shrinkage control |

| Vent Depth | 0.01 – 0.025 mm | Micrometer/Profiler | Air entrapment elimination, weld line strength |

Precision in HDPE mold manufacturing is not merely a specification; it is the foundational element ensuring production efficiency, part quality, and ultimate product performance. Wuxi Lead Precision Machinery leverages decades of advanced CNC engineering expertise and rigorous validation protocols, forged in elite applications, to deliver HDPE molds that consistently achieve first-article success and sustained high-yield production for our global manufacturing partners. Trust in precision engineered for results.

Precision Specs & Tolerances

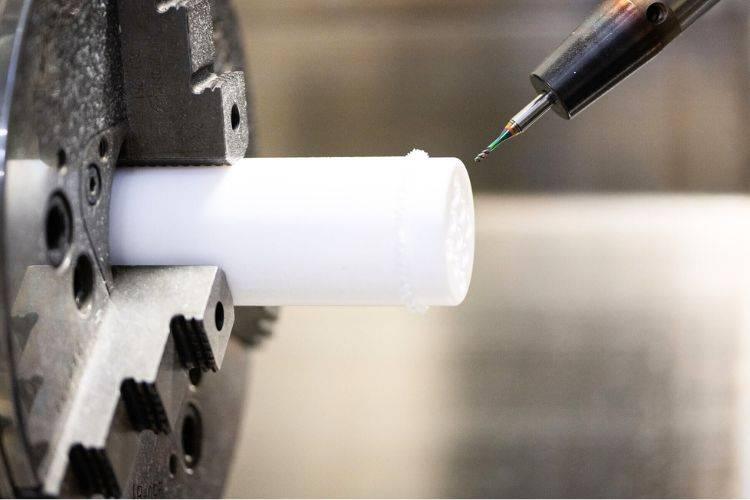

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industries such as automotive, aerospace, energy, and medical. At the core of our production infrastructure is a fully integrated suite of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These state-of-the-art machines provide simultaneous multi-axis motion, allowing for intricate contouring, deep cavity machining, and reduced setup times—critical for manufacturing high-density polyethylene (HDPE) molds that require tight tolerances and superior thermal management.

Our 5-axis CNC systems are operated by certified machinists with over a decade of experience in precision mold manufacturing. Each machine is maintained to OEM standards and equipped with high-speed spindles, automatic tool changers, and real-time tool monitoring systems to ensure process stability. The integration of advanced CAM software allows for optimized toolpaths, minimizing cycle times while maximizing material removal efficiency and part consistency. This digital workflow ensures seamless transition from CAD model to finished mold, supporting both prototype and high-volume production runs.

Quality assurance is embedded throughout our manufacturing process. Every HDPE mold undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), ensuring dimensional compliance with customer specifications. The CMM system provides micron-level measurement accuracy across complex surfaces and internal features, generating full GD&T reports for traceability and customer validation. In addition to CMM inspection, we employ surface roughness testers, hardness gauges, and optical comparators to verify critical mold characteristics.

We maintain strict environmental controls in our inspection lab to eliminate thermal distortion during measurement, ensuring repeatable and reliable results. All inspection data is documented and archived for full production traceability, meeting ISO 9001 standards and customer-specific quality requirements. Our quality engineers work in parallel with production teams to implement corrective actions in real time, minimizing deviations and ensuring first-time quality.

The following table outlines the standard technical specifications and tolerances achievable with our 5-axis CNC and inspection systems:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Accuracy | ±0.01 mm | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.012 mm | ±0.008 mm |

| Geometric Tolerance (GD&T) | ±0.015 mm | ±0.006 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm (polished finishes) |

| Maximum Work Envelope (mm) | 1200 x 800 x 750 | Custom upon request |

| Material Compatibility | Steel, Stainless Steel, Aluminum, Brass, Titanium | On-demand alloys |

| Inspection Accuracy (CMM) | ±(2.5 + L/300) µm | Calibrated to ISO 10360-2 |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality control to deliver HDPE molds that meet the highest standards of performance and reliability. Our technical capabilities ensure consistent repeatability, reduced lead times, and long-term mold durability in high-cycle production environments.

Material & Finish Options

Material Selection Fundamentals for HDPE Injection Molds

Selecting the optimal material for HDPE injection molds is critical for achieving production efficiency, part quality, and mold longevity. HDPE processing involves moderate temperatures but significant cyclic stress, demanding materials balancing thermal management, wear resistance, and cost-effectiveness. At Wuxi Lead Precision Machinery, we prioritize matching material properties precisely to your production volume, part complexity, and surface finish requirements. Misalignment here directly impacts cycle times, maintenance frequency, and total cost of ownership.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity accelerates cooling cycles, crucial for HDPE’s crystallization behavior, potentially reducing cycle times by 20-30% compared to steel. This makes aluminum ideal for startups, complex geometries requiring quick thermal response, or applications where time-to-market is paramount. However, aluminum’s lower hardness necessitates protective surface treatments like hard anodizing for extended wear life in higher-volume runs.

Tool steels such as P20, H13, and S136 dominate medium-to-high volume HDPE manufacturing. Offering excellent hardness (typically 28-52 HRC after heat treatment), superior wear resistance, and good polishability, they withstand the abrasive nature of filled HDPE grades and prolonged production cycles. P20 provides a cost-effective balance for standard applications, while H13 offers enhanced toughness for demanding cores/cavities. Corrosion-resistant grades like S136 are essential for medical or clear HDPE parts requiring mirror finishes. Steel molds represent the optimal investment for volumes exceeding 100,000 parts.

Titanium alloys present a specialized solution for extreme corrosion resistance needs, such as highly aggressive HDPE formulations or ultra-pure medical applications. While offering exceptional strength-to-weight ratio and near immunity to chemical attack, titanium’s high cost, challenging machinability, and lower thermal conductivity generally limit its use to niche scenarios where other materials fail. It is rarely the primary choice for standard HDPE molding.

Surface Finishing: The Anodizing Imperative for Aluminum

Hard anodizing (Type III) is non-negotiable for aluminum HDPE molds. This electrolytic process transforms the surface into a dense, hard aluminum oxide layer (typically 50-75 µm thick), dramatically improving wear resistance, release properties, and corrosion protection against HDPE additives. Without it, aluminum molds suffer rapid degradation from polymer abrasion and cleaning agents. Wuxi Lead Precision applies precision-controlled anodizing to ensure uniform thickness and optimal surface hardness (60-70 HRC equivalent), directly extending mold life in HDPE service.

Material Comparison for HDPE Molding Applications

| Material | Hardness Range | Thermal Conductivity (W/mK) | Corrosion Resistance | Best Use Case Volume | Relative Cost |

|---|---|---|---|---|---|

| Aluminum Alloys | 100-150 HB | 130-180 | Low (Requires Anodizing) | < 50,000 parts | Low |

| P20 Tool Steel | 28-32 HRC | 28-36 | Moderate | 50,000 – 500,000 parts | Medium |

| H13 Tool Steel | 40-52 HRC | 25-30 | Good | 100,000 – 1,000,000+ parts | Medium-High |

| S136 Stainless | 38-42 HRC | 20-25 | Excellent | High-volume critical parts | High |

| Titanium Alloys | 33-38 HRC | 7-10 | Exceptional | Specialized low-volume | Very High |

Wuxi Lead Precision Machinery engineers collaborate closely with clients to analyze your specific HDPE grade, part geometry, and production targets. This ensures the selected material and finish deliver maximum performance and economic return throughout the mold’s operational life. Contact our technical team for a detailed feasibility assessment.

Manufacturing Process & QC

The production process for high-density polyethylene (HDPE) molds at Wuxi Lead Precision Machinery follows a rigorously structured workflow designed to ensure zero defects and maximum performance in industrial applications. Our approach integrates precision engineering, advanced prototyping, and scalable manufacturing techniques tailored to the unique thermal and mechanical demands of HDPE molding.

The process begins with comprehensive design engineering. Utilizing 3D CAD software, our team develops mold architectures optimized for HDPE’s specific flow characteristics, shrinkage rates, and cooling requirements. Finite element analysis (FEA) is applied to simulate stress distribution, thermal cycling, and ejection forces, ensuring structural integrity over extended production runs. Design for manufacturability (DFM) reviews are conducted in collaboration with clients to align technical specifications with operational goals, minimizing cycle time and maximizing part consistency.

Following design approval, we proceed to prototyping. A functional prototype is machined using the same tool steels and CNC processes intended for full-scale production, enabling accurate evaluation of mold performance under real-world conditions. This stage includes mold flow analysis to validate gate placement, cooling channel efficiency, and part ejection dynamics. Any deviations in dimensional accuracy or surface finish are corrected through iterative refinement, ensuring the final mold meets ISO 9001-certified quality standards. Prototyping not only verifies design integrity but also serves as a risk mitigation step, reducing the likelihood of costly adjustments during mass production.

Mass production is executed on high-precision CNC machining centers, wire EDM, and surface grinding equipment, all maintained to micron-level tolerances. Each mold undergoes strict in-process inspections at critical stages—cavity milling, core finishing, and assembly—to ensure compliance with geometric dimensioning and tolerancing (GD&T) requirements. Hardened tool steels such as H13 or P20 are selected based on expected production volume and wear resistance needs. Surface treatments, including nitriding or chrome plating, are applied to enhance corrosion resistance and facilitate demolding of HDPE parts.

Final quality assurance includes a full dimensional audit, hardness testing, and a dry-run cycle under simulated production pressure. Every mold is delivered with a detailed inspection report and performance documentation, guaranteeing traceability and adherence to zero-defect objectives.

The following table outlines key specifications and capabilities for HDPE mold production:

| Parameter | Specification |

|---|---|

| Material Options | P20, H13, 718H, S136 (stainless) |

| Tolerance Range | ±0.005 mm |

| Surface Finish | Ra 0.1–0.4 µm (polished to SPI standards) |

| Mold Life Expectancy | 500,000+ cycles (depending on steel and use) |

| Cooling Channel Design | Conformal or straight, CNC-drilled |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–50 days |

| Quality Standard | ISO 9001:2015, Full CMM Inspection |

This disciplined progression from design to prototyping to mass production ensures that every HDPE mold delivered by Wuxi Lead Precision Machinery meets the highest benchmarks in reliability, precision, and longevity.

Why Choose Wuxi Lead Precision

Elevate Your HDPE Molding Performance Through Precision Engineering

Precision HDPE molding demands uncompromising accuracy in tooling to ensure optimal cycle times, part consistency, and extended mold longevity. At Wuxi Lead Precision Machinery, we engineer custom metal molds that directly address the thermal and mechanical challenges inherent in HDPE processing. Our CNC-driven manufacturing process eliminates common failure points like thermal distortion, premature wear, and dimensional drift—critical factors that impact your production yield and total cost of ownership. By integrating advanced material science with sub-micron machining tolerances, we deliver molds that maintain integrity across 500,000+ cycles, even under aggressive cooling protocols required for HDPE’s high crystallinity.

Our technical approach begins with material selection tailored to your resin grade and production volume. We utilize premium pre-hardened steels like NAK80 or custom P20 variants with enhanced thermal conductivity, ensuring uniform cooling and minimizing sink marks. Each mold undergoes rigorous finite element analysis (FEA) to simulate stress distribution during injection, followed by 5-axis CNC milling that achieves ±0.005mm cavity tolerances. Surface treatments such as nitriding or PVD coatings further reduce friction and prevent polymer adhesion—a frequent pain point in HDPE molding. This end-to-end control guarantees dimensional stability within ISO 2768-mK standards, directly translating to reduced scrap rates and faster time-to-market for your end products.

The table below summarizes our core capabilities for HDPE-specific mold manufacturing:

| Specification | Performance Standard | Industry Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.02 mm |

| Surface Roughness (Cavity) | Ra 0.05 µm | Ra 0.4 µm |

| Thermal Conductivity | 35–40 W/m·K (optimized) | 25–30 W/m·K |

| Lead Time (Complex Mold) | 45–60 days | 70–90 days |

| Expected Cycle Life | 500,000+ cycles | 200,000–300,000 |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic ally invested in your operational success. We do not merely supply molds; we co-engineer solutions that integrate seamlessly into your production ecosystem, backed by real-time technical support from our application engineers. Our clients—global leaders in packaging, automotive, and medical device manufacturing—rely on us to mitigate downtime risks and achieve repeatable part quality in high-volume HDPE runs.

Initiate your next project with engineering certainty. Contact our technical sales team at [email protected] to discuss your HDPE molding requirements. Include your target cycle time, part geometry, and resin specifications for a tailored capability assessment within 24 hours. Let us demonstrate how precision metal manufacturing elevates your HDPE output from functional to exceptional. Wuxi Lead Precision Machinery: Where Engineering Excellence Drives Your Production Advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.