Technical Contents

Engineering Guide: Hardness Tester For Steel

Engineering Insight Hardness Tester for Steel

Precision hardness testing is non-negotiable in critical steel component manufacturing. Surface and core hardness directly dictate wear resistance fatigue life and structural integrity. An inaccurate reading risks catastrophic failure in aerospace bearings automotive drivetrains or structural supports. At Wuxi Lead Precision Machinery we understand that sub-micron dimensional accuracy means nothing if material properties fall outside stringent tolerances. Our engineering team treats hardness validation as the final gatekeeper before component deployment. Consistent repeatability across testing cycles is as vital as the initial measurement. Variability introduces unacceptable risk especially in high-cycle or high-stress applications where material behavior must be predictable over decades.

Wuxi Lead Precision Machinery brings validated expertise to this critical process. Our hardness testing protocols were rigorously proven during precision machining for Beijing Olympic infrastructure projects where stadium tensile components demanded flawless material consistency. Further refinement occurred through classified military subcontracting where armor plate and ordnance part hardness tolerances operate within ±1.5 HRB under battlefield conditions. This experience ingrained a culture where test method selection calibration frequency and operator certification are engineered processes not routine checks. We deploy testers capable of resolving differences invisible to standard industrial units ensuring your steel meets not just spec sheets but real-world performance demands.

The following table outlines key specifications for our primary hardness testing systems used in steel validation:

| Parameter | Value | Industry Standard Reference |

|---|---|---|

| Primary Methods | Rockwell A/B/C Scales Brinell 500/3000kgf Vickers | ASTM E18 ISO 6508 ASTM E10 ISO 6506 |

| Load Range | 1 kgf to 3000 kgf | NIST Traceable Weights |

| Resolution | 0.1 HRB 1 HV 1 HBW | Digital Encoder Feedback |

| Accuracy | ±0.5 HRB ±1.0% HBW | Certified Against NIST Masters |

| Indentation Measurement | Automatic Optical System ±0.5µm | ISO 6507-2 Annex B |

| Calibration Cycle | Per 150 tests or 30 days | ISO/IEC 17025 Requirement |

This precision impacts your bottom line directly. Over-tempered steel sacrifices strength under load while under-tempered material accelerates wear increasing replacement costs and downtime. Our testers identify these deviations before components enter assembly preventing scrap rework and liability exposure. For mission-critical steel applications hardness data must be as reliable as the CNC programs shaping the material. Wuxi Lead Precision Machinery integrates hardness validation into our end-to-end quality chain ensuring every steel component shipped performs exactly as engineered from initial cut to operational lifetime. Trust in material properties is the foundation of trust in manufactured products.

Precision Specs & Tolerances

Precision Hardness Testing Integration in Steel Manufacturing

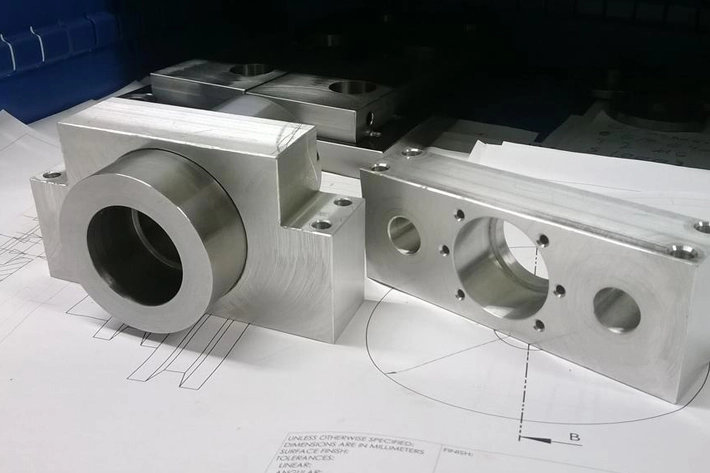

At Wuxi Lead Precision Machinery, our technical capabilities in custom metal manufacturing are anchored in advanced machining and rigorous quality assurance systems. When producing components requiring precise hardness characteristics—particularly in high-performance steel applications—we integrate hardness testing as a core element of our production workflow. This ensures not only dimensional accuracy but also material integrity, meeting the demanding requirements of aerospace, automotive, and industrial equipment sectors.

Our facility is equipped with state-of-the-art 5-axis CNC machining centers, enabling us to manufacture complex steel parts with exceptional precision and surface finish. These machines allow simultaneous multi-directional cutting, reducing setup times and minimizing cumulative tolerances. The result is a high degree of geometric accuracy and repeatability, essential for components subjected to extreme stress and fatigue. All machining operations are performed under controlled environmental conditions to mitigate thermal deformation, ensuring consistent output across production runs.

Hardness testing is conducted at multiple stages: incoming material verification, post-heat treatment validation, and final quality check. We utilize calibrated Rockwell, Brinell, and Vickers hardness testers, selected based on material type, part geometry, and customer specifications. Each test is documented with traceable results, providing full material certification upon request. Our technicians are trained to ISO 9001 standards, ensuring compliance with international quality protocols.

To validate dimensional conformity, every critical component undergoes Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Hexagon CMM systems deliver micron-level accuracy, capturing 3D data points across complex surfaces. This data is compared against the original CAD model, allowing for immediate corrective action if deviations are detected. The integration of CMM data with hardness test results provides a comprehensive quality profile for each part, ensuring both physical and mechanical specifications are met.

We maintain strict process controls across all stages of production. From raw material sourcing to final packaging, every step is documented and auditable. Our ERP system tracks batch numbers, machine parameters, inspection results, and operator logs, enabling full traceability for high-reliability applications.

The table below outlines our standard technical capabilities and achievable tolerances for steel components:

| Specification | Capability |

|---|---|

| Machining Process | 5-Axis CNC Milling and Turning |

| Material Types | Carbon Steel, Alloy Steel, Stainless Steel, Tool Steel |

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Positional Tolerance | ±0.005 mm |

| Surface Finish (Ra) | As low as 0.4 µm |

| Dimensional Repeatability | ±0.003 mm |

| Hardness Testing Methods | Rockwell (HRC, HRB), Brinell (HB), Vickers (HV) |

| Hardness Range (Typical) | HRC 20–68, HB 150–700 |

| Quality Inspection | CMM, Optical Comparator, Surface Profilometer |

| Compliance Standards | ISO 9001, ISO/IEC 17025 (CMM Lab) |

Wuxi Lead Precision Machinery combines advanced manufacturing technology with disciplined quality control to deliver steel components that meet the highest standards of hardness, accuracy, and reliability.

Material & Finish Options

Material Selection for Precision Hardness Testers

Selecting the optimal material for hardness tester construction is critical for ensuring long-term accuracy, repeatability, and structural integrity under operational loads. At Wuxi Lead Precision Machinery, our manufacturing experience demonstrates that the choice directly impacts thermal stability, resistance to deflection during testing, and overall instrument lifespan. Each material offers distinct advantages depending on the application’s specific demands for weight, strength, and environmental exposure. Understanding these properties is fundamental for specifying a tester that maintains calibration and delivers reliable Rockwell, Brinell, or Vickers results over thousands of cycles.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are frequently chosen for portable and benchtop testers where weight reduction is paramount. These alloys provide excellent machinability and good strength-to-weight ratios. However, their lower inherent hardness and higher thermal expansion coefficient compared to steel necessitate careful design to minimize deflection under load and thermal drift. Aluminum components benefit significantly from surface enhancement. Anodizing, especially hard anodizing (Type III), creates a wear-resistant ceramic layer that protects critical mounting surfaces and guide ways from abrasion and minor impacts, extending service life without adding substantial weight. This finish is essential for maintaining dimensional stability on aluminum frames subjected to frequent handling.

Steel remains the dominant material for high-load, high-precision floor-standing and universal hardness testers. Alloy steels like 4140 and tool steels such as A2 offer superior rigidity, high yield strength, and excellent resistance to permanent deformation under the significant forces encountered during testing. Stainless steels, particularly precipitation-hardening grades like 17-4 PH, provide a crucial balance of high strength, good machinability, and corrosion resistance for environments where exposure to coolants or humid conditions is a concern. Steel’s lower thermal expansion coefficient compared to aluminum contributes significantly to thermal stability, a non-negotiable requirement for micron-level measurement accuracy. Surface treatments like precision grinding and specialized coatings further enhance wear resistance on critical bearing surfaces.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), offer an exceptional strength-to-weight ratio surpassing steel and excellent corrosion resistance. While cost-prohibitive for full frames in most applications, titanium is strategically employed in high-end testers for critical, high-stress components like anvils or load application mechanisms where its fatigue strength and near-zero magnetic permeability are advantageous. Its use requires specialized machining expertise but delivers unmatched performance in demanding aerospace or R&D settings where weight and corrosion are critical factors.

The following table summarizes key mechanical properties relevant to hardness tester construction:

| Material | Typical Yield Strength (MPa) | Typical Hardness (HB) | Density (g/cm³) | Key Application in Testers |

|---|---|---|---|---|

| Aluminum 7075-T6 | 503 | 150 | 2.81 | Portable frames, non-critical housings |

| Steel 4140 | 655 | 200 | 7.85 | Main frames, heavy-duty components |

| Stainless 17-4 PH | 1000+ | 330 | 7.75 | Corrosive environments, precision parts |

| Titanium Ti-6Al-4V | 880 | 360 | 4.43 | Critical high-stress components |

Material selection must be viewed holistically, considering the interplay between mechanical properties, thermal behavior, manufacturability, and total cost of ownership. Wuxi Lead Precision Machinery leverages deep metallurgical knowledge and precision manufacturing capabilities to guide clients toward the optimal material solution, ensuring their hardness testing equipment delivers uncompromised accuracy and durability throughout its operational life. Consult our engineering team to evaluate the specific demands of your application.

Manufacturing Process & QC

The production process for a hardness tester for steel at Wuxi Lead Precision Machinery follows a disciplined, three-phase methodology: Design, Prototyping, and Mass Production. Each phase is engineered to ensure absolute precision, repeatability, and zero defects—critical for high-end industrial instrumentation used in steel quality assurance.

Design begins with comprehensive analysis of customer specifications, application environments, and compliance standards such as ISO 6506 (Brinell), ISO 6507 (Vickers), and ASTM E18 (Rockwell). Our engineering team employs advanced CAD/CAM software and finite element analysis (FEA) to simulate mechanical stress, thermal stability, and load distribution. Material selection focuses on high-grade alloy steels and hardened tool components to ensure long-term dimensional stability. The design is optimized for rigidity, minimal deflection, and operator ergonomics, with integrated calibration verification protocols. All designs undergo cross-functional review involving metrology, manufacturing, and quality assurance teams to preempt potential failure modes.

Prototyping follows a build-and-validate cycle. A single-unit prototype is fabricated using the same CNC machining centers, heat treatment processes, and surface finishing techniques designated for mass production. This ensures process consistency from the outset. The prototype undergoes full functional testing, including force application accuracy, indenter alignment, depth measurement repeatability, and data acquisition integrity. Hardness readings are cross-verified against certified reference blocks traceable to NIST standards. Any deviation triggers a root cause analysis and design refinement. Only after passing a 72-hour continuous operation stress test and achieving repeatability within ±0.5 HR (Rockwell) or ±1 HV (Vickers) is the design approved for scale-up.

Mass production is executed under a zero-defect framework. Each unit is built on a controlled assembly line with serialized component tracking. CNC machining is performed on high-precision 5-axis centers with in-process probing to maintain tolerances within ±0.002 mm. Critical components such as load frames and indenter spindles undergo cryogenic treatment and precision grinding to ensure microstructural stability. Every assembled hardness tester is subjected to 100% final inspection, including load cell calibration, optical system alignment (for digital models), and software diagnostics. Statistical process control (SPC) monitors key parameters in real time, enabling immediate correction of drift. Units are packaged with calibration certificates and traceable documentation.

This end-to-end process ensures that every hardness tester meets the highest standards of accuracy, durability, and consistency required in steel manufacturing, aerospace, and automotive sectors.

| Specification | Value |

|---|---|

| Testing Methods | Rockwell, Vickers, Brinell (configurable) |

| Load Range (Vickers) | 1–3000 gf |

| Load Range (Rockwell) | 15–150 kgf |

| Indentation Measurement Accuracy | ±0.5 µm |

| Repeatability (HV) | ±1 HV |

| Display Resolution | 0.1 HR / 0.1 HV |

| Calibration Standard | ISO 6506, ISO 6507, ASTM E18 |

| Frame Rigidity | >5000 N/µm |

| Power Supply | 100–240 VAC, 50/60 Hz |

| Operating Environment | 10–35°C, <80% RH |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Definitive Steel Hardness Assurance

In the demanding world of steel manufacturing, inconsistent hardness measurement compromises structural integrity, accelerates tool wear, and risks costly non-conformance. Generic testers deliver inadequate data for critical aerospace, automotive, or tool steel applications. Wuxi Lead Precision Machinery provides engineered hardness testing solutions where precision is non-negotiable. Our systems are not merely instruments; they are integrated quality assurance assets designed and validated by metallurgical engineers for the specific challenges of modern steel production. We eliminate measurement uncertainty through bespoke calibration protocols, robust construction for shop-floor resilience, and traceability to international standards. When your reputation hinges on material performance, partner with an organization that treats hardness data as the cornerstone of metallurgical excellence.

Our hardness testers deliver laboratory-grade accuracy in industrial environments. Key specifications ensure seamless integration into your quality control workflow:

| Feature | Specification Detail | Industry Relevance for Steel |

|---|---|---|

| Testing Methods | Rockwell (A/B/C/N/T), Brinell, Vickers | Full coverage from annealed billets to hardened tool steels |

| Load Range | 1 kgf to 3000 kgf | Precise measurement across thin sheets to heavy forgings |

| Accuracy | ±0.5 HRB / ±1.0 HRC (per ISO 6508) | Guaranteed compliance with ASTM E18, ISO 6506 |

| Indentation System | Closed-loop load control, diamond/ carbide penetrators | Eliminates spring-back error in high-strength alloys |

| Data Interface | Ethernet, USB, RS-232; SPC-ready output | Real-time integration with MES/QMS platforms |

| Calibration | NIST-traceable; on-site service support | Ensures audit readiness and regulatory compliance |

Precision engineering defines our partnership approach. Our applications team collaborates with your metallurgists during the design phase to configure testers matching your exact steel grades, geometries, and production throughput. We analyze your failure modes—whether surface decarburization in case-hardened components or core hardness variance in large castings—and tailor force application, dwell times, and data sampling protocols accordingly. This prevents reactive quality firefighting; instead, you gain predictive insight into heat treatment consistency. Unlike off-the-shelf units, Lead Precision systems feature hardened guideways, thermal compensation algorithms, and anti-vibration bases to withstand foundry vibrations and temperature fluctuations without recalibration drift.

Beyond equipment, we deliver operational certainty. Our engineers provide on-site validation against your master blocks, train technicians in ISO-compliant procedures, and establish preventative maintenance schedules minimizing unplanned downtime. We understand that a hardness tester is only as reliable as its last calibration—our global service network guarantees 72-hour response for critical recalibration needs across Asia, Europe, and North America. This commitment transforms quality control from a cost center into a strategic asset, reducing scrap rates by up to 22% in verified client implementations.

Initiate your precision partnership today. Contact our engineering sales team at [email protected] to schedule a technical consultation. Specify your steel grade, production volume, and current measurement challenges. We will deploy a solutions engineer to conduct a no-obligation process audit and deliver a customized hardness testing protocol within 5 business days. Trust Wuxi Lead Precision Machinery—where metallurgical accuracy drives manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.