Technical Contents

Engineering Guide: Gusset Steel Plate

Engineering Insight: The Critical Role of Precision in Gusset Steel Plate Fabrication

In structural engineering, the gusset steel plate serves as a pivotal load-transfer component, reinforcing joints in trusses, bridges, towers, and heavy industrial frameworks. While often concealed within larger assemblies, its performance directly influences the integrity, safety, and longevity of the entire structure. At Wuxi Lead Precision Machinery, we recognize that even minor deviations in geometry, hole placement, or material consistency can compromise structural behavior under dynamic loads. This understanding drives our commitment to precision in every gusset plate we manufacture.

Gusset plates are typically subjected to complex stress distributions—tension, compression, shear, and bending—particularly in seismic or high-wind environments. Their connection points must align perfectly with supporting members to prevent eccentric loading, which can lead to premature fatigue or failure. This demands not only high-grade steel but also exacting fabrication standards. Our CNC-controlled cutting, drilling, and forming systems ensure tolerances within ±0.1 mm, guaranteeing dimensional accuracy that meets or exceeds international codes such as AISC, EN 1090, and ISO 9001.

Material selection is equally critical. We primarily utilize Q345B, Q235B, and ASTM A36 steels, chosen for their optimal balance of tensile strength, weldability, and ductility. Each plate undergoes rigorous material certification and non-destructive testing (NDT), including ultrasonic and magnetic particle inspection, to detect subsurface anomalies. Post-fabrication, surface treatments such as sandblasting and hot-dip galvanizing are applied to enhance corrosion resistance—essential for outdoor or marine-exposed applications.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in custom metal manufacturing, with a demonstrated track record in mission-critical projects. Our gusset plates have been integrated into structural frameworks for Olympic-grade sports facilities and defense-related infrastructure, where failure is not an option. These high-profile engagements demanded not only technical excellence but also strict adherence to project timelines and documentation standards—hallmarks of our operational discipline.

Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, optimizing plate geometry and connection layouts to reduce assembly complexity and field welding. This proactive approach minimizes on-site errors and accelerates construction schedules. Whether producing prototype units or high-volume batches, we maintain full traceability from raw material to final shipment.

The following table outlines key fabrication specifications we adhere to in gusset steel plate production:

| Parameter | Specification |

|---|---|

| Material Grades | Q235B, Q345B, ASTM A36, S355JR |

| Thickness Range | 6 mm – 50 mm |

| Dimensional Tolerance | ±0.1 mm (CNC Machined), ±1 mm (Cut-to-size) |

| Hole Position Tolerance | ±0.2 mm |

| Surface Finish | As-rolled, Sandblasted, Hot-Dip Galvanized |

| Welding Standards | ISO 5817 (B-level), Pre-qualified WPS |

| Testing Methods | Ultrasonic Testing (UT), MPI, Dimensional CMM |

| Certifications | ISO 9001:2015, EN 1090-2, AISC 360 |

Precision in gusset steel plate fabrication is not merely a technical requirement—it is a responsibility to structural safety and performance. At Wuxi Lead Precision Machinery, we combine advanced manufacturing technology with deep engineering insight to deliver components that perform flawlessly under real-world demands.

Precision Specs & Tolerances

Technical Capabilities for Gusset Steel Plate Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision in custom gusset steel plate manufacturing, serving demanding structural and heavy industrial applications globally. Our integrated technical capabilities, anchored in advanced 5-axis CNC machining and rigorous quality control, ensure components meet the highest structural integrity and dimensional accuracy standards required in critical infrastructure, bridge construction, and heavy machinery. We hold ISO 9001 certification, reflecting our systematic approach to quality management throughout the production lifecycle.

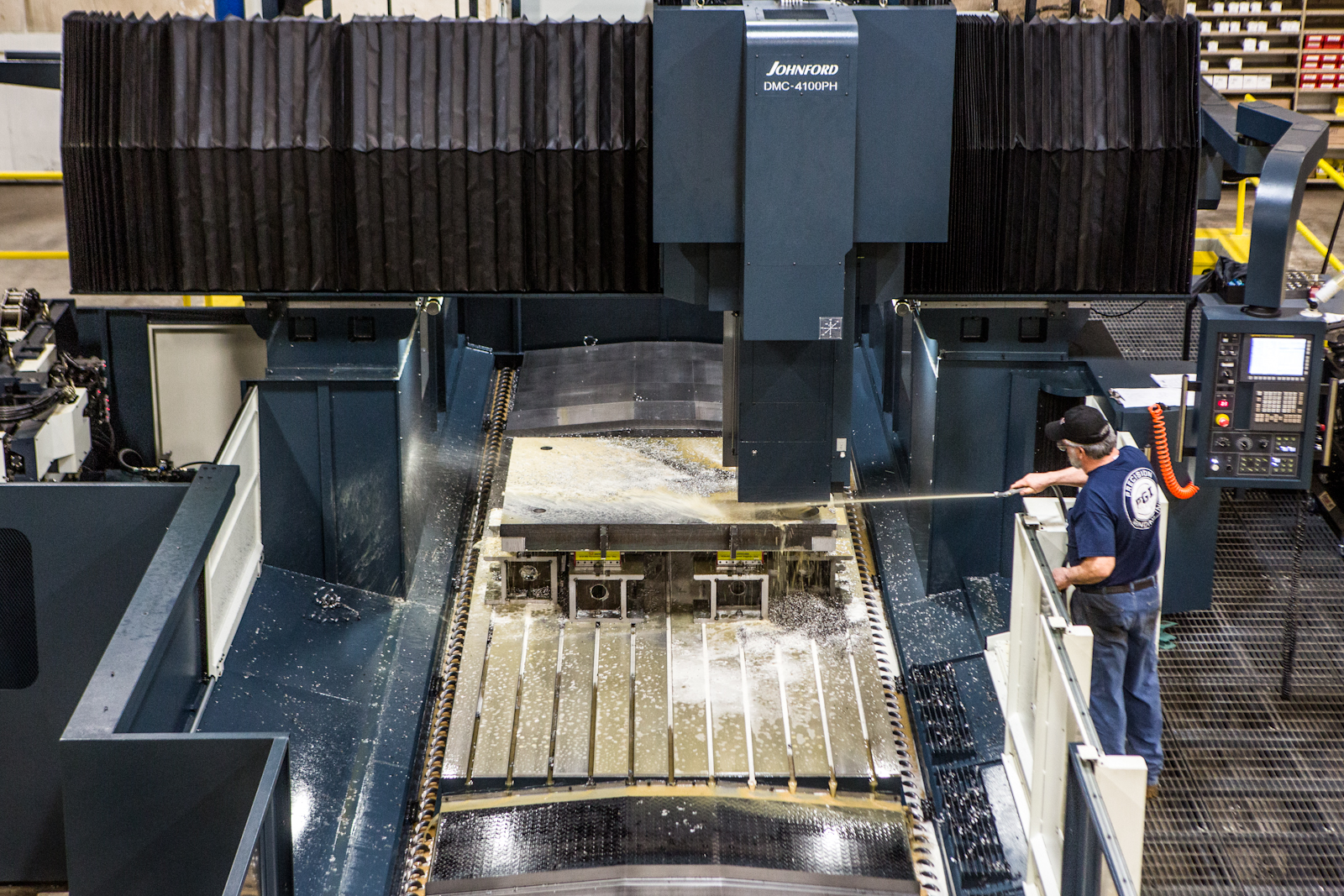

Our core manufacturing strength lies in state-of-the-art 5-axis CNC milling and drilling centers. These systems enable the precise, single-setup machining of complex gusset geometries featuring compound angles, intricate hole patterns, beveled edges, and contoured surfaces. This eliminates cumulative errors from multiple setups, significantly enhancing positional accuracy between critical features like bolt holes and connection points. We routinely process structural steel grades including Q235, Q345, ASTM A36, and A572, handling plate thicknesses from 6mm to 100mm and part dimensions up to 3000mm x 1500mm. Advanced toolpath simulation ensures optimal material removal rates while maintaining stringent surface finish requirements essential for subsequent welding or coating processes.

Quality verification is non-negotiable for structural components. Every critical gusset plate undergoes comprehensive inspection using Zeiss CONTURA and GLOBAL coordinate measuring machines (CMM). Our CMM protocols validate all geometric dimensions and tolerances per ASME Y14.5 or ISO 1101 standards, including positional accuracy of hole patterns, angularity of connection faces, flatness of bearing surfaces, and overall profile conformity. This data-driven inspection provides certified traceability, ensuring components fit seamlessly during assembly and perform reliably under load, eliminating costly field rework or structural compromises.

The following table details our standard and enhanced tolerance capabilities for gusset steel plate features, achievable through optimized CNC programming and CMM validation:

| Feature | Standard Capability | Enhanced Capability (Quoted) |

|---|---|---|

| Linear Dimensions | ±0.1 mm | ±0.05 mm |

| Hole Position (Dia) | ±0.15 mm | ±0.08 mm |

| Angular Features | ±0.1° | ±0.05° |

| Flatness (per sq.m) | 0.3 mm | 0.1 mm |

| Profile Tolerance | ±0.2 mm | ±0.1 mm |

| Surface Finish (Ra) | 6.3 µm | 3.2 µm |

These capabilities are supported by robust material certification traceability and in-process inspection checks. We understand that gusset plate performance is fundamental to structural safety; therefore, our engineering team collaborates closely with clients during the quoting phase to define precise tolerance requirements matching the application’s criticality. Contact Wuxi Lead Precision Machinery to discuss how our technical capabilities ensure your gusset steel plate components exceed performance expectations.

Material & Finish Options

Material Selection for Gusset Steel Plates: Engineering Performance and Finish Options

Selecting the appropriate material for gusset steel plates is critical to ensuring structural integrity, longevity, and compatibility with environmental and operational demands. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to high-load, precision applications. While the term “gusset steel plate” typically implies carbon or alloy steel, advanced applications may benefit from aluminum or titanium alternatives depending on performance requirements. Each material offers distinct mechanical properties, weight characteristics, and corrosion resistance profiles.

Carbon and low-alloy steels remain the most widely used materials for gusset plates due to their high tensile strength, weldability, and cost efficiency. These materials are ideal for structural frameworks in construction, bridge systems, and heavy machinery where load-bearing capacity is paramount. For enhanced durability in corrosive environments, we recommend weathering steel (e.g., ASTM A588) or protective coatings in conjunction with proper design.

Aluminum alloys, such as 6061-T6 or 7075-T6, provide a lightweight alternative with excellent corrosion resistance and moderate strength. These are particularly advantageous in aerospace, transportation, and marine applications where weight reduction directly impacts performance and fuel efficiency. While aluminum lacks the raw strength of steel, its strength-to-weight ratio makes it a strategic choice in dynamic load scenarios.

Titanium, primarily Grade 5 (Ti-6Al-4V), delivers exceptional strength, corrosion resistance, and performance at elevated temperatures. Though significantly more expensive, titanium is optimal for critical aerospace, defense, and offshore applications where failure is not an option. Its biocompatibility also makes it suitable for specialized medical or cleanroom equipment structures.

Surface finishing plays a crucial role in enhancing durability and appearance. Anodizing is a widely used electrochemical process for aluminum components, creating a robust oxide layer that improves wear and corrosion resistance. Type II (sulfuric acid) anodizing is standard for general protection and dyeing, while Type III (hardcoat anodizing) offers superior thickness and hardness for industrial wear surfaces. Note that anodizing is exclusive to aluminum and cannot be applied to steel or titanium.

For steel gusset plates, alternative finishes such as hot-dip galvanizing, powder coating, or zinc flake coating are recommended to combat oxidation. Titanium naturally forms a passive oxide layer, providing inherent corrosion resistance without additional surface treatment.

Below is a comparative overview of key material properties for gusset plate applications.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| ASTM A36 Steel | 400–550 | 250 | 7.85 | Moderate (with coating) | Construction, Industrial Frames |

| 6061-T6 Aluminum | 310 | 276 | 2.70 | High | Aerospace, Marine Supports |

| Ti-6Al-4V | 900 | 830 | 4.43 | Very High | Defense, High-Performance Structures |

| ASTM A588 Steel | 470–630 | 345 | 7.85 | High (weathering) | Bridges, Outdoor Structures |

At Wuxi Lead Precision Machinery, we guide our clients through material and finish selection based on load dynamics, environmental exposure, lifecycle costs, and regulatory standards. Our engineering team supports material certification, prototyping, and DFM analysis to ensure optimal performance in every gusset plate solution.

Manufacturing Process & QC

Gusset Steel Plate Production: Precision Engineering from Concept to Completion

At Wuxi Lead Precision Machinery, our gusset steel plate manufacturing process is engineered for uncompromising quality and structural integrity, adhering strictly to the Zero Defects philosophy. This systematic approach—Design, Prototyping, Mass Production—ensures every component meets the exacting demands of critical infrastructure, heavy machinery, and aerospace applications. We eliminate guesswork and mitigate risk through rigorous, integrated workflows.

The Design phase begins with deep collaboration. Our senior engineers work directly with your technical team to translate structural requirements into optimized CAD models. Finite Element Analysis (FEA) validates stress distribution, weld accessibility, and load paths under real-world conditions. Material selection is critical; we specify certified grades like ASTM A36, A572 Gr.50, or S355J2 based on your environmental and strength needs, ensuring full traceability from mill certificate to final part. CAM programming is then meticulously developed, defining optimal toolpaths, fixturing strategies, and machining sequences to achieve micron-level accuracy while maximizing material yield. This phase is foundational—errors here cascade; our focus is absolute precision before metal is cut.

Prototyping transforms digital designs into physical validation. Using the same CNC equipment and processes destined for full production, we manufacture 1-3 prototype gussets. These undergo comprehensive dimensional inspection via CMM (Coordinate Measuring Machine) against the original CAD model, verifying critical hole patterns, edge geometries, and overall flatness. Non-destructive testing (NDT), such as ultrasonic or magnetic particle inspection, checks for internal material flaws. Crucially, prototypes are evaluated in simulated assembly jigs to confirm fit-up with mating components. This stage catches potential interface or tolerance stack-up issues early, preventing costly rework during mass production. Client sign-off on the approved prototype is mandatory before proceeding.

Mass Production leverages the validated process for flawless scale. Our automated CNC machining centers—featuring 5-axis capability for complex bevels and contours—execute the CAM program with repeatability of ±0.02mm. In-process inspections occur at defined intervals using calibrated gauges and laser scanners, monitoring key dimensions in real-time. Every plate undergoes 100% final inspection: geometric tolerances, surface finish, weld prep angles, and material certification documentation are verified against your purchase order and international standards. Strict environmental controls in our facility minimize thermal drift. The result is consistent, defect-free output where every gusset plate is identical to the approved prototype, guaranteeing seamless integration and long-term structural performance.

This integrated methodology—grounded in engineering rigor and proactive quality control—delivers gusset plates that perform reliably under extreme loads. Wuxi Lead transforms complex specifications into precision assets, safeguarding your project timeline and structural integrity.

| Critical Production Specification | Wuxi Lead Precision Standard | Industry Typical Standard |

|---|---|---|

| Thickness Tolerance | ±0.05 mm | ±0.20 mm |

| Hole Position Tolerance (Dia ≤ 25mm) | ±0.08 mm | ±0.25 mm |

| Surface Roughness (Machined Areas) | Ra 1.6 µm Max | Ra 6.3 µm Max |

| Flatness (per 1m²) | 0.15 mm | 0.50 mm |

| Material Certification Traceability | Full Heat No. to Final Part | Mill Cert Only |

| In-Process Inspection Frequency | Every 5 Parts + Real-Time | Batch Sampling (10-20%) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Gusset Steel Plate Fabrication

When structural integrity, precision engineering, and long-term reliability are non-negotiable, Wuxi Lead Precision Machinery stands as your trusted partner in custom gusset steel plate manufacturing. With over 15 years of specialization in high-tolerance metal fabrication for global industrial clients, we deliver engineered solutions that meet the most rigorous performance standards. Our integrated production capabilities, from CNC cutting to robotic welding and stress-relieved finishing, ensure every gusset plate we produce exceeds expectations in load-bearing applications across construction, bridge engineering, heavy machinery, and offshore infrastructure.

At Lead Precision, we understand that gusset plates are more than connectors—they are critical load-transfer components that demand exacting material selection, dimensional accuracy, and weld integrity. That’s why we utilize premium-grade structural steels such as Q355, Q235, and ASTM A36, processed through advanced laser and plasma cutting systems with tolerances as tight as ±0.1 mm. Each plate undergoes comprehensive quality verification, including ultrasonic testing, dimensional inspection, and weld seam certification, to guarantee performance under dynamic stress conditions.

Our engineering team collaborates directly with your design and project management staff to interpret structural drawings, optimize joint configurations, and recommend material thicknesses and hole patterns for maximum efficiency. Whether you require small-batch prototypes or high-volume production runs, our flexible manufacturing cells support rapid turnaround without compromising consistency. We also offer galvanization, powder coating, and weathering steel options to ensure long-term corrosion resistance in demanding environments.

Below are key specifications for our standard gusset steel plate offerings:

| Specification | Details |

|---|---|

| Material Grades | Q235, Q355, ASTM A36, S235JR, S355JR, Custom Alloys |

| Thickness Range | 6 mm – 100 mm |

| Plate Dimensions (Max) | 3000 mm × 12000 mm |

| Cutting Tolerance | ±0.1 mm (Laser), ±0.5 mm (Plasma) |

| Hole Drilling Accuracy | ±0.05 mm (CNC Machining Center) |

| Welding Standards | ISO 3834, AWS D1.1, Full Penetration Welds with UT Testing Available |

| Surface Treatment | Sandblasting (Sa2.5), Hot-Dip Galvanizing, Primer Coating, Weathering Finish |

| Certifications | ISO 9001:2015, CE, Third-Party Inspection Reports (SGS, BV, TÜV Available) |

Partnering with Wuxi Lead Precision Machinery means gaining more than a supplier—you gain a committed engineering ally focused on structural excellence and project success. Our global logistics network ensures timely delivery to North America, Europe, Southeast Asia, and the Middle East, with full documentation and customs compliance.

For technical consultations, material certifications, or custom quotes, contact us today at [email protected]. Let Lead Precision be the foundation of strength in your next structural project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.