Technical Contents

Engineering Guide: Glow Molds Christmas

Engineering Insight: Glow Molds for Christmas – Precision at the Heart of Holiday Innovation

In the world of seasonal consumer goods, few products capture the imagination quite like glow molds for Christmas decorations. These intricately designed molds are responsible for producing luminous figurines, ornaments, and festive lighting elements that define modern holiday aesthetics. Behind every radiant snowman or glowing reindeer lies a foundation of advanced metal manufacturing—where micron-level precision determines not only visual fidelity but also production efficiency and long-term durability.

At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-demand applications, and our approach to glow mold engineering reflects the same rigor applied to Olympic-grade equipment and military-spec components. Precision in mold fabrication directly influences surface finish, dimensional accuracy, and cycle life—critical factors when producing thousands of consistent, high-clarity resin or plastic pieces under tight seasonal deadlines.

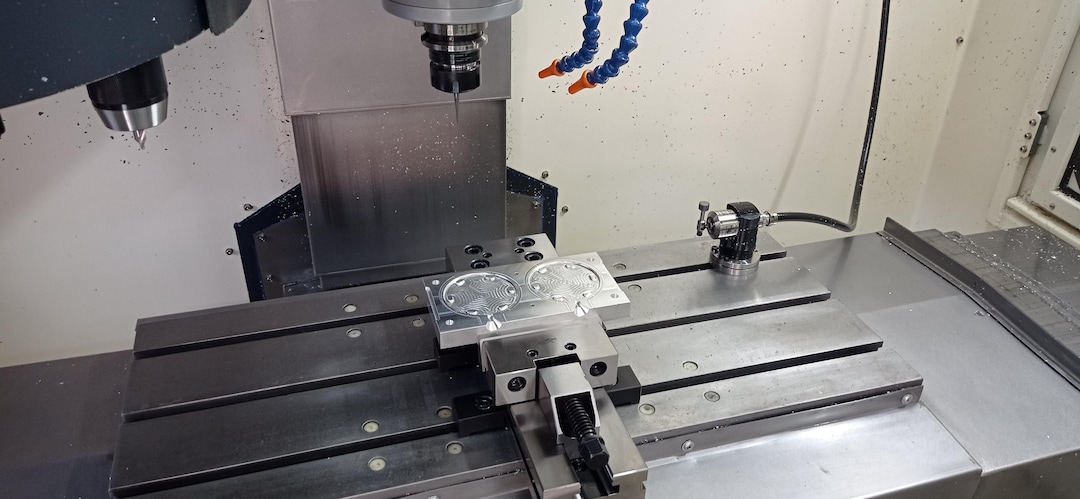

Glow molds often require complex internal channeling for LED integration, seamless parting lines to avoid post-processing, and thermal uniformity to support rapid curing. These demands necessitate CNC-machined steel or aluminum tooling with tolerances within ±0.005 mm. At Lead Precision, our engineering team leverages multi-axis machining centers, coordinate measuring machines (CMM), and 3D laser scanning to validate mold geometry before deployment. This ensures that each cavity replicates the original design with absolute fidelity—down to the finest snowflake texture.

Our experience in mission-critical manufacturing sectors has taught us that reliability cannot be compromised. A single micron of deviation in a glow mold can result in flashing, incomplete fills, or inconsistent light diffusion—defects that cascade through production and impact brand reputation. By applying aerospace-level quality control protocols, we deliver molds that sustain over 100,000 cycles without degradation, offering clients a superior return on investment.

Beyond precision, we emphasize material science integration. Depending on the resin type—whether thermoplastic polyurethane (TPU) or epoxy-based luminous compounds—we tailor mold steel selection, surface coatings (such as PVD or Ni-P-PTFE), and cooling channel layouts to optimize release properties and thermal efficiency. This holistic engineering approach minimizes downtime and maximizes output during peak production seasons.

For global manufacturers aiming to differentiate their Christmas product lines, partnering with a precision-focused mold maker is not a cost—it’s a strategic advantage. At Wuxi Lead Precision Machinery, we bring over a decade of high-stakes engineering experience to every glow mold project, ensuring that the magic of the holidays is backed by industrial excellence.

| Specification | Detail |

|---|---|

| Typical Tolerance | ±0.005 mm |

| Material Options | NAK80, S136, 718H, Aluminum 7075 |

| Surface Finish | Ra ≤ 0.2 µm (polished), optional anti-reflective coating |

| Machining Capabilities | 5-axis CNC, Wire EDM, High-Speed Milling |

| Quality Assurance | CMM inspection, 3D laser scan, first-article reporting |

| Expected Mold Life | 100,000 – 500,000 cycles (depending on material and design) |

| Lead Time (Standard) | 25–35 days from approved design |

Precision Specs & Tolerances

Technical Capabilities for Precision Luminous Component Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision for complex luminous holiday components, including critical structural and optical elements for glow-based Christmas applications. Our facility integrates advanced 5-axis CNC machining centers to produce intricate geometries required for light diffusion, structural integrity, and seamless assembly in high-end decorative products. These machines eliminate multi-setup errors, ensuring micron-level accuracy across compound angles and undercuts essential for consistent light transmission and aesthetic refinement. All equipment operates within controlled environmental conditions to mitigate thermal drift, maintaining repeatability for both prototyping and high-volume production runs.

Our quality assurance protocol begins with material certification and extends through every machining phase. Critical dimensions undergo rigorous verification via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), programmed to ISO 10360-2 standards. This non-contact optical and tactile inspection methodology validates geometric tolerances, surface continuity, and positional accuracy against CAD models, guaranteeing components meet stringent optical performance criteria. Each part receives a full inspection report traceable to international standards, including ISO 9001:2015 compliance documentation. This closed-loop process ensures zero-defect delivery for applications where light leakage or dimensional variance would compromise product functionality.

Material versatility supports diverse luminous component requirements. We machine aerospace-grade aluminum alloys (6061-T6, 7075-T6), stainless steels (304, 316L), and engineered plastics (PEEK, Delrin) optimized for thermal stability, corrosion resistance, and optical clarity. Secondary operations including micro-milling, precision tapping, and surface texturing are performed in-house to achieve specified light-scattering properties. All processes adhere to strict clean-room protocols to prevent particulate contamination that could impair light diffusion.

Achievable manufacturing specifications are summarized below for reference:

| Parameter | Standard Capability | Enhanced Capability |

|---|---|---|

| Linear Tolerance | ±0.010 mm | ±0.005 mm |

| Angular Tolerance | ±0.05° | ±0.02° |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Geometric Tolerance (GD&T) | ±0.015 mm | ±0.008 mm |

| Max Work Envelope | 1200 x 800 x 600 mm | 800 x 500 x 400 mm |

This technical foundation enables reliable production of glow mold components where dimensional precision directly impacts light uniformity, structural durability, and assembly efficiency. We collaborate with clients during DFM analysis to optimize part geometry for manufacturability while preserving optical performance targets. Our engineering team provides actionable feedback on material selection, tolerance allocation, and feature design to reduce costs without sacrificing quality. For critical luminous applications demanding sub-10-micron accuracy, we implement enhanced process controls including in-process probing and thermal compensation algorithms. Wuxi Lead Precision Machinery remains committed to delivering technically superior components that elevate the performance and reliability of your luminous holiday products.

Material & Finish Options

Material Selection for High-Precision Glow Molds in Christmas Applications

When manufacturing glow molds for Christmas lighting and decorative components, material selection is critical to achieving optimal performance, durability, and aesthetic quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-end applications, where precision and reliability are non-negotiable. For glow molds used in seasonal lighting systems—such as LED housings, diffusers, and embedded glow elements—three primary metals stand out: Aluminum, Steel, and Titanium. Each offers distinct advantages depending on production volume, thermal requirements, and environmental exposure.

Aluminum is the most widely used material for glow mold construction due to its excellent thermal conductivity, lightweight nature, and machinability. It dissipates heat efficiently, which is crucial when molds are subjected to repeated thermal cycling during injection or encapsulation processes. Its low density reduces overall mold weight, facilitating easier handling and integration into automated production lines. Furthermore, aluminum responds exceptionally well to anodizing, a surface treatment that enhances corrosion resistance and allows for decorative color finishes—ideal for holiday-themed manufacturing where visual appeal matters.

Steel, particularly tool steel variants like P20 or H13, is preferred for high-volume production runs. While heavier and more challenging to machine than aluminum, steel offers superior hardness and wear resistance. This makes it ideal for molds expected to endure thousands of cycles without dimensional deviation. Steel molds maintain edge definition and surface integrity over time, ensuring consistent optical clarity in glow components. However, steel requires additional surface treatments such as plating or polishing to resist corrosion, especially in humid or outdoor environments common in Christmas lighting applications.

Titanium is reserved for extreme conditions where both strength and corrosion resistance are paramount. Though significantly more expensive and difficult to machine, titanium’s exceptional strength-to-density ratio and inertness to most chemicals make it suitable for specialized, long-life molds exposed to aggressive materials or outdoor elements. Its biocompatibility and non-magnetic properties also make it a candidate for niche applications in high-end decorative lighting.

Anodizing is a key finishing process, especially for aluminum molds. This electrochemical treatment creates a durable, porous oxide layer that can be dyed in various colors—red, green, gold, or blue—aligning with festive themes. The anodized layer improves surface hardness and protects against wear and oxidation, directly contributing to mold longevity and consistent part quality.

Below is a comparative overview of the three materials based on key manufacturing parameters.

| Property | Aluminum | Steel (P20/H13) | Titanium |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.8 | 4.5 |

| Thermal Conductivity (W/mK) | 150–220 | 25–35 | 7–10 |

| Hardness (HRC) | 40–60 (anodized) | 28–50 | 35–45 |

| Corrosion Resistance | High (with anodizing) | Moderate (with coating) | Excellent |

| Machinability | Excellent | Good | Poor |

| Typical Use Case | Low to medium volume, decorative molds | High-volume production | Extreme environments, specialty molds |

Selecting the right material for glow molds in Christmas applications requires balancing performance, cost, and lifecycle expectations. At Wuxi Lead Precision Machinery, we work closely with clients to match material and finish to application demands, ensuring precision, efficiency, and long-term reliability in every mold we produce.

Manufacturing Process & QC

Precision Engineering for Glow Mold Christmas Production: The Zero Defects Pathway

At Wuxi Lead Precision Machinery, manufacturing high-integrity glow molds for Christmas applications demands an uncompromising, integrated process. These specialized molds require exceptional dimensional accuracy and surface finish to ensure consistent phosphorescent performance and aesthetic quality in final decorations. Our proprietary pathway from concept to mass production eliminates defects at every stage, guaranteeing reliability for your seasonal production runs.

The Design phase begins with rigorous analysis of your luminescent material properties and part geometry. Our engineering team utilizes advanced CAD/CAM suites to model mold cavities, cooling channels, and ejection systems, optimizing for uniform heat transfer critical to glow material integrity. Finite Element Analysis (FEA) predicts thermal stresses and potential warpage, while Moldflow simulation validates flow dynamics of the phosphorescent compound. Critical tolerances for cavity surfaces (±0.005mm) and alignment features are defined early, ensuring the mold structure supports micron-level precision required for intricate festive designs. Material selection focuses on hardened tool steels with specialized coatings to resist abrasion from filled glow compounds and ensure longevity.

Prototyping transforms the digital model into a physical validation asset. We employ high-speed CNC machining and sinker EDM to fabricate a single-cavity prototype mold using the exact production-grade steel. This prototype undergoes rigorous testing cycles with your specified glow material under production-simulated conditions. We measure critical outputs: light emission uniformity, cycle time stability, part dimensional conformity against CAD data, and surface replication fidelity. Any micro-defects in part ejection or flash formation are identified and corrected through iterative mold adjustments. This phase is non-negotiable; only when the prototype consistently delivers flawless parts meeting all optical and dimensional specs does the design lock for production.

Mass Production leverages our certified ISO 9001 facility and closed-loop quality systems. Multi-cavity production molds are machined on 5-axis CNC centers with real-time tool wear compensation. In-process monitoring via Statistical Process Control (SPC) tracks cavity pressure, temperature, and cycle time deviations. Every mold undergoes 100% geometric inspection using CMMs against the master CAD model before shipment. Our Zero Defects commitment is operationalized through automated vision systems checking critical features on production parts and mandatory first-article inspections for every production batch. This integrated approach ensures your glow molds deliver peak performance, season after season.

Critical Production Specifications for Glow Molds Christmas

| Parameter | Specification | Tolerance/Control Method |

|---|---|---|

| Cavity Surface Finish | Mirror Polish (SPI-A1) | Ra ≤ 0.025µm (Profilometer) |

| Critical Dimension Tol. | Cavity Core/Cavity Dimensions | ±0.005mm (CMM Verification) |

| Alignment Precision | Cavity to Cavity / Ejector | ±0.01mm (Coordinate Measuring) |

| Cooling Channel Accuracy | Diameter / Placement | ±0.05mm (CT Scan Validation) |

| Production Cycle Time | Optimized for Glow Material | ±2% Stability (SPC Monitoring) |

| Zero Defects Gate | First Article Inspection Pass Rate | 100% Conformance Required |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

When it comes to producing high-performance components for specialized applications such as glow molds for Christmas lighting systems, precision, consistency, and material integrity are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions engineered to meet the most demanding industrial requirements. Our advanced CNC machining, deep-draw forming, and surface treatment capabilities ensure that every glow mold we produce supports optimal thermal distribution, structural durability, and long-term performance in seasonal lighting applications.

We understand that glow molds used in Christmas lighting must maintain tight dimensional tolerances to ensure uniform light diffusion and efficient production cycles. Our engineering team works closely with clients to analyze thermal expansion characteristics, material selection, and mold release dynamics, ensuring that each component is optimized for both manufacturing efficiency and end-use reliability. Whether you require molds for LED filament encapsulation, epoxy lens forming, or electroluminescent tube shaping, our solutions are built to enhance yield, reduce downtime, and extend service life.

Our manufacturing facility in Wuxi, China, is equipped with state-of-the-art CNC lathes, wire EDM systems, and multi-axis milling centers, enabling us to produce complex mold geometries with tolerances as tight as ±0.005 mm. We utilize high-grade tool steels and corrosion-resistant alloys, with optional surface treatments including nitriding, hard chrome plating, and PVD coatings to improve wear resistance and thermal stability.

Every project at Lead Precision begins with a collaborative design review. Our engineers provide DFM (Design for Manufacturability) feedback to streamline production, minimize material waste, and accelerate time-to-market. We support low-volume prototyping through high-volume production runs, offering full traceability, first-article inspection reports, and ongoing quality assurance per ISO 9001 standards.

Below are key technical specifications for our glow mold manufacturing services:

| Specification | Detail |

|---|---|

| Material Options | SKD11, H13, S136, 420SS, Invar, and custom alloys |

| Tolerance | ±0.005 mm (standard), ±0.002 mm (precision) |

| Surface Finish | Ra 0.05–0.8 μm (polished, EDM-textured, or coated) |

| Max Mold Size | 600 mm × 400 mm × 300 mm |

| Production Lead Time | 15–25 days (depending on complexity) |

| Quality Standards | ISO 9001:2015, First Article Inspection, PPAP Level 3 |

| Secondary Processes | Heat treatment, nitriding, PVD, laser engraving |

Partnering with Wuxi Lead Precision Machinery means aligning with a team committed to engineering excellence and responsive client service. We support global clients across Europe, North America, and Southeast Asia with English-speaking project managers, real-time production updates, and reliable logistics coordination.

To discuss your glow mold requirements for Christmas lighting systems or to request a detailed quotation, contact us today at [email protected]. Let Lead Precision be your trusted manufacturing partner—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.