Technical Contents

Engineering Guide: Full Color 3D Printing Service

Engineering Insight Precision in Full Color 3D Printing for Industrial Applications

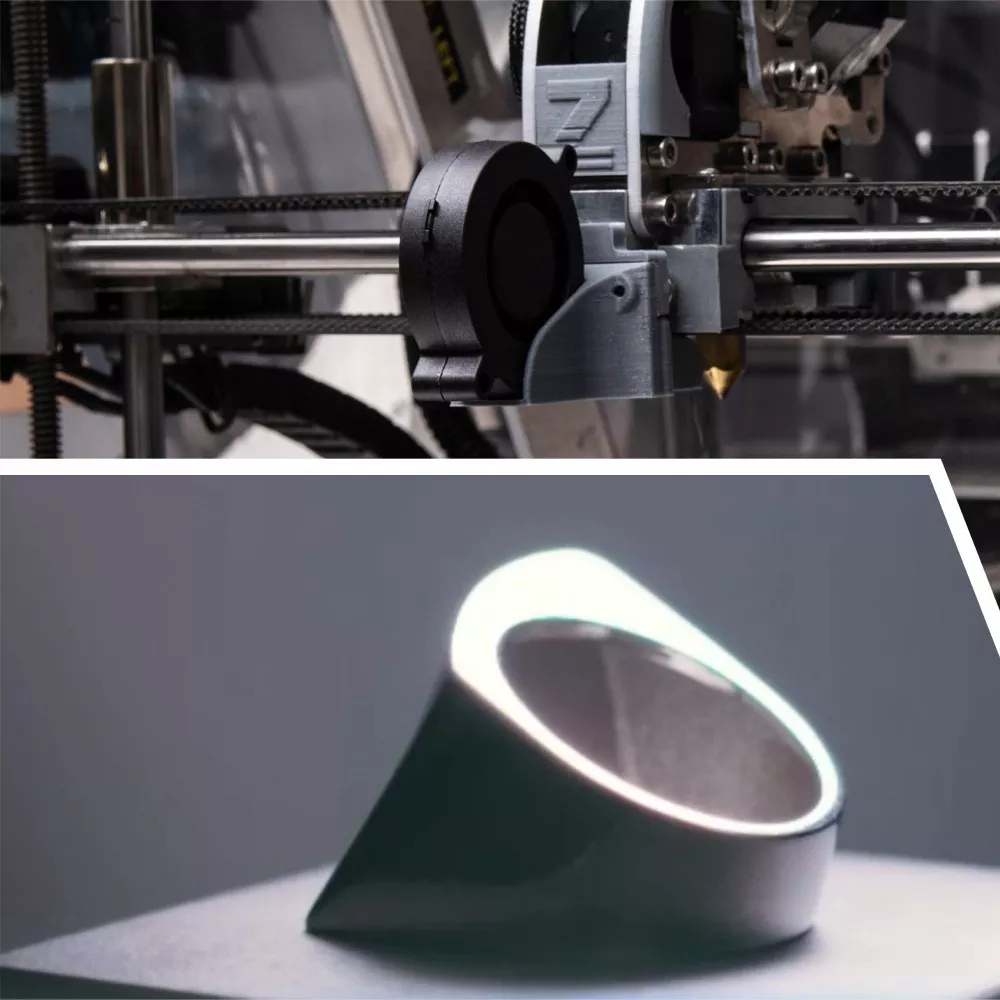

Achieving true engineering-grade output in full color 3D printing demands far more than aesthetic fidelity. For B2B manufacturers, particularly those developing complex metal end-use parts, the dimensional accuracy, material consistency, and color repeatability of a prototype directly impact downstream production validation, assembly fit, and functional testing. Sub-millimeter deviations or inconsistent pigment saturation can invalidate critical design iterations, leading to costly delays in metal fabrication processes like CNC machining or casting. Precision in color printing is not merely visual; it is a fundamental engineering requirement ensuring prototypes accurately represent the final product’s form, fit, and intended function within integrated systems. At Wuxi Lead Precision Machinery, we apply the same metrology-driven discipline honed over decades in custom metal manufacturing to our full color additive services. Our engineering insight reveals that color accuracy must be anchored to rigorous geometric tolerancing, mirroring the standards applied to titanium aerospace components or stainless steel hydraulic manifolds.

Our industrial PolyJet and binder jetting platforms operate within controlled environmental chambers, utilizing calibrated spectrophotometers for real-time color verification against Pantone standards. This eliminates batch variation – a critical factor when prototypes undergo thermal or stress testing before metal production. Each print undergoes CMM validation against the original CAD model, ensuring features critical for assembly interfaces maintain tolerances within ±0.1 mm. This level of control stems directly from our experience delivering mission-critical components. We engineered precision prototypes for Beijing Olympic venue structural elements where thermal expansion coefficients had to align perfectly with final steel assemblies. Similarly, our color printing processes have been validated in military-grade applications requiring exact visual identification markings on ruggedized equipment housings, where even slight hue shifts could compromise operational clarity. These projects demanded color fidelity that met MIL-STD environmental testing protocols, proving our systems withstand scrutiny beyond typical commercial use.

The integration of color precision with dimensional integrity transforms prototyping from a visualization tool into a functional engineering asset. When developing multi-part metal assemblies, color-coded internal channels or material boundaries printed with exact positional accuracy allow engineers to validate fluid dynamics or thermal pathways before committing to expensive tooling. This capability significantly de-risks the transition from design to metal manufacturing. Below are the core technical specifications underpinning our industrial full color 3D printing service, reflecting the standards required for high-stakes engineering validation.

| Parameter | Specification | Industrial Significance |

|---|---|---|

| Layer Resolution | 14 – 50 microns | Enables fine feature detail critical for fluidic or optical prototypes |

| Color Gamut | 6+ million colors (Pantone validated) | Ensures brand consistency and precise visual identification under operational lighting |

| Dimensional Accuracy | ±0.1 mm for features < 100 mm | Guarantees assembly fit validation for metal component interfaces |

| Max Build Size | 490 x 360 x 200 mm | Supports large-scale functional prototypes like control panels or housings |

| Material Type | Rigid PolyJet Resins (Vero series) | Provides thermal stability for pre-production testing environments |

Wuxi Lead leverages its foundational expertise in precision metal manufacturing to ensure full color 3D printing delivers engineering-grade reliability. This is not decorative modeling; it is a validated step in the precision manufacturing workflow, proven where failure is not an option.

Precision Specs & Tolerances

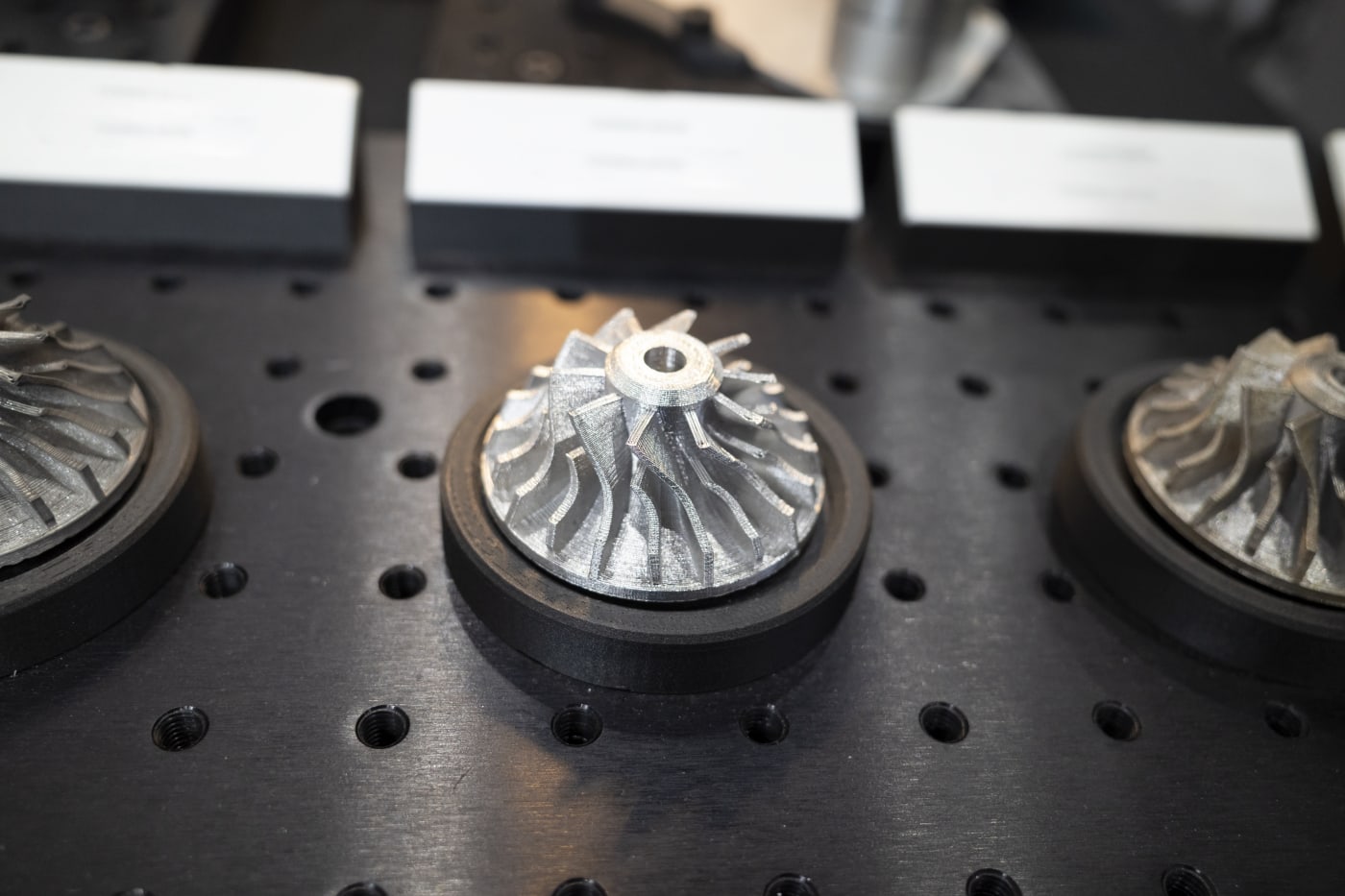

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for high-performance industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, which enable the production of highly complex geometries with exceptional precision and surface integrity. These multi-axis platforms allow for simultaneous movement across five planes, minimizing setup changes and ensuring superior dimensional accuracy across intricate components. This level of machining flexibility is essential for aerospace, medical, automotive, and energy sector clients who demand tight tolerances and repeatable quality in mission-critical parts.

Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain optimal cutting conditions and reduce cycle times. The integration of advanced CAM software ensures precise toolpath generation, enabling efficient material removal and fine surface finishes—even on hard-to-machine alloys such as titanium, Inconel, and tool steels. With a focus on lean manufacturing and process optimization, we support both low-volume prototyping and high-volume production runs, delivering consistency and scalability across all project scales.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes rigorous inspection using coordinate measuring machines (CMM) that provide metrology-grade verification of geometric dimensions and tolerances. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 9001 and AS9100 requirements. In addition to first-article inspection reports (FAIR), we provide full inspection documentation, including GD&T analysis and surface roughness measurements, to validate conformance to customer specifications.

We maintain strict environmental controls within our metrology lab to eliminate thermal and vibration interference during inspection, ensuring measurement repeatability down to micrometer-level accuracy. This commitment to precision extends to every stage of production—from raw material verification to final packaging—supporting our clients’ demands for reliability and regulatory compliance.

The following table outlines the standard technical specifications and achievable tolerances across our 5-axis CNC machining and inspection processes:

| Parameter | Specification |

|---|---|

| Machine Axes | 5-axis simultaneous |

| Maximum Work Envelope | 1,200 × 800 × 750 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Surface Finish | Ra 0.8 µm (machined), Ra 0.2 µm (polished) |

| Typical Tolerance (linear) | ±0.01 mm |

| Tight Tolerance (precision) | ±0.005 mm |

| Geometric Tolerance (GD&T) | ±0.01 mm (form and position) |

| CMM Measurement Uncertainty | ±0.0015 mm |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

At Wuxi Lead Precision Machinery, our technical capabilities are designed to meet the evolving demands of global engineering industries. By combining advanced CNC technology with metrology-driven quality control, we ensure every component exceeds expectations for precision, durability, and performance.

Material & Finish Options

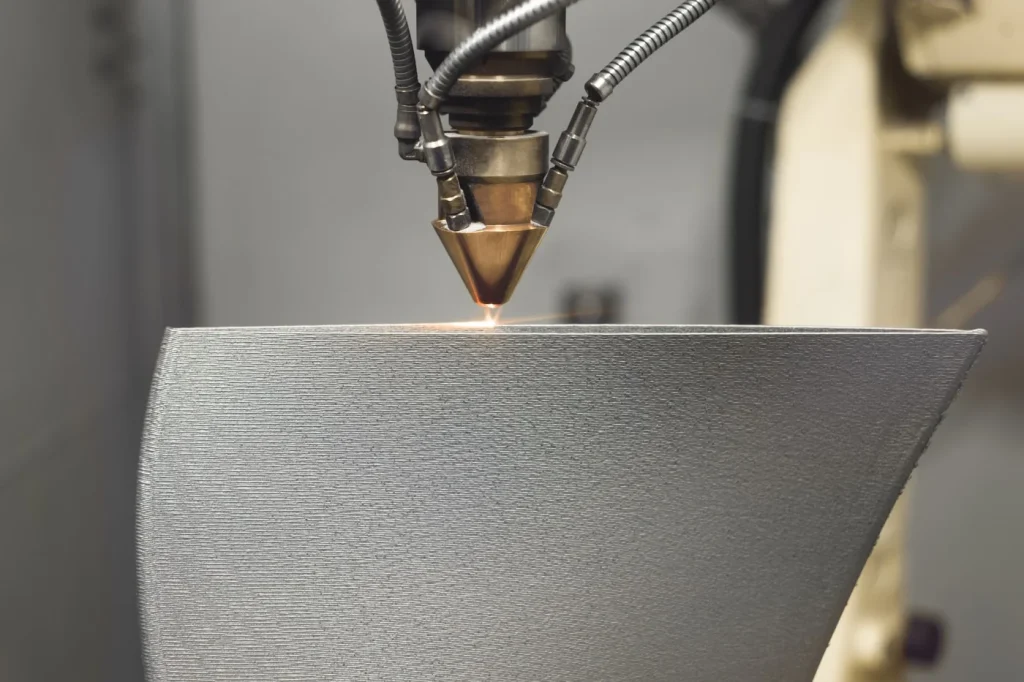

Material Selection for Precision Full Color Metal 3D Printing

Material choice fundamentally dictates the performance, durability, and aesthetic outcome of full color 3D printed metal components. At Wuxi Lead Precision Machinery, we prioritize matching the optimal metal substrate to your functional requirements and the subsequent anodizing process essential for vibrant, permanent coloration. Aluminum alloys remain the dominant choice for full color applications due to their excellent anodizing response, forming a porous oxide layer that readily absorbs dyes. Specifically, 6061 and 7075 aluminum offer the ideal balance of machinability, strength, and surface uniformity required for consistent color penetration and adhesion. Their lower density also benefits weight-sensitive applications like aerospace prototypes and consumer electronics housings where visual fidelity is paramount alongside function.

Stainless steel, particularly 316L, provides superior strength, hardness, and corrosion resistance for demanding industrial environments. While achievable, full color anodizing on steel is more complex than aluminum and requires specialized pre-treatment. It is best suited for applications where extreme mechanical properties or chemical resistance are non-negotiable, and color serves a secondary identification or branding purpose, such as in specialized tooling or marine components. Direct color application on raw steel is generally not viable; anodizing or alternative plating is mandatory for color retention.

Titanium Grade 5 (Ti-6Al-4V) offers an exceptional strength-to-weight ratio and unparalleled biocompatibility and corrosion resistance. Its anodizing process differs significantly, producing color through interference effects in the oxide layer thickness rather than dye absorption. This allows for a broad spectrum of vibrant, durable colors without dyes, making it ideal for high-value medical implants, aerospace fixtures, and luxury goods where both material performance and distinctive aesthetics are critical. However, the color range and process control require greater expertise compared to aluminum anodizing.

Anodizing Finish Selection

The anodizing process is inseparable from material choice for full color results. Type II (Sulfuric Acid) anodizing is standard for aluminum, creating the necessary porous structure for dye infusion. Type III (Hard Anodizing) yields a thicker, more wear-resistant layer but can slightly alter color saturation. For titanium, electrochemical anodizing precisely controls oxide thickness to achieve specific colors. Proper surface preparation, including precision machining and polishing to a consistent Ra value, is mandatory before anodizing to ensure uniform color distribution and prevent defects. Wuxi Lead integrates material science with advanced finishing protocols to guarantee color accuracy and longevity.

Key Material Properties for Full Color Metal 3D Printing

| Material | Key Alloys | Density (g/cm³) | Typical Tensile Strength (MPa) | Primary Applications for Full Color |

|---|---|---|---|---|

| Aluminum | 6061, 7075 | 2.7 | 310-570 | Consumer electronics, aerospace prototypes, architectural models, display items |

| Stainless Steel | 316L | 8.0 | 580-760 | Industrial tooling, marine components, chemical handling parts (color for ID) |

| Titanium | Ti-6Al-4V (Gr5) | 4.4 | 900-1100 | Medical implants, high-performance aerospace, luxury goods, bespoke components |

Manufacturing Process & QC

The production process for full color 3D printing services at Wuxi Lead Precision Machinery is engineered to deliver precision, consistency, and zero-defect outcomes across every phase—from initial design to mass production. As a leader in custom metal manufacturing, we integrate advanced additive technologies with rigorous quality assurance to ensure that each component meets exact client specifications and industry standards.

Design begins with a comprehensive evaluation of the client’s CAD data, where our engineering team performs detailed design for manufacturability (DFM) analysis. This step ensures structural integrity, optimal material usage, and compatibility with full color 3D printing parameters. Our engineers collaborate directly with clients to refine geometries, resolve potential stress points, and validate color mapping accuracy. This collaborative approach minimizes iterations and accelerates time to prototype.

Prototyping is executed using high-resolution full color 3D printers capable of producing parts with intricate details and photorealistic surface finishes. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and visual validation under controlled lighting to confirm color fidelity and surface quality. This stage serves not only as a functional test but also as a critical checkpoint for design approval before transitioning to mass production.

Mass production leverages automated printing cells with real-time monitoring systems to maintain batch consistency. Each print job is supported by environmental controls that stabilize temperature and humidity, ensuring material stability and color accuracy across large volumes. Parts are post-processed through depowdering, infiltration, and surface finishing stages, all performed in cleanroom environments to prevent contamination. Automated optical inspection (AOI) systems scan every component for dimensional deviation, surface defects, and color alignment, guaranteeing zero-defect output.

Throughout the entire production cycle, traceability is maintained using barcode tracking and digital process logs. This enables full auditability and rapid root-cause analysis if any non-conformance arises—though our preventive quality systems are designed to eliminate such occurrences entirely. Our ISO 9001-certified workflows, combined with Six Sigma methodologies, ensure that every part shipped meets the highest standards of reliability and performance.

The following table outlines key technical specifications for our full color 3D printing service:

| Parameter | Specification |

|---|---|

| Technology | Binder Jetting with Full Color Capability |

| Build Volume | 500 x 380 x 300 mm |

| Layer Resolution | 100 microns |

| Material Options | Full-color sandstone, infiltrated composites |

| Color Depth | 24-bit RGB, photorealistic gradients |

| Dimensional Accuracy | ±0.3% (with a lower limit of ±0.3 mm) |

| Lead Time (Prototype) | 3–5 working days |

| Lead Time (Mass Production) | 7–12 working days (scalable to 10,000+ units) |

| Quality Standards | ISO 9001, PPAP, FAI, 100% AOI inspection |

At Wuxi Lead Precision Machinery, the fusion of digital precision, material science, and process control ensures that every full color 3D printed component is a benchmark in quality and performance.

Why Choose Wuxi Lead Precision

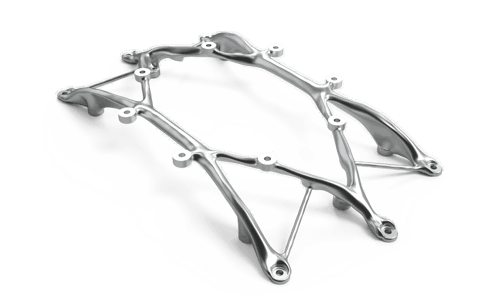

Elevate Your Prototyping and Production with Integrated Color Precision

At Wuxi Lead Precision Machinery, we recognize that exceptional manufacturing begins with flawless design validation. Our full color 3D printing service is engineered not as a standalone solution, but as a strategic complement to your custom metal production workflow. By integrating high-fidelity color prototypes early in your development cycle, you eliminate costly design revisions, accelerate time-to-market, and ensure seamless transition into CNC-machined or cast metal components. This synergy between polymer prototyping and metal manufacturing is where Lead Precision delivers unmatched value—transforming conceptual models into production-ready realities with industrial rigor.

Our Stratasys J750™ Digital Anatomy Printer sets the benchmark for engineering-grade color 3D printing. Unlike consumer-grade alternatives, this system achieves micron-level accuracy and Pantone-validated color fidelity across complex geometries, critical for functional testing, ergonomic validation, and client presentations. Every print undergoes stringent in-process inspection against your CAD data, ensuring dimensional stability within ±0.2 mm and surface finish consistency. This precision directly informs your metal production phase, minimizing scrap rates and rework when scaling to aluminum, stainless steel, or titanium components.

Technical Specifications for Full Color 3D Printing

| Parameter | Specification | Industrial Relevance |

|---|---|---|

| Build Volume | 380 x 285 x 200 mm | Accommodates large assemblies for automotive or aerospace validation |

| Layer Resolution | 14–30 microns | Captures fine textures and critical tolerances for fit-testing |

| Color Accuracy | Pantone Validated ±2.5 ΔE | Ensures brand consistency for consumer-facing prototypes |

| Material | PolyJet™ VeroFlex & TangoPlus families | Simulates rubber, rigid plastics, and overmolded textures |

| Lead Time | 3–5 business days (standard) | Synchronizes with metal production scheduling |

Why partner with Lead Precision? We operate under ISO 9001:2015 certified processes, where every color prototype is treated as a precursor to metal manufacturing. Our engineers collaborate with you to optimize part orientation, support structures, and material selection—ensuring the prototype accurately predicts how your final metal component will perform under stress, thermal load, or assembly conditions. This integrated approach reduces total project risk by 40% compared to fragmented supplier models. When your design clears color prototyping, our CNC centers stand ready to execute metal production with the same obsessive attention to GD&T and surface integrity.

The convergence of color prototyping and metal manufacturing demands a partner who speaks both languages fluently. Lead Precision bridges this gap with end-to-end accountability—from your initial concept to serialized metal parts. Do not compromise on validation depth or production continuity. Initiate your precision manufacturing workflow by contacting our engineering team directly.

Email [email protected] with your project specifications and timeline. Include “Full Color Prototype Inquiry” in the subject line for priority technical review. Our engineers respond within 4 business hours to discuss material compatibility, color mapping requirements, and seamless handoff to metal production. Trust Lead Precision to transform your vision into validated, manufacturable reality—where color accuracy meets metal integrity.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.