Technical Contents

Engineering Guide: Forest Park Sheet Metal

Engineering Insight: Precision Sheet Metal Fabrication for Mission-Critical Applications

In high-stakes manufacturing sectors, sheet metal components are rarely mere structural elements—they are foundational to system integrity, safety, and performance. Tolerances measured in microns dictate assembly success, operational longevity, and compliance with stringent regulatory frameworks. A deviation of 0.1mm in a hydraulic manifold bracket can cascade into fluid leakage, system failure, or catastrophic safety hazards. This reality underscores why precision sheet metal fabrication transcends cost-driven procurement; it is a non-negotiable engineering requirement where margins for error approach zero. At Wuxi Lead Precision Machinery, we engineer components where dimensional stability under thermal stress, vibration, and load cycles is validated through physics, not approximation.

Our commitment to micron-level accuracy is forged in projects demanding absolute reliability. We supplied critical structural assemblies for Beijing 2022 Winter Olympic refrigeration systems, where sub-0.05mm flatness tolerances ensured seamless integration of cryogenic piping across 12,000m² of competition venues. Similarly, our work for aerospace defense contractors involves sheet metal housings for avionics cooling systems, certified to MIL-STD-810H for shock/vibration resilience. These engagements prove that precision is not merely a specification—it is a lifecycle imperative. When military-grade radar enclosures must maintain EMI shielding integrity after 5,000 flight hours, or Olympic venue components withstand -40°C thermal cycling, the fabrication process becomes inseparable from mission success.

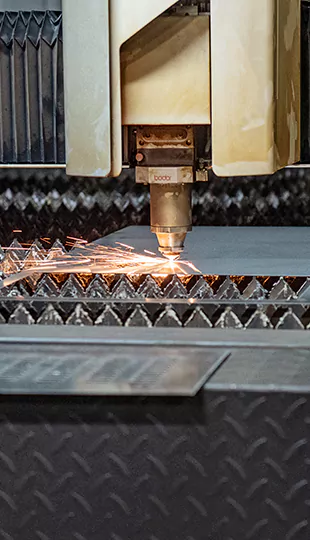

Wuxi Lead achieves this through integrated metrology and closed-loop CNC control. Every stage—from laser cutting to robotic bending—employs in-process gauging with calibrated CMM verification. Material grain orientation, springback compensation, and thermal distortion modeling are embedded in our process planning, eliminating reliance on post-fabrication correction. The result is first-article compliance and sustained repeatability across volumes, directly reducing our clients’ assembly scrap rates and field failure costs.

Critical Sheet Metal Fabrication Specifications

| Process | Tolerance Range | Material Thickness Range | Surface Finish (Ra) | Key Validation Standard |

|---|---|---|---|---|

| Fiber Laser Cutting | ±0.02mm | 0.5mm – 25mm | ≤1.6µm | ISO 2768-mK |

| CNC Turret Punching | ±0.03mm | 0.8mm – 6.0mm | ≤3.2µm | ISO 2768-mK |

| Precision Bending | ±0.1° angular | 0.5mm – 12mm | N/A | DIN 6935 Class A |

| Welding (TIG/MIG) | ±0.2mm distortion | 1.0mm – 10mm | ≤6.3µm | AWS D1.1/D1.2 |

The true measure of precision lies not in isolated part metrics, but in system-level performance. Wuxi Lead’s engineering team collaborates from DFM through FAI to ensure every bend, hole, and edge contributes to the end application’s functional resilience. In sectors where failure is not an option, precision sheet metal fabrication is the silent guardian of operational excellence—a principle we’ve proven across Olympic infrastructure, defense systems, and advanced industrial machinery. Partner with us to transform tolerances from constraints into competitive advantage.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industrial applications. Our technical capabilities are built around a foundation of cutting-edge equipment, rigorous quality control, and deep engineering expertise. Central to our production capacity is our integration of 5-axis CNC machining technology, which enables complex geometries and tight-tolerance components that meet the demands of aerospace, medical, energy, and advanced automation industries.

The adoption of 5-axis CNC systems allows for simultaneous multi-directional machining, significantly reducing setup times and improving dimensional accuracy. Unlike conventional 3-axis systems, our 5-axis platforms provide two additional rotational axes, enabling tools to approach the workpiece from nearly any angle. This capability is especially critical in fabricating intricate sheet metal enclosures, brackets, housings, and structural components where angular features, compound curves, and deep cavities are common. By minimizing repositioning, we ensure consistency across high-mix, low-volume, and high-volume production runs.

All fabricated components undergo comprehensive quality validation through our Coordinate Measuring Machine (CMM) inspection system. This metrology-grade process verifies geometric dimensions, surface relationships, and positional tolerances with micron-level precision. Our CMM system is integrated into both pre-production sampling and full production cycles, ensuring every part conforms to engineering specifications. Real-time data reporting allows for immediate process correction, maintaining continuous compliance with ISO 9001 standards and customer-specific quality requirements.

Our facility supports a wide range of sheet metal materials, including stainless steel, aluminum alloys, carbon steel, and specialty alloys. With automated tooling, high-speed spindles, and adaptive control systems, we maintain efficiency without compromising precision. Secondary operations such as deburring, tapping, bending, and surface finishing are performed in-house, ensuring seamless workflow and faster turnaround.

The following table outlines our standard technical tolerances for sheet metal fabrication and 5-axis CNC machining:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.1 mm | ±0.05 mm |

| Hole Positioning | ±0.15 mm | ±0.08 mm |

| Angular Tolerance | ±0.2° | ±0.1° |

| Surface Flatness (per 100 mm) | 0.1 mm | 0.05 mm |

| Thread Accuracy | ISO 965 Class 6 | ISO 965 Class 4 |

| Feature-to-Feature (CMM-Verified) | ±0.12 mm | ±0.06 mm |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC fabrication with systematic quality assurance to deliver components that meet the most stringent engineering requirements. Our technical capabilities are designed to support innovation in complex sheet metal applications, ensuring reliability, repeatability, and precision across every production phase.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material choice fundamentally dictates performance, cost, and manufacturability in high-precision sheet metal applications. At Wuxi Lead Precision Machinery, we guide clients through this critical decision by aligning material properties with functional requirements, environmental exposure, and lifecycle costs. Aluminum alloys, particularly 6061-T6, dominate aerospace and electronics due to their exceptional strength-to-weight ratio, corrosion resistance, and weldability. This grade maintains dimensional stability during CNC punching and bending, minimizing springback errors. For structural components requiring higher tensile strength and impact resistance, cold-rolled carbon steel (CRCA) offers cost efficiency but mandates protective finishes like powder coating to prevent oxidation. Stainless steel 304 remains the benchmark for medical and food-grade applications, leveraging chromium content for inherent corrosion resistance without secondary treatments. Titanium Grade 2 emerges for extreme environments—such as marine or chemical processing—where its unparalleled strength, biocompatibility, and resistance to pitting corrosion justify premium costs. Its low thermal conductivity, however, demands specialized tooling and slower machining parameters to avoid work hardening.

Surface finishing transforms functional parts into engineered solutions. Anodizing is our recommended process for aluminum components requiring enhanced durability, electrical insulation, or aesthetic control. Type II (sulfuric acid) anodizing provides a versatile, decorative finish with dyeing capabilities for branding, while Type III (hardcoat) delivers 50-100µm wear-resistant layers essential for hydraulic manifolds or military hardware. Critical to success is strict bath chemistry control and voltage sequencing—parameters our ISO-certified facility monitors in real-time to ensure pore uniformity and adhesion. Unlike paint, anodizing integrates with the substrate, eliminating flaking risks in vibration-prone assemblies.

Material specifications directly impact fabrication yield. The following table outlines key properties influencing process selection:

| Material | Typical Thickness Range | Tensile Strength (MPa) | Key Fabrication Considerations | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 0.5–6.0 mm | 310 | Low springback; excellent for laser cutting | Enclosures, heat sinks |

| Stainless 304 | 0.8–8.0 mm | 515 | High work hardening; requires sharp tools | Medical devices, valves |

| CRCA | 0.6–10.0 mm | 340 | Prone to rust; needs immediate finishing | Brackets, chassis frames |

| Titanium Gr2 | 0.8–5.0 mm | 480 | Slow machining; inert gas shielding | Aerospace fittings, implants |

Selecting suboptimal materials incurs hidden costs through rework, accelerated wear, or premature failure. Wuxi Lead’s engineering team conducts material suitability assessments during the quoting phase, analyzing stress points, environmental exposure, and lifecycle demands. We validate selections via prototyping with your exact finish requirements—ensuring anodized layers meet ASTM B580 thickness tolerances or steel components pass salt-spray testing per ISO 9227. Partner with us to transform material science into manufacturing advantage: share your performance targets, and we’ll deliver a fabrication-ready solution balancing precision, longevity, and total cost.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the sheet metal fabrication process begins with a comprehensive design phase, where engineering excellence meets client-specific requirements. Our in-house design team collaborates closely with clients to translate conceptual ideas into technically feasible, manufacturable designs. Utilizing advanced CAD software such as SolidWorks, AutoCAD, and Siemens NX, we ensure every component is optimized for structural integrity, material efficiency, and ease of assembly. Design for Manufacturability (DFM) principles are rigorously applied to minimize production complexity and eliminate potential failure points before physical production begins. Finite Element Analysis (FEA) and thermal stress simulations are employed when necessary to validate performance under real-world conditions. This proactive engineering approach ensures that the foundation of every product is not only accurate but inherently robust.

Prototyping: Validating Performance and Fit

Following design finalization, we move into the prototyping stage—a critical checkpoint for quality assurance and functional validation. Wuxi Lead employs high-precision laser cutting, CNC punching, and bending technologies to fabricate prototypes that mirror final production quality. These prototypes are subjected to rigorous dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify tolerances within ±0.05 mm. Functional testing, including fit checks, weld integrity assessments, and surface finish evaluation, ensures compatibility with assembly lines and end-use environments. Clients receive detailed inspection reports and sample units for approval, enabling feedback integration before scaling to mass production. This iterative validation process is central to our zero-defect philosophy, effectively catching discrepancies at the earliest possible stage.

Mass Production: Consistency Through Automation and Control

With prototype approval, production transitions seamlessly into high-volume manufacturing. Wuxi Lead’s fully integrated production floor leverages automated material handling, robotic bending cells, and real-time monitoring systems to maintain consistency across thousands of units. Each stage—from blanking to forming, welding, and surface treatment—is governed by standardized work instructions and statistical process control (SPC) protocols. In-process inspections occur at critical control points, ensuring deviations are detected and corrected immediately. Our ISO 9001-certified quality management system underpins every operation, enforcing traceability, documentation, and continuous improvement.

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance Control | ±0.05 mm (cutting), ±0.1° (bending) |

| Maximum Part Size | 3000 mm × 1500 mm |

| Processing Speed | Up to 25 m/min (laser cutting) |

| Production Capacity | 500,000+ units/month |

| Quality Standard | ISO 9001:2015, ISO 14001, IATF 16949 (automotive) |

Through seamless integration of design intelligence, prototype validation, and disciplined mass production, Wuxi Lead delivers forest park sheet metal components with uncompromising quality—ensuring zero defects and total client confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Precision Sheet Metal Fabrication Authority

In the demanding landscape of high-integrity sheet metal fabrication, component precision directly impacts your product performance, assembly efficiency, and time-to-market. Generic suppliers cannot consistently deliver the micron-level accuracy required for aerospace assemblies, medical enclosures, or energy sector components. Wuxi Lead Precision Machinery operates at the intersection of advanced engineering and uncompromising quality control, transforming complex sheet metal designs into certified, production-ready parts. We understand that tolerances measured in hundredths of a millimeter are non-negotiable when failure is not an option. Our integrated facility in Wuxi, China, combines German-engineered machinery with ISO 9001-certified processes, ensuring every bend, cut, and weld meets your exact specifications—on schedule, every time.

Our technical capabilities are engineered for mission-critical applications. We specialize in low-volume, high-mix production where material integrity and geometric precision are paramount. Whether your project requires 0.5mm stainless steel medical housings or 6mm aluminum structural frames for renewable energy systems, our CNC-controlled processes eliminate variability. Key technical parameters underpinning our reliability include:

| Process | Material Thickness Range | Tolerance Capability | Max Sheet Size | Key Certifications |

|---|---|---|---|---|

| Fiber Laser Cutting | 0.5mm – 25mm | ±0.05mm | 3000 x 1500mm | ISO 9001, ISO 13849 |

| CNC Turret Punching | 0.8mm – 6.0mm | ±0.08mm | 2500 x 1250mm | CE, RoHS Compliance |

| Precision Bending | 0.5mm – 12mm | ±0.1° angular | 4000 x 2000mm | EN 1090, AS9100 Support |

| Robotic Welding | 0.8mm – 10mm | ±0.2mm positional | Custom Fixturing | AWS D1.1, ISO 3834 |

This technical foundation enables us to solve persistent industry challenges: minimizing secondary operations through nested laser cutting, eliminating springback in high-strength alloys via adaptive bending algorithms, and ensuring weld integrity through real-time monitoring. Our engineering team collaborates during your design phase to optimize manufacturability—reducing costs without sacrificing performance. Unlike volume-focused competitors, we prioritize traceability; every component receives full material certification and first-article inspection reports compliant with ASME Y14.5 standards.

The true measure of a fabrication partner lies in their responsiveness when your production line faces critical path delays. At Lead Precision, dedicated project managers provide 24-hour engineering feedback and real-time production dashboards. We maintain strategic raw material inventory for common aerospace-grade alloys (304/316L stainless, 5052/6061 aluminum) to accelerate turnaround. When your next-generation product demands flawless sheet metal execution, initiate a technical consultation. Email [email protected] with your CAD files and requirements. Our engineering team will respond within 8 business hours with a detailed manufacturability analysis and formal quotation—no generic templates, only actionable data. Trust Wuxi Lead Precision Machinery to become your silent partner in precision, where every micron delivered strengthens your competitive edge. Your assembly line won’t wait for rework; neither should you.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.