Technical Contents

Engineering Guide: Flexible Rubber Molding

Engineering Insight: The Critical Role of Precision in Flexible Rubber Molding

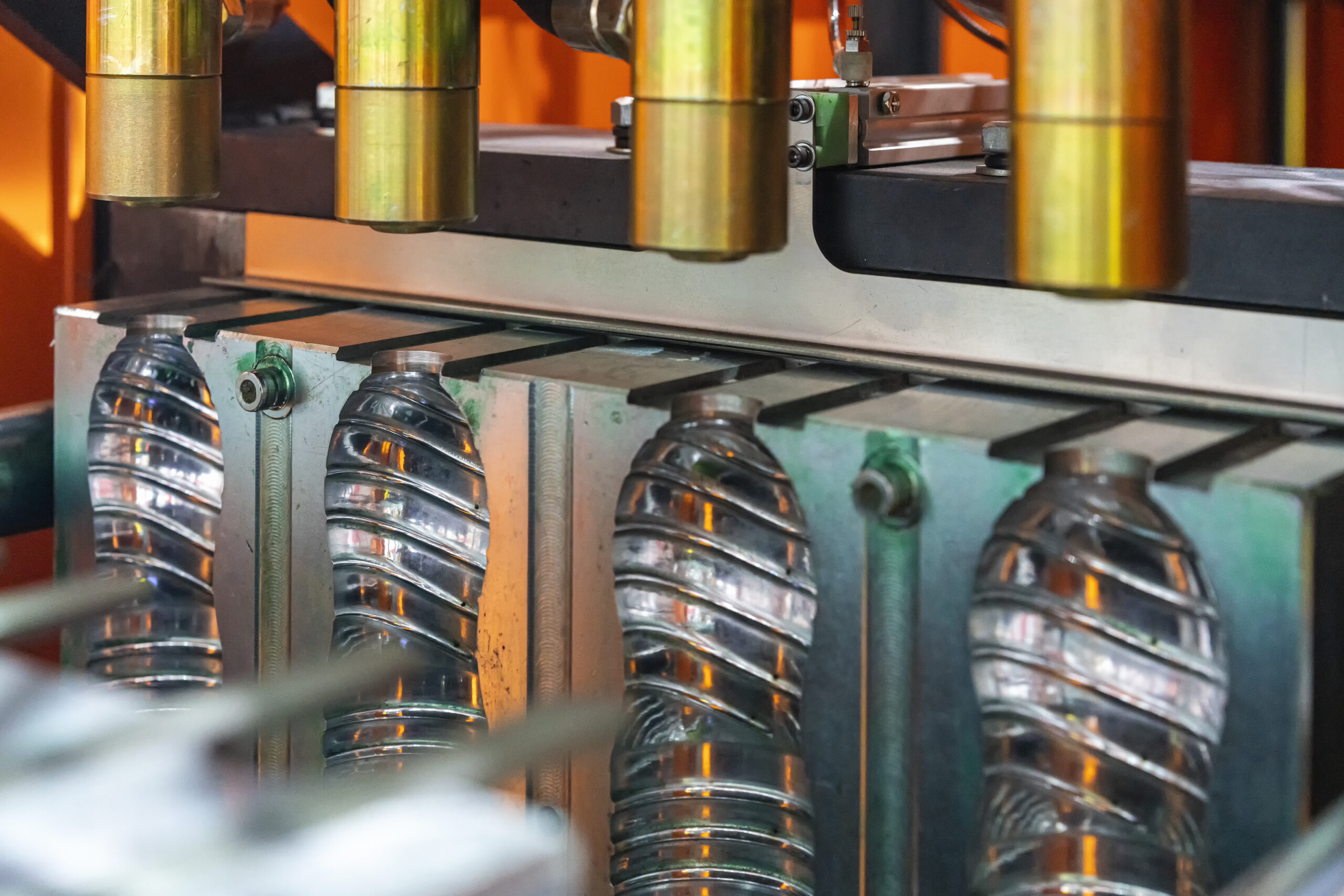

In the realm of custom metal manufacturing, flexible rubber molding stands as a pivotal process for producing high-performance components used across aerospace, defense, medical, and advanced industrial applications. While rubber is inherently pliable, the molding process demands exceptional precision to ensure dimensional accuracy, material integrity, and long-term reliability. At Wuxi Lead Precision Machinery, we understand that success in this domain is not defined by the elasticity of the material, but by the rigidity of engineering control throughout production.

Flexible rubber molding involves shaping elastomeric compounds into complex geometries under tightly regulated temperature, pressure, and time parameters. Even minor deviations in mold design, cavity tolerance, or curing conditions can result in part inconsistency, seal failure, or premature degradation. This is especially critical in mission-critical environments—such as military hardware or Olympic-grade sporting equipment—where component performance directly impacts safety, efficiency, and precision.

Our experience at Wuxi Lead spans over a decade of delivering precision-engineered solutions for high-stakes industries. We have supplied components used in Olympic athletic equipment, where millimeter-level tolerances influence competitive outcomes, and in military-grade systems, where environmental resilience and repeatability under extreme conditions are non-negotiable. These applications demand not only advanced tooling and process control but also a deep understanding of material behavior under dynamic stress.

At the core of our flexible rubber molding capability is a commitment to metrology-driven manufacturing. We utilize CNC-machined steel molds with tolerances held to ±0.005 mm, ensuring repeatable cavity geometry across production runs. Our in-house vulcanization monitoring systems track cure time and temperature in real time, preventing under- or over-curing that could compromise elastic properties. Every batch undergoes rigorous inspection using coordinate measuring machines (CMM) and optical profilometry to validate conformity to specification.

Material selection is equally critical. We work with a range of elastomers—including silicone, nitrile, EPDM, and fluorocarbon compounds—each chosen based on thermal stability, chemical resistance, and mechanical performance. Our engineering team collaborates directly with clients to match material characteristics with operational demands, ensuring optimal performance in the field.

The fusion of advanced tooling, process discipline, and material science defines modern flexible rubber molding. At Wuxi Lead Precision Machinery, we bring military-grade precision to every component, ensuring that flexibility never comes at the cost of accuracy.

| Specification | Detail |

|---|---|

| Material Options | Silicone, Nitrile (NBR), EPDM, Fluorocarbon (FKM), Neoprene |

| Mold Tolerance | ±0.005 mm |

| Vulcanization Control | Real-time temperature and time monitoring |

| Production Capacity | 500–10,000 units per batch |

| Inspection Tools | CMM, Optical Profilometer, Hardness Tester (Shore A/D) |

| Industry Applications | Aerospace, Defense, Medical Devices, High-Performance Sports Equipment |

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Tooling for Flexible Rubber Molding

Wuxi Lead Precision Machinery delivers mission-critical metal tooling solutions engineered specifically for high-integrity flexible rubber molding applications. Our expertise centers on producing complex, durable molds and components where dimensional stability, surface finish, and repeatability directly impact the performance of the final rubber product. We bridge the gap between demanding rubber material behavior and the uncompromising precision required in aerospace, medical, and automotive sealing systems.

Precision Machining Capabilities

Our core manufacturing platform integrates advanced 5-axis CNC machining centers, enabling the production of intricate mold cavities, cores, and inserts with geometric complexity unattainable through conventional methods. This technology allows for single-setup machining of compound angles, undercuts, and micro-features essential for sealing surfaces and part ejection in rubber molding. We utilize high-rigidity machines with sub-micron positional accuracy, coupled with optimized toolpath strategies that minimize thermal distortion and ensure consistent surface integrity across hardened tool steels (including H13, S7, and specialty alloys). Material removal rates are calibrated to preserve the metallurgical properties critical for mold longevity under high-temperature, high-pressure rubber vulcanization cycles.

Quality Assurance Protocol

Every component undergoes a rigorous, documented inspection regime anchored by Zeiss CONTURA CMM systems operating within an ISO 17025-accredited metrology lab. Full 3D scanning validates conformity to CAD models across all critical features, with emphasis on sealing lands, venting channels, and alignment surfaces where rubber flow and part integrity are most sensitive. Surface roughness is verified via profilometry to ensure optimal release characteristics and prevent rubber adhesion. Dimensional reports include GD&T analysis per ASME Y14.5, providing clients with actionable data on form, orientation, and location tolerances. Statistical process control (SPC) is implemented for high-volume runs, guaranteeing sustained capability.

Critical Tolerance Performance

The table below reflects our standard achievable tolerances for finished mold components under controlled production conditions. Actual performance may vary based on part geometry, material, and feature size, with tighter tolerances achievable upon engineering review.

| Feature Category | Capability | Typical Standard |

|---|---|---|

| Linear Dimensions | ±0.005 mm (0.0002″) | ±0.012 mm (0.0005″) |

| Angular Features | ±0.001° | ±0.005° |

| Surface Roughness (Ra) | 0.2 µm (8 µin) | 0.8 µm (32 µin) |

| Profile of Surface | 0.008 mm (0.0003″) | 0.025 mm (0.001″) |

| Positional Tolerance | 0.008 mm (0.0003″) | 0.025 mm (0.001″) |

Integrated Value Proposition

Wuxi Lead’s technical capabilities translate directly into reduced rubber part defects, extended mold service life, and accelerated time-to-market for our clients. By mastering the interplay between ultra-precise metal fabrication and the dynamic requirements of rubber molding processes, we ensure molds consistently produce parts meeting stringent functional specifications. Our engineering team collaborates early in the design phase to optimize mold geometry for manufacturability and performance, mitigating risks associated with rubber shrinkage, flash formation, and ejection forces. This holistic approach to precision metal manufacturing forms the foundation for reliable, high-yield rubber component production in the most demanding applications.

Material & Finish Options

Material Selection for Flexible Rubber Molding Components

In the realm of custom metal manufacturing for flexible rubber molding applications, material selection plays a decisive role in tool longevity, production efficiency, and part consistency. At Wuxi Lead Precision Machinery, we specialize in crafting high-precision molding tools and components from aluminum, steel, and titanium—each offering distinct advantages depending on the operational demands of the molding process. The choice of base material directly influences thermal conductivity, wear resistance, weight, and compatibility with secondary finishing processes such as anodizing.

Aluminum is widely favored for prototyping and low-to-medium volume production due to its excellent machinability and high thermal conductivity. These properties allow for faster cycle times and efficient heat dissipation during rubber curing. While not as wear-resistant as steel, modern high-strength aluminum alloys provide sufficient durability for many industrial molding applications. Additionally, aluminum is significantly lighter than steel or titanium, reducing overall tooling weight and easing handling during maintenance.

Steel, particularly tool steel grades such as H13 or P20, is the standard for high-volume rubber molding operations. Its superior hardness and resistance to deformation under repeated thermal cycling make it ideal for long production runs. Steel molds maintain dimensional stability over thousands of cycles, ensuring consistent part quality. However, steel’s lower thermal conductivity compared to aluminum may require additional cooling solutions to maintain cycle efficiency.

Titanium offers a unique combination of high strength-to-density ratio and excellent corrosion resistance, making it suitable for specialized molding environments involving aggressive chemicals or extreme conditions. While less common due to higher material and machining costs, titanium is selected when weight reduction and long-term durability in harsh environments are critical. Its biocompatibility also makes it a candidate for medical-grade rubber molding applications.

Surface finishing is equally important in optimizing mold performance. Anodizing, particularly hard anodizing, is a key post-processing treatment for aluminum components. This electrochemical process enhances surface hardness, improves wear and corrosion resistance, and provides electrical insulation. The resulting oxide layer can also be dyed for identification or aesthetic purposes. While anodizing is not applicable to steel or titanium in the same way, these materials can be treated with nitriding, chrome plating, or PVD coatings to achieve similar performance enhancements.

Below is a comparative overview of key material properties relevant to flexible rubber molding tooling.

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Anodizing Compatible | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum (6061) | 310 | 167 | 95 | Yes | Prototyping, low-volume production |

| Steel (H13) | 1,560 | 36 | 230 | No | High-volume, high-temperature molding |

| Titanium (Grade 5) | 900 | 7.2 | 330 | No | Corrosive environments, aerospace |

Selecting the optimal material and finish requires a thorough understanding of production volume, rubber compound type, cycle frequency, and environmental exposure. Wuxi Lead Precision Machinery supports clients in making informed decisions through engineering consultation and material performance analysis, ensuring each molding solution is tailored for maximum efficiency and reliability.

Manufacturing Process & QC

Flexible Rubber Molding: Precision Engineering from Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our flexible rubber molding process for custom metal components integrates advanced engineering with rigorous quality control, ensuring seamless transition from initial concept to flawless high-volume output. We eliminate defects at the source through a disciplined three-phase methodology, leveraging our expertise in metal tooling and material science to deliver components meeting the most stringent aerospace, medical, and industrial specifications. This systematic approach guarantees performance integrity and cost efficiency for your critical applications.

The Design phase establishes the foundation for zero defects. Our engineering team collaborates closely with clients using advanced CAD/CAM systems and finite element analysis (FEA) to optimize part geometry, gating, and material flow for rubber compounds like silicone, EPDM, or nitrile. Critical factors including thermal expansion coefficients, metal-rubber adhesion requirements, and post-mold assembly tolerances are meticulously modeled. This virtual validation identifies potential stress points, flash risks, or cure inconsistencies before tooling begins, significantly reducing downstream rework and ensuring the design is manufacturable to micron-level tolerances from day one. Material selection is rigorously matched to chemical resistance, temperature range, and mechanical duty cycles.

Prototyping utilizes production-intent CNC-machined aluminum tooling, not soft prototypes, enabling true process validation under actual production parameters. This phase is critical for verifying the design’s manufacturability and fine-tuning cure cycles, pressure profiles, and ejection sequences. Every prototype undergoes comprehensive dimensional inspection against the original CAD model and functional testing for sealing integrity, compression set, and adhesion strength. The data captured here directly informs the final mass production process window, ensuring scalability without compromise. Key validation metrics achieved during prototyping include:

| Parameter | Prototype Validation Target | Measurement Method |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | CMM Scanning |

| Durometer (Shore A) | ±3 points | ASTM D2240 |

| Adhesion Strength | >1.5 MPa (peel) | ASTM D429 Method B |

| Compression Set | <15% (70°C, 24h) | ASTM D395 Method B |

| Visual Defects | Zero flash/parting line | ISO 13091-1 |

Mass Production executes the perfected process within a controlled environment governed by statistical process control (SPC) and real-time monitoring. Our automated presses feature closed-loop feedback systems tracking temperature, pressure, and cure time for every cycle, with automatic rejection of any out-of-spec shot. In-process inspections occur at defined intervals using calibrated gauges and vision systems, while final lot acceptance requires full dimensional reports and material certification traceable to raw compound batches. This relentless focus on process stability, combined with operator training emphasizing a zero-defect culture, ensures consistent delivery of rubber-molded metal components where failure is not an option. Every shipment from Wuxi Lead represents the culmination of precision engineering validated through prototyping and sustained by disciplined production control.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Flexible Rubber Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance custom metal manufacturing solutions tailored to the evolving demands of modern industry. Our expertise extends into the precise integration of flexible rubber molding with precision-engineered metal components, offering clients a seamless fusion of durability, elasticity, and dimensional accuracy. As global manufacturing grows more complex, the need for reliable, high-tolerance hybrid parts has never been greater. Lead Precision stands at the forefront of this innovation, combining advanced CNC machining, die casting, and rubber overmolding technologies to deliver components that meet the most stringent application requirements.

Our engineering team works closely with clients across automotive, medical, aerospace, and industrial equipment sectors to develop custom solutions that balance material performance with production efficiency. Whether you require rubber seals with metal inserts, vibration-damping assemblies, or fluid-handling components with integrated metal frameworks, our process ensures consistent quality, long service life, and optimal functionality under demanding conditions. We utilize silicone, EPDM, NBR, and other high-grade elastomers, bonded to aluminum, stainless steel, and other engineered metals using state-of-the-art injection and compression molding techniques.

What sets Lead Precision apart is our commitment to precision and partnership. We don’t just manufacture parts—we engineer performance. From initial design consultation and material selection to prototyping, tooling, and high-volume production, we provide full-cycle support backed by ISO 9001-certified quality systems. Our in-house tooling department ensures rapid turnaround, while our metrology lab guarantees that every part meets exact specifications.

Below are key technical capabilities that define our flexible rubber molding services:

| Specification | Detail |

|---|---|

| Rubber Materials | Silicone, EPDM, NBR, FKM, Neoprene, Natural Rubber |

| Metal Substrates | Aluminum Alloys, Stainless Steel, Carbon Steel, Brass |

| Molding Processes | Injection Molding, Compression Molding, Transfer Molding |

| Tolerance Range | ±0.05 mm to ±0.15 mm (depending on part size and geometry) |

| Part Size Range | 10 mm to 300 mm in maximum dimension |

| Bonding Strength | Up to 8 MPa (tested per ASTM D429) |

| Production Capacity | 1,000 to 500,000 units per month |

| Secondary Operations | CNC Finishing, Cleaning, Assembly, Packaging |

| Quality Standards | ISO 9001:2015, RoHS, REACH compliance available |

We invite engineering teams, procurement managers, and product developers to contact us directly at [email protected]. Let our experts help you overcome design challenges, reduce assembly costs, and improve product reliability through integrated flexible rubber molding solutions. At Wuxi Lead Precision Machinery, we don’t just meet specifications—we build partnerships that drive manufacturing excellence. Reach out today to start your next project with a trusted leader in precision hybrid component manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.