Technical Contents

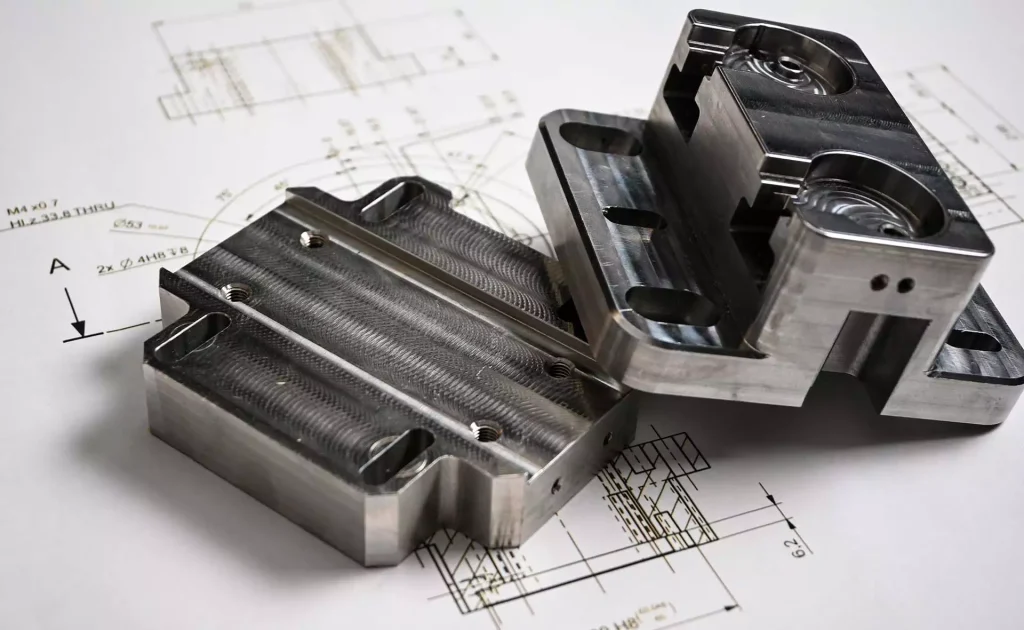

Engineering Guide: Flash Parts

Engineering Insight: The Critical Role of Precision in Flash Part Manufacturing

In the realm of high-performance metal manufacturing, flash parts represent a unique intersection of engineering complexity and functional necessity. These components, typically formed during forging or molding processes, require meticulous post-processing to achieve final dimensional accuracy and surface integrity. At Wuxi Lead Precision Machinery, we recognize that the removal and control of flash are not merely finishing steps—they are precision-critical operations that define the reliability, safety, and performance of the end product.

Flash formation is an inherent byproduct of high-pressure metal forming, where molten or semi-solid material escapes the die cavity. While unavoidable in certain processes, uncontrolled flash compromises part geometry, weakens structural integrity, and introduces variability in downstream assembly. The challenge lies not in its existence, but in its consistent and precise elimination. This demands advanced CNC machining capabilities, adaptive tooling strategies, and a deep understanding of material behavior under stress.

At Wuxi Lead, our approach to flash part processing is rooted in over a decade of experience serving mission-critical industries. Our work with aerospace, defense, and Olympic-grade equipment manufacturers has honed our ability to manage tolerances at micron-level precision. For instance, components used in military-grade actuators or high-altitude sensor housings require flash removal without inducing micro-cracks or residual stress. Our multi-axis CNC systems, combined with in-process metrology, ensure that each operation is both repeatable and traceable.

Precision in flash management also extends to material conservation and sustainability. Excessive machining to remove flash increases cycle time, tool wear, and material waste—factors that directly impact production costs and environmental footprint. By optimizing die design and leveraging predictive simulation software, we minimize flash volume at the source, reducing the burden on secondary operations while maintaining conformity to ISO and MIL-STD specifications.

Our facility in Wuxi is equipped with high-speed machining centers, robotic deburring systems, and laser scanning for real-time quality verification. These technologies enable us to process flash-sensitive components in titanium, Inconel, and high-strength aluminum alloys—materials where precision is non-negotiable.

The following table outlines key technical specifications we maintain for flash part processing:

| Parameter | Standard Capability | High-Precision Option | Material Compatibility |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm | ±0.005 mm | Titanium, Aluminum, Inconel, Steel |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | All aerospace-grade alloys |

| Flash Removal Accuracy | ±0.03 mm | ±0.01 mm | Forged, Die-cast, Stamped parts |

| Maximum Part Size | 1200 x 800 x 600 mm | 800 x 500 x 400 mm | Custom fixturing available |

| Process Turnaround | 7–10 days | 3–5 days (express) | With full inspection report |

Our work on Olympic timing systems and military communication enclosures exemplifies the standard we uphold—where every micron removed is accounted for, and every edge meets functional perfection. In flash part manufacturing, precision is not an option. It is the foundation.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

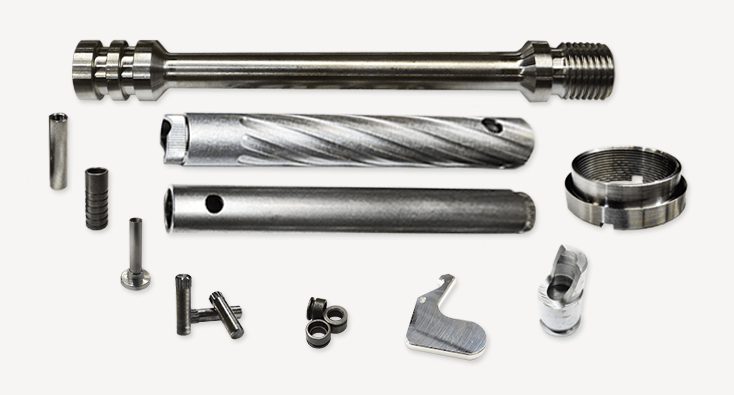

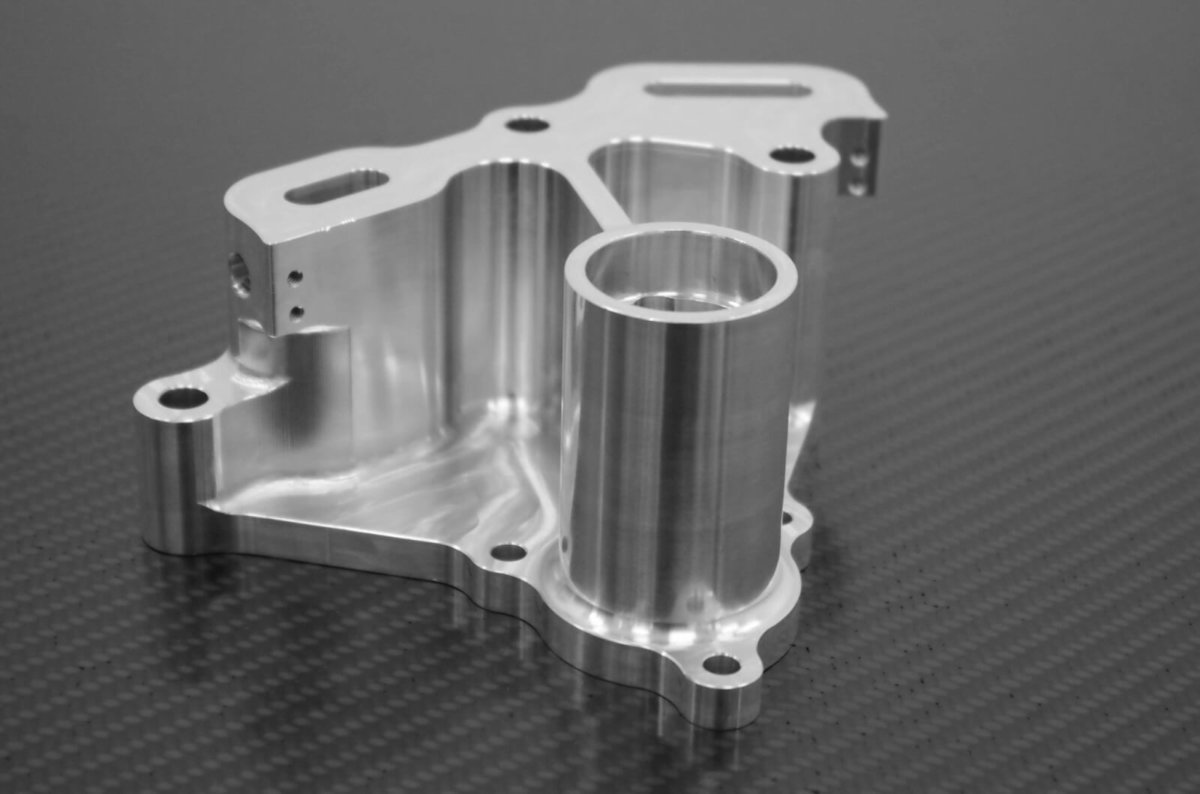

At Wuxi Lead Precision Machinery, our technical foundation is built upon advanced 5-axis CNC machining centers, enabling the production of complex geometries with uncompromising accuracy for critical flash parts. We deploy state-of-the-art DMG MORI and MAZAK multi-axis systems, featuring simultaneous 5-axis interpolation, high-speed spindles (up to 24,000 RPM), and integrated probing. This infrastructure eliminates secondary operations, minimizes part handling errors, and ensures geometric integrity across intricate contours, deep cavities, and undercuts common in aerospace, medical, and energy sector components. Our facility processes a wide spectrum of engineering alloys, including aerospace-grade aluminum (7075-T6, 2024), titanium (Ti-6Al-4V), stainless steels (17-4 PH, 316L), and high-temperature superalloys (Inconel 718), with strict material traceability from certified suppliers.

Rigorous quality control is non-negotiable. Every flash part undergoes comprehensive dimensional validation using Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMMs), programmed to ISO 10360 standards. Our inspection protocol includes first-article reporting (FAI), in-process checks, and final batch verification, with full GD&T analysis against client CAD models. Statistical process control (SPC) data is maintained for all critical features, ensuring repeatability and enabling proactive process adjustments. This closed-loop system guarantees conformance to even the most stringent industry specifications, such as AS9100 for aerospace or ISO 13485 for medical devices.

Tolerance achievement is central to our value proposition. The table below details our standard and precision capability ranges, reflecting real-world production performance under controlled environmental conditions (20±1°C). These values are validated across our entire material portfolio and part envelope (up to Ø600 x 500mm).

| Feature Type | Standard Capability | Precision Capability | Key Influencing Factors |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Material stability, part complexity |

| Angular Tolerances | ±0.05° | ±0.01° | Fixture rigidity, machine calibration |

| Positional Accuracy | ±0.020 mm | ±0.008 mm | Probe compensation, thermal management |

| Surface Finish (Ra) | 0.8 μm | 0.2 μm | Toolpath strategy, tool selection |

| Geometric Deviation (Flatness) | 0.03 mm/m² | 0.005 mm/m² | Stress relief, clamping methodology |

Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance allocation. This proactive approach mitigates production risks, reduces lead times, and eliminates costly iterations. By integrating cutting-edge 5-axis technology with metrology-grade verification, Wuxi Lead delivers flash parts that meet the exacting demands of high-reliability industries. We transform complex designs into mission-critical components with documented precision, ensuring your supply chain operates with zero compromise on quality or performance. Trust our capabilities to elevate your most challenging metal fabrication requirements.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing part performance, durability, and cost. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components for high-demand industries such as aerospace, automotive, and medical devices. Our expertise enables clients to make informed decisions when selecting between aluminum, steel, and titanium—three of the most widely used materials in advanced manufacturing. Each material offers distinct mechanical properties, weight characteristics, and environmental resistance, making them suitable for specific applications.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight components without sacrificing structural integrity. 6061-T6 and 7075-T6 are among the most commonly used aluminum alloys in precision machining, with the latter offering higher strength for aerospace-grade requirements. Aluminum is particularly well-suited for parts exposed to outdoor environments due to its natural oxide layer, which inhibits degradation.

Steel, particularly in its stainless and alloy forms, provides superior strength, hardness, and wear resistance. 304 and 316 stainless steels are widely used for their excellent corrosion resistance and suitability in sterile or high-moisture environments, making them ideal for medical and food processing applications. For high-stress mechanical components, alloy steels such as 4140 and 4340 offer enhanced toughness and fatigue resistance. While heavier than aluminum, steel’s durability ensures long service life under demanding operational conditions.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the premium choice for applications where extreme strength, low density, and exceptional corrosion resistance are paramount. It performs reliably in high-temperature and highly corrosive environments, making it indispensable in aerospace, defense, and marine engineering. Though more challenging and costly to machine, titanium’s performance justifies its use in mission-critical components.

Surface finishing further enhances material performance. Anodizing is a key process for aluminum, providing increased surface hardness, wear resistance, and aesthetic control. Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat anodizing) delivers superior thickness and durability for industrial applications. Anodized layers are electrically insulating and can be dyed in various colors for identification or branding.

Below is a comparative overview of key material specifications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Enclosures, brackets | Anodizing, bead blasting |

| Stainless 316 | 8.0 | 580 | Very High | Medical devices, marine parts | Passivation, polishing |

| Steel 4140 | 7.85 | 655 | Moderate | Shafts, gears | Zinc plating, powder coating |

| Titanium Ti-6Al-4V | 4.42 | 950 | Excellent | Aerospace, defense | Anodizing, laser marking |

Selecting the right material and finish ensures optimal performance, longevity, and cost-efficiency. Wuxi Lead Precision Machinery provides expert consultation to match your design requirements with the most suitable material and surface treatment options.

Manufacturing Process & QC

Precision Execution: From Design to Zero-Defect Mass Production for Mission-Critical Flash Parts

At Wuxi Lead Precision Machinery, the production of high-integrity flash parts—components where microscopic deviations trigger catastrophic system failure—demands an uncompromising, closed-loop process. We eliminate defects at origin, not through final inspection. Our integrated workflow ensures dimensional and material perfection from initial concept to full-scale delivery, critical for aerospace actuators, semiconductor lithography components, and medical implant interfaces.

The foundation is collaborative Design for Manufacturability (DFM). Our engineering team partners with clients during the conceptual phase, utilizing advanced GD&T analysis and finite element simulation. We rigorously assess material selection, geometric complexity, and tolerance stack-ups against our machine capabilities and process physics. This proactive engagement prevents inherent design flaws, ensuring the blueprint is manufacturable to zero-defect standards before metal is cut. Misalignment between design intent and production reality is the primary source of downstream failures; our DFM gate eliminates this risk.

Prototyping transitions theory into validated practice under production-equivalent conditions. We utilize the same multi-axis CNC machining centers, metrology equipment, and material lots intended for volume production. Each prototype undergoes full first-article inspection (FAI) per AS9102 or client-specific standards, with CMM data mapped directly to the 3D CAD model. This phase isn’t merely functional validation; it’s process qualification. We refine cutting strategies, fixture designs, and in-process gaging protocols, establishing the exact parameters that guarantee repeatability. Our rapid iteration capability delivers qualified prototypes within 72 hours, compressing development cycles without sacrificing rigor.

Mass production executes the proven process with embedded quality control. Every component is manufactured under strictly controlled environmental conditions with real-time SPC monitoring of critical dimensions. Our cell-based production employs poka-yoke fixtures and automated in-machine probing, measuring features during machining to instantly correct drift. 100% of critical features undergo post-process verification using calibrated CMMs and optical comparators, with data fed into our central quality database for trend analysis. Zero defects are achieved by preventing variation at the source, not by sorting it out later. Statistical process capability (Cp/Cpk > 2.0) is continuously maintained, not merely targeted.

The table below defines the measurable precision envelope we consistently deliver for flash part production:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.0001″ (2.5 µm) | ASME Y14.5-2018 |

| Surface Roughness (Ra) | 0.8 µin (0.02 µm) | ISO 4287 |

| Geometric Tolerance | ±0.00004″ (1 µm) positional | ISO 1101 |

| Material Integrity | Zero inclusions/porosity per AMS 2644 | ASTM E3023 |

| Process Capability | Cp ≥ 1.67, Cpk ≥ 1.33 | ISO 22514-3 |

This disciplined progression—rigorous DFM, production-identical prototyping, and statistically controlled mass production—forms our Zero Defects guarantee. We transform exacting flash part requirements into flawless physical reality, ensuring your mission-critical systems perform with absolute reliability. Partner with Wuxi Lead for manufacturing where perfection is the only acceptable outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that in high-performance industries, every component must meet exacting standards. Whether you’re in aerospace, medical device manufacturing, automation, or advanced robotics, the integrity, precision, and repeatability of your metal parts directly impact your product’s success. That’s why forward-thinking engineering teams choose Lead Precision as their trusted manufacturing partner. We don’t just produce parts—we deliver precision-engineered solutions that align with your technical demands, timelines, and quality expectations.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, multi-axis turning systems, and advanced inspection technologies. With over 15 years of experience in custom metal manufacturing, we specialize in low-to-medium volume production runs where complexity, tight tolerances, and material integrity are non-negotiable. From prototype development to full-scale batch production, our team ensures every flash part is machined to specification, inspected to international standards, and delivered on schedule.

We work with a broad range of materials, including aerospace-grade aluminum, stainless steel, titanium, brass, and specialty alloys. Our processes are supported by ISO 9001-certified quality management systems, in-process inspections, and final QA checks using coordinate measuring machines (CMM) and optical comparators. This ensures every component meets or exceeds your dimensional, surface finish, and mechanical property requirements.

What sets us apart is our engineering-first approach. We don’t just interpret drawings—we collaborate. Our technical team engages early in the design-for-manufacturability (DFM) phase, offering actionable feedback to optimize part geometry, reduce machining time, and lower overall costs—without sacrificing performance.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Processes | 3- to 5-axis CNC milling, CNC turning, multi-tasking machining |

| Tolerances | ±0.005 mm (±0.0002″) standard; tighter upon request |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 5), Brass, Inconel, PEEK |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finishes | As-machined, anodizing (Type II & III), passivation, powder coating, polishing |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP documentation |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Partnering with Lead Precision means gaining a responsive, technically proficient ally who treats your project as mission-critical. We support global clients with English-speaking engineering coordination, real-time production updates, and reliable logistics via air or sea freight with full customs documentation.

Your next high-precision metal component deserves more than a vendor—it deserves a partner. Contact us today at [email protected] to discuss your requirements, request a quote, or receive a DFM analysis. Let’s build precision, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.