Technical Contents

Engineering Guide: Fireproof Sheet Metal

Engineering Insight: Precision as the Foundation of Fireproof Sheet Metal Performance

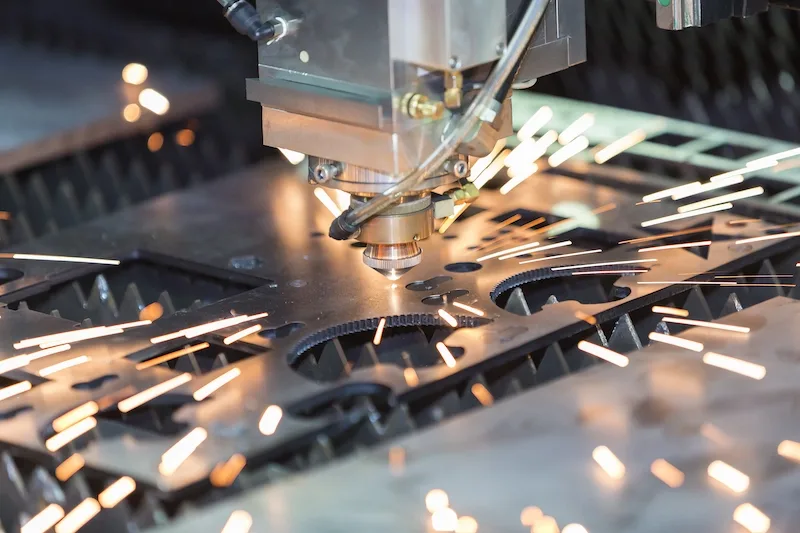

In fireproof sheet metal fabrication, dimensional precision is not merely a quality metric—it is a non-negotiable safety imperative. Sub-millimeter deviations in cut edges, bend angles, or seam alignment can compromise structural integrity during extreme thermal exposure, creating pathways for flame propagation or toxic gas infiltration. Fire-rated assemblies demand absolute consistency in material thickness, joint tightness, and geometric stability to maintain compartmentalization under ASTM E119 or EN 1364-1 fire endurance tests. At Wuxi Lead Precision Machinery, we treat tolerances as critical safety parameters, not production variables. Our CNC-controlled laser cutting and press brake systems enforce 0.05mm positional accuracy and ±0.2° angular repeatability, ensuring every panel, duct, or enclosure meets the exact thermal expansion coefficients and load-bearing requirements of fire-rated designs.

This rigor stems from direct experience in mission-critical applications. Our engineering team has delivered fireproof structural components for Beijing Winter Olympic venue ventilation systems and armored vehicle compartments meeting MIL-STD-810H specifications. These projects demanded zero-defect fabrication under third-party witnessed testing—where a single misaligned weld seam could invalidate an entire fire rating. We translate this discipline into every client project through material traceability protocols, in-process thermal distortion compensation algorithms, and post-fabrication flatness validation. Precision here prevents catastrophic failure modes: warped panels creating gaps in fire barriers, or stressed joints fracturing under rapid temperature gradients.

Material selection and processing must align with fire performance classifications. Below are key specifications our CNC workflows consistently achieve for fireproof sheet metal assemblies:

| Parameter | Standard Requirement | Wuxi Lead Precision Capability | Verification Method |

|---|---|---|---|

| Material Thickness Tolerance | ±0.08mm (EN 10029) | ±0.05mm | Laser micrometer scanning |

| Panel Flatness (per m²) | ≤1.5mm | ≤0.1mm | CMM metrology mapping |

| Bend Angle Tolerance | ±0.5° | ±0.2° | Optical angle sensors |

| Seam Gap Tolerance | ≤0.3mm | ≤0.1mm | Go/no-go gauging |

| Fire Rating Compliance | EN 13501-1 Class A1 | Validated to Class A1+A2 | Third-party furnace testing |

Our approach integrates material science with sub-50-micron machining control. For example, galvanized steel substrates require compensating for zinc layer vaporization during laser cutting—a variable we model using real-time spectrometer feedback to maintain edge quality for subsequent intumescent coating adhesion. Similarly, stainless steel fire barriers undergo stress-relief annealing within our CNC bending cells to eliminate micro-crack risks from cold working. This level of process ownership ensures fireproof assemblies perform identically in laboratory tests and real-world emergencies.

When lives and assets depend on fire containment, precision engineering is the only acceptable standard. Wuxi Lead Precision Machinery applies Olympic-grade manufacturing discipline to industrial fireproofing—transforming sheet metal into reliable passive fire protection. Contact our engineering team to discuss tolerance-critical fireproof fabrication for your next project.

Precision Specs & Tolerances

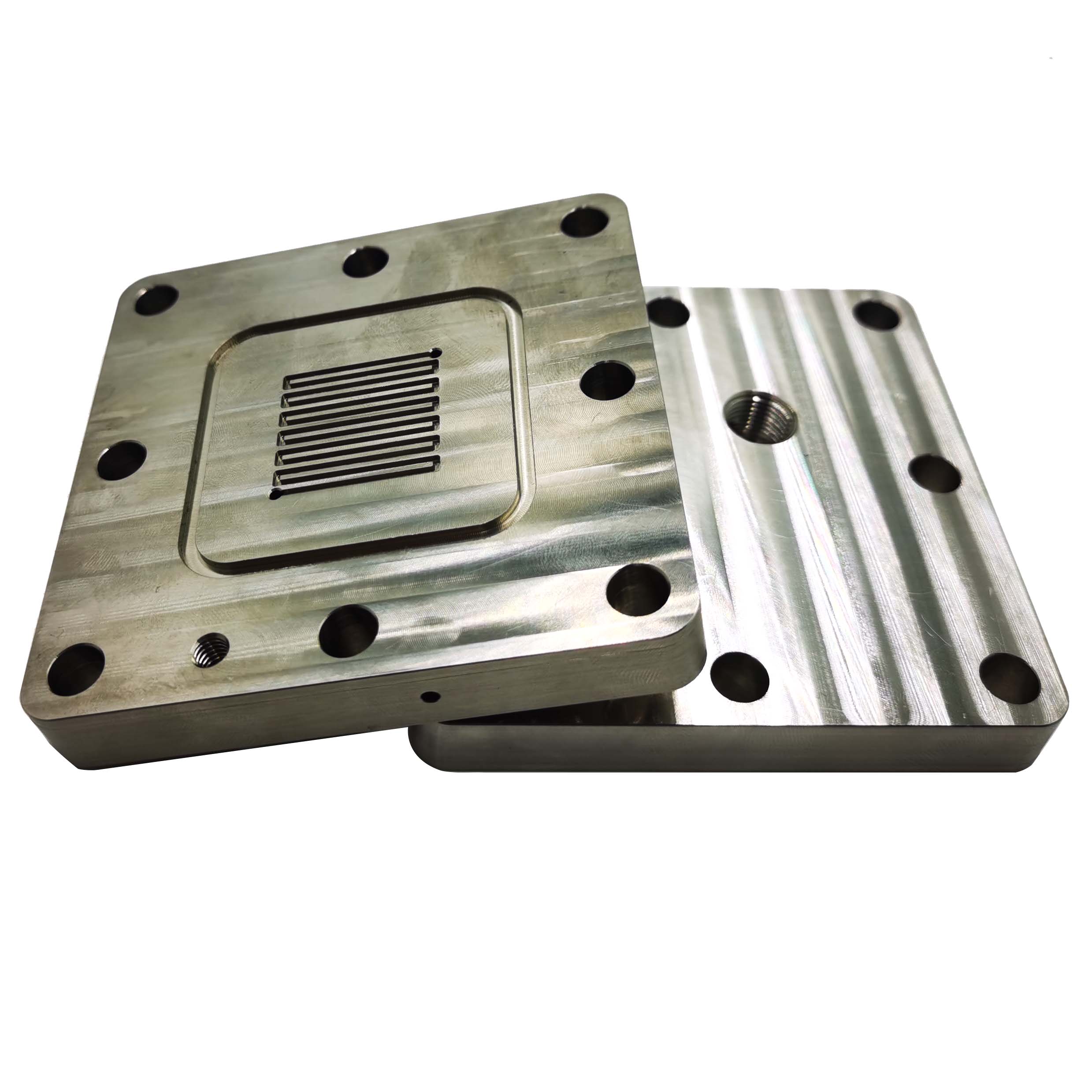

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-performance industrial applications, including fireproof and fire-resistant metal systems. Our technical capabilities are engineered to meet stringent safety, durability, and precision requirements essential in sectors such as construction, transportation, energy, and industrial equipment. Central to our manufacturing excellence is our integration of 5-axis CNC machining technology, which enables complex geometries, tight tolerances, and seamless multi-plane processing—all critical when fabricating fire-rated enclosures, protective housings, and structural fire barriers.

Our 5-axis CNC platforms provide simultaneous movement across five axes, allowing for intricate cutting, bending, and milling operations in a single setup. This reduces cumulative error, improves surface finish, and enhances dimensional consistency—particularly vital when working with layered or composite fireproof sheet metal assemblies. These systems support a wide range of materials, including galvanized steel, stainless steel, aluminum, and specialty alloys designed for high-temperature resistance. With automated tool changers and high-speed spindles, our CNC centers ensure rapid turnaround without compromising accuracy.

Quality control is embedded at every stage of production. All fireproof sheet metal components undergo rigorous inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. The CMM system captures thousands of data points across complex surfaces, verifying form, position, and dimensional accuracy to within microns. This metrology-grade validation is essential for components used in fire safety systems, where fit, alignment, and structural integrity directly impact performance under extreme conditions.

We maintain full traceability through digital quality records, including first-article inspection reports, process capability studies, and final inspection certifications. Our quality management system is ISO 9001 certified, ensuring consistent adherence to process controls and continuous improvement.

The following table outlines the standard technical tolerances achievable across our sheet metal fabrication processes for fireproof and high-integrity applications.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.1 mm | ±0.05 mm | Up to 2000 mm length |

| Hole Position | ±0.1 mm | ±0.05 mm | Relative to datum |

| Angular Tolerance | ±0.2° | ±0.1° | For bent and formed features |

| Surface Flatness | 0.15 mm/m² | 0.08 mm/m² | For post-formed panels |

| Feature Repeatability (Cp/Cpk) | ≥1.33 | ≥1.67 | Statistical process control applied |

| Wall Thickness Variation | ±0.08 mm | ±0.05 mm | For machined and formed zones |

Our technical infrastructure ensures that fireproof sheet metal components not only meet design intent but also perform reliably under thermal stress and mechanical load. By combining 5-axis precision, advanced materials processing, and metrology-backed quality assurance, Wuxi Lead Precision Machinery sets the benchmark in high-end sheet metal fabrication for mission-critical applications.

Material & Finish Options

Material Science for Fire-Resistant Sheet Metal Fabrication

Selecting appropriate sheet metal for fire-resistant applications requires precise understanding of material behavior under extreme thermal stress. True “fireproof” metals do not exist; however, specific alloys offer critical resistance through high melting points, slow oxidation kinetics, and structural integrity retention. At Wuxi Lead Precision Machinery, we prioritize materials meeting stringent ASTM E119 and UL 263 fire endurance standards for structural safety. Aluminum alloys like 6061-T6 provide lightweight solutions but possess a relatively low melting point. Under intense fire conditions, aluminum rapidly loses strength and melts, limiting its use to non-structural components where fire exposure is brief or secondary. Its primary value lies in weight-sensitive applications outside core fire barriers.

Carbon steel, particularly ASTM A36 and higher-grade structural steels, remains the industry benchmark for fire-resistant construction. These materials maintain load-bearing capacity significantly longer than aluminum due to higher melting points and predictable oxidation. Properly protected structural steel assemblies can achieve 1-4 hour fire resistance ratings essential for building columns, beams, and critical enclosures. The key lies in understanding that fire resistance depends not solely on the base metal but also on protective coatings and design geometry. Titanium alloys, such as Grade 2, offer exceptional performance with very high melting points and outstanding oxidation resistance at elevated temperatures. While cost-prohibitive for most large-scale applications, titanium is indispensable in aerospace and specialized defense components where extreme fire exposure is anticipated and weight savings are paramount.

Surface finishes like anodizing serve decorative and corrosion-resistant purposes for aluminum but provide negligible fire resistance benefit. The anodized layer itself burns off rapidly in a fire, leaving the underlying aluminum vulnerable. Fire performance is fundamentally governed by the base metal’s thermal properties and the overall system design, not surface treatments. Specifying the correct base material is therefore the foundational engineering decision.

The following table summarizes critical fire-related properties for common sheet metal fabrication materials:

| Material | Typical Melting Point (°C) | Fire Resistance Rating Capability (Minutes) | Primary Fire-Resistant Applications |

|---|---|---|---|

| Aluminum 6061-T6 | 582 | 0-30 | Non-structural panels, secondary enclosures (limited) |

| Carbon Steel A36 | 1425 | 60-240+ | Structural beams, columns, fire-rated partitions |

| Titanium Grade 2 | 1668 | 120+ | Aerospace components, critical defense systems |

Material selection directly dictates achievable fire performance and must align with project-specific safety codes and load requirements. At Wuxi Lead, our CNC fabrication expertise ensures precise forming and assembly of these materials into components that meet exacting fire safety specifications. We collaborate closely with engineering teams to translate material properties into reliable, code-compliant solutions, leveraging advanced machining to maintain critical tolerances even in demanding fire-resistant designs. The optimal choice balances performance, cost, and manufacturability for your specific safety mandate.

Manufacturing Process & QC

Design Phase: Precision Engineering for Fireproof Performance

At Wuxi Lead Precision Machinery, the production of fireproof sheet metal components begins with a rigorously structured design phase. This stage integrates material science, thermal dynamics, and structural integrity to ensure compliance with international fire resistance standards such as UL, EN 1364, and GB 50016. Our engineering team utilizes advanced CAD software—SolidWorks and AutoCAD—to develop 3D models that incorporate precise geometries, thermal expansion allowances, and fire barrier integration points. Finite Element Analysis (FEA) is applied to simulate high-temperature exposure, validating that the design maintains structural stability for a minimum of 60 to 180 minutes under standard fire curves. Material selection is critical; we primarily use galvanized steel, stainless steel (304/316), and aluminum alloys with intumescent coatings or mineral wool insulation layers, depending on the application. All designs undergo cross-functional review involving R&D, quality assurance, and client engineering teams to ensure manufacturability and performance compliance.

Prototyping: Validating Performance Before Scale

Following design approval, a functional prototype is produced under controlled workshop conditions. The prototyping phase serves as a critical validation step, combining CNC laser cutting, precision bending via hydraulic press brakes (accuracy ±0.1°), and automated MIG/TIG welding. Each prototype is subjected to a comprehensive test regimen, including dimensional inspection using coordinate measuring machines (CMM), weld integrity testing via ultrasonic scanning, and small-scale fire resistance trials in our certified thermal testing chamber. These trials replicate ISO 834 or ASTM E119 fire curves to verify insulation performance, integrity, and load-bearing capability. Any deviations are documented through our Non-Conformance Report (NCR) system, triggering immediate design or process adjustments. Client feedback is integrated at this stage, ensuring alignment with operational and installation requirements before transitioning to mass production.

Mass Production: Zero-Defect Manufacturing Execution

With prototype validation complete, production shifts to our automated manufacturing line, engineered for zero-defect output. The process leverages Industry 4.0 principles, including real-time machine monitoring, automated material handling, and in-process quality checks at every station. Laser cutting accuracy is maintained within ±0.05 mm, while robotic bending cells ensure angular consistency. All welds are executed by certified operators or automated systems, followed by 100% visual and spot NDT inspection. Final assemblies undergo full-scale fire testing in accordance with project-specific certification requirements. Each batch is traceable via a digital production log, recording material lot numbers, machine parameters, and inspector IDs. Our ISO 9001 and IATF 16949-certified quality management system enforces strict adherence to tolerances and performance benchmarks.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.1° |

| Welding Standards | ISO 5817 (B Grade) |

| Fire Resistance Duration | 60 – 180 minutes |

| Surface Treatment | Intumescent coating, powder coating, or galvanization |

| Quality Certification | ISO 9001, IATF 16949, UL Listed (upon request) |

Through this disciplined progression from design to prototyping to mass production, Wuxi Lead ensures every fireproof sheet metal component meets the highest standards of safety, durability, and precision.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Fireproof Sheet Metal Solutions

In high-stakes industrial applications where fire integrity determines safety and compliance, precision fabrication is non-negotiable. Wuxi Lead Precision Machinery delivers engineered fireproof sheet metal components that exceed global safety standards, leveraging 15 years of specialized CNC expertise. Our ISO 9001-certified facility in Wuxi integrates advanced laser cutting, robotic welding, and precision bending to transform fire-resistant alloys into components that perform under extreme thermal stress. We understand that tolerances of ±0.05mm or material inconsistencies can compromise fire barriers—this is why every part undergoes rigorous in-process validation, including ASTM E136 combustion testing and dimensional audits traceable to NIST standards.

Our technical capabilities are built for the demands of aerospace, marine safety systems, and critical infrastructure projects. Below are core specifications we consistently achieve for fireproof sheet metal fabrication:

| Specification Category | Performance Standard |

|---|---|

| Material Grades | ASTM A666 Type 304/316, EN 1.4404, Corten A (fire-retardant coatings) |

| Thickness Range | 0.5 mm – 6.0 mm |

| Dimensional Tolerance | ±0.05 mm (laser-cut), ±0.1° (bent angles) |

| Fire Resistance Rating | Up to 120 minutes (ISO 834-1 certified assemblies) |

| Surface Treatment | Intumescent coatings, ceramic silicate finishes |

Partnering with Lead Precision means eliminating supply chain vulnerabilities in fire-critical projects. We collaborate from design validation through to serial production, providing DFM feedback that reduces material waste by 18–22% while ensuring compliance with NFPA 285, UL 263, and local fire codes. Our engineering team conducts thermal deformation simulations pre-production, preventing field failures in smoke control ducts, fire-rated partitions, and emergency shelter components. Unlike generic fabricators, we prioritize material grain orientation and weld penetration depth to maintain structural integrity at 1,000°C+ exposure—a detail that defines life-saving performance.

When fireproofing is your priority, settle for nothing less than engineered certainty. Contact our technical sales team to submit your project specifications or request a material compliance dossier. We respond to all inquiries within 4 business hours with actionable feasibility analysis—not generic quotations. For immediate assistance with fire-resistant sheet metal fabrication, email [email protected]. Include your required certifications, volume, and thermal performance targets to accelerate your quotation. Let Wuxi Lead Precision Machinery become your certified partner in building safer infrastructure, one precision component at a time.

[email protected]

Wuxi Lead Precision Machinery: Precision Engineered for Fire Safety

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.