Technical Contents

Engineering Guide: Fine Precision Cnc Machining

Engineering Insight: The Non-Negotiable Imperative of Fine Precision CNC Machining

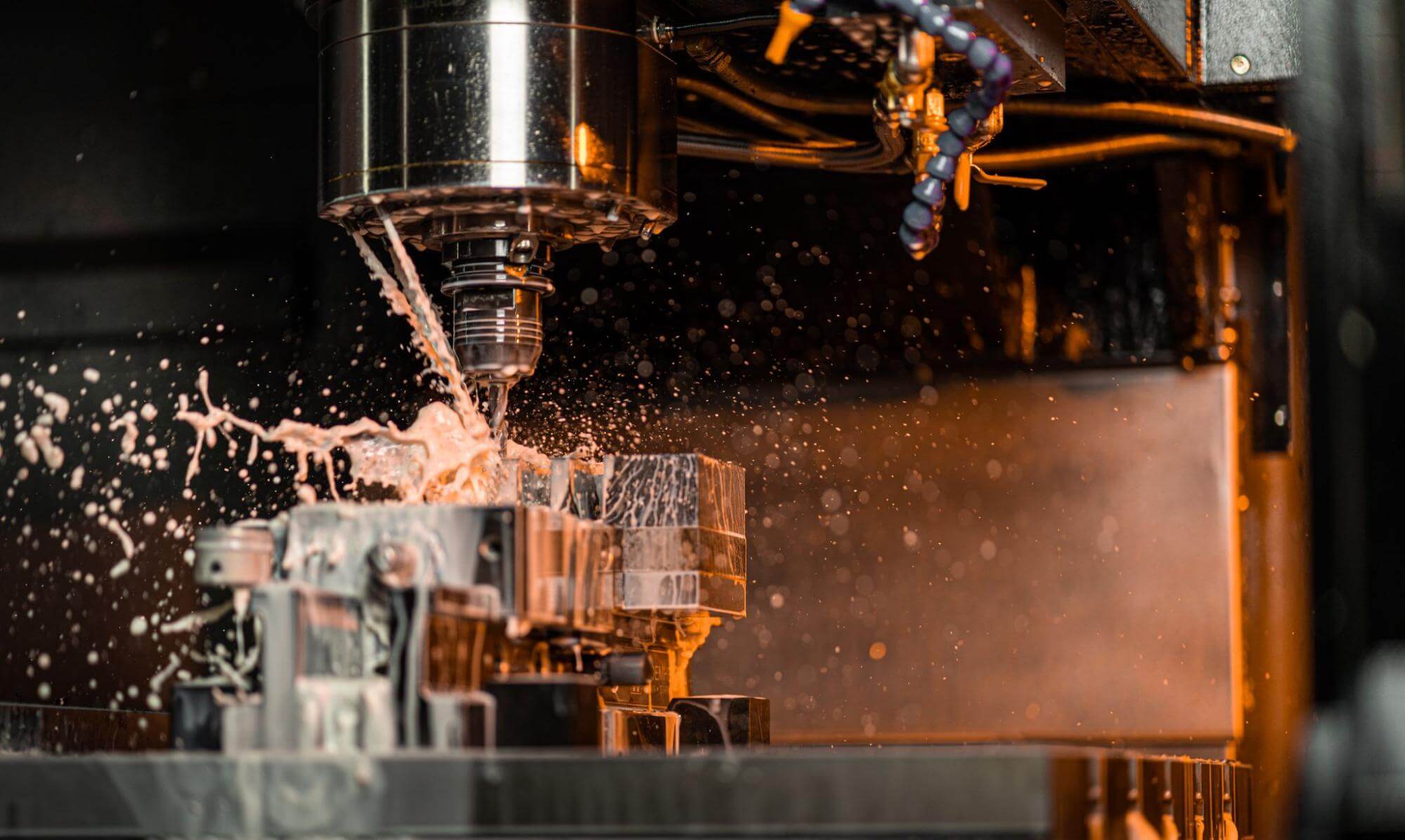

In high-stakes manufacturing sectors, precision transcends mere specification; it defines functional integrity, safety, and ultimate product success. Fine precision CNC machining operates at the extreme edge of dimensional and geometric control, where tolerances often reach ±0.0005 mm (±0.00002 inches) and surface finishes dip below Ra 0.1 µm. This level of accuracy is not an academic exercise but a fundamental requirement for components operating in environments demanding flawless performance under extreme stress, temperature, or motion. Achieving such precision requires moving beyond standard machining protocols. It demands mastery of thermal stability management to counteract minute expansion from spindle heat or ambient shifts, ultra-rigid machine structures to eliminate micro-vibrations, and sophisticated process compensation algorithms that account for tool deflection and material behavior at microscopic scales. Material selection and pre-treatment become equally critical, as residual stresses or inconsistent grain structures can compromise outcomes even with perfect machine execution. The cost of failure here is catastrophic – a turbine blade operating at supersonic speeds, a satellite guidance component, or a life-support medical implant cannot tolerate deviation.

Wuxi Lead Precision Machinery has honed its expertise through direct engagement with the world’s most stringent applications. Our engineering teams have delivered mission-critical components for the Beijing Winter Olympics snowmaking systems, where hydraulic manifold precision directly impacted athlete safety and event viability under sub-zero conditions. Equally significant is our proven capability in classified military and aerospace programs, where parts for navigation systems and propulsion assemblies undergo rigorous validation to meet MIL-STD and AS9100 requirements. These projects are not merely contracts; they are validations of our process discipline, metrology rigor, and unwavering commitment to zero-defect outcomes. Each component produced for such applications undergoes multi-stage verification using calibrated CMMs, optical comparators, and surface profilers traceable to national standards, ensuring every micron aligns with the design intent.

The technical foundation for this capability is quantifiable. Our advanced multi-axis CNC platforms, combined with proprietary process controls, consistently achieve the following benchmarks across diverse materials:

| Critical Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ±0.0005 mm (±0.00002″) |

| Geometric Tolerance (GD&T) | ±0.002 mm (±0.00008″) | ±0.0001 mm (±0.000004″) |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.05 µm (2 µin) |

| Materials Range | Aluminum, Steel, Stainless | Titanium, Inconel, Ceramics, Composites |

| Max. Part Complexity | 5-Axis Simultaneous | Micro-features < 0.1 mm |

This level of precision engineering is a strategic partnership. It requires deep collaboration between client design teams and our process engineers from the earliest concept stages to anticipate manufacturability challenges and material interactions. At Wuxi Lead, we view fine precision not as a service offering, but as an engineering philosophy embedded in every spindle rotation and measurement cycle. When your application demands perfection that impacts human safety, national security, or technological advancement, the margin for error ceases to exist – and that is where our expertise delivers.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Machining

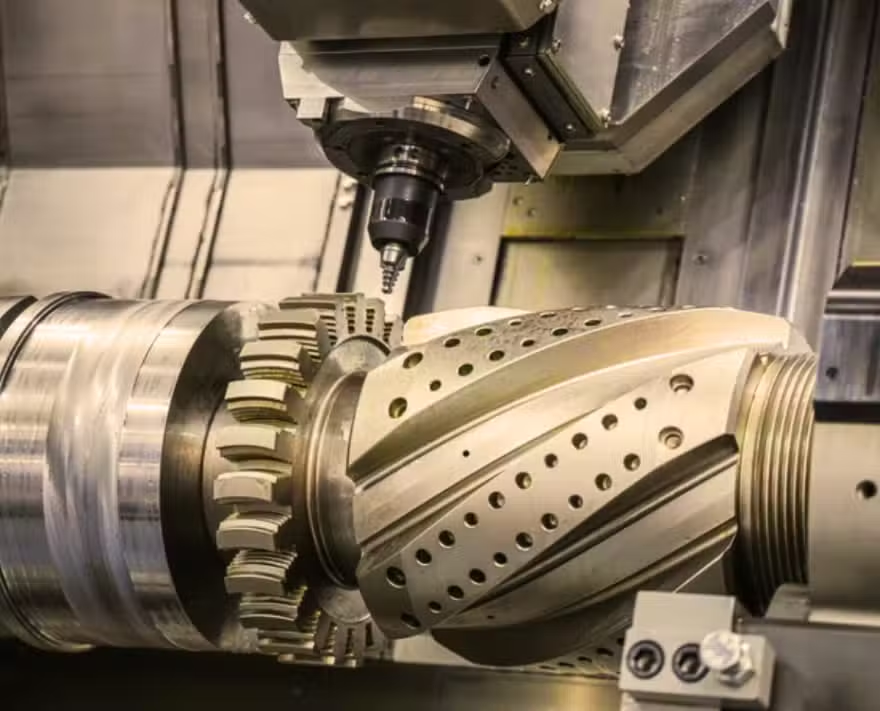

Wuxi Lead Precision Machinery stands at the forefront of high-precision manufacturing, delivering mission-critical components for industries where accuracy, repeatability, and material integrity are paramount. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional surface finish and dimensional consistency. Unlike conventional 3-axis platforms, our 5-axis machines provide simultaneous multi-directional tool movement, allowing for single-setup machining of intricate parts. This reduces cumulative error, improves part accuracy, and significantly shortens lead times—critical advantages in aerospace, medical, and semiconductor applications.

Our machining centers are equipped with high-speed spindles, thermal compensation systems, and advanced tool monitoring, ensuring stable performance during extended production runs. We support a wide range of engineering-grade materials including aluminum alloys, titanium, stainless steel, Inconel, and engineered plastics such as PEEK and PTFE. Each machine is operated by certified CNC programmers and machinists who apply deep process knowledge to optimize cutting strategies, minimize tool wear, and maintain tight tolerances across batch quantities.

Quality control is integrated into every phase of production. We employ Coordinate Measuring Machine (CMM) inspection as a core verification method, enabling full 3D metrology of critical features with micron-level resolution. Our CMM systems are calibrated to international standards and operated in temperature-controlled environments to eliminate measurement drift. In addition to first-article inspection reports (FAIR), we conduct in-process and final inspections to ensure 100% compliance with customer specifications. All inspection data is documented and traceable, supporting full quality audits and regulatory compliance.

Our commitment to precision is reflected in the tolerances we consistently achieve across diverse part configurations and materials. The following table outlines our standard and advanced tolerance capabilities under controlled conditions.

| Feature Type | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, High-Precision Micrometers |

| Angular Dimensions | ±0.1° | ±0.05° | CMM, Optical Comparator |

| Positional Tolerance | ±0.012 mm | ±0.006 mm | CMM, GD&T Analysis |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm (polished finish) | Surface Roughness Tester |

| Feature-to-Feature | ±0.01 mm | ±0.003 mm | CMM, Laser Scanning |

| Hole Diameter | ±0.01 mm | ±0.005 mm (reamed/ground) | Air Gauges, CMM |

All tolerances are achievable on parts up to 800 mm in length, depending on geometry and material stability. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to ensure optimal tolerance allocation without compromising cost-efficiency. At Wuxi Lead Precision Machinery, technical capability is not just about equipment—it’s about precision engineered into every process, measurement, and partnership.

Material & Finish Options

Material Selection for Precision CNC Machining: Engineering Excellence Starts Here

Material selection fundamentally dictates the performance, durability, and cost-effectiveness of precision CNC machined components. At Wuxi Lead Precision Machinery, our decades of experience machining complex geometries to micron tolerances inform critical decisions between Aluminum, Steel, and Titanium. Each material offers distinct advantages and machining considerations essential for demanding aerospace, medical, and industrial applications. Understanding these properties ensures optimal part function and manufacturability.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate where lightweight strength and excellent machinability are paramount. 6061 offers superior weldability and corrosion resistance for structural frames and enclosures, while 7075 delivers near-steel strength for high-stress aerospace fittings. Aluminum’s low density reduces inertia in moving parts and its thermal conductivity aids heat dissipation. However, its relative softness necessitates careful toolpath strategies to prevent burring on thin features. Steel, especially hardened alloys like 4140, 4340, and 17-4 PH stainless, provides exceptional strength, wear resistance, and dimensional stability under heavy load. These materials are indispensable for hydraulic manifolds, shafts, and tooling fixtures. Machining hardened steel demands rigid setups, specialized carbide tooling, and precise control of cutting parameters to manage heat and tool wear, often requiring post-machining stress relief. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are the pinnacle choice for extreme strength-to-weight ratio, biocompatibility, and corrosion resistance in aerospace actuators and medical implants. Its low thermal conductivity causes significant heat buildup at the cutting edge, requiring lower speeds, higher feeds, and aggressive coolant application to prevent work hardening and tool failure. Titanium machining is inherently slower and more costly but delivers unmatched performance in critical environments.

Surface finishing, particularly anodizing, significantly enhances aluminum component performance. Type II (Sulfuric Acid) anodizing provides standard corrosion and wear resistance with dyeing capability for identification. For mission-critical applications, Type III (Hardcoat) anodizing creates a much thicker, harder ceramic layer (50-70μm) offering superior abrasion resistance, electrical insulation, and extended service life in harsh conditions. Proper masking and racking are vital to maintain critical tolerances on precision features during the anodizing process.

The optimal material choice balances application requirements with manufacturability. Wuxi Lead’s engineering team collaborates closely with clients to analyze load conditions, environmental exposure, and lifecycle costs, ensuring the selected material and finish achieve peak performance within budget. Our advanced CNC platforms and process expertise guarantee these demanding materials are machined to the tightest tolerances consistently.

Key material properties for precision CNC machining are summarized below:

| Material Group | Common Alloys | Density (g/cm³) | Tensile Strength (MPa) | Key Machinability Notes | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7-2.8 | 310-570 | Excellent speed/feed rates; prone to burring; requires sharp tools | Enclosures, brackets, aerospace fittings, heat sinks |

| Steel | 4140, 4340, 17-4 PH | 7.8-7.9 | 655-1400+ | Requires rigid setup; tool wear management critical; often needs stress relief | Shafts, hydraulic components, tooling, high-strength fixtures |

| Titanium | Ti-6Al-4V (Grade 5) | 4.4 | 900-1000 | Low thermal conductivity; high cutting forces; strict coolant requirements; slow speeds | Aerospace structural parts, medical implants, marine components |

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our fine precision CNC machining process is engineered for excellence, consistency, and zero defects. We adhere to a rigorously controlled workflow that spans from initial design through prototyping to full-scale mass production. Each phase integrates advanced technology, strict quality assurance protocols, and expert engineering oversight to ensure that every component meets the highest standards of dimensional accuracy, surface finish, and material integrity.

The process begins with collaborative design engineering. Our team works closely with clients to review technical drawings, 3D CAD models, and performance requirements. Utilizing advanced simulation software, we conduct design for manufacturability (DFM) analysis to identify potential issues early, optimize toolpaths, and ensure compliance with tight tolerances—often as precise as ±0.002 mm. This stage minimizes rework and accelerates time-to-market while ensuring that every design is not only functional but also optimized for precision machining.

Once the design is finalized, we proceed to prototyping. A small batch of components is produced using the same CNC machines, tooling, and materials intended for mass production. This ensures that the prototype accurately reflects final part quality. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Any deviations are analyzed and corrected before moving forward. This iterative validation process is critical to achieving zero defects in high-volume runs.

Upon client approval, we transition seamlessly into mass production. Our state-of-the-art facility in Wuxi is equipped with multi-axis CNC machining centers, automated tool changers, and real-time monitoring systems. Production is managed through a digital workflow that tracks every operation, tool wear, and inspection result. In-process quality checks are performed at defined intervals, and final inspection covers 100% of critical dimensions for high-risk components. Statistical process control (SPC) is employed to maintain consistency and detect trends before they impact output.

Our commitment to zero defects is reinforced by ISO 9001-certified processes, full traceability of materials and operations, and continuous staff training in lean manufacturing and Six Sigma principles. Whether producing aerospace components, medical devices, or high-performance industrial parts, our production system ensures repeatability, reliability, and compliance with global quality standards.

The following table outlines key performance specifications achievable through our fine precision CNC machining process:

| Parameter | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Positional Accuracy | ±0.001 mm |

| Process Capability (Cp/Cpk) | ≥1.67 / ≥1.33 |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, Calipers, Micrometers |

Through this disciplined, technology-driven approach, Wuxi Lead Precision Machinery delivers precision-engineered components with uncompromising quality at every stage of production.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing with Certified Precision Engineering

In high-stakes industries like aerospace, medical device manufacturing, and semiconductor equipment, component failure is not an option. Tolerances measured in microns dictate performance, safety, and regulatory compliance. Wuxi Lead Precision Machinery exists to transform these exacting requirements into reality. We do not merely machine parts; we engineer solutions where consistency, material integrity, and geometric perfection are non-negotiable. Our ISO 9001 and IATF 16949 certified processes ensure every component meets the most stringent global standards, from prototyping through high-volume production.

Our technical capabilities are engineered for the extraordinary. The table below details the precision envelope we reliably operate within, reflecting our investment in cutting-edge multi-axis CNC systems, metrology infrastructure, and process control.

| Specification Category | Capability Range | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | CMM, Optical Comparators, Laser Scanning |

| Surface Finish | Ra 0.05 µm (2 µin) to Ra 1.6 µm (63 µin) | Profilometry, Visual Standards |

| Material Compatibility | Titanium Alloys, Inconel, Hastelloy, Medical-Grade Stainless Steels, Engineered Plastics | Material Certificates, Batch Traceability |

| Max Work Envelope | Ø 600 mm x 1000 mm (24″ x 39″) | 5-Axis Milling/Turning Centers |

| Critical Feature Repeatability | Cp/Cpk ≥ 1.67 | SPC-Controlled Processes, Real-Time Monitoring |

This precision is sustained through rigorous process validation. Every workpiece undergoes multi-stage inspection protocols, including pre-machining material verification, in-process gaging, and final first-article inspection reports compliant with AS9102 or customer-specific formats. Our engineers collaborate directly with your design and quality teams to preemptively resolve manufacturability challenges, reducing time-to-market without compromising integrity. We integrate seamlessly into complex global supply chains, providing full documentation traceability and responsive communication channels tailored to your project management framework.

Partnering with Wuxi Lead Precision Machinery means securing a technical extension of your own engineering capability. We eliminate the guesswork in precision manufacturing by applying decades of applied metrology expertise to your most demanding applications. Whether you require single-component excellence or integrated sub-assemblies for mission-critical systems, our facility operates as a calibrated node in your value stream—delivering parts that perform exactly as designed, every time.

Initiate your precision workflow with confidence. Contact our engineering team directly at [email protected] to discuss your specific tolerances, materials, and volume requirements. Provide your project specifications, and we will respond within 24 business hours with a detailed capability assessment and actionable next steps. Do not compromise on the foundation of your product’s performance. Let Wuxi Lead Precision Machinery become your definitive partner in precision. Your components demand nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.