Technical Contents

Engineering Guide: Fiber Laser Cutting Services

Engineering Insight: Precision as the Non-Negotiable Foundation in Fiber Laser Cutting

In high-stakes sheet metal fabrication, precision in fiber laser cutting transcends mere dimensional accuracy; it is the critical enabler of downstream assembly integrity, structural performance, and overall product lifecycle reliability. Tolerances measured in hundredths of a millimeter directly impact weld fit-up, component alignment in complex sub-assemblies, and the functional performance of end products operating under extreme conditions. Substandard edge quality or positional deviation introduces cumulative errors that escalate costs through rework, scrap, and delayed time-to-market. True precision demands not only advanced hardware but also deep process mastery—understanding material behavior under intense thermal input, optimizing assist gas dynamics, and implementing rigorous in-process metrology. This level of control is non-negotiable for industries where failure is not an option, from aerospace structural components to medical device housings.

Wuxi Lead Precision Machinery has honed this precision capability through demanding, real-world validation. Our engineering teams executed critical components for Beijing Winter Olympics infrastructure, where environmental resilience and flawless dimensional consistency were paramount under tight deadlines. Similarly, our adherence to stringent military-grade specifications for defense sector applications has proven our ability to deliver zero-defect parts under uncompromising quality protocols. This experience translates directly to our commercial fiber laser cutting services, embedding a culture of traceability, process validation, and continuous improvement that standard workshops cannot replicate. We treat every client project with the same rigor applied to mission-critical defense contracts.

The technical foundation of this precision is anchored in our advanced machine park and calibrated processes. Below are key performance specifications consistently achieved across our production floor for critical cutting parameters:

| Parameter | Typical Performance | Measurement Standard | Key Impact Area |

|---|---|---|---|

| Positioning Accuracy | ±0.02 mm | ISO 230-2 | Part-to-part consistency |

| Repeatability | ≤ 0.015 mm | ISO 230-2 | High-volume batch uniformity |

| Edge Perpendicularity | ≤ 0.05 mm / 10 mm | ASME Y14.5 | Weld prep & assembly fit |

| Kerf Width Tolerance | ±0.03 mm | In-house CMM protocol | Nesting efficiency & material yield |

| Max. Cut Thickness (Mild Steel) | 30 mm | Bystronic BySprint | Versatility for structural parts |

This documented capability, validated daily on client production runs, ensures your designs translate into reality without compromise. Precision cutting minimizes secondary operations, reduces material waste, and guarantees that every part meets the exacting demands of modern manufacturing. At Wuxi Lead Precision Machinery, we engineer cut quality into every micron—because your product’s performance starts with the integrity of its foundational components. Partner with a provider whose precision credentials are proven where excellence is mandatory, not optional.

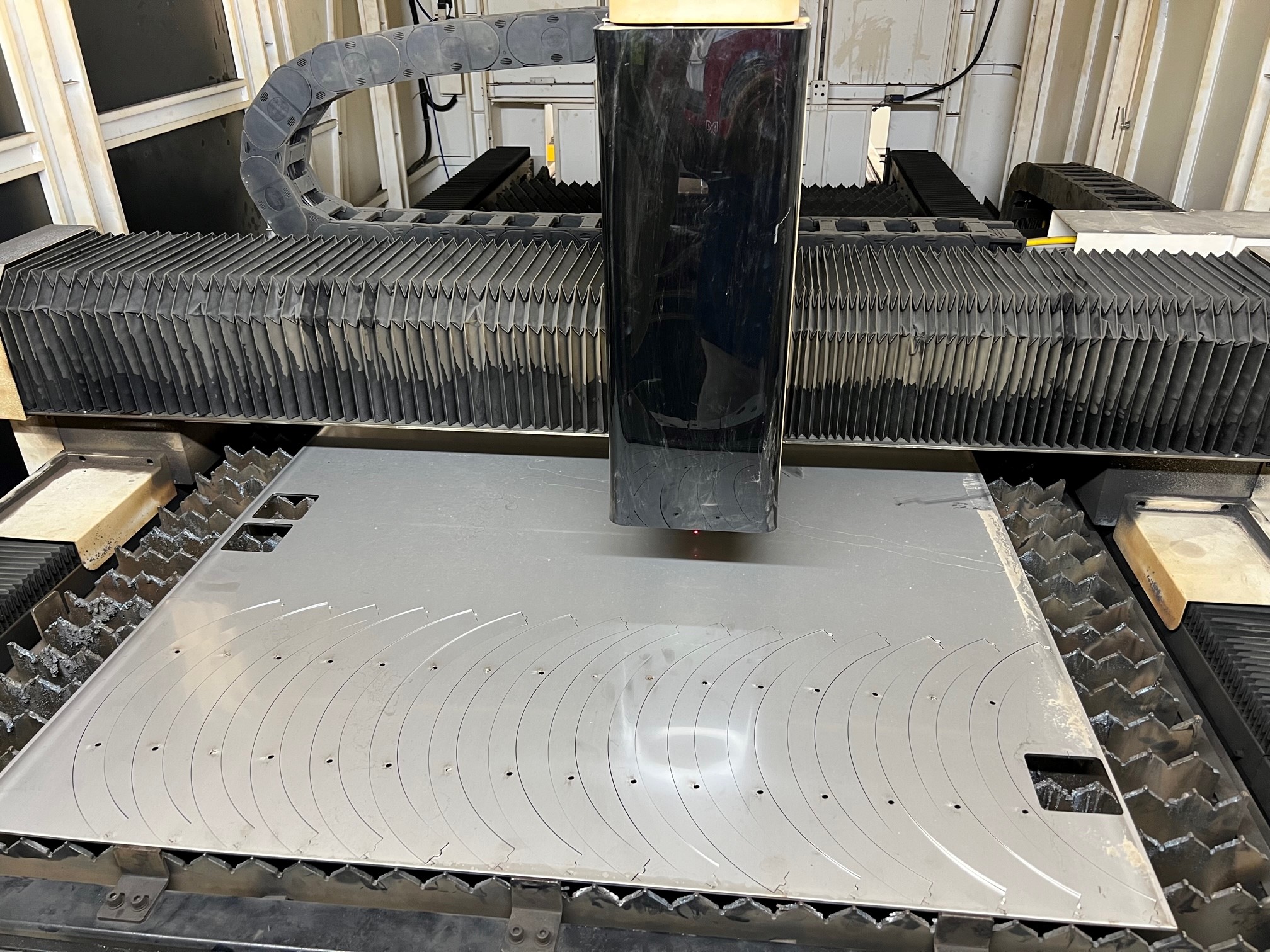

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced fiber laser cutting services tailored to high-precision sheet metal fabrication for global industrial clients. Our technical capabilities are anchored in state-of-the-art 5-axis CNC fiber laser systems, enabling complex geometries, tight tolerances, and superior edge quality across a wide range of conductive and non-conductive materials. These systems integrate dynamic motion control with high-beam quality lasers, ensuring clean, dross-free cuts even at high speeds. The 5-axis capability allows for bevel cutting, countersinking, and angled features without secondary operations, significantly reducing lead times and improving part accuracy.

Our fiber laser platforms support material thicknesses from 0.5 mm up to 25 mm, depending on material type, with maximum cutting areas reaching 4000 mm × 2000 mm. This scalability makes our services ideal for both prototyping and high-volume production runs in aerospace, automotive, medical, and energy sectors. Materials routinely processed include stainless steel, carbon steel, aluminum, brass, and copper, all cut with minimal heat-affected zones, preserving material integrity and weldability.

Precision is enforced through a comprehensive quality control system anchored by Coordinate Measuring Machine (CMM) inspection. Every critical dimension is verified using Zeiss and Hexagon CMMs, ensuring full compliance with ISO 10360 standards. In addition to dimensional accuracy, surface finish, edge perpendicularity, and feature alignment are systematically validated. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to traceability, repeatability, and continuous improvement.

All programming is performed using advanced CAD/CAM software, including SolidWorks, Siemens NX, and Autodesk PowerMill, enabling seamless translation from design to production. Nesting optimization algorithms maximize material utilization, reducing waste and lowering overall project costs. Real-time monitoring and adaptive control systems ensure consistent performance, with automated calibration routines maintaining peak machine accuracy over extended operations.

The following table outlines the standard technical specifications and achievable tolerances for our fiber laser cutting services:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser, 3 kW – 12 kW |

| Axis Configuration | 5-Axis CNC Control |

| Max Cutting Area | 4000 mm × 2000 mm |

| Material Thickness Range | 0.5 mm – 25 mm (varies by material) |

| Positioning Accuracy | ±0.02 mm/m |

| Repeatability | ±0.01 mm |

| Linear Dimensional Tolerance | ±0.1 mm (up to 100 mm), ±0.2 mm (up to 500 mm) |

| Angular Tolerance | ±0.5° |

| Edge Perpendicularity | ≤ 0.1 mm over 10 mm height |

| Surface Roughness (Ra) | ≤ 6.3 µm (typical) |

| Minimum Hole Diameter | 1.0 × material thickness (min 0.8 mm) |

| Lead Time (Standard) | 5–7 working days (varies by complexity) |

Wuxi Lead Precision Machinery combines cutting-edge technology with rigorous quality assurance to deliver fiber laser cutting solutions that meet the most demanding engineering requirements. Our technical expertise ensures every component conforms to exact design intent, providing reliability and performance across critical applications.

Material & Finish Options

Material Selection for Precision Fiber Laser Cutting

Selecting optimal materials is critical for achieving cost efficiency and performance in fiber laser cutting. At Wuxi Lead Precision Machinery, our 6kW–12kW fiber laser systems deliver micron-level accuracy across diverse alloys, but material properties directly impact cut quality, speed, and secondary processing. Below we detail key considerations for aluminum, steel, and titanium, with emphasis on manufacturability and finish compatibility.

Carbon and Stainless Steel

Low-carbon steel (A36, 1018) cuts efficiently with oxygen assist gas, producing smooth edges up to 30mm thickness. Stainless steel grades 304 and 316 require high-purity nitrogen to prevent oxidation, maintaining corrosion resistance critical for medical and food-grade applications. Edge squareness tolerances of ±0.1mm are achievable across 0.5–25mm sheets. Note that high-sulfur steels may cause dross adhesion; we recommend pre-cutting material certification checks.

Aluminum Alloys

5052 and 6061 aluminum are preferred for laser cutting due to balanced reflectivity and thermal conductivity. Reflectivity challenges necessitate specialized anti-reflective optics and pulsed laser modes to avoid beam back-reflection damage. Nitrogen assist gas ensures oxide-free edges essential for welding or anodizing. Thickness limitations apply: 0.8–15mm for optimal results. Material flatness deviations exceeding 0.5mm/meter risk focal point drift, requiring our flatness correction protocols.

Titanium Alloys

Grade 2 and Grade 5 titanium demand strict inert gas shielding (argon or helium) to prevent heat-affected zone contamination. Our systems cut 0.5–12mm sheets at slower speeds than steel due to titanium’s low thermal conductivity, but achieve burr-free edges for aerospace components. Material traceability documentation is non-negotiable; we verify mill certificates for oxygen/nitrogen content to avoid embrittlement.

Anodizing Compatibility

Anodizing requires laser-cut aluminum surfaces free of embedded contaminants. Our process includes:

1. Alkaline cleaning to remove laser slag

2. Acid etching for uniform surface activation

3. Strict control of cut edge roughness (Ra ≤ 3.2μm)

Avoid anodizing immediately after cutting; residual thermal stress may cause coating adhesion failure. We recommend a 24-hour stabilization period.

Material Processing Specifications

| Material | Thickness Range (mm) | Max Laser Power | Assist Gas | Edge Quality (Ra μm) |

|---|---|---|---|---|

| Stainless Steel | 0.5–25 | 12 kW | Nitrogen | ≤ 1.6 |

| Aluminum 6061 | 0.8–15 | 8 kW | Nitrogen | ≤ 3.2 |

| Titanium Grade 5 | 0.5–12 | 6 kW | Argon | ≤ 2.5 |

| Carbon Steel | 1.0–30 | 12 kW | Oxygen | ≤ 6.3 |

Material selection must align with end-use requirements and downstream processes. Wuxi Lead’s engineering team provides pre-production material validation, including spectrographic analysis and cut parameter simulation, to eliminate costly rework. Contact us for application-specific feasibility studies backed by 15+ years of precision fabrication data.

Manufacturing Process & QC

From Design to Mass Production: Achieving Zero Defects in Fiber Laser Cutting

At Wuxi Lead Precision Machinery, our fiber laser cutting services are engineered for precision, efficiency, and flawless repeatability. We follow a disciplined production process that spans from initial design to prototyping and finally mass production, ensuring every component meets the highest standards of quality and consistency. This structured workflow is the foundation of our zero-defect manufacturing philosophy.

The process begins with design optimization. Our engineering team collaborates closely with clients to review technical drawings, material specifications, and geometric tolerances. Using advanced CAD/CAM software, we simulate the fiber laser cutting path to identify potential weaknesses such as thermal distortion, material warping, or feature inaccuracies. This virtual validation ensures manufacturability before any metal is cut, reducing rework and accelerating time-to-market.

Once the design is finalized, we move into the prototyping phase. A small batch of parts is produced using the same fiber laser systems and material grades intended for full-scale production. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, edge quality, and feature alignment are verified against the original specifications. Any discrepancies trigger immediate process adjustments, ensuring that only validated parameters advance to mass production.

Mass production is executed on our high-power fiber laser cutting platforms, which deliver exceptional speed and precision across a wide range of sheet metals. Our automated material handling systems, integrated with real-time process monitoring, maintain consistent beam focus, assist gas pressure, and cutting speed. Each machine is calibrated daily, and environmental controls minimize thermal fluctuations that could affect cut quality. Throughout the production run, statistical process control (SPC) tracks key variables, enabling predictive maintenance and instant correction of deviations.

Quality assurance is embedded at every stage. In-process inspections occur at defined intervals, and final parts are subjected to 100% visual inspection and random sampling for metrological validation. Traceability is maintained through digital logs that record machine settings, operator IDs, and inspection results for each batch.

Our commitment to zero defects is not aspirational—it is operational. By integrating precision engineering, closed-loop feedback systems, and rigorous quality protocols, Wuxi Lead ensures that every fiber laser cut part meets exacting industrial standards.

Fiber Laser Cutting Specifications

| Parameter | Specification |

|---|---|

| Laser Power Range | 1 kW – 12 kW |

| Max Cutting Speed | Up to 100 m/min (thin sheet) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Material Thickness Range | 0.5 mm – 25 mm (steel), up to 20 mm (aluminum) |

| Supported Materials | Mild steel, stainless steel, aluminum, brass |

| Cut Edge Roughness (Ra) | ≤ 3.2 µm (typical) |

| Minimum Feature Size | 1.2 x material thickness |

| Nesting Software | Lantek, SigmaNEST, or client-integrated CAD |

Why Choose Wuxi Lead Precision

Elevate Your Production Capabilities Through Strategic Partnership

At Wuxi Lead Precision Machinery, we recognize that selecting a fiber laser cutting partner is a strategic decision impacting your product quality, production efficiency, and market competitiveness. As a certified ISO 9001 manufacturer with 15 years of specialization in high-precision sheet metal fabrication, we deliver more than cutting services—we provide engineered solutions that integrate seamlessly into your supply chain. Our 24/7 operational model ensures on-time delivery for global clients, while our in-house engineering team collaborates proactively to optimize your designs for manufacturability, reducing material waste by up to 22% without compromising structural integrity.

Our investment in next-generation fiber laser technology guarantees micron-level accuracy across diverse materials, from aerospace-grade aluminum to hardened stainless steel. Unlike conventional systems, our automated material handling and real-time process monitoring eliminate human error, ensuring batch consistency critical for medical, automotive, and defense applications. Every component undergoes rigorous first-article inspection with full traceability documentation, meeting AS9100 and ITAR compliance standards.

Technical Specifications for Precision Execution

| Parameter | Capability | Tolerance Range | Supported Materials |

|---|---|---|---|

| Laser Power | 12kW – 30kW | N/A | Carbon Steel, Stainless Steel, Aluminum, Brass, Copper |

| Max Cutting Thickness | 40mm (Mild Steel), 30mm (Stainless) | N/A | Titanium, Galvanized Steel (up to 25mm) |

| Positioning Accuracy | ±0.03mm | N/A | All sheet/coil formats |

| Repeatability | ±0.02mm | N/A | Thickness Range: 0.5mm – 25mm |

| Surface Finish | Ra ≤ 3.2μm | Burr-free edges | Custom finishes available |

| Software Integration | SolidWorks, AutoCAD, STEP, DXF | Nesting optimization | Full 3D CAD/CAM support |

Partnering with Lead Precision means accessing a dedicated technical account manager who oversees your projects from RFQ to shipment. We implement dynamic production scheduling to accommodate urgent prototypes or large-volume runs within compressed timelines—reducing lead times by 35% compared to industry averages. Our facility in Wuxi operates under stringent environmental controls, maintaining ±1°C temperature stability to prevent thermal distortion during cutting, a critical factor often overlooked by competitors.

Your next project demands a partner who treats your specifications as non-negotiable commitments. We invite you to submit your technical drawings for a confidential feasibility assessment and cost analysis. Contact our engineering team directly at [email protected] to discuss material certifications, capacity planning, or NDA-protected collaboration. Specify your required delivery window and material grades in your inquiry to receive a prioritized response within 4 business hours. Accelerate your production timeline with precision that meets the exacting standards of Tier-1 global manufacturers.

Wuxi Lead Precision Machinery: Where Advanced Laser Technology Meets Uncompromising Accountability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.