Technical Contents

Engineering Guide: Fdm Printing Service

Engineering Insight: The Role of Precision in FDM Printing Services

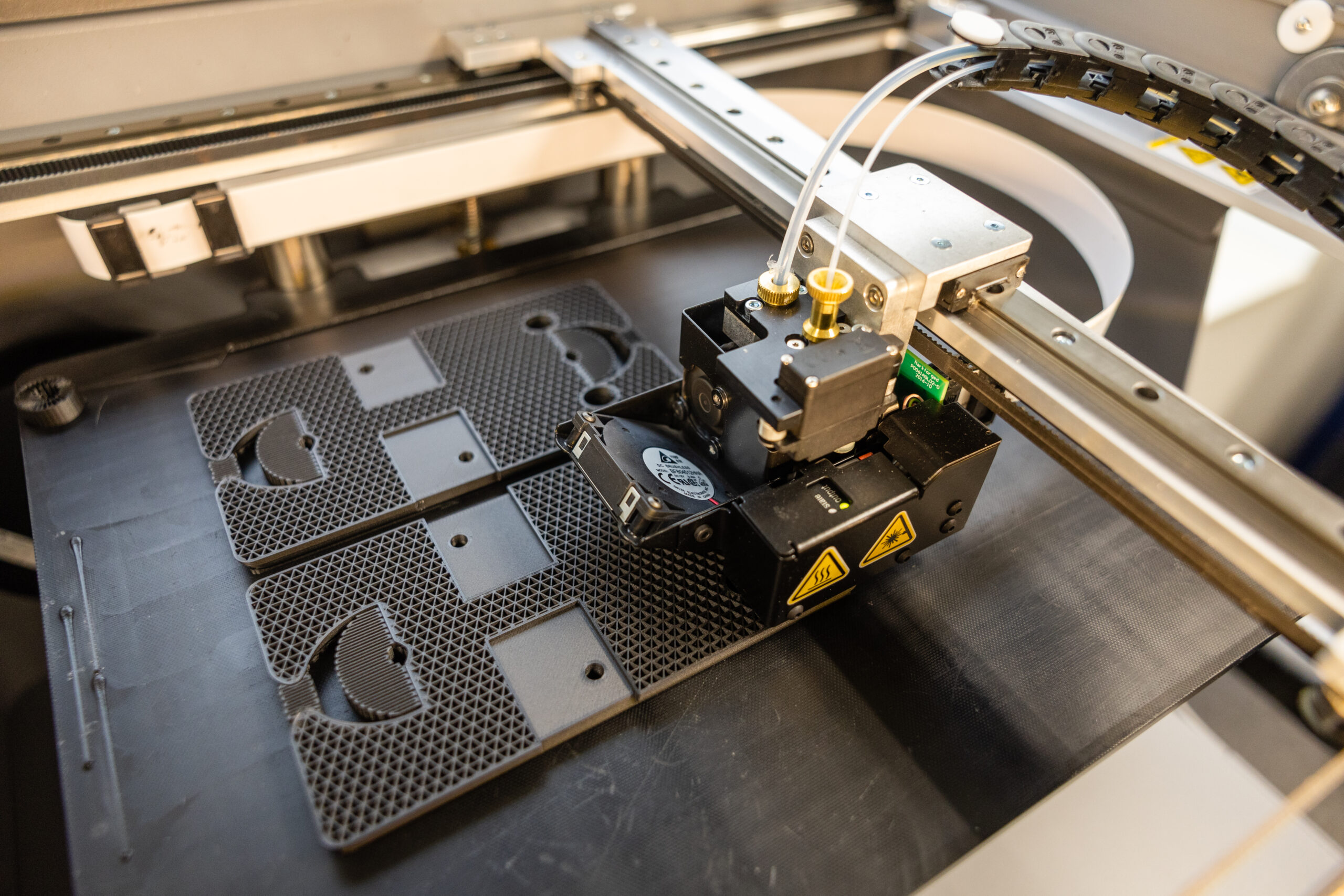

In the realm of advanced manufacturing, FDM (Fused Deposition Modeling) printing has evolved from a prototyping tool into a critical process for producing functional, end-use components—especially when integrated with high-precision metal manufacturing workflows. At Wuxi Lead Precision Machinery, we recognize that the true value of an FDM printing service lies not just in its ability to fabricate complex geometries, but in its consistency, dimensional accuracy, and repeatability. These factors are paramount when serving industries where failure is not an option.

Precision in FDM printing begins with material science and machine calibration. Industrial-grade thermoplastics such as ULTEM, PEEK, and ABS must be processed under tightly controlled thermal conditions to minimize warping and internal stress. Our FDM systems operate within climate-controlled environments, ensuring layer adhesion and dimensional stability meet ISO 2768-mK standards. Each print undergoes rigorous in-process inspection using laser micrometry and post-build CMM validation, guaranteeing tolerances are maintained within ±0.1 mm for critical features.

What sets Wuxi Lead apart is our integration of FDM printing within a broader precision metal manufacturing ecosystem. While FDM excels in lightweight, complex structures, it often serves as a complement to CNC-machined aluminum, titanium, or stainless steel components. Our engineering team routinely designs hybrid assemblies—where FDM-printed jigs, fixtures, or housings interface directly with high-tolerance metal parts—requiring alignment precision down to the micron level. This synergy is essential in aerospace, defense, and high-performance automotive applications.

Our experience in delivering components for Olympic-standard equipment and military-grade systems underscores our commitment to excellence. For instance, we supported the development of custom sensor enclosures for a national defense contractor, where FDM-printed parts had to withstand extreme vibration and temperature cycling while maintaining signal integrity. The success of such projects hinges on predictive modeling, material validation, and iterative testing—all grounded in precision engineering.

At Wuxi Lead, we do not treat FDM as a standalone service but as a strategic manufacturing lever. Our engineers work upstream in the design phase, advising on topology optimization, support structure reduction, and anisotropic strength compensation. This proactive approach mitigates risk and accelerates time-to-deployment.

Below are key specifications reflecting our FDM printing capabilities:

| Parameter | Specification |

|---|---|

| Layer Resolution | 0.1 mm – 0.3 mm |

| Build Envelope | 1000 x 600 x 600 mm |

| Dimensional Tolerance | ±0.1 mm (typical), ±0.05 mm (tight tolerance) |

| Supported Materials | ABS, PC, ULTEM 9085, ULTEM 1010, PEEK, Nylon |

| Infill Density Options | 10% – 100% (adjustable by zone) |

| Post-Processing Available | Vapor smoothing, CNC trimming, coating |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (aerospace-ready) |

Precision is not an outcome—it is a discipline. At Wuxi Lead Precision Machinery, we apply decades of experience in mission-critical manufacturing to ensure every FDM-printed component meets the highest standards of performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Machining Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for mission-critical metal components, leveraging advanced subtractive manufacturing technologies. While additive processes like FDM serve specific prototyping needs, our core expertise and investment focus on high-accuracy CNC metal machining for end-use production parts demanding superior strength, thermal stability, and surface integrity unattainable with polymer-based printing. We specialize in transforming complex metal geometries from aerospace alloys, medical-grade titanium, hardened steels, and exotic materials into functional components meeting the most stringent industrial requirements. Our integrated manufacturing environment centers on multi-axis CNC machining, ensuring dimensional fidelity and repeatability essential for sectors including aerospace, energy, and high-end medical device manufacturing.

Our production floor is anchored by a modern fleet of 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems provide simultaneous multi-directional tool movement, enabling the complete machining of intricate contours, deep cavities, and compound angles in a single setup. This eliminates cumulative fixture errors, significantly reduces lead times, and achieves superior part consistency compared to 3-axis or indexed 4-axis processes. Capabilities encompass high-speed milling, precision turning with live tooling, fine boring, and complex contouring on materials ranging from aluminum and stainless steel to Inconel and tool steels. All machines operate under strict environmental controls to minimize thermal drift, ensuring micron-level accuracy across extended production runs.

Rigorous quality control is non-negotiable. Every critical dimension undergoes verification using state-of-the-art Coordinate Measuring Machines (CMM), including Hexagon GLOBAL S and Brown & Sharpe systems. Our certified metrology lab performs full First Article Inspections (FAI) per AS9102 standards and conducts in-process and final inspections against customer engineering specifications. This data-driven QC process, combined with real-time machine tool probing and thermal compensation, guarantees that every component shipped meets the defined tolerances. Statistical Process Control (SPC) methodologies are applied to high-volume runs, providing continuous feedback for process optimization and sustained quality.

The following table details our standard achievable geometric tolerances for machined metal components, reflecting our commitment to precision engineering. Tighter tolerances are attainable for specific features or materials upon engineering review.

| Feature Type | Standard Tolerance | Typical Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | Up to 150 mm; ±0.020 mm for >300 mm |

| Geometric (Flatness) | 0.010 mm | 0.005 mm | Per ISO 2768-mK on surfaces ≤ 100 mm² |

| Geometric (Roundness) | 0.008 mm | 0.003 mm | For diameters ≤ 50 mm |

| Positional (Holes) | ±0.015 mm | ±0.008 mm | Relative to datum; includes concentricity |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Achieved via fine milling/turning; polish available |

This combination of advanced 5-axis CNC technology, stringent environmental controls, and comprehensive CMM-based quality assurance forms the foundation of Wuxi Lead’s precision metal manufacturing capability. We consistently deliver components that perform reliably in the most demanding operational environments, backed by full traceability and documentation meeting aerospace and medical industry standards. Partner with us for metal parts where precision is not just a specification, but a critical performance requirement.

Material & Finish Options

Material Selection for High-Precision FDM Printing Services in Custom Metal Manufacturing

When integrating FDM (Fused Deposition Modeling) printing services into custom metal manufacturing workflows, material selection plays a pivotal role in determining the performance, durability, and functionality of end-use parts. At Wuxi Lead Precision Machinery, we recognize that while FDM is traditionally associated with thermoplastics, its application in metal manufacturing often involves the use of metal-filled filaments or serves as a prototyping step before final metal production. However, for functional metal components produced via complementary processes such as CNC machining or investment casting—guided by FDM prototypes—material choice remains critical. The most widely used metals in such advanced manufacturing ecosystems are aluminum, steel, and titanium, each offering distinct mechanical and thermal properties.

Aluminum is favored for applications requiring a high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance. It is commonly used in aerospace, automotive, and consumer electronics. When paired with FDM prototypes for design validation, aluminum ensures lightweight performance without sacrificing structural integrity. Steel, particularly stainless and tool steel variants, delivers superior hardness, wear resistance, and load-bearing capability. It is ideal for industrial tooling, molds, and high-stress mechanical components. Titanium stands at the premium end of the spectrum, offering exceptional strength-to-density ratio, biocompatibility, and resistance to extreme temperatures and corrosive environments. Its use is prevalent in aerospace, medical implants, and high-performance racing components.

Post-processing finishes further enhance the functional and aesthetic qualities of metal parts. Anodizing is one of the most effective surface treatments for aluminum. This electrochemical process thickens the natural oxide layer, improving corrosion and wear resistance while allowing for color coding through dye integration. Anodized finishes also provide excellent adhesion for paint primers and glues, making them ideal for components requiring secondary assembly or coating. While anodizing is specific to aluminum and certain aluminum alloys, steel and titanium benefit from alternative treatments such as passivation, plating, or thermal spraying—though these fall outside the scope of this section.

The table below summarizes key mechanical and physical properties of the three primary metals used in conjunction with FDM-driven manufacturing workflows.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.70 | 310 | 276 | High | Aerospace frames, enclosures, heat sinks |

| Stainless Steel 304 | 8.00 | 505 | 215 | Very High | Food processing, medical devices, chemical tanks |

| Titanium Grade 5 (Ti-6Al-4V) | 4.43 | 900 | 830 | Excellent | Aircraft components, surgical implants, racing parts |

Selecting the right material begins with understanding the operational environment, mechanical demands, and lifecycle expectations of the final component. At Wuxi Lead Precision Machinery, we support clients in aligning FDM prototyping with optimal metal selection and finishing strategies to ensure precision, repeatability, and long-term performance in end-use applications.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Concept to Zero-Defect Fulfillment

Wuxi Lead Precision Machinery delivers exceptional custom metal components through a rigorously controlled production sequence designed for absolute reliability. While FDM printing serves specific plastic prototyping needs, our core expertise and this guide focus on high-integrity CNC machining and metal fabrication processes essential for demanding industrial applications. We implement a seamless, quality-integrated workflow spanning Design, Prototyping, and Mass Production, with Zero Defects as the non-negotiable outcome.

The process begins with collaborative Design Engineering. Our engineers work directly with client specifications, applying deep manufacturing knowledge to optimize part geometry for CNC machinability, material performance, and functional requirements. Critical factors like geometric dimensioning and tolerancing (GD&T), material selection (aluminum alloys, stainless steels, titanium, brass), and surface finish are rigorously defined using advanced CAD/CAM software. This phase ensures the digital model is not only functional but inherently manufacturable to exacting standards, eliminating potential flaws at the source. Design validation includes comprehensive simulation for stress, thermal behavior, and toolpath optimization, preventing costly errors before metal is cut.

Prototyping transitions the validated design into physical reality under full production conditions. We utilize the same high-precision CNC machining centers and quality protocols intended for the final production run. This critical stage involves producing a limited quantity of parts for functional testing, fit verification, and client approval. Every prototype undergoes our First Article Inspection (FAI) protocol, meticulously measuring all critical dimensions against the approved drawing using CMMs, optical comparators, and surface roughness testers. This step confirms process capability and identifies any unforeseen issues, ensuring the path to mass production is flawless.

Mass Production leverages the validated process for consistent, high-volume output. Our automated CNC machining cells, operated by certified technicians, execute the optimized programs with unwavering precision. Real-time Statistical Process Control (SPC) monitors key parameters like tool wear, dimensional drift, and surface quality. In-process inspections at defined intervals, coupled with 100% critical feature verification for high-risk components, guarantee conformance. Final inspection employs the full suite of metrology equipment against the original FAI baseline. This integrated quality system, embedded within every production step, ensures every component shipped meets the stringent zero-defect standard demanded by aerospace, medical, and industrial OEMs.

Wuxi Lead Precision CNC Machining Core Specifications

| Parameter | Capability | Standard Tolerance | Quality Standard |

|---|---|---|---|

| Machining Types | 3/4/5-Axis Milling, CNC Turning, Mill-Turn | ±0.005 mm (0.0002″) | ISO 2768-mK |

| Materials | Aluminum (6061, 7075), Stainless (303, 304, 316), Titanium, Brass, Steel Alloys | ±0.010 mm (0.0004″) | ISO 2768-f |

| Max Work Envelope | 1000 x 600 x 500 mm (Milling), Ø300 mm x 500 mm (Turning) | Surface Ra ≤ 0.8 µm | ASME Y14.5 GD&T |

| Key Equipment | DMG MORI, MAZAK, HAAS CNC Centers; Zeiss CMMs; Mitutoyo Measuring Tools | Critical Features: ±0.002 mm | ISO 9001:2015 |

This disciplined progression, underpinned by advanced technology and an uncompromising quality culture, transforms client concepts into mission-critical metal components with guaranteed precision and zero-defect delivery. Wuxi Lead ensures your production process is not just efficient, but inherently reliable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched FDM Printing Services in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in bridging the gap between rapid prototyping and high-precision metal manufacturing. Our FDM printing services are engineered to support forward-thinking industries—from aerospace and automotive to medical device development and industrial automation. As a trusted partner in custom metal manufacturing, we understand that innovation begins with a prototype, and that prototype must be reliable, repeatable, and representative of the final product. This is where our advanced fused deposition modeling (FDM) capabilities deliver exceptional value.

Our FDM printing service is not a standalone solution—it is a strategic component of an integrated manufacturing ecosystem. We utilize industrial-grade 3D printing systems to produce high-strength, dimensionally stable thermoplastic components that serve as functional prototypes, jigs, fixtures, and even end-use parts in non-structural applications. These printed components are seamlessly integrated with our CNC machining, sheet metal fabrication, and surface treatment processes, enabling clients to accelerate product development cycles without compromising on quality or precision.

What sets our FDM printing apart is not just the technology, but the engineering expertise behind it. Our team of CNC engineers and manufacturing specialists work closely with clients to optimize part design for printability, structural integrity, and compatibility with downstream metal processes. Whether you’re validating a new housing design, creating custom assembly aids, or preparing for low-volume production, we ensure every printed part meets strict performance and tolerance standards.

We support a wide range of high-performance thermoplastics, including ABS, PC, Nylon, and ULTEM, allowing material selection based on thermal resistance, chemical exposure, and mechanical load requirements. All prints are produced under controlled environmental conditions to minimize warping and ensure layer adhesion, followed by rigorous inspection to verify dimensional accuracy.

Our clients benefit from a streamlined workflow that connects digital design to physical realization in days, not weeks. By combining FDM printing with our in-house metal manufacturing capabilities, we eliminate the delays and inconsistencies associated with multi-vendor sourcing.

Partner with Wuxi Lead Precision Machinery to transform your design concepts into production-ready realities. We don’t just print parts—we engineer solutions.

For technical inquiries, project consultations, or to request a quote, contact us at [email protected]. Our engineering team is ready to support your next innovation.

| Specification | Detail |

|---|---|

| Build Volume | Up to 900 x 600 x 900 mm |

| Layer Resolution | 0.1 mm – 0.3 mm |

| Supported Materials | ABS, PC, Nylon, ULTEM, ASA |

| Positional Accuracy | ±0.1 mm |

| Post-Processing Options | Sanding, Priming, Painting, Vapor Smoothing |

| Lead Time | 3–7 days (standard), expedited options available |

| File Formats Accepted | STEP, IGES, STL, DWG, PDF |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.