Technical Contents

Engineering Guide: Fdm Parts

Engineering Insight Precision in Metal Manufacturing Beyond FDM Limitations

The term “FDM parts” commonly refers to components produced via Fused Deposition Modeling, an additive process primarily for thermoplastics. At Wuxi Lead Precision Machinery, our core expertise and value proposition reside firmly within high-precision custom metal manufacturing – a domain demanding fundamentally different engineering rigor than plastic prototyping. Confusing these processes risks underestimating the critical tolerances and material performance required for mission-critical metal components. True precision engineering for metal parts transcends basic form; it demands absolute control over dimensional accuracy, material integrity, surface finish, and repeatability under operational stress. This level of control is non-negotiable in sectors where failure is not an option.

Precision in metal fabrication is not merely a specification; it is the foundation of functional reliability. Microscopic deviations in critical dimensions can cascade into catastrophic system failures in aerospace assemblies, lead to premature wear in heavy machinery, or compromise the sealing integrity of hydraulic components. Achieving micron-level tolerances consistently across diverse alloys requires more than advanced machinery. It necessitates deep material science understanding, sophisticated process validation, and an ingrained quality culture that anticipates variables from raw material grain structure to thermal deformation during machining. This is where theoretical capability meets practical execution.

Wuxi Lead Precision Machinery has honed this execution through decades of delivering components where precision is paramount. Our engineering teams possess direct experience manufacturing parts certified for Olympic-standard equipment, where flawless motion and durability under extreme competition are essential. More significantly, we maintain stringent protocols developed through supplying precision metal components for demanding military applications. These projects demanded adherence to exacting national and international military standards (MIL-STD), rigorous traceability, and zero-defect delivery under tight deadlines – proving our capability when consequences are highest. This heritage shapes our approach to every custom metal project, regardless of sector.

Understanding the specific precision requirements is the first engineering step. The table below outlines typical capabilities achievable through our integrated CNC machining, grinding, and finishing processes for critical metal components. These figures represent baseline performance; tighter tolerances are attainable through specialized processes and enhanced inspection protocols for the most demanding applications.

| Specification Category | Standard Capability | Enhanced Capability (Project Dependent) |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.001 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Geometric Tolerance (GD&T) | ±0.01 mm | ±0.002 mm |

| Material Range | Aluminum, Steel, Stainless, Titanium, Brass, Exotics | Specialized Alloys per Requirement |

| Max Part Weight | 5,000 kg | 10,000 kg |

Precision in metal manufacturing is an active engineering discipline, not a passive outcome. It requires anticipating how every process interaction affects the final part’s performance in its real-world environment. Wuxi Lead Precision Machinery leverages its proven experience in the most demanding sectors – from the global stage of the Olympics to the uncompromising standards of defense – to ensure your custom metal components meet not just the drawing, but the mission. Contact our engineering team to discuss how our precision manufacturing philosophy applies to your specific application requirements.

Precision Specs & Tolerances

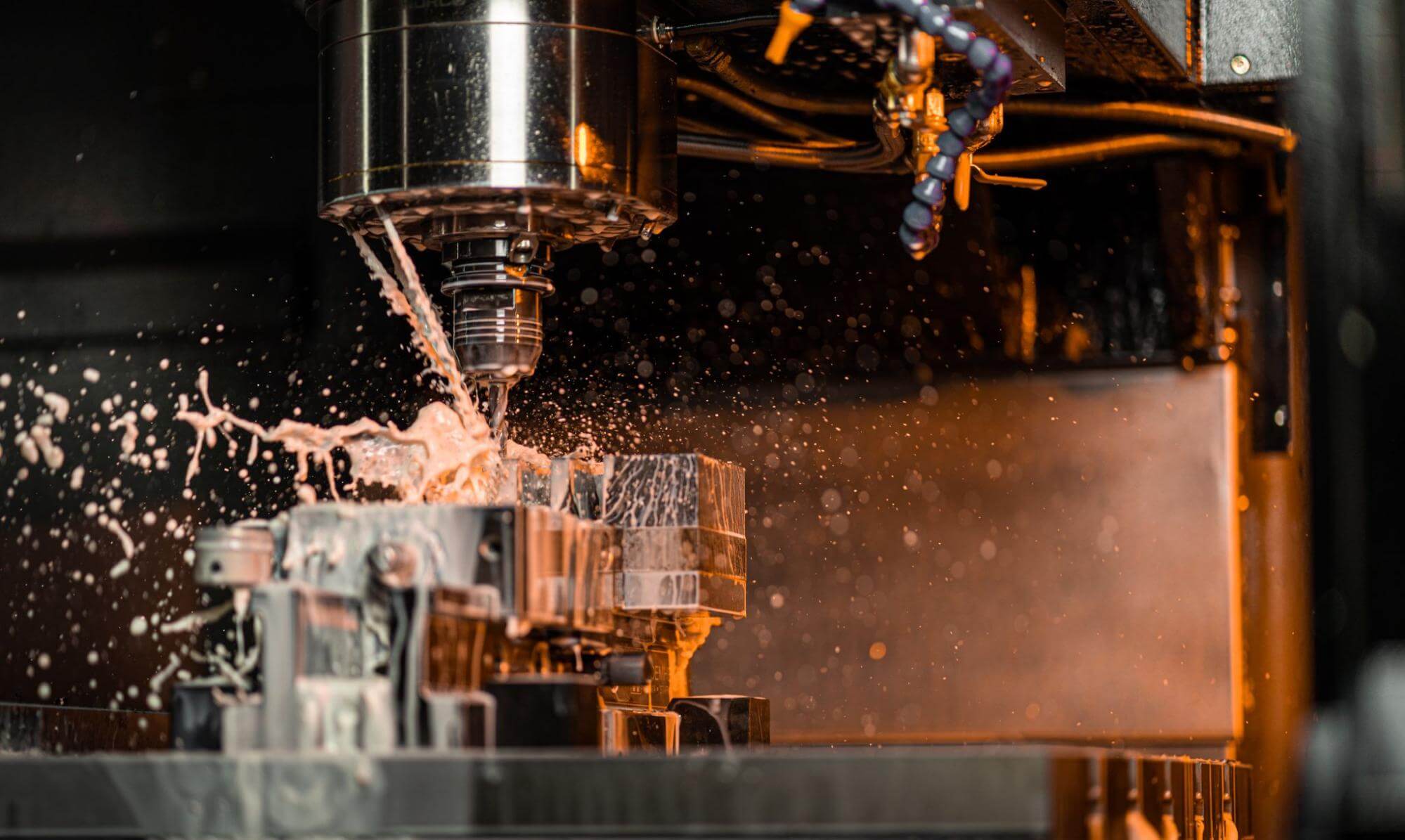

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for industries demanding precision, reliability, and repeatability. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining platform, enabling us to produce complex, high-integrity components with exceptional accuracy. These multi-axis systems allow simultaneous machining from five different directions, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is particularly critical when producing FDM (Functional Dimensional Metal) parts, where geometric complexity, tight tolerances, and surface integrity are paramount.

Our 5-axis CNC machines are equipped with high-speed spindles, dynamic tool compensation, and real-time monitoring systems, ensuring consistent material removal rates and dimensional stability across diverse alloys. We routinely work with aerospace-grade aluminum, stainless steel, titanium, and high-temperature superalloys, adapting cutting strategies to maintain part integrity and surface finish. The integration of advanced CAM software allows for optimized toolpaths, minimizing cycle time while maximizing precision and tool life.

To ensure every component meets exacting specifications, we employ a rigorous quality control protocol anchored by CMM (Coordinate Measuring Machine) inspection. Each FDM part undergoes comprehensive dimensional verification using Zeiss and Hexagon CMM systems, providing micron-level measurement accuracy across complex geometries. Our inspection process includes first-article inspection (FAI), in-process checks, and final certification, with full traceability and detailed inspection reports available upon request. This systematic approach ensures compliance with ISO 9001 standards and industry-specific requirements such as AS9100 for aerospace applications.

Our commitment to precision is reflected in the tolerances we consistently achieve. Below is a summary of our standard and precision machining capabilities.

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 500 mm length |

| Diameter Tolerance | ±0.03 mm | ±0.005 mm | Internal and external |

| Positional Tolerance | ±0.05 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.05 mm per 100 mm | 0.01 mm per 100 mm | Measured via CMM |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | Achieved with fine finishing passes |

| Angular Tolerance | ±0.1° | ±0.05° | Critical for mating surfaces |

These tolerances are not theoretical benchmarks—they are routinely achieved across production batches, supported by environmental controls, calibrated tooling, and operator expertise. Our technical team collaborates closely with clients during the design-for-manufacturability phase, offering feedback on geometry, material selection, and tolerance stack-up to ensure optimal outcomes.

At Wuxi Lead Precision Machinery, our 5-axis CNC capabilities combined with metrology-grade inspection form the foundation of our reputation for delivering mission-critical metal components that perform under the most demanding conditions.

Material & Finish Options

Material Selection for Precision Metal Components: Beyond FDM Limitations

Wuxi Lead Precision Machinery specializes in high-integrity CNC-machined metal components, not FDM (Fused Deposition Modeling) plastic parts. FDM processes are unsuitable for demanding metal applications requiring precision, strength, and thermal stability. For critical metal parts, material selection is foundational to performance, longevity, and cost-efficiency. Our engineering team prioritizes matching material properties to your specific operational environment and functional requirements. Aluminum, steel, and titanium represent core solutions for aerospace, medical, and industrial sectors where failure is not an option.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications needing an optimal strength-to-weight ratio and excellent thermal/electrical conductivity. They machine efficiently, reducing lead times and costs for complex geometries. While inherently corrosion-resistant, anodizing significantly enhances surface hardness and wear resistance for components exposed to abrasion or harsh environments. Aluminum excels in structural brackets, heat sinks, and non-ferrous housings.

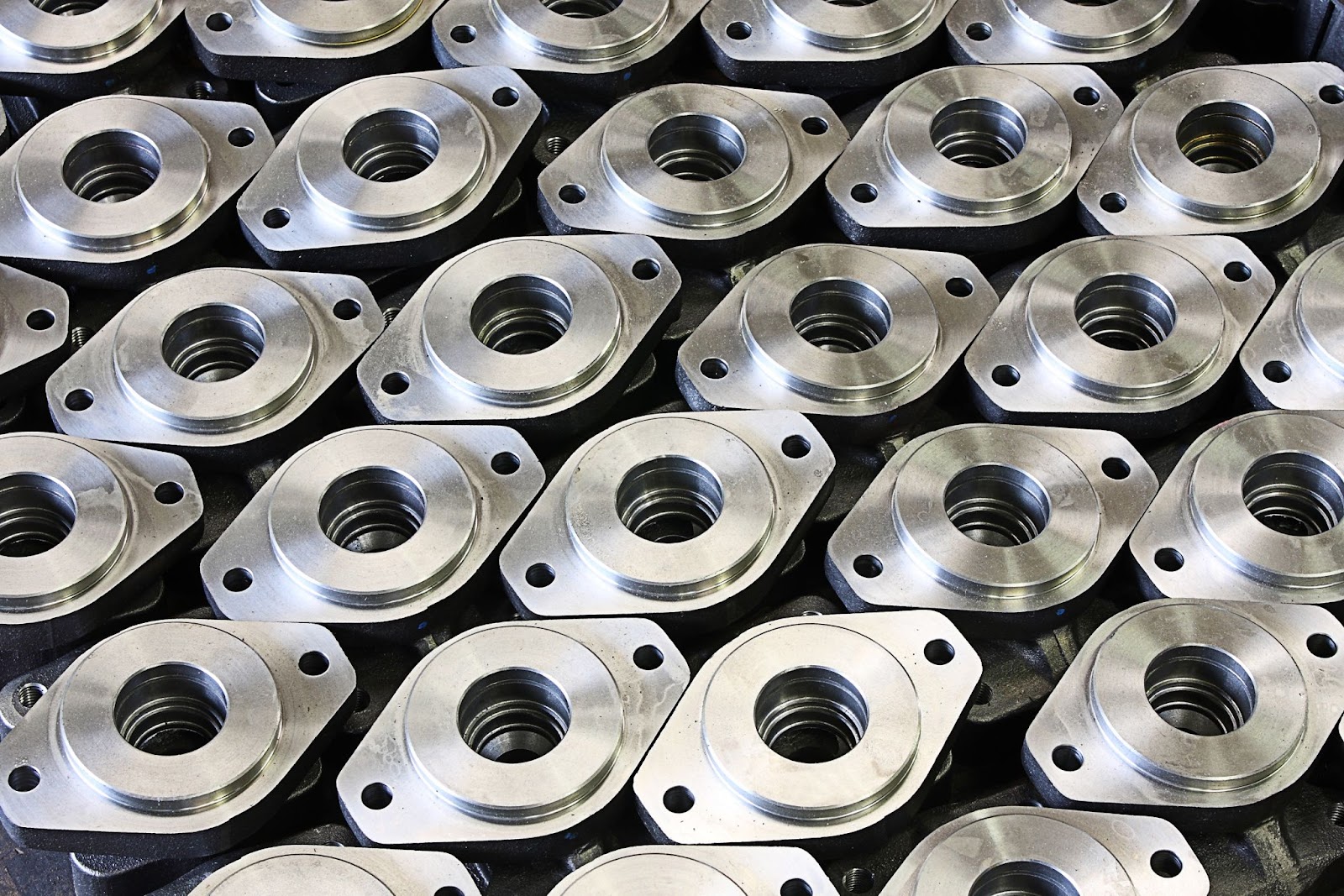

Carbon and stainless steels (e.g., 4140, 17-4 PH, 304, 316) deliver superior tensile strength, hardness, and wear resistance essential for high-load applications like shafts, gears, and tooling. Stainless variants provide critical corrosion resistance in medical or marine settings. Machinability varies significantly; free-machining grades improve throughput, while high-strength alloys require specialized tooling and processes. Steel components often benefit from post-machining treatments like nitriding or passivation alongside precision grinding.

Titanium (primarily Grade 5, Ti-6Al-4V) is the premium choice for extreme strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. It withstands high temperatures and aggressive chemicals, making it indispensable for aerospace actuators, medical implants, and deep-sea components. However, titanium’s low thermal conductivity and chemical reactivity demand meticulous CNC programming, rigid setups, and dedicated toolpaths to prevent work hardening and ensure dimensional accuracy. Cost and machining complexity are higher, justified only by mission-critical performance needs.

Anodizing: Essential Surface Enhancement for Aluminum

While not applicable to steel or titanium in the same manner, anodizing is a vital post-process for aluminum components. This electrochemical conversion creates a dense, non-conductive oxide layer integral to the base metal. Hard anodizing (Type III) achieves thicknesses of 25-50+ µm, dramatically improving surface hardness (up to 600 HV), wear resistance, and corrosion protection compared to standard decorative anodizing (Type II). It also provides an excellent base for adhesives and seals. Wuxi Lead offers precision-controlled anodizing with tight thickness tolerances and consistent coloration for functional and aesthetic requirements.

Selecting the optimal material requires balancing mechanical demands, environmental exposure, regulatory constraints, and total cost of ownership. Our engineering team collaborates closely with clients during the design phase to evaluate trade-offs and recommend the most efficient manufacturing path. Do not compromise performance with inappropriate processes like FDM for metal applications. Partner with Wuxi Lead for material science expertise applied through precision CNC machining and finishing.

| Material Family | Key Alloys | Strength-to-Weight | Corrosion Resistance | Machinability Rating | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | Excellent | Good (Anodized: V.Good) | Excellent | Brackets, Housings, Heat Sinks, Drones |

| Steel | 4140, 17-4 PH | Good | Fair (SS: Excellent) | Moderate to Good | Shafts, Gears, Tooling, Hydraulic Parts |

| Titanium | Ti-6Al-4V (Gr5) | Exceptional | Excellent | Poor | Aerospace Components, Medical Implants |

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for FDM (Fused Deposition Modeling) parts is engineered to deliver precision, repeatability, and zero-defect outcomes across every phase—Design, Prototyping, and Mass Production. As a leader in custom metal manufacturing, we integrate advanced additive methodologies with rigorous quality assurance to ensure that every component meets the exacting standards demanded by aerospace, medical, and industrial automation sectors.

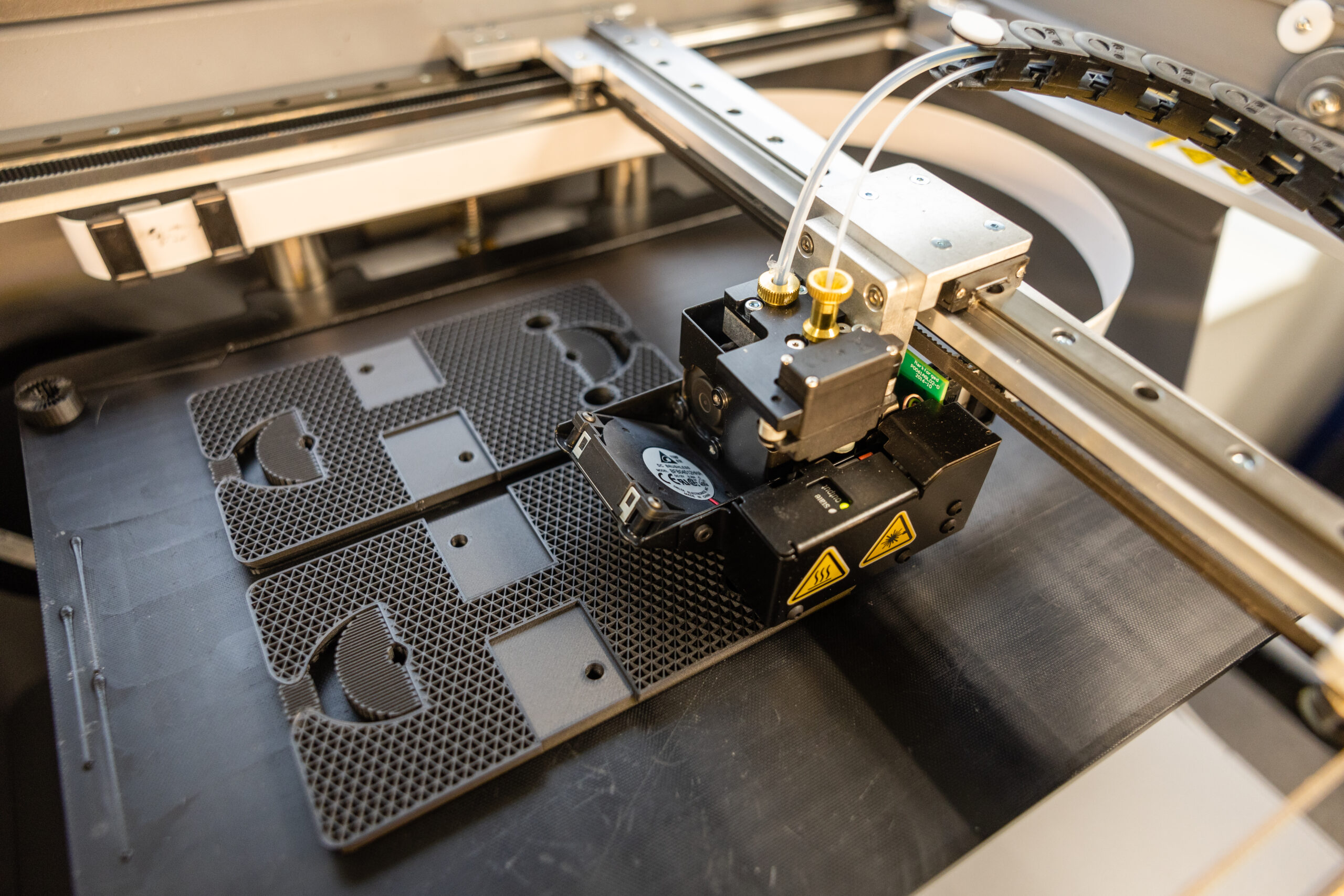

The process begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable digital models. Utilizing CAD software and simulation tools, we evaluate structural integrity, thermal behavior, and material compatibility. This stage includes Design for Manufacturing (DFM) analysis to preemptively resolve potential production challenges. Our engineers ensure optimal geometry, support structure layout, and orientation for FDM printing, maximizing both strength and dimensional accuracy.

Prototyping follows, serving as a critical validation step before scaling to full production. We produce functional prototypes using industrial-grade FDM systems, allowing for real-world testing of fit, form, and function. These prototypes are subjected to mechanical, thermal, and environmental stress tests to verify performance under operational conditions. Any necessary design refinements are implemented at this stage, minimizing risk during mass production. Our rapid prototyping capabilities enable turnaround times as fast as 5 working days, accelerating time-to-market without compromising quality.

Mass Production is executed under tightly controlled conditions, leveraging automated build platforms, climate-regulated chambers, and in-process monitoring systems. Each print job is monitored in real time using layer inspection algorithms and thermal imaging to detect anomalies. Post-processing includes precision machining, heat treatment, surface finishing, and metrology verification using CMM (Coordinate Measuring Machines) and optical scanning. Our production lines operate under ISO 9001-certified protocols, ensuring full traceability and consistency across batches.

To maintain zero-defect standards, we employ a closed-loop quality system. Every component undergoes 100% inspection based on client-specified tolerances. Non-conforming parts are immediately quarantined, and root cause analysis is conducted to prevent recurrence. This proactive approach to quality management ensures that only fully compliant parts are delivered.

The following table outlines key technical specifications for our FDM production process:

| Parameter | Specification |

|---|---|

| Layer Resolution | 0.08 mm – 0.33 mm |

| Build Envelope | Up to 900 x 600 x 900 mm |

| Dimensional Tolerance | ±0.1 mm (standard), ±0.05 mm (precision) |

| Material Options | ULTEM™ 9085, ABS-M30, PC-ISO, Nylon 12 |

| Surface Roughness (Ra) | 6.3 – 12.5 µm (as-printed), down to 1.6 µm (finished) |

| Post-Processing | CNC Machining, Vapor Smoothing, Bead Blasting, Anodizing |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace compliance) |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures that every FDM part is manufactured with uncompromising precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components

At Wuxi Lead Precision Machinery, we engineer solutions where precision is non-negotiable. While FDM (Fused Deposition Modeling) serves prototyping needs in plastics, your high-stakes industrial applications demand the strength, thermal stability, and longevity only custom metal manufacturing delivers. We specialize in transforming complex metal part designs into reality through advanced CNC milling, turning, grinding, and multi-axis machining. Our ISO 9001-certified facility in Wuxi, China, operates under stringent quality protocols to ensure every component meets aerospace, medical, and energy sector tolerances. Partnering with us mitigates supply chain volatility while guaranteeing repeatability you cannot afford to compromise.

We understand your end products face extreme operational stresses. Our technical team collaborates from initial design review to final inspection, identifying cost-saving optimizations without sacrificing integrity. Whether you require low-volume precision housings or high-volume production runs, our 50+ CNC centers—including 5-axis mills and Swiss-type lathes—deliver micron-level accuracy across challenging materials like titanium, Inconel, and hardened steel. We eliminate the guesswork in metal fabrication through real-time process monitoring and First Article Inspection reports traceable to your specifications.

Technical Capabilities at a Glance

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.001 mm (GD&T compliant) |

| Material Expertise | Aluminum, Stainless Steel, Titanium, Copper Alloys, Inconel, Tool Steels |

| Max Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Typical Lead Time | 10–25 days (including QA documentation) |

Choosing a manufacturing partner is a strategic decision impacting your product lifecycle and reputation. Offshore suppliers often promise cost savings but deliver inconsistent quality, hidden rework costs, and communication delays. At Lead Precision, we assign a dedicated engineering liaison to your account, providing weekly progress updates in your time zone and transparent documentation at every stage. Our zero-defect culture is proven through 98.7% on-time delivery and a 40% reduction in client scrap rates year-over-year.

Do not risk performance-critical applications on generic vendors. Contact our engineering team today to discuss how our metal manufacturing expertise solves your specific challenges. Send your RFQs, CAD files, or technical queries to [email protected]. Include your required tolerances, material grades, and annual volume for a tailored capability assessment within 24 business hours. Let us prove why global leaders in fluid control, robotics, and power generation trust Lead Precision as their metal fabrication partner. Your next breakthrough component starts with an email. Reach out now.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.