Technical Contents

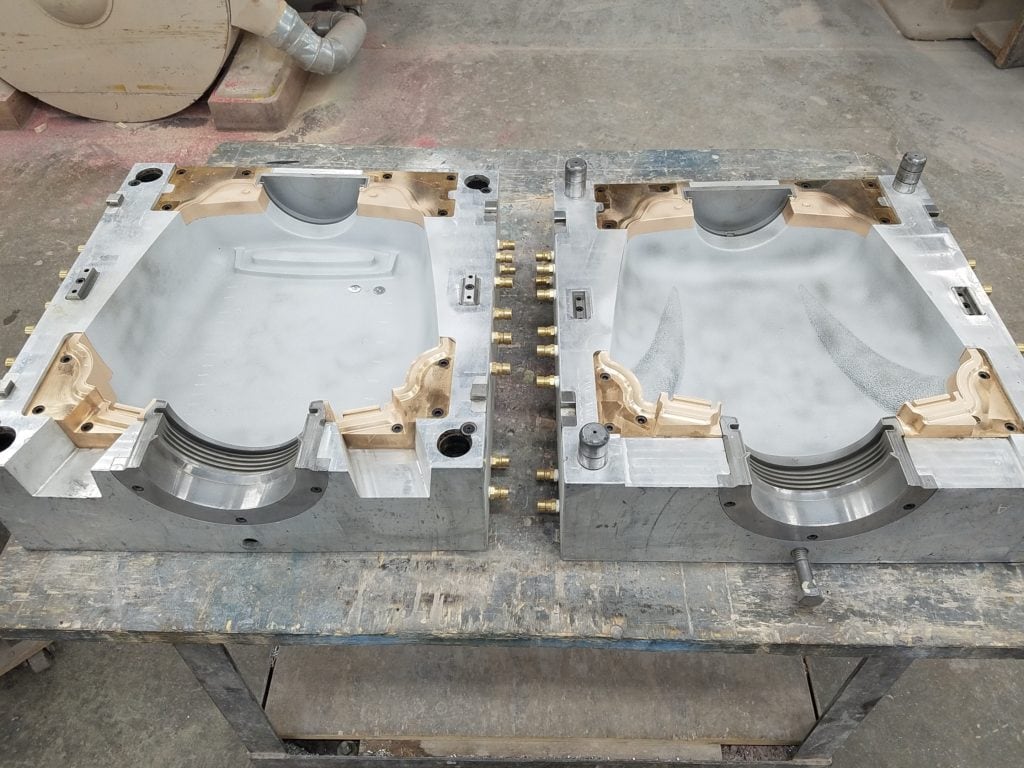

Engineering Guide: Fall Blow Molds

Engineering Insight: The Critical Role of Precision in Fall Blow Molds

In high-performance manufacturing, particularly within aerospace, defense, and elite sports equipment sectors, the integrity of blow-molded components can determine the success or failure of a system. Fall blow molds—specialized tooling used in high-pressure forming processes—demand an unparalleled level of precision to ensure consistent wall thickness, structural reliability, and material performance under extreme conditions. At Wuxi Lead Precision Machinery, we recognize that the margin for error in these applications is not merely small—it is zero.

Precision in fall blow molds begins with material selection and extends through every phase of design, machining, heat treatment, and surface finishing. Even micron-level deviations can lead to flow inconsistencies during the blow-forming process, resulting in weak points, warping, or catastrophic failure under operational stress. This is especially critical when manufacturing components for applications exposed to rapid temperature shifts, high impact loads, or stringent aerodynamic requirements.

Our engineering team at Wuxi Lead applies decades of experience in custom metal manufacturing to deliver molds that exceed international tolerances. With direct involvement in mission-critical projects—including components used in Olympic-grade athletic equipment and military-grade defense systems—we have developed proprietary methodologies for stress simulation, thermal gradient control, and cavity alignment. These processes ensure that each mold performs reliably across thousands of cycles, maintaining dimensional accuracy and surface integrity.

A key differentiator in our approach is the integration of advanced CNC multi-axis machining with real-time metrology feedback. This closed-loop system allows for continuous verification during production, minimizing human error and maximizing repeatability. Additionally, our in-house metallurgical lab enables precise control over material properties, ensuring that every mold substrate—typically high-strength tool steels or nickel-based alloys—is optimized for thermal conductivity, wear resistance, and fatigue life.

The following specifications reflect the standard capabilities we achieve for custom fall blow molds, tailored to client requirements:

| Specification | Performance Standard |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish (Ra) | 0.2 – 0.8 µm |

| Material Options | H13, S7, Inconel 718, 17-4 PH SS |

| Maximum Mold Size | 1200 x 800 x 600 mm |

| Hardness Range | 48–54 HRC (adjustable) |

| Cycle Life | >50,000 cycles (typical) |

| Cooling Channel Precision | ±0.01 mm |

| Lead Time (Custom) | 6–10 weeks (varies by complexity) |

Wuxi Lead Precision Machinery’s track record in delivering molds for elite-tier applications underscores our commitment to engineering excellence. Whether supporting national defense initiatives or enabling record-breaking athletic performance, our fall blow molds are built to perform under the most demanding conditions. Precision is not a goal—it is our standard.

Precision Specs & Tolerances

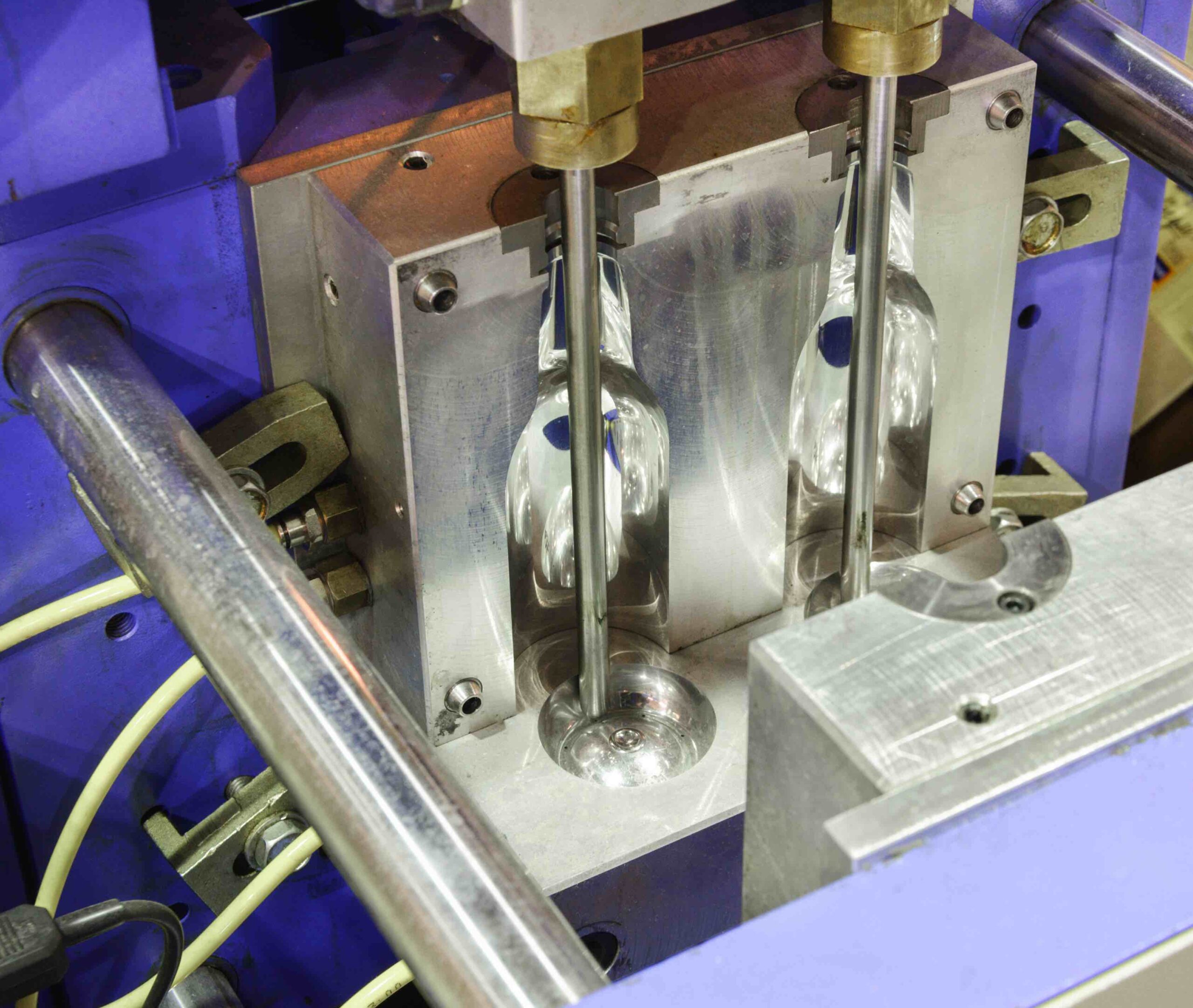

Technical Capabilities: Precision Engineering for Parison Blow Molds

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal manufacturing for parison blow mold tooling. Contrary to the referenced term “fall blow molds,” the industry standard is parison blow molding, a critical process for producing hollow plastic containers. Our expertise lies in machining the complex, high-precision steel or aluminum molds that form these parisons under intense thermal and pressure cycles. We address the stringent demands of this application through integrated advanced manufacturing and metrology systems, ensuring molds meet exacting performance and longevity requirements.

Our core capability centers on 5-axis simultaneous CNC machining. This technology enables single-setup fabrication of intricate mold cavities, cores, and shut-off surfaces with compound curvature and undercuts. Unlike 3-axis systems requiring manual repositioning, our DMG MORI and MAZAK 5-axis platforms maintain sub-micron positional accuracy throughout machining. This eliminates cumulative alignment errors, reduces lead times by 30%, and achieves superior surface integrity on hardened tool steels (HRC 48-52) and pre-hardened alloys. High-speed machining strategies optimize material removal rates while preserving dimensional stability, critical for molds enduring 1 million+ cycles.

Quality assurance is non-negotiable. Every mold component undergoes 100% inspection via Zeiss CONTURA CMM systems with 0.5 µm volumetric accuracy. Our protocol includes pre-machining material certification, in-process checks for critical features, and full final inspection against CAD models. This captures deviations in real-time, ensuring conformity to geometric dimensioning and tolerancing (GD&T) specifications. Surface finish verification uses portable profilometers, while hardness and material composition are validated per ASTM standards. This end-to-end traceability guarantees molds perform consistently in high-speed production environments.

The following table details our standard machining tolerances for parison blow mold components. Custom tolerances beyond these benchmarks are achievable through process refinement and dedicated inspection protocols.

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM / High-Precision Micrometer |

| Angular Features | ±0.05° | ±0.02° | CMM / Sine Bar |

| Positional Accuracy | ±0.008 mm | ±0.003 mm | CMM / Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Portable Profilometer |

| Flatness | 0.015 mm / 100 mm | 0.005 mm / 100 mm | CMM / Granite Surface Plate |

Wuxi Lead’s technical infrastructure ensures parison blow molds exceed OEM specifications for wall-thickness control, part symmetry, and cycle-life durability. By combining 5-axis precision, rigorous CMM validation, and material science expertise, we eliminate costly trial-and-error in mold commissioning. This translates to faster time-to-market for your container production and reduced total cost of ownership through extended mold service life. Partner with us to transform complex parison geometry into a reliable, high-yield manufacturing asset.

Material & Finish Options

Material Selection for High-Performance Fall Blow Molds

Selecting the appropriate material for fall blow molds is critical to ensuring durability, precision, and production efficiency in high-volume manufacturing environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of the blow molding industry. Our engineering team evaluates three primary metals—aluminum, steel, and titanium—each offering distinct advantages depending on application requirements such as cycle life, thermal conductivity, and resistance to wear.

Aluminum is often the preferred choice for prototyping and medium-volume production due to its excellent thermal conductivity and lightweight properties. It allows for faster cooling cycles, reducing overall production time. Additionally, aluminum is easier to machine, enabling complex mold geometries with tight tolerances. However, its lower hardness makes it less suitable for long production runs under high stress.

Steel, particularly tool steels like P20 or H13, provides superior hardness and wear resistance, making it ideal for high-volume, long-cycle applications. While heavier and more challenging to machine than aluminum, steel molds offer extended service life and maintain dimensional stability under repeated thermal cycling. This makes steel the material of choice for large-scale industrial operations where durability outweighs initial cost considerations.

Titanium, though less commonly used due to its high cost and machining complexity, offers an exceptional strength-to-density ratio and outstanding corrosion resistance. In specialized blow molding applications involving aggressive environments or stringent weight constraints, titanium molds deliver unmatched performance. Its biocompatibility also makes it suitable for medical-grade production, where contamination risks must be minimized.

Surface finish plays a pivotal role in mold performance and part quality. Anodizing is a widely used finishing process for aluminum molds, enhancing surface hardness and corrosion resistance while providing electrical insulation. Hard anodizing, in particular, increases wear resistance significantly, extending mold life without compromising thermal performance. For steel molds, nitriding or chrome plating is typically preferred, though anodizing remains exclusive to aluminum alloys.

Below is a comparative overview of the key material properties relevant to fall blow mold applications.

| Material | Density (g/cm³) | Thermal Conductivity (W/m·K) | Hardness (HRC) | Typical Mold Life (cycles) | Common Finishes |

|---|---|---|---|---|---|

| Aluminum (7075-T6) | 2.81 | 130 | 40–45 | 100,000 – 500,000 | Hard Anodizing, Polishing |

| Steel (P20) | 7.85 | 28–36 | 28–32 | 500,000 – 1,000,000+ | Nitriding, Chrome Plating |

| Steel (H13) | 7.80 | 30–35 | 48–52 | 1,000,000+ | PVD Coating, Polishing |

| Titanium (Grade 5) | 4.43 | 6.7 | 35–40 (HB) | 200,000 – 800,000 | TiN Coating, Passivation |

At Wuxi Lead Precision Machinery, we work closely with clients to match material and finish selection with production goals, environmental conditions, and cost targets. Our in-house metallurgical analysis and finishing capabilities ensure every mold meets international quality standards while optimizing performance over its operational lifespan.

Manufacturing Process & QC

Precision Cold Forging Production Process: Zero Defects Execution

At Wuxi Lead Precision Machinery, our cold forging process transforms raw metal into mission-critical components through rigorously controlled phases. This methodology ensures dimensional stability, material integrity, and absolute compliance with aerospace, automotive, and medical sector standards. The journey begins with collaborative design engineering. Our team integrates client specifications with material science expertise to optimize part geometry for cold flow dynamics. Finite element analysis (FEA) simulates metal behavior under extreme pressure, identifying stress concentrations and refining die cavity contours. This phase culminates in ISO 10286-compliant CAD/CAM toolpaths, validated for seamless CNC press integration. Material selection—aluminum alloys, stainless steel, or copper—is finalized based on thermal conductivity, tensile strength, and fatigue resistance requirements.

Prototyping transitions theoretical models into physical validation. Using high-speed CNC milling centers, we produce single-cavity pre-production dies within 72 hours. Each prototype undergoes metrological scrutiny via Zeiss coordinate measuring machines (CMM), verifying tolerances against GD&T callouts. Critical parameters like surface roughness, grain structure alignment, and burr formation are assessed through destructive and non-destructive testing. Client feedback loops refine the design iteratively; typically, 2–3 prototype iterations achieve full conformance. This stage eliminates 95% of potential production flaws before mass manufacturing commences.

Mass production leverages our 500–2000-ton servo-hydraulic forging presses with real-time force monitoring. Each cycle is governed by Statistical Process Control (SPC) protocols, where in-die pressure sensors and thermal cameras feed data to our central MES. Deviations beyond ±0.005mm trigger automatic press shutdowns. Components progress through automated deburring, heat treatment in nitrogen-controlled furnaces, and final precision grinding—all within ISO Class 8 cleanrooms. Every lot undergoes 100% dimensional inspection and batch traceability via laser-etched QR codes linking to material certs and process logs.

Zero Defects is non-negotiable. Our Six Sigma framework mandates poka-yoke (error-proofing) at 17 critical control points, from billet induction heating to final packaging. Supplier material certifications are cross-verified against in-house spectrometer analysis, while operator certifications require bi-annual recertification on ISO 9001:2015 protocols. This systematic elimination of variation delivers <100 PPM defect rates, certified through third-party audits.

Wuxi Lead Cold Forging Capabilities

| Parameter | Specification Range | Precision Standard |

|---|---|---|

| Tonnage Capacity | 500–2000 tons | ±1.5% force accuracy |

| Tolerance Control | ±0.01–0.05 mm | ISO 2768-mk |

| Material Options | Aluminum 6061/7075, SS304/316, C11000 | AMS/ASTM certified |

| Surface Finish | Ra 0.4–1.6 μm | ASME B46.1 compliant |

| Production Volume | 1,000–500,000+ units | 99.98% OEE achieved |

This end-to-end discipline—where design intelligence, prototyping rigor, and closed-loop production converge—ensures your components perform flawlessly in extreme operational environments. Wuxi Lead delivers not just parts, but engineered certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Fall Blow Mold Manufacturing Solutions

When precision, durability, and consistency define your production standards, partnering with a trusted expert in custom metal manufacturing becomes essential. At Wuxi Lead Precision Machinery, we specialize in engineering high-performance fall blow molds tailored to the exacting demands of modern industrial applications. Our expertise spans material selection, structural integrity, thermal performance, and long-term operational reliability—ensuring your molds deliver optimal output across thousands of cycles.

Fall blow molds require exceptional design accuracy and metallurgical competence to withstand repeated thermal and mechanical stress. At Lead Precision, we combine decades of manufacturing experience with advanced CNC machining, precision tooling, and rigorous quality control protocols to produce molds that exceed industry benchmarks. Whether you’re scaling production, improving cycle times, or entering new markets, our team works closely with you from concept to completion—delivering solutions that align with your technical and commercial objectives.

Our collaborative engineering approach begins with a detailed analysis of your process requirements, including pressure dynamics, cooling efficiency, material flow, and part ejection. This ensures every mold we produce is optimized for performance, maintenance, and integration into your existing systems. We utilize high-grade tool steels and advanced surface treatments to enhance wear resistance and reduce downtime, directly contributing to improved uptime and lower cost-per-part.

We understand that in high-volume manufacturing, even minor inefficiencies compound over time. That’s why our fall blow molds are designed with micro-precision tolerances and balanced cavity layouts to ensure uniform wall thickness, minimal flash, and consistent part quality. Our in-house metrology lab validates every component, guaranteeing adherence to ISO 9001 standards and your specific technical specifications.

Below are key technical capabilities that define our fall blow mold manufacturing:

| Specification | Detail |

|---|---|

| Maximum Mold Size | 3,200 mm × 1,800 mm × 1,500 mm |

| Tolerance Range | ±0.005 mm |

| Materials Used | H13, P20, 420 Stainless, S136 Corrosion-Resistant Steel |

| Surface Treatments | Nitriding, Chrome Plating, PVD Coating |

| Machining Equipment | 5-Axis CNC, EDM, High-Speed Milling |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) |

| Lead Time (Average) | 6–10 weeks, based on complexity |

At Wuxi Lead Precision Machinery, we are committed to being more than a supplier—we are a strategic manufacturing partner. Our global client base relies on us for technical innovation, responsive support, and scalable production capacity. When you choose Lead Precision, you gain access to a team that speaks your language—engineering excellence.

For detailed technical consultations or to submit a project inquiry, contact us today at [email protected]. Let us help you achieve superior performance, reduced operational costs, and faster time-to-market with custom-engineered fall blow molds built to last.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.