Technical Contents

Engineering Guide: Fabrication Prototype

Engineering Insight: The Critical Role of Precision in Fabrication Prototyping

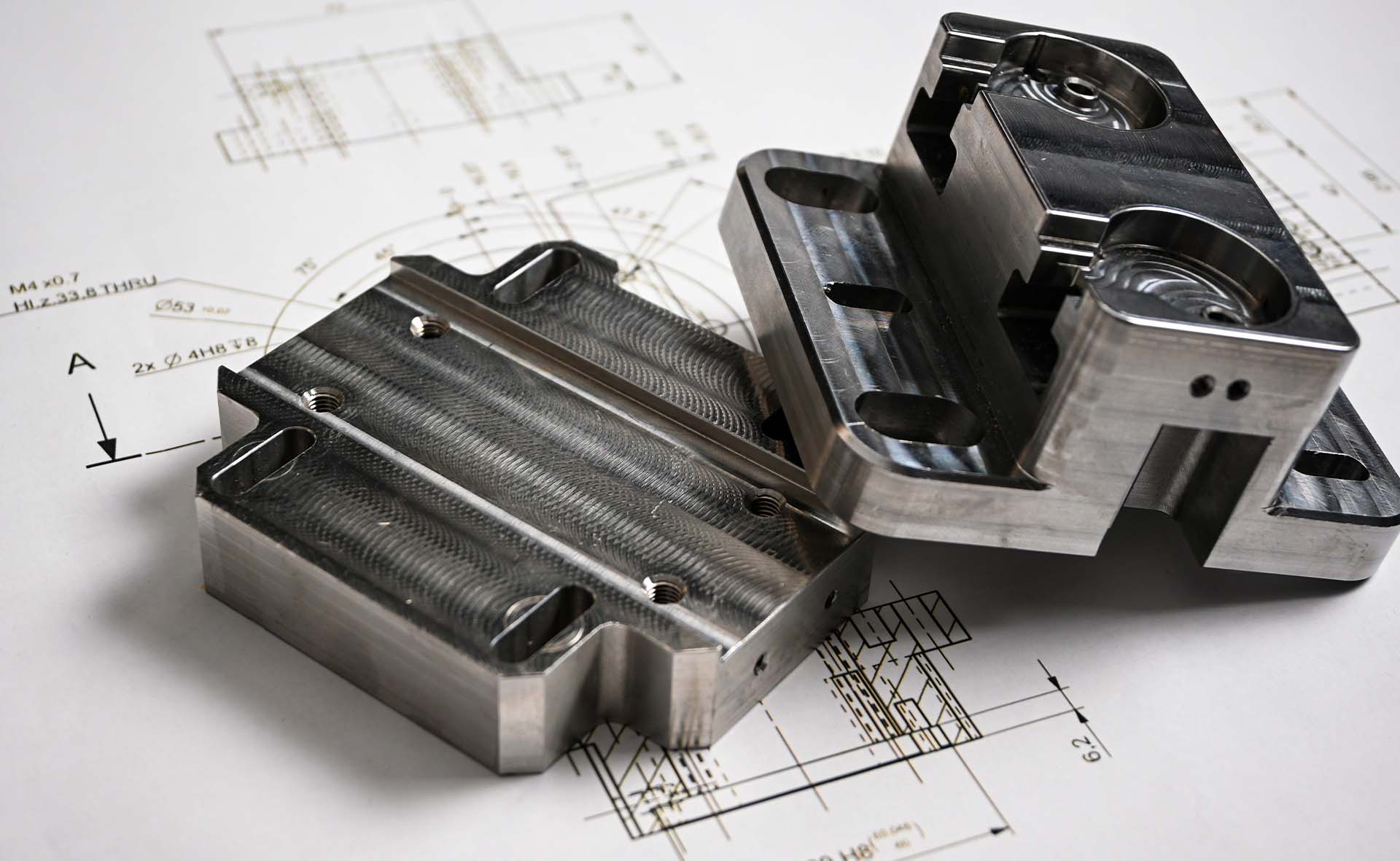

In the realm of sheet metal fabrication, the prototype phase is far more than a preliminary step—it is the foundation upon which product integrity, manufacturability, and long-term success are built. At Wuxi Lead Precision Machinery, we define a fabrication prototype as a fully representative model of a component or assembly, produced using the same materials, tooling, and processes intended for final production. This approach ensures that design assumptions are validated under real-world conditions, minimizing risk during scale-up.

Precision in prototyping is non-negotiable. Even minor deviations in dimensional accuracy, material behavior, or joint integrity can cascade into significant performance issues, especially in high-stakes applications. For industries such as aerospace, defense, and advanced industrial equipment, where components face extreme loads, thermal cycles, and safety-critical operations, tolerances measured in tenths of a millimeter directly influence reliability and compliance. Our engineering team emphasizes tight process control from the outset—leveraging CNC punching, laser cutting, press braking, and robotic welding systems calibrated to maintain ±0.1 mm dimensional accuracy across all prototype builds.

Wuxi Lead’s expertise in precision prototyping is proven through our contributions to projects demanding the highest levels of quality and traceability. We have supported components for Olympic-grade timing and sensor systems, where mechanical consistency impacts global competition outcomes. Additionally, our facility has fulfilled military-grade fabrication requirements, adhering to stringent documentation, material certification, and inspection protocols required for defense applications. These experiences have refined our ability to deliver prototypes that not only meet but exceed functional expectations.

Our prototyping workflow integrates Design for Manufacturability (DFM) analysis at the earliest stages, allowing us to identify potential issues in form, fit, and assembly before metal is cut. This proactive engineering review reduces iteration cycles, accelerates time-to-market, and ensures that the transition from prototype to volume production is seamless. By utilizing advanced 3D modeling and simulation tools, we validate bend allowances, weld distortions, and assembly sequences digitally, further enhancing first-time accuracy.

Each prototype is subject to rigorous in-process and final inspection using coordinate measuring machines (CMM) and laser scanning, ensuring full compliance with customer specifications. Material traceability, surface finish control, and weld integrity are documented and reported, providing complete transparency for engineering validation.

Below are key technical capabilities that define our fabrication prototyping services:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 10 mm |

| Dimensional Tolerance | ±0.1 mm |

| Laser Cutting Accuracy | ±0.05 mm |

| Press Brake Bending Tolerance | ±0.2° |

| Supported Materials | Cold-rolled steel, stainless steel, aluminum, copper, brass |

| Max Prototype Panel Size | 3000 mm × 1500 mm |

| Welding Processes | TIG, MIG, Spot Welding (with certified welders) |

| Quality Standards | ISO 9001, ISO 14001, GB/T 19001 |

At Wuxi Lead Precision Machinery, we treat every prototype as a promise—an assurance that the final product will perform exactly as intended. Precision is not an add-on; it is engineered into every process, component, and collaboration.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication for Prototyping

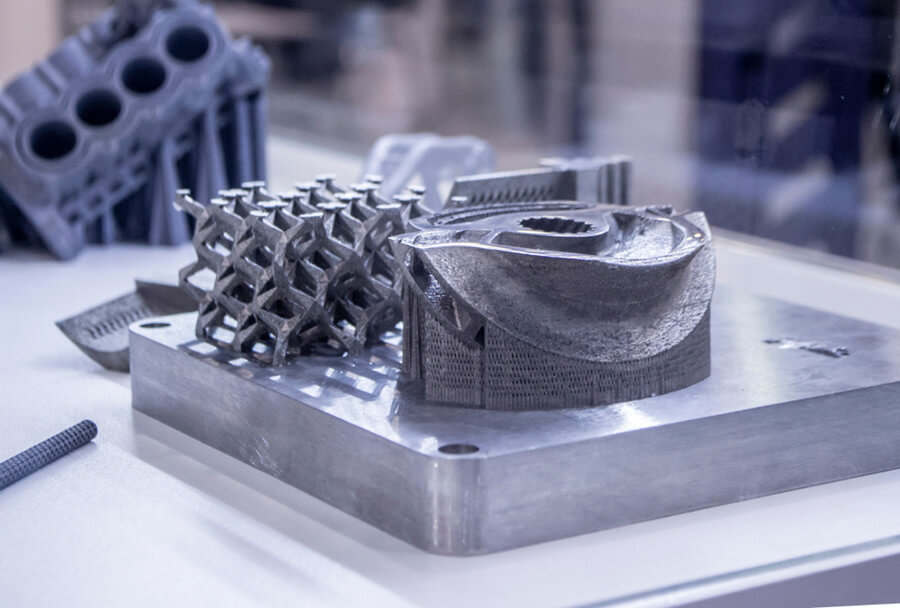

Wuxi Lead Precision Machinery delivers uncompromising accuracy in sheet metal fabrication prototyping through advanced 5-axis CNC machining and rigorous quality control. Our integrated manufacturing ecosystem ensures prototypes meet exacting engineering specifications while accelerating time-to-market for aerospace, medical, and industrial clients. Unlike conventional 3-axis systems, our 5-axis CNC platforms eliminate repositioning errors by machining complex geometries in a single setup. This capability is critical for prototypes requiring undercuts, organic contours, or multi-faceted features—common in fluid dynamics housings, surgical instrument frames, and robotics enclosures. High-speed spindles (24,000 RPM) paired with Renishaw probing systems maintain ±0.005 mm positional accuracy across aluminum, stainless steel, titanium, and copper alloys up to 6 mm thickness. Material efficiency is maximized through dynamic toolpath optimization, reducing waste by 18% compared to traditional methods.

Quality validation begins at the design phase with our DFM analysis and culminates in certified dimensional verification. Every prototype undergoes 100% CMM inspection using Zeiss CONTURA systems calibrated to ISO 17025 standards. Our metrology lab captures full 3D point clouds against CAD models, generating AS9102-compliant First Article Inspection reports with GD&T analysis. Surface roughness is quantified via Mitutoyo profilometers, ensuring Ra values as low as 0.4 µm for critical sealing surfaces. Statistical process control (SPC) monitors feature drift in real-time, with corrective actions triggered at 75% of tolerance limits—preventing non-conformances before they occur.

Tolerances achieved reflect our commitment to engineering excellence. The following table details standard and tight-tolerance capabilities for sheet metal prototypes:

| Feature | Standard Tolerance | Tight Tolerance | Applicable Standards |

|---|---|---|---|

| Linear Dimensions | ±0.10 mm | ±0.025 mm | ISO 2768-mK |

| Hole Diameter | ±0.05 mm | ±0.01 mm | ISO 286-2 (H7) |

| Hole Position | ±0.10 mm | ±0.03 mm | ISO 1101 |

| Bend Angle | ±0.5° | ±0.2° | ISO 2768-f |

| Flatness (per 100 mm) | 0.10 mm | 0.03 mm | ISO 2768-2 |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | ISO 1302 |

These specifications apply to materials including 5052/6061-T6 aluminum, 304/316 stainless steel, and 1018 cold-rolled steel. For exotic alloys like Inconel 718 or beryllium copper, we implement specialized fixturing and thermal compensation protocols to maintain ±0.008 mm repeatability. Our engineers collaborate with clients during tolerance allocation to balance performance requirements with prototyping speed—typically delivering fully validated parts within 72 hours of CAD approval. This precision foundation ensures prototypes function as true representations of final production intent, de-risking NPI cycles and eliminating costly design iterations. Partner with Wuxi Lead to transform conceptual designs into metrology-certified physical assets with industrial-grade reliability.

Material & Finish Options

Material Selection for Sheet Metal Fabrication Prototypes

Selecting the appropriate material is critical when developing high-precision sheet metal fabrication prototypes. At Wuxi Lead Precision Machinery, we prioritize material performance, manufacturability, and end-use requirements to ensure optimal results. The most commonly used metals in prototype fabrication are aluminum, steel, and titanium, each offering distinct mechanical and chemical properties suited to different industrial applications.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for lightweight structural components, aerospace systems, and electronic enclosures. Grade 6061-T6 is particularly popular due to its weldability and moderate strength. For applications requiring enhanced surface durability and aesthetic control, aluminum is often finished with anodizing—a process that electrochemically forms a protective oxide layer. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior wear resistance for high-stress environments.

Steel remains the backbone of industrial fabrication, offering high tensile strength, durability, and cost efficiency. Cold-rolled steel (CRS) and stainless steel (particularly grades 304 and 316) are frequently used. While CRS provides excellent formability and a smooth surface for painting or powder coating, stainless steel delivers inherent corrosion resistance, making it suitable for medical, food processing, and outdoor applications. However, steel’s higher density makes it less ideal for weight-sensitive designs.

Titanium, though more expensive and challenging to process, is unmatched in strength-to-density ratio and resistance to extreme environments. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are commonly used in aerospace, defense, and high-performance automotive prototypes. Its exceptional performance at elevated temperatures and in corrosive media justifies its use in mission-critical components. Titanium’s reactivity during machining requires specialized tooling and expertise, which Wuxi Lead Precision Machinery provides through our advanced CNC and forming capabilities.

Surface finishing plays a pivotal role in both functionality and appearance. Anodizing, primarily applied to aluminum, enhances wear resistance, allows for color coding, and improves adhesion for paint primers. The process is environmentally stable and does not chip or peel under proper application.

Below is a comparative overview of key material properties for prototype fabrication.

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Advantages | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052 | 310 | 2.7 | Lightweight, corrosion resistant, conductive | Anodizing, powder coating |

| Steel | 304, 316, CR1018 | 440–760 | 7.8 | High strength, cost-effective, versatile | Painting, plating, passivation |

| Titanium | Grade 2, Grade 5 | 345–900 | 4.5 | High strength-to-weight, extreme environment resistance | Bead blasting, anodizing (Type II) |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application demands, production scalability, and performance criteria. Our engineering team ensures every prototype meets exacting standards from concept to realization.

Manufacturing Process & QC

Sheet Metal Fabrication Production Process: From Design to Zero Defect Mass Production

Our rigorous production process at Wuxi Lead Precision Machinery transforms conceptual designs into flawless, high-volume sheet metal components. We integrate advanced engineering with stringent quality protocols across three critical phases, ensuring Zero Defects is not merely a goal but an executable standard. This systematic approach minimizes risk, accelerates time-to-market, and guarantees manufacturability at scale.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the initial design phase, utilizing advanced CAD/CAM simulation software to identify potential fabrication challenges. We scrutinize material selection, bend allowances, weld accessibility, and tolerance stack-ups before any metal is cut. This proactive validation prevents costly downstream errors, optimizes material yield, and ensures the design is inherently suited for high-precision, repeatable production. Early DFM intervention is paramount for achieving Zero Defects in subsequent stages.

Prototyping is the indispensable validation step. We fabricate functional prototypes using the exact materials, tooling, and processes planned for mass production. This is not merely a form check; it is a comprehensive performance and process verification. Prototypes undergo rigorous dimensional inspection in our dedicated metrology lab using CMMs and optical comparators, alongside functional testing to confirm fit, assembly, and performance under real-world conditions. Any deviation triggers immediate root cause analysis and process refinement. This phase proves the manufacturability of the design and locks the validated process parameters essential for defect-free scaling.

Transitioning to Mass Production, the validated prototype process becomes the immutable standard. Our integrated manufacturing cells, featuring state-of-the-art CNC punch presses, laser cutters, press brakes, and robotic welding, operate under real-time Statistical Process Control (SPC). Every critical dimension is monitored continuously, with automated feedback loops adjusting machine parameters instantly to maintain tolerances. In-process inspections are statistically validated, not random checks. Final inspection employs AQL sampling plans significantly tighter than industry norms, supported by full traceability records. This closed-loop system, born from the prototype phase, ensures consistent output meeting the exact specifications validated earlier, delivering true Zero Defect production.

The following table outlines key process capabilities enabling this seamless transition and quality assurance:

| Parameter | Capability Range | Quality Control Method |

|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm (Stainless, Al, Steel) | Incoming Material Certification & Verification |

| Tolerance (Form) | ±0.05 mm (Critical Features) | CMM, Optical Comparator, In-Process Gauging |

| Tolerance (Bend) | ±0.5° (Repeatability) | Statistical Process Control (SPC) Monitoring |

| Prototype Lead Time | 5-10 Working Days | Full Dimensional & Functional Validation |

| Mass Production | Scalable from 100 to 100,000+ units | Real-Time SPC, AQL 0.65 Final Inspection |

This disciplined progression—Design validation, prototype verification, and statistically controlled mass production—is the cornerstone of our Zero Defects commitment. Wuxi Lead Precision Machinery provides not just fabrication, but a guaranteed pathway from concept to reliable, high-volume output, eliminating waste and ensuring your product’s success. Partner with us for precision you can measure and depend on.

Why Choose Wuxi Lead Precision

When developing high-performance sheet metal fabrication prototypes, the partnership you choose directly impacts your product’s time to market, reliability, and scalability. At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered fabrication prototypes that meet the exacting standards of aerospace, medical, industrial automation, and advanced electronics industries. Our end-to-end capabilities combine expert engineering insight with state-of-the-art manufacturing technology to transform your concept into a fully functional, production-ready prototype—fast.

Partnering with Lead Precision means gaining access to a team that treats your project as a strategic collaboration. From the initial design review to final prototype delivery, our engineers work closely with your R&D and product teams to optimize manufacturability, material selection, and cost-efficiency. We understand that prototype development is not just about building a part—it’s about validating a concept, identifying potential risks, and accelerating your path to volume production. Our ISO 9001-certified processes, combined with real-time quality control, ensure that every prototype meets tight tolerances and strict compliance requirements.

Our advanced sheet metal fabrication capabilities include high-precision laser cutting, CNC punching, automated bending, robotic welding, and custom finishing. We support a wide range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys, enabling us to match your prototype’s performance needs with the ideal material properties. Whether you require a single prototype or low-volume pilot runs, our flexible production systems adapt to your timeline without sacrificing quality.

Below are key technical specifications that define our fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 12 mm |

| Tolerance (Bending) | ±0.1 mm |

| Laser Cutting Accuracy | ±0.05 mm |

| Max. Part Size | 4000 mm × 2000 mm |

| Supported File Formats | STEP, IGES, DXF, DWG, SolidWorks, PDF |

| Production Lead Time | 7–15 working days (varies by complexity) |

| Surface Finishes Available | Anodizing, Powder Coating, Passivation, Plating |

| Quality Standards | ISO 9001:2015, RoHS, Full First Article Inspection |

We pride ourselves on transparency, responsiveness, and technical excellence. Every client receives a dedicated project manager, detailed progress updates, and comprehensive documentation, including inspection reports and material certifications.

If you’re ready to move from concept to prototype with a partner who combines precision, speed, and engineering depth, contact us today. Send your design files and project requirements to [email protected]. Our engineering team will respond within 12 hours with a feasibility assessment, detailed quote, and recommendations for optimization. At Wuxi Lead Precision Machinery, we don’t just build prototypes—we help bring innovations to life.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.