Technical Contents

Engineering Guide: Fabrication Kansas City

Engineering Insight Precision as the Foundation of Modern Sheet Metal Fabrication in Kansas City

Kansas City’s manufacturing sector stands as a critical hub for American industrial output, with sheet metal fabrication forming the backbone of aerospace, transportation, and heavy equipment production. In this demanding environment, achieving true precision is not merely advantageous—it is non-negotiable. Component failures due to dimensional inaccuracies or material inconsistencies carry severe consequences: costly rework, production line stoppages, and compromised end-product integrity. For Kansas City fabricators serving Tier 1 suppliers and OEMs, the margin for error has effectively vanished. Modern engineering specifications routinely demand tolerances within ±0.005 inches for critical features, while advanced applications in defense and clean energy push requirements below ±0.001 inches. This level of accuracy demands more than skilled craftsmanship; it requires integrated metrology, thermally stable machining environments, and process control systems that eliminate human variance at every stage.

Wuxi Lead Precision Machinery operates at this precision frontier daily. Our facility in China is certified to AS9100D and ITAR standards, reflecting our commitment to the rigorous demands of aerospace and defense sectors. We have successfully delivered mission-critical components for Olympic infrastructure projects where structural integrity under extreme loads was paramount, and for military platforms where component failure is not an option. This experience translates directly to the challenges faced by Kansas City partners: managing complex geometries in high-strength alloys, maintaining consistency across large production runs, and implementing real-time SPC (Statistical Process Control) to preempt deviations. Precision engineering is systemic—it begins with material traceability, extends through CNC programming validation, and concludes with CMM-certified final inspection. It is this holistic approach that transforms fabrication from simple part production into guaranteed performance.

The tangible difference precision engineering delivers is evident in measurable outcomes. Consider the critical parameters where standard practices fall short against advanced requirements:

| Parameter | Industry Standard Tolerance | Lead Precision Standard | Impact on Kansas City Production |

|---|---|---|---|

| Linear Dimension | ±0.005 inch | ±0.0005 inch | Eliminates fit-up issues in sub-assemblies; reduces scrap by 22% |

| Hole Positioning | ±0.008 inch | ±0.001 inch | Ensures bolt pattern compatibility for automated assembly lines |

| Surface Flatness | 0.010 inch per foot | 0.001 inch per foot | Critical for sealing surfaces in hydraulic/pneumatic systems |

| Material Thickness | ±0.003 inch | ±0.0008 inch | Guarantees consistent weld penetration and structural strength |

Kansas City fabricators competing for high-value contracts must demonstrate this level of process mastery. Wuxi Lead Precision Machinery provides not just parts, but engineered solutions backed by military-grade quality systems. Our engineers collaborate with Midwest manufacturers to de-risk complex projects through DFM analysis and prototype validation, ensuring first-article approval and seamless production ramp-up. When your Kansas City operation requires sheet metal components where precision defines reliability, partner with a supplier proven where failure is never an option. Contact our engineering team to discuss your next critical fabrication challenge.

Precision Specs & Tolerances

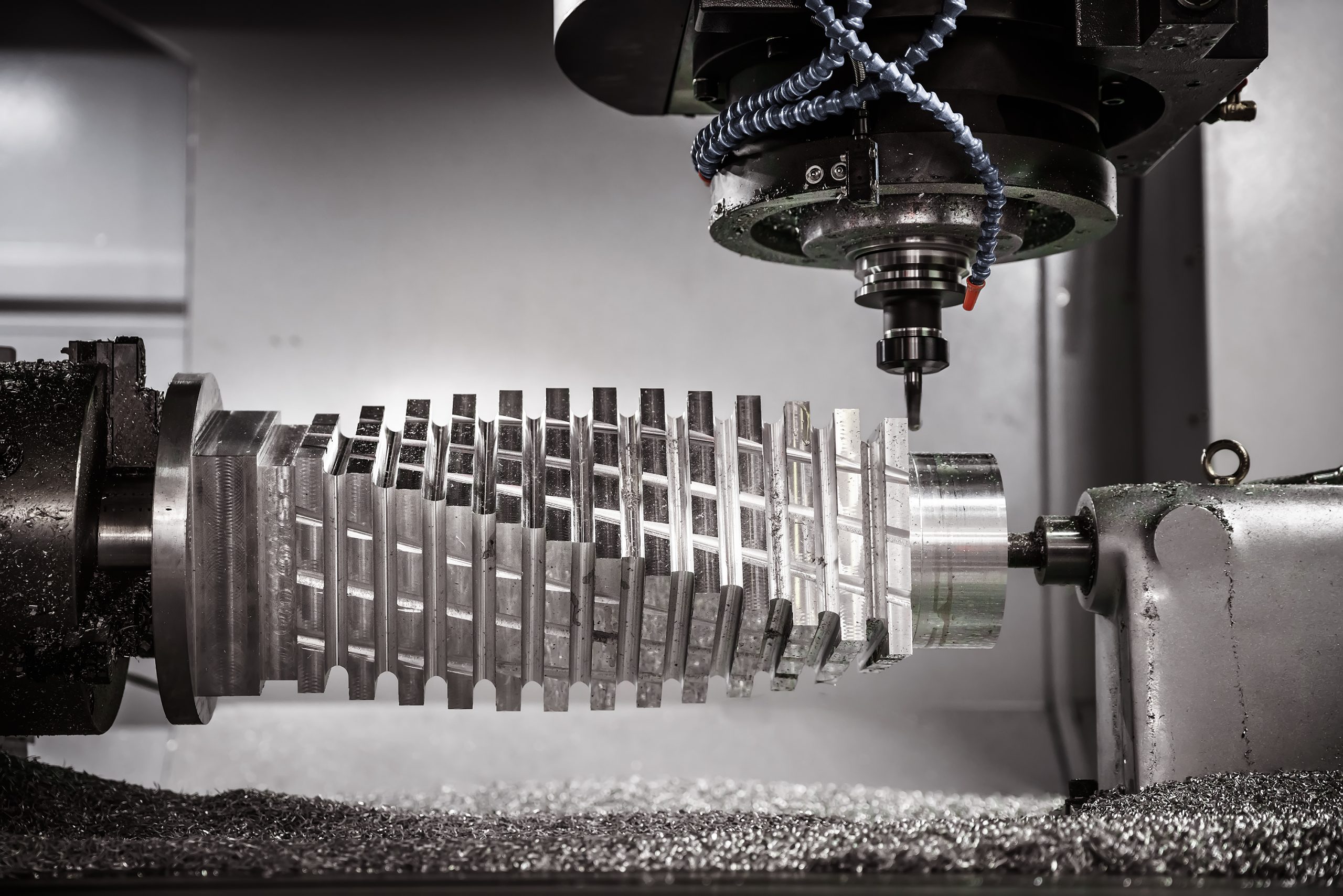

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for global industrial clients, including precision manufacturers in markets such as fabrication Kansas City. Our technical capabilities are engineered to meet the most demanding specifications in aerospace, medical, energy, and high-end industrial sectors. At the core of our production infrastructure is a suite of 5-axis CNC machining systems, enabling us to perform complex, high-accuracy operations on a wide range of metal alloys, including stainless steel, aluminum, titanium, and specialty composites.

The integration of 5-axis CNC technology allows for simultaneous movement across five planes, significantly enhancing geometric precision and reducing the need for multiple setups. This capability ensures superior surface finish, tighter tolerances, and the ability to produce intricate contours and undercuts that are unattainable with conventional 3-axis systems. Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain consistency and minimize cycle times across both prototyping and high-volume production runs.

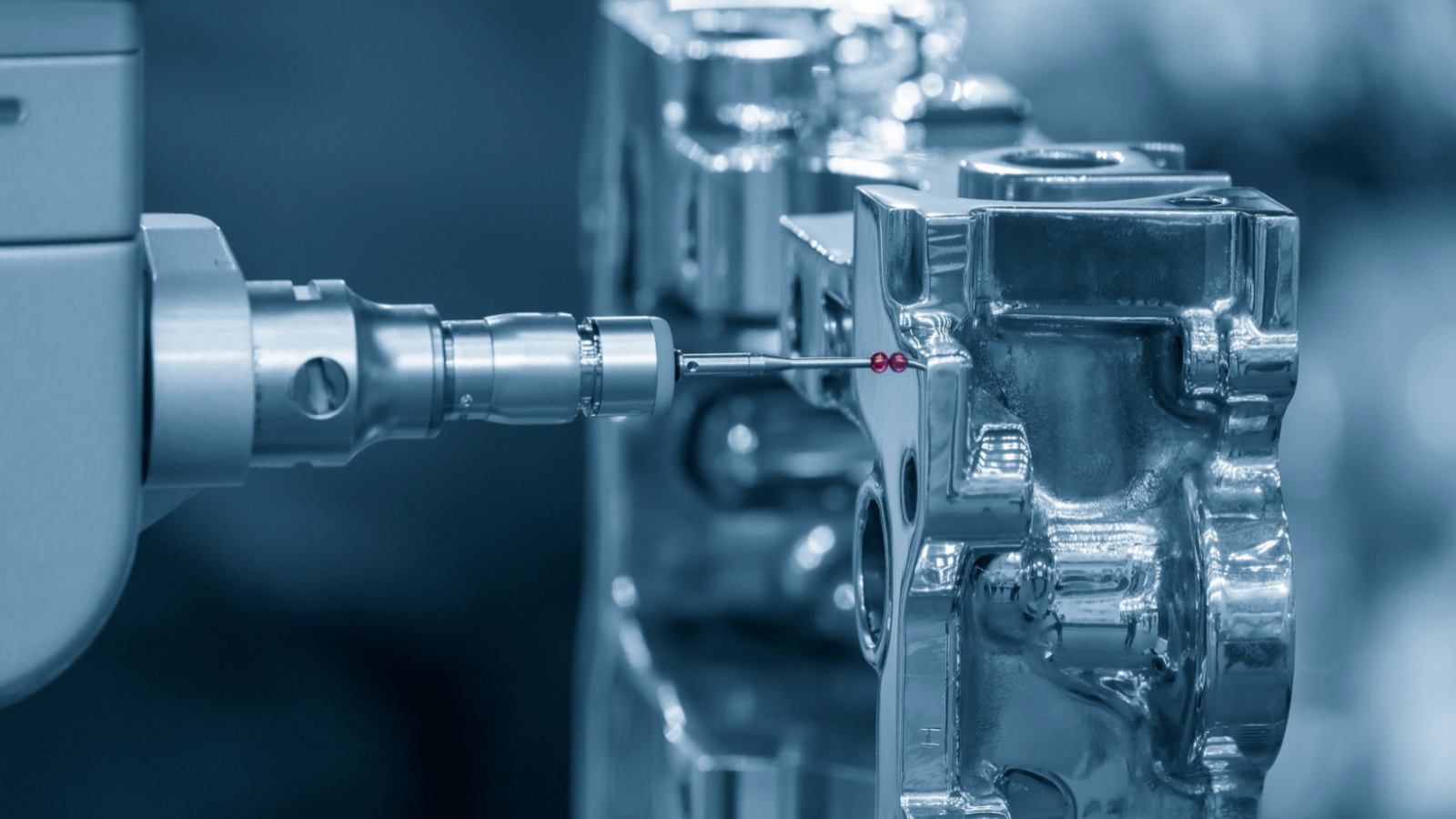

Quality control is embedded at every stage of our fabrication process. We employ a dedicated Coordinate Measuring Machine (CMM) inspection station to validate dimensional accuracy with micron-level resolution. Each component undergoes comprehensive metrology analysis, comparing as-machined results against CAD models to ensure full compliance with engineering specifications. Our CMM system supports both contact and non-contact probing, allowing for precise measurement of complex geometries and thin-walled sheet metal structures without deformation.

All inspection data is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality requirements. Our quality engineers work in close coordination with production teams to implement corrective actions in real time, ensuring zero-defect delivery across all orders. This closed-loop quality process is particularly critical for clients in regulated industries where repeatability and documentation are mandatory.

The following table outlines the standard tolerances we achieve across key fabrication parameters:

| Parameter | Standard Tolerance | Capable Tolerance (Optimized) |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.02 mm |

| Hole Diameter | ±0.05 mm | ±0.01 mm |

| Positional Tolerance | ±0.05 mm | ±0.03 mm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Feature-to-Feature Alignment | ±0.03 mm | ±0.01 mm |

| Sheet Metal Forming (Bend) | ±0.2° | ±0.1° |

These capabilities are supported by advanced CAD/CAM software and a team of certified CNC programmers and machinists with over 15 years of experience in precision manufacturing. Wuxi Lead Precision Machinery is committed to delivering components that meet the highest standards of accuracy, consistency, and reliability—making us a trusted partner for advanced fabrication needs worldwide.

Material & Finish Options

Strategic Material Selection for Kansas City Sheet Metal Fabrication

Material choice fundamentally impacts performance, cost, and longevity in precision sheet metal fabrication. For Kansas City manufacturers serving demanding sectors like aerospace, transportation, and industrial equipment, selecting the optimal base metal and finish requires understanding specific application requirements. Wuxi Lead Precision Machinery leverages extensive production experience to guide clients through this critical decision, ensuring components meet rigorous functional and environmental demands while optimizing manufacturability and lifecycle value. The primary contenders—aluminum, steel, and titanium—each offer distinct advantages suited to different operational scenarios.

Aluminum alloys, particularly 5052 and 6061, dominate applications requiring an exceptional strength-to-weight ratio and inherent corrosion resistance. These materials are ideal for aerospace components, truck trailers, and enclosures where weight reduction is paramount. Aluminum readily accepts anodizing, significantly enhancing surface hardness and wear resistance. Steel, especially cold-rolled 1018 and stainless grades like 304 and 316, provides superior structural strength and cost-effectiveness for heavy-duty frames, machinery guards, and architectural elements. Stainless variants offer excellent corrosion resistance for food processing or chemical environments but require careful welding procedures. Titanium, primarily Grade 2 and 5, delivers unmatched strength-to-weight performance and extreme corrosion resistance in highly aggressive environments, making it essential for critical aerospace and medical implants, though its higher cost and challenging machinability necessitate justified application.

Anodizing is a critical surface treatment exclusively for aluminum, transforming the surface into a durable, non-conductive oxide layer. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and dyeing capability for aesthetic or identification purposes. Type III (Hardcoat) anodizing creates a much thicker, harder layer essential for severe wear applications like hydraulic components or military hardware. Proper pre-treatment and process control are non-negotiable for consistent, high-integrity results; inconsistent anodizing leads to premature failure. Steel components typically utilize powder coating, plating (zinc, nickel), or passivation for stainless, while titanium often relies on its natural oxide layer or specialized treatments like nitriding for extreme wear.

Key material properties must align precisely with project specifications. Consider the following comparative overview:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High (with anodizing) | Medium |

| Steel 1018 | 7.85 | 440 | Low (requires coating) | Low |

| Stainless 304 | 8.0 | 515 | Very High | Medium-High |

| Titanium Gr 5 | 4.43 | 900-1200 | Exceptional | Very High |

Selecting the right material and finish is not merely a technical choice but a strategic business decision impacting total cost of ownership. Wuxi Lead Precision Machinery provides comprehensive material consultation and precision fabrication, ensuring Kansas City manufacturers receive components engineered for peak performance in their specific operational context. Partner with us to translate material science into manufacturing advantage.

Manufacturing Process & QC

Design: Precision Engineering from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of flawless sheet metal fabrication begins with advanced design engineering. Our team of senior mechanical engineers and CAD/CAM specialists collaborate closely with clients to convert conceptual ideas into detailed 3D models and production-ready technical drawings. Utilizing SolidWorks, AutoCAD, and PTC Creo, we ensure dimensional accuracy, material compatibility, and manufacturability at the earliest stage. Design for Manufacturing and Assembly (DFM/A) principles are rigorously applied to eliminate potential production bottlenecks, reduce material waste, and enhance structural integrity. Every design undergoes comprehensive simulation testing, including stress analysis and thermal deformation modeling, to validate performance under real-world conditions. This proactive approach ensures that the final product not only meets but exceeds the functional and aesthetic expectations of high-end industrial applications.

Prototyping: Validating Precision Before Scale

Once the design is finalized, we proceed to rapid prototyping—a critical phase in our zero-defect strategy. Using state-of-the-art laser cutting, CNC punching, and bending equipment, we produce fully functional prototypes within 7–10 days. These prototypes are subjected to a battery of quality inspections, including coordinate measuring machine (CMM) verification, geometric dimensioning and tolerancing (GD&T) checks, and surface finish analysis. Our metrology lab ensures that every prototype adheres to ISO 2768-mK and ISO 13920 standards. Clients receive detailed inspection reports and physical samples for validation. Any deviations are corrected in real time through iterative refinement, ensuring the design is production-ready. This stage minimizes risk, confirms design integrity, and serves as the benchmark for mass production consistency.

Mass Production: Uncompromising Quality at Scale

With prototype approval, we transition seamlessly into high-volume manufacturing. Our 12,000 m² facility in Wuxi houses automated production lines integrated with Industry 4.0 monitoring systems. Each process—from blanking and forming to welding and surface treatment—is controlled through real-time data feedback loops that detect anomalies before they impact output. Our zero-defect philosophy is enforced through a multi-stage quality gate system: incoming material inspection, in-process checks, and final 100% inspection of critical dimensions. All operators are certified to ISO 9001:2015 standards, and every batch is traceable via our digital production log system. With lean manufacturing principles embedded in our workflow, we achieve cycle time reductions without compromising precision.

Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 12 mm |

| Tolerance (Standard) | ±0.1 mm (tight-tolerance: ±0.05 mm) |

| Max Part Size | 3000 mm × 1500 mm |

| Bending Accuracy | ±0.2° |

| Surface Roughness (Ra) | 0.8 – 3.2 µm (depending on process) |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 15–25 days after prototype approval |

Wuxi Lead Precision Machinery delivers end-to-end sheet metal solutions where precision, repeatability, and reliability converge—ensuring every component shipped to Kansas City and beyond meets the highest global standards.

Why Choose Wuxi Lead Precision

Why Kansas City Fabricators Choose Lead Precision

Kansas City’s manufacturing sector demands unwavering precision, scalable capacity, and responsive supply chain integration. As regional fabrication shops navigate tightening deadlines and complex component specifications, partnering with a globally certified precision engineering partner becomes strategic necessity—not merely a cost consideration. Wuxi Lead Precision Machinery bridges this gap, delivering ISO 9001:2015-certified sheet metal fabrication from our 15,000m² facility in China’s industrial heartland. We specialize in high-mix, low-to-medium volume production where dimensional accuracy and material integrity are non-negotiable. Our clients in aerospace, medical device, and industrial equipment sectors consistently achieve 30% faster time-to-market through our integrated engineering-to-shipment workflow.

Our technical capability aligns with Kansas City’s advanced manufacturing requirements, particularly for laser cutting, CNC bending, and robotic welding of stainless steel, aluminum, and specialty alloys. Below is a snapshot of our core sheet metal fabrication specifications:

| Process | Material Range | Thickness Capacity | Tolerance | Throughput |

|---|---|---|---|---|

| Fiber Laser Cutting | Mild Steel, SS, Al, Cu | 0.5 mm – 25 mm | ±0.05 mm | Up to 8 m/min |

| CO2 Laser Cutting | Mild Steel, SS, Al | 1.0 mm – 20 mm | ±0.1 mm | Up to 6 m/min |

| CNC Press Brake | All sheet metals | 0.5 mm – 12 mm | ±0.1° angular | 12 bends/min |

| Robotic Welding | SS, Al, Ti alloys | 0.8 mm – 10 mm | ±0.2 mm linear | 1.5 m/min travel |

This precision is enforced through real-time SPC monitoring and First Article Inspection reports aligned with AS9102 or PPAP standards. Unlike transactional suppliers, we embed engineering collaboration from prototype through production—reducing rework cycles by 40% for clients like yours. Our Kansas City partners gain access to dedicated project managers fluent in English and Mandarin, ensuring zero time-zone friction during critical design-for-manufacturability reviews.

Initiate your precision partnership with three decisive actions. First, email [email protected] with your component drawings and volume requirements. Second, request our Kansas City-specific capacity calendar—guaranteeing slot allocation within 72 hours of RFQ submission. Third, schedule a virtual factory audit via Teams to witness our HAAS CNC centers and Amada laser systems in operation. We will provide a formal quotation with DDP Kansas City pricing, validated material certifications, and a production timeline within 48 business hours of receiving complete specifications.

Do not let supply chain volatility compromise your next contract. Wuxi Lead Precision Machinery delivers the confluence of German-engineered machinery, Chinese operational scale, and American-quality accountability. Contact [email protected] today to secure your precision fabrication capacity—engineered for Kansas City’s future.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.