Technical Contents

Engineering Guide: End Molding

Engineering Insight: The Critical Role of Precision in End Molding

End molding in custom metal manufacturing is a specialized process that demands the highest levels of accuracy, consistency, and material integrity. Unlike conventional molding techniques, end molding focuses on forming or shaping the terminal ends of metal components—such as tubes, shafts, or housings—to meet exact dimensional, structural, and functional requirements. This process is pivotal in industries where component failure is not an option, including aerospace, defense, medical devices, and high-performance automotive systems.

At Wuxi Lead Precision Machinery, we recognize that precision in end molding is not merely a quality benchmark—it is an engineering necessity. Even minor deviations in wall thickness, taper angle, or end contour can lead to catastrophic failures in high-stress applications. Our advanced CNC-controlled end molding systems ensure micron-level repeatability, enabling us to produce components that meet the most stringent international standards. With over 15 years of experience in high-tolerance metal fabrication, we have refined our processes to deliver flawless results across complex geometries and exotic alloys.

Our expertise has been validated through participation in mission-critical projects, including the supply of precision-molded components for Olympic-grade sports equipment and military-grade defense systems. These applications demand not only precision but also full traceability, rigorous testing, and zero defect tolerance. Our end molding solutions have consistently met and exceeded these demands, reinforcing our reputation as a trusted partner in high-end manufacturing.

Material selection plays a crucial role in the success of end molding operations. We work with a wide range of metals, including stainless steel, titanium, aluminum alloys, and nickel-based superalloys. Each material presents unique challenges in terms of ductility, springback, and thermal response during forming. Our engineering team conducts detailed finite element analysis (FEA) simulations to predict material behavior and optimize tooling design, ensuring optimal forming pressure, temperature control, and cycle time.

In addition to precision and material science, tooling design is a cornerstone of successful end molding. Custom dies and mandrels are manufactured in-house using hardened tool steels and coated with wear-resistant layers to extend service life and maintain dimensional stability over high-volume production runs. Our closed-loop monitoring systems provide real-time feedback on force, position, and temperature, allowing for immediate adjustments and ensuring every component conforms to specification.

Below are key performance specifications achieved through our end molding process:

| Parameter | Typical Range | Tolerance Control |

|---|---|---|

| Outer Diameter (OD) | 6 mm – 150 mm | ±0.02 mm |

| Wall Thickness | 0.5 mm – 8 mm | ±0.03 mm |

| End Taper Angle | 0° – 45° | ±0.1° |

| Length Consistency | Up to 1,200 mm | ±0.05 mm |

| Materials Supported | SS304/316, Ti-6Al-4V, Al6061, Inconel 718 | Full material certification |

| Production Volume Capacity | 1 – 50,000 pcs/month | Fully scalable |

At Wuxi Lead Precision Machinery, we combine engineering rigor with advanced manufacturing technology to deliver end molding solutions that stand up to the most demanding environments. Our commitment to precision ensures that every component we produce contributes to the reliability, safety, and performance of the final assembly.

Precision Specs & Tolerances

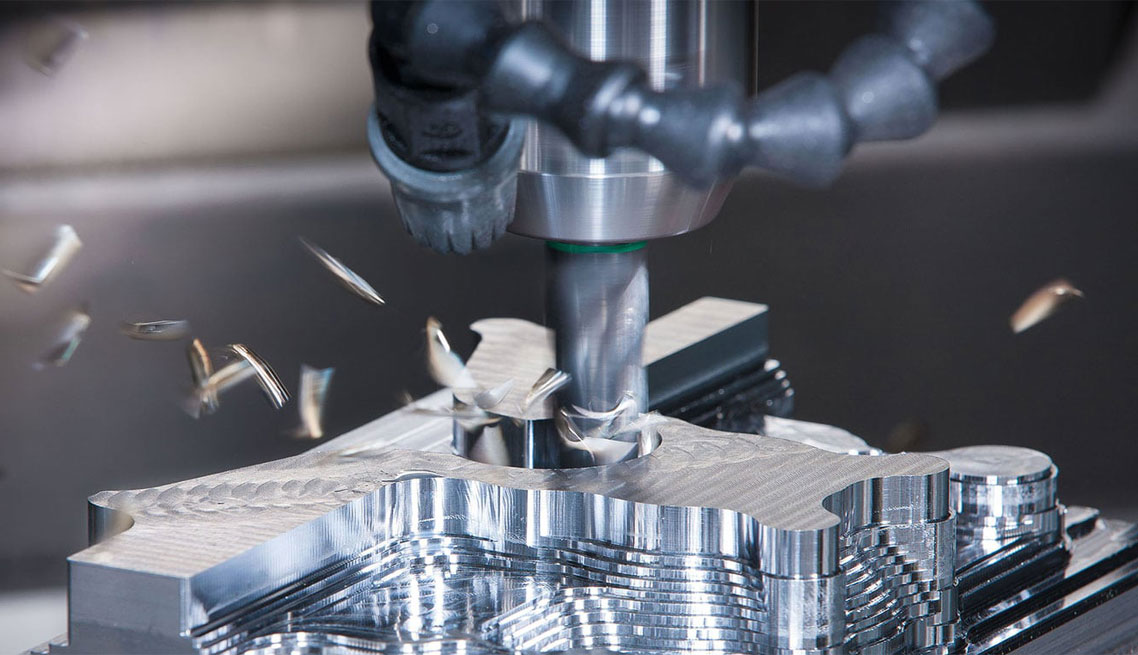

Technical Capabilities: Precision End Milling for Critical Metal Components

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing, specializing in complex end milling operations for mission-critical components. Our facility integrates state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Hermle C400 U, engineered to handle demanding geometries in aerospace alloys, medical-grade titanium, hardened tool steels, and high-temperature superalloys like Inconel 718. These machines feature simultaneous five-axis interpolation, high-torque spindles (up to 42,000 RPM), and integrated probing systems, enabling single-setup machining of intricate contours, deep cavities, and undercuts that define modern end-milled components. Material removal rates are optimized through adaptive high-speed machining strategies, reducing cycle times by 30% while maintaining surface integrity for fatigue-critical applications.

Our technical mastery extends beyond raw machining power to intelligent process integration. All programs originate from validated 3D CAD/CAM models (Siemens NX, Mastercam), with toolpath simulations rigorously verified for collision avoidance and thermal stability. This digital thread ensures geometric accuracy from design intent to physical part, eliminating costly rework. Crucially, our 5-axis capability minimizes workholding transitions—often machining fully finished parts in one operation—thereby eliminating cumulative errors from multiple setups and preserving critical datum relationships across complex features. This approach is essential for end-milled components requiring tight positional alignment between functional surfaces, such as hydraulic manifolds, turbine blade roots, and surgical instrument housings.

Quality assurance is embedded at every process stage, not merely a final checkpoint. Every component undergoes 100% geometric inspection using Zeiss CONTURA G2 coordinate measuring machines (CMMs) with VAST XT gold probes and Calypso software. Our CMM protocols follow ASME Y14.5-2018 standards, capturing full 3D point clouds to validate form, profile, and positional tolerances against nominal CAD data. Statistical Process Control (SPC) monitors critical dimensions in real-time during production runs, enabling immediate corrective action to sustain ±0.005 mm capability. This closed-loop system guarantees first-time-right production, even for low-volume, high-mix orders where traditional batch inspection would introduce delays.

The following table outlines achievable geometric tolerances under standard production conditions for end-milled features in aluminum, steel, and titanium alloys. These values reflect sustained process capability, not theoretical best-case scenarios:

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 | ±0.005 |

| Positional Tolerance (mm) | ±0.020 | ±0.008 |

| Flatness (mm) | 0.025 per 100 mm | 0.005 per 100 mm |

| Circular Runout (mm) | 0.015 | 0.003 |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

This combination of advanced hardware, process discipline, and metrology rigor allows Wuxi Lead to consistently produce end-milled components that meet stringent aerospace (NADCAP), medical (ISO 13485), and energy sector requirements. We transform challenging design specifications into reality with reduced lead times and zero-defect delivery—proving that precision is not an option, but the foundation of industrial excellence.

Material & Finish Options

Material Selection for End Molding: Precision Engineering with Aluminum, Steel, and Titanium

In high-precision end molding applications, material selection directly influences product performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing, leveraging advanced CNC and molding technologies to deliver components that meet exacting industrial standards. The choice between aluminum, steel, and titanium depends on mechanical requirements, environmental exposure, and functional lifespan. Each material offers distinct advantages, and understanding their properties ensures optimal part design and manufacturing efficiency.

Aluminum is widely favored for end molding due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for aerospace, automotive, and consumer electronics applications where weight reduction is critical without compromising structural integrity. The 6061 and 7075 aluminum alloys are commonly used, offering good weldability and high tensile strength. When combined with anodizing, aluminum achieves enhanced surface hardness and wear resistance, making it ideal for both functional and aesthetic components.

Steel remains the go-to material for applications requiring high strength, impact resistance, and thermal stability. Alloy steels and stainless steels such as 304 and 4140 provide excellent durability in harsh environments, including high-stress mechanical systems and industrial equipment. While heavier than aluminum, steel’s superior fatigue resistance and dimensional stability under load make it indispensable in structural end molding components. Post-machining treatments such as passivation or powder coating further improve corrosion resistance and surface longevity.

Titanium stands at the pinnacle of performance materials, offering exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive media. Grade 5 (Ti-6Al-4V) is frequently used in aerospace, medical, and defense applications where reliability under extreme conditions is non-negotiable. Though more challenging to machine and higher in cost, titanium’s longevity and performance justify its use in mission-critical end molding parts.

Surface finishing, particularly anodizing, plays a crucial role in enhancing material performance. Anodizing aluminum creates a controlled oxide layer that improves wear resistance, allows for color coding, and increases adhesion for paint primers. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with the latter providing superior hardness for industrial use.

Below is a comparative overview of key material properties for end molding applications.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Alloys | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum | 310–570 | 2.7 | High | 6061, 7075 | Anodizing, Powder Coating |

| Steel | 500–2000 | 7.8 | Moderate to High | 304, 4140, 4340 | Passivation, Plating, Painting |

| Titanium | 900–1200 | 4.5 | Exceptional | Gr2, Gr5 (Ti-6Al-4V) | Anodizing, Polishing |

Selecting the right material and finish for end molding requires a detailed understanding of operational demands. Wuxi Lead Precision Machinery supports clients in making informed decisions, ensuring every component meets the highest standards of precision, reliability, and performance.

Manufacturing Process & QC

Precision End Forming: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our end forming process—specializing in high-integrity terminal operations like flanging, hemming, and contouring for critical metal components—executes a rigorously defined pathway from initial design through to flawless mass production. This systematic approach, engineered for zero defects, ensures your components meet exacting aerospace, medical, and automotive specifications without compromise. We treat dimensional accuracy and material integrity as non-negotiable outcomes, not aspirations.

The process commences with integrated Design for Manufacturability (DFM) analysis. Our engineering team collaborates directly with your designers, utilizing advanced simulation software to model material flow, stress distribution, and springback behavior specific to your chosen alloy. This phase identifies potential forming challenges—such as thinning risks or geometric instabilities—before tooling begins, optimizing the design for both performance and producibility. Material certification and strict lot traceability are mandated at this stage to guarantee baseline quality.

Prototyping transitions theory into validated practice under production-intent conditions. We fabricate initial tools using hardened, wear-resistant alloys and run short batches on our high-tonnage, servo-hydraulic forming presses. Every prototype undergoes comprehensive metrology: CMM inspection verifies geometric dimensioning and tolerancing (GD&T) compliance, while destructive testing confirms metallurgical properties and structural integrity. This phase is not merely validation; it is critical process refinement. Data from prototype runs feeds directly into final tooling adjustments and establishes precise machine parameters for volume production, eliminating guesswork.

Mass production leverages the insights gained, operating within a closed-loop quality management system. Our CNC-controlled forming cells integrate real-time in-process monitoring—measuring force profiles, stroke position, and part presence—to detect deviations instantly. Statistical Process Control (SPC) charts track critical dimensions with sub-micron resolution, triggering automatic machine adjustments before non-conformances occur. 100% automated vision inspection complements manual audits, ensuring every component meets the Zero Defects standard. Continuous operator training and preventive maintenance protocols sustain this precision over extended production runs.

Wuxi Lead’s end forming capabilities deliver uncompromised quality at scale:

| Parameter | Capability Range | Precision Standard |

|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | ±0.02 mm |

| Tolerance (GD&T) | Complex geometries | ±0.05 mm (Typical) |

| Process Capability | Cp/Cpk | ≥1.67 (Routine) |

| Material Compatibility | Stainless Steel, Aluminum Alloys, Ti | Full Material Traceability |

| Max Part Dimension | 500 mm x 500 mm | Customizable |

| Production Volume | Prototypes to 500,000+ units/year | Zero Defects Target |

This end-to-end methodology transforms design intent into physically perfect metal components. Wuxi Lead Precision Machinery guarantees that every part shipped embodies the convergence of intelligent engineering, empirical validation, and disciplined execution—delivering true manufacturing excellence for your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced End Molding Solutions

At Wuxi Lead Precision Machinery, we understand that precision, durability, and consistency define success in high-end metal manufacturing. As a trusted leader in custom metal solutions, we specialize in end molding processes that meet the rigorous demands of aerospace, automotive, medical, and industrial sectors. Our engineering expertise, combined with state-of-the-art CNC technology and strict quality control, ensures that every component we produce exceeds industry standards.

End molding is not just a process—it’s a science. It requires exact material selection, thermal control, and tooling precision to achieve seamless integration between metal ends and composite or polymer elements. At Lead Precision, we bring decades of metallurgical experience and advanced manufacturing capabilities to deliver end-molded components with superior structural integrity, dimensional accuracy, and surface finish. Whether you are developing high-pressure fluid systems, precision sensors, or mission-critical enclosures, our solutions are engineered to perform under extreme conditions.

We don’t just manufacture parts—we engineer partnerships. From initial design consultation to final production, our team works closely with your engineers to optimize material selection, reduce assembly complexity, and improve overall product performance. Our in-house prototyping and rapid validation cycles accelerate time-to-market, while our scalable production lines ensure seamless transition from prototype to volume manufacturing.

Our facility in Wuxi, China, is equipped with ISO 9001-certified processes, real-time monitoring systems, and a dedicated quality assurance team that performs 100% inspection on critical dimensions. We support a wide range of materials, including stainless steel, aluminum alloys, titanium, and specialty nickel-based alloys, ensuring compatibility with your specific application requirements.

Below are key specifications that define our end molding capabilities:

| Specification | Capability |

|---|---|

| Material Compatibility | Stainless Steel (304, 316, 17-4PH), Aluminum (6061, 7075), Titanium (Grade 5), Inconel, Brass |

| Tolerance Range | ±0.02 mm to ±0.05 mm (depending on geometry) |

| Minimum Feature Size | 0.3 mm |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm (custom finishes available) |

| Production Capacity | 1,000 to 500,000 units per month |

| Secondary Operations | CNC Machining, Laser Welding, Passivation, Anodizing, CMM Inspection |

| Quality Standards | ISO 9001:2015, RoHS, REACH, PPAP, FAIR Reporting |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to innovation, reliability, and long-term success. Our global clients trust us to deliver components that perform flawlessly in the most demanding environments.

Ready to elevate your end molding projects? Contact us today at [email protected] to speak with one of our engineering specialists. Let’s build the future of precision manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.