Technical Contents

Engineering Guide: Electronic Overmolding

Engineering Insight: Electronic Overmolding and the Critical Role of Precision

Electronic overmolding is a specialized manufacturing process that integrates electronic components within a protective polymer encapsulation, combining mechanical durability with electrical functionality. This technique is increasingly vital in high-performance sectors such as aerospace, defense, medical devices, and advanced consumer electronics, where reliability under extreme conditions is non-negotiable. At the core of successful electronic overmolding lies precision—both in component fabrication and in the overmolding execution itself. Even minor deviations in wall thickness, alignment, or thermal management can compromise signal integrity, thermal dissipation, or environmental sealing.

At Wuxi Lead Precision Machinery, we approach electronic overmolding as a convergence of micro-precision metalwork and advanced polymer science. Our expertise in custom metal manufacturing ensures that embedded components—such as connectors, shielding cans, or heat-dissipating substrates—are produced to exacting tolerances, often within ±0.005 mm. This level of accuracy is essential to maintain consistent mold flow, prevent flash, and ensure uniform encapsulation without damaging sensitive circuitry. Our in-house CNC machining, stamping, and laser cutting capabilities allow us to produce metal inserts with optimal surface finish and dimensional stability, directly influencing the quality of the final overmolded assembly.

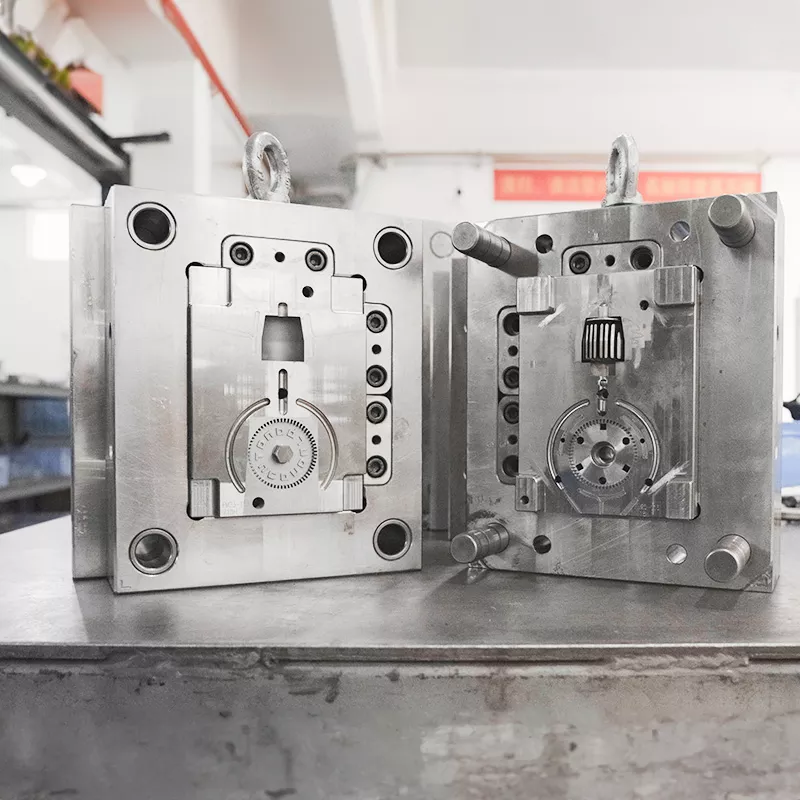

Precision extends beyond the metal component. Mold design must account for material shrinkage, thermal expansion differentials between metal and polymer, and the need for hermetic sealing. At Lead Precision, we employ finite element analysis (FEA) and mold flow simulation to anticipate and correct potential defects before tooling begins. This proactive engineering approach reduces development cycles and ensures first-time-right performance, especially critical in low-volume, high-reliability applications.

Our experience in delivering components for Olympic-grade timing systems and military-grade communication devices underscores our capability in mission-critical manufacturing. These projects demanded not only zero-failure performance but also compliance with stringent environmental standards, including resistance to shock, vibration, moisture, and extreme temperatures. The same rigorous standards are applied to our electronic overmolding solutions, ensuring that every part meets or exceeds global reliability benchmarks.

We understand that in high-end manufacturing, consistency is as important as initial performance. Our production processes are ISO 9001 and IATF 16949 certified, with full traceability and in-process inspection protocols. Whether producing prototype inserts or scaling to medium-volume production, we maintain tight control over every variable—from raw material sourcing to final assembly.

Below are key specifications reflecting our electronic overmolding capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Insert Material Options | Stainless steel, copper alloys, aluminum |

| Compatible Polymers | Silicone, LSR, PPS, PEEK, Polyamide |

| Operating Temperature Range | -60°C to +220°C (depending on material) |

| IP Rating (Sealing) | Up to IP68 |

| Production Volume Flexibility | Prototypes to 500,000 units/year |

| Quality Standards | ISO 9001, IATF 16949, MIL-STD-810 compliant |

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer reliability into every part. For electronic overmolding applications where failure is not an option, precision is not a feature. It is the foundation.

Precision Specs & Tolerances

Technical Capabilities for Precision Electronic Overmolding Components

Electronic overmolding integrates sensitive electronic assemblies within protective polymer housings, demanding exceptional dimensional stability and surface integrity from underlying metal components. At Wuxi Lead Precision Machinery, our advanced manufacturing ecosystem is engineered specifically for these high-stakes applications. We address the core challenges of thermal distortion, micron-level feature alignment, and contamination control inherent in overmolding processes through dedicated CNC infrastructure and rigorous quality protocols.

Our foundation lies in a fleet of 15 state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Makino D200Z models. These systems enable single-setup machining of complex geometries—such as nested cavities, undercuts, and conformal cooling channels—critical for thermal management in overmolded electronics. High-speed spindles (up to 24,000 RPM) paired with sub-micron linear encoders ensure minimal vibration during fine-feature milling of aluminum 6061-T6, stainless steel 316L, and copper alloys. Real-time thermal compensation software actively counteracts ambient and process-induced expansion, maintaining tolerances even during extended production runs. This capability eliminates secondary operations that risk contaminating surfaces prior to overmolding.

Quality verification is non-negotiable for hermetic sealing and connector reliability. Every component undergoes 100% inspection via Zeiss CONTURA G3 CMMs equipped with HP-V3 probing systems and Calypso software. Our protocol includes:

Full GD&T validation against CAD models with automated reporting

Surface roughness analysis (Ra 0.4 µm to 1.6 µm) using Taylor Hobson systems

Critical feature measurement at controlled 20°C ±0.5°C environments to negate thermal drift

Traceable calibration to NIST standards with certificates provided per batch

The table below details our standard and enhanced tolerance capabilities for electronic overmolding substrates:

| Parameter | Standard Capability | Enhanced Capability (Electronic Overmolding Focus) | Material Notes |

|---|---|---|---|

| Linear Dimension | ±0.025 mm | ±0.005 mm (critical features) | Aluminum, Stainless Steel, Copper |

| Angular Tolerance | ±0.1° | ±0.02° | All materials |

| Positional Accuracy | ±0.015 mm | ±0.003 mm (datum-referenced) | Critical for pin/connector loci |

| Surface Flatness | 0.05 mm | 0.008 mm | Sealing surfaces only |

| Hole Concentricity | 0.03 mm | 0.005 mm | Multi-cavity alignment |

These specifications are consistently achieved through our integrated approach: CNC programs undergo virtual collision simulation and thermal distortion analysis pre-machining, while in-process probing validates workholding stability. For overmolding-critical surfaces, we implement non-contact optical scanning to detect micro-burrs or tool marks invisible to tactile probes. This prevents polymer leakage paths during molding.

Partnering with Wuxi Lead ensures your metal substrates meet the uncompromising demands of electronic overmolding. We deliver not just precision parts, but validated process stability that directly enhances your overmolding yield and end-product reliability. Our engineering team collaborates from DFM through production to mitigate risks like resin flash or substrate warpage—turning complex electronic packaging challenges into competitive advantages.

Material & Finish Options

Material Selection for Electronic Overmolding: Precision in Performance

In electronic overmolding, the structural integrity and thermal performance of the metal substrate are critical to the reliability and longevity of the final component. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that meet the exacting demands of high-performance electronics. The selection of the appropriate base material—aluminum, steel, or titanium—directly influences the component’s mechanical behavior, weight, corrosion resistance, and compatibility with overmolded polymers.

Aluminum is the most widely used material in electronic overmolding due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grades such as 6061-T6 and 7075-T6 are particularly favored for enclosures and heat sinks, where efficient heat dissipation is essential. Aluminum’s natural oxide layer provides moderate corrosion resistance, which can be significantly enhanced through anodizing. This makes it ideal for consumer electronics, automotive sensors, and industrial control units exposed to varying environmental conditions.

Stainless steel, particularly grades 304 and 316, offers superior mechanical strength and exceptional resistance to corrosion and high temperatures. While heavier than aluminum, steel is preferred in applications requiring extreme durability, such as medical devices, marine electronics, and downhole instrumentation. Its lower thermal conductivity compared to aluminum must be considered in thermal management design, but its structural robustness ensures long-term reliability under mechanical stress and harsh operating environments.

Titanium, specifically Grade 5 (Ti-6Al-4V), is selected for mission-critical applications where weight savings and performance under extreme conditions are paramount. Aerospace, defense, and high-end medical implants often utilize titanium due to its outstanding strength-to-density ratio and biocompatibility. Though more challenging to machine and costlier than aluminum or steel, titanium provides unmatched performance in corrosive or high-temperature environments and exhibits excellent adhesion with specialized overmolding compounds.

Surface finishing plays a crucial role in enhancing material performance. Anodizing, particularly Type II (sulfuric acid) and Type III (hard coat), is the preferred finish for aluminum components. It increases surface hardness, improves wear resistance, and creates a porous layer that promotes strong mechanical bonding with overmolded polymers. Different anodizing thicknesses and sealing methods allow customization based on environmental exposure and functional requirements.

The table below summarizes key material properties and finishing options relevant to electronic overmolding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 167 | Anodizing (Type II/III) | Consumer electronics, heat sinks |

| Stainless Steel 316 | 8.0 | 570 | 16 | Passivation, electropolish | Medical, marine, chemical processing |

| Titanium Ti-6Al-4V | 4.4 | 900 | 6.7 | Anodizing, plasma spray | Aerospace, defense, implants |

Selecting the right material and finish is not a one-size-fits-all decision. At Wuxi Lead Precision Machinery, we work closely with design engineers to match material properties with application requirements, ensuring optimal performance, manufacturability, and cost-efficiency in every overmolded component.

Manufacturing Process & QC

Electronic Overmolding: Precision Production Process for Zero Defects

At Wuxi Lead Precision Machinery, electronic overmolding demands an uncompromising, integrated production process to achieve true Zero Defects performance in demanding B2B applications. Our methodology rigorously connects Design, Prototyping, and Mass Production, eliminating traditional handoffs that introduce risk. This ensures your metal components and embedded electronics achieve seamless integration, environmental resilience, and absolute reliability from the first part to the millionth.

The process begins with intensive Design for Manufacturability (DFM) Analysis. Our engineering team collaborates closely with your design inputs, focusing on critical metal-to-polymer interface integrity. We analyze thermal expansion coefficients, metal insert geometry stability under injection pressure, gate location impact on wire encapsulation, and material compatibility between your specified engineering resin and metal substrate. Finite Element Analysis (FEA) predicts stress points and potential delamination risks, optimizing the design before tooling. This phase defines the foundational tolerances and material specifications essential for Zero Defects, preventing costly iterations later.

Prototyping utilizes production-intent tooling and materials, not rapid prototypes. We produce functional units under actual production parameters, subjecting them to accelerated life testing, environmental stress screening (thermal cycling, humidity, chemical exposure), and rigorous electrical validation. This phase validates the DFM conclusions and the real-world performance of the metal-polymer bond. Any micro-defects in wire strain relief or seal integrity are identified and resolved through iterative adjustments to the molding parameters or minor insert modifications. Only when prototypes consistently pass all performance and dimensional criteria do we approve the process for scale-up.

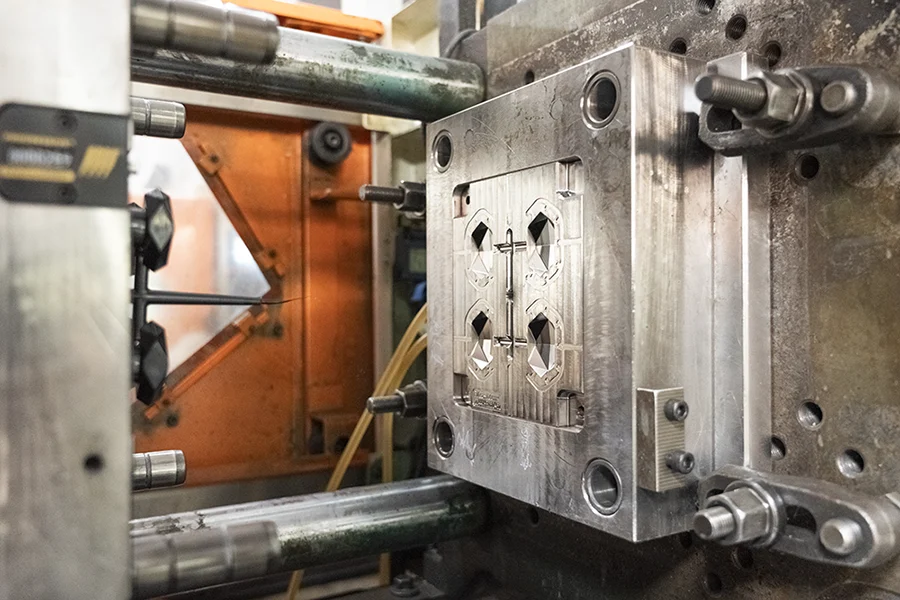

Mass Production executes the validated process under our Zero Defects Manufacturing System. Every stage is monitored with Statistical Process Control (SPC), tracking critical parameters like melt temperature consistency, injection pressure profiles, and cooling rates in real-time. Automated vision systems perform 100% inspection of critical features: metal insert position, overmold coverage completeness, absence of flash near electrical contacts, and seal bead formation. Our cleanroom molding cells maintain strict environmental controls. Traceability is absolute, with every unit linked to its specific material lot and process data. Continuous SPC feedback ensures immediate correction, guaranteeing Cpk > 1.67 for all critical dimensions and zero escape of non-conforming parts.

The table below summarizes the critical parameters controlled throughout our Zero Defects electronic overmolding process.

| Phase | Key Activities | Critical Parameters | Quality Controls |

|---|---|---|---|

| Design | DFM, FEA, Material Selection | CTE Match, Insert Geometry Tolerance | Simulation Validation, Material Certs |

| Prototyping | Production Tool Molding, Environmental Testing | Bond Strength, Wire Strain Relief | 100% Electrical Test, Accelerated Life |

| Mass Production | SPC-Controlled Molding, 100% Inspection | Melt Temp Stability, Cooling Rate | Real-time SPC, Automated Vision, Cpk >1.67 |

Wuxi Lead Precision Machinery guarantees Zero Defects through this closed-loop process. We transform complex electronic overmolding challenges into reliable, high-yield production, protecting your brand reputation and end-product performance. Partner with us for overmolded components where failure is never an option.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Electronic Overmolding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions tailored to the evolving demands of modern electronics. Our expertise in electronic overmolding integrates advanced CNC machining, precision metal fabrication, and polymer encapsulation to produce robust, high-performance components for industries such as automotive, medical devices, industrial automation, and consumer electronics. When you partner with us, you gain access to a vertically integrated manufacturing ecosystem designed for reliability, repeatability, and engineering excellence.

Electronic overmolding is more than an assembly process—it is a strategic enhancement that improves durability, environmental resistance, and electrical insulation. Our engineering team collaborates closely with clients from concept through production, ensuring seamless integration of metal substrates with engineered thermoplastics. Utilizing state-of-the-art injection molding systems, cleanroom environments, and in-house tooling design, we maintain tight tolerances and consistent quality across high-volume and low-volume production runs.

Our facility in Wuxi, China, is equipped with ISO 9001-certified processes and advanced metrology systems, including CMM and optical inspection, to validate every stage of production. We support materials ranging from stainless steel, aluminum, and copper alloys to high-temperature thermoplastics such as PPS, PEEK, and LCP—ensuring compatibility with demanding thermal, chemical, and mechanical environments.

Below are key technical capabilities that define our electronic overmolding services:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.005 mm (precision CNC) |

| Insert Material Types | Stainless steel, aluminum, brass, copper alloys |

| Overmolding Materials | PPS, PEEK, PA6, PA66, LCP, TPU |

| Maximum Part Size | 300 mm × 200 mm × 100 mm |

| Minimum Wall Thickness (plastic) | 0.4 mm |

| Production Capacity | Up to 500,000 units/month |

| Tooling Lead Time | 15–25 days (in-house design & fabrication) |

| Quality Standards | ISO 9001, RoHS, IATF 16949 (automotive) |

| Secondary Operations | Thread cutting, laser marking, plating, ultrasonic welding |

We understand that success in electronic overmolding lies in the synergy between material science, precision engineering, and process control. Our engineers provide full DFM analysis, mold flow simulation, and prototyping support to de-risk your project before volume production. Whether you are developing next-generation sensors, connectors, or power electronics, our team ensures your design is optimized for performance, manufacturability, and cost-efficiency.

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that values innovation, precision, and long-term collaboration. We are committed to delivering solutions that exceed expectations and drive your product’s success in competitive global markets.

For technical consultations or project inquiries, contact us today at [email protected]. Let’s engineer the future together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.