Technical Contents

Engineering Guide: Ejection Molding

Engineering Insight: Precision Ejection Molding in High-Performance Manufacturing

Ejection molding represents a critical phase within the metal forming process, where microscopic dimensional deviations or force inconsistencies directly determine final part integrity and production viability. In high-end custom manufacturing, particularly for aerospace, defense, and precision instrumentation, the ejection sequence is not merely a concluding step but a fundamental engineering challenge demanding micron-level control. Imperfect ejection force distribution, timing errors, or guide mechanism inaccuracies induce part distortion, surface blemishes, or catastrophic ejection failure, rendering high-value components unusable. The cumulative impact of sub-micron variations during ejection propagates through assembly, compromising the entire system’s performance and reliability. Precision here is non-negotiable; it is the baseline requirement for mission-critical applications where failure is not an option.

At Wuxi Lead Precision Machinery, our engineering philosophy treats ejection as a core discipline, not an afterthought. Decades of refining ejection systems for extreme environments underpin our approach. We engineered ejection mechanisms for components within precision-guided munitions systems, where tolerances below 0.005mm and flawless repeatability under high-G forces are mandatory. Similarly, our molds supplied components for Olympic-grade timing systems demanded ejection stability capable of maintaining micron accuracy across thousands of cycles under intense operational scrutiny. This experience translates directly to our commercial clients: we understand that vibration resistance, thermal stability of guide pillars, and real-time force monitoring are essential, not optional, features for high-yield production of complex geometries in hardened alloys or tight-tolerance assemblies.

Our high-precision ejection solutions integrate advanced materials science with closed-loop control systems. Key performance metrics distinguish industry-standard capability from the precision required for leading-edge applications, as demonstrated below.

| Parameter | Standard Industrial | Lead Precision High-End |

|---|---|---|

| Positional Accuracy | ±0.02 mm | ±0.003 mm |

| Stroke Repeatability | ±0.015 mm | ±0.002 mm |

| Force Uniformity | ±5% | ±1.5% |

| Guide Wear Resistance | Moderate | Ultra-High (Aerospace Grade) |

| Thermal Drift (100°C) | ±0.03 mm | ±0.005 mm |

| Vibration Tolerance | Low | Military Spec (MIL-STD-810G) |

This level of precision is achieved through proprietary hardened guide systems, in-situ force sensors feeding adaptive controllers, and finite element analysis optimizing load paths to eliminate deflection. The result is consistent part release without stress marks, dimensional shift, or secondary operations – essential for components destined for satellite systems, medical implants, or next-generation semiconductor tooling. When your application demands absolute fidelity from the mold cavity to the finished part, the ejection system must perform with the same rigor as the forming process itself. Wuxi Lead Precision Machinery delivers this assurance through engineering rigor proven in the most demanding global projects. Contact our engineering team to discuss how our precision ejection expertise can secure your critical manufacturing outcomes.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industrial applications. At the core of our production infrastructure is a fully integrated suite of 5-axis CNC machining centers, enabling us to execute complex geometries with exceptional accuracy and surface finish. These state-of-the-art systems provide simultaneous multi-axis motion, allowing for intricate part features to be machined in a single setup. This reduces cumulative error, improves repeatability, and significantly enhances productivity—critical advantages when producing mission-critical components for aerospace, medical, energy, and automation sectors.

Our 5-axis CNC platforms are operated by certified machinists with extensive experience in high-tolerance metal fabrication. Each machine is maintained to OEM specifications and equipped with high-resolution probing systems for in-process verification. This ensures consistent tool alignment, real-time compensation for thermal drift, and precise workpiece positioning. We work with a broad range of engineering metals, including titanium alloys, Inconel, stainless and tool steels, aluminum alloys, and specialty brass compositions. Material selection is supported by our in-house metallurgical database, ensuring optimal machining parameters and post-processing protocols.

Quality control is embedded throughout the manufacturing workflow. Every component undergoes comprehensive inspection using a Zeiss DuraMax and CONTURA G2 Coordinate Measuring Machine (CMM), providing metrology-grade verification of geometric dimensions and tolerances. Our CMM systems are calibrated annually to ISO 17025 standards and operated by ASQ-certified inspectors. Data from each inspection is documented in a full First Article Inspection (FAI) report, available to clients upon request. Surface roughness, edge integrity, and form accuracy are also evaluated using portable profilometers and optical comparators, ensuring compliance with drawing specifications.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC and inspection processes:

| Feature Type | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Air Gauges, CMM |

| Positional Tolerance | ±0.020 mm | ±0.005 mm | CMM, Optical Probe |

| Flatness | 0.01 mm/m | 0.003 mm/m | CMM, Surface Plate + Dial |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | Portable Profilometer |

| Angular Features | ±0.05° | ±0.01° | Optical Comparator, CMM |

These capabilities are supported by full digital traceability, with all machining programs backed by Siemens NX and Mastercam simulations to prevent collisions and ensure toolpath integrity. Wuxi Lead Precision Machinery maintains ISO 9001:2015 certification, reinforcing our commitment to precision, consistency, and continuous improvement in every manufacturing cycle.

Material & Finish Options

Material Selection for Precision Ejection Systems in Metal Casting

Selecting optimal materials for ejection components is critical in high-intensity metal casting processes like die casting and permanent mold casting. Misnomer correction: “Ejection molding” refers to plastic processes; for metal, we discuss ejection systems within casting dies. Wuxi Lead Precision Machinery emphasizes that material choice directly impacts cycle life, release reliability, and final part quality under extreme thermal and mechanical stress. Aluminum alloys offer lightweight solutions with excellent thermal conductivity, ideal for cores or slides in lower-pressure aluminum die casting where rapid heat dissipation is needed. However, their lower hardness limits use in high-wear ejection pin applications. Tool steels, particularly air-hardening grades like H13, are the industry standard for ejector pins and sleeves. H13 provides exceptional toughness, thermal fatigue resistance, and the ability to maintain hardness at elevated operating temperatures encountered in zinc, aluminum, and magnesium die casting. For the most demanding aerospace or high-temperature applications, titanium alloys like Ti-6Al-4V present superior strength-to-weight ratio and corrosion resistance but require specialized machining and handling due to cost and reactivity concerns.

Material properties dictate performance under cyclic thermal loading. The table below summarizes key characteristics relevant to ejection component design and longevity.

| Material | Typical Grade | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Coefficient of Thermal Expansion (10⁻⁶/K) | Primary Ejection Application |

|---|---|---|---|---|---|---|

| Aluminum Alloy | 6061-T6 | 310 | 30-35 | 167 | 23.6 | Mold cores, non-critical slides |

| Tool Steel | H13 | 1650 | 48-52 | 34.9 | 12.4 | Ejector pins, sleeves, wear plates |

| Titanium Alloy | Ti-6Al-4V | 900 | 36-41 | 7.2 | 8.6 | High-temp aerospace components |

Surface finishing, particularly anodizing, is non-negotiable for aluminum ejection components and often beneficial for steel. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and moderate wear protection for aluminum cores at thicknesses of 10-25μm. For critical ejection surfaces requiring maximum release performance and wear resistance, Type III (Hardcoat) anodizing is essential. Applied to aluminum at 25-50μm thickness, it creates a dense, hard ceramic layer (60-70 HRC) that drastically reduces galling and improves part release, especially in high-pressure aluminum casting. Hardcoat anodizing on steel components is less common but feasible for specific corrosion-prone environments; nitriding or physical vapor deposition (PVD) coatings like TiN are typically preferred for steel ejector pins to enhance surface hardness beyond 70 HRC without dimensional change.

Wuxi Lead Precision Machinery engineers recommend matching material and finish precisely to the casting alloy, cycle volume, and thermal profile. For high-cycle aluminum die casting, H13 steel ejector pins with a supplementary PVD coating or precision-ground surface finish often deliver the optimal balance of durability and release performance. Consult our technical team to analyze your specific thermal and mechanical loads for a validated ejection system solution.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the ejection molding process begins with meticulous design engineering. Our team of CNC specialists and mechanical engineers collaborate closely with clients to translate product concepts into manufacturable designs. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we develop 3D models that integrate functional requirements, material behavior, and geometric complexity. Finite Element Analysis (FEA) is applied to simulate stress distribution, thermal dynamics, and ejection forces, ensuring structural integrity under operational loads. Design for Manufacturability (DFM) principles are enforced to minimize material waste, reduce cycle time, and prevent defects such as warping or incomplete filling. Every design is validated through digital mold flow analysis, confirming optimal gate placement, cooling channel layout, and ejection system alignment before any physical prototype is produced.

Prototyping: Validating Performance and Precision

Once the design is finalized, we proceed to low-volume prototyping using high-precision CNC machining and rapid tooling techniques. This phase is critical for verifying dimensional accuracy, surface finish, and mechanical performance. Prototypes are manufactured from the same aerospace-grade aluminum, tool steel, or stainless alloys intended for mass production, ensuring realistic evaluation conditions. Each prototype undergoes rigorous metrological inspection using Coordinate Measuring Machines (CMM), optical profilometers, and laser scanning to confirm tolerances within ±0.005 mm. Functional testing includes ejection cycle simulation, pressure endurance, and thermal cycling to detect early signs of fatigue or misalignment. Client feedback is integrated iteratively, allowing for rapid design refinement. Only after full approval—both technical and aesthetic—do we transition to full-scale production.

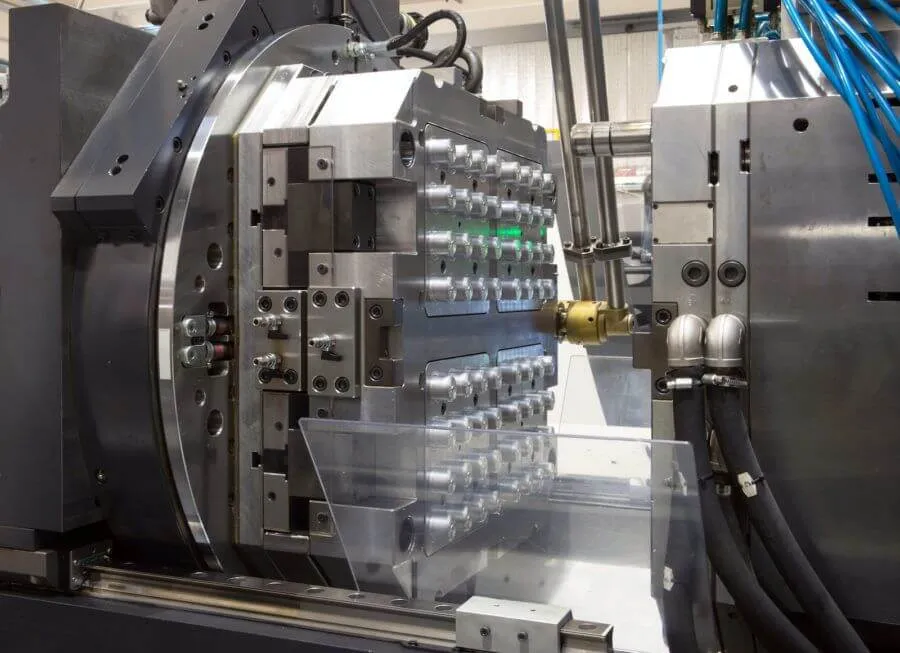

Mass Production: Zero Defects Through Automation and Control

Our mass production line leverages state-of-the-art CNC-controlled ejection molding presses, integrated with real-time monitoring systems to maintain zero-defect output. Each mold is mounted on automated hydraulic or servo-electric platforms capable of repeatable tonnage control up to 2,500 tons. In-process sensors track temperature, pressure, and ejection speed, feeding data to a centralized SCADA system that triggers alerts for any deviation beyond set parameters. Statistical Process Control (SPC) is employed to analyze trends and preempt quality issues before they manifest. Parts are continuously inspected via inline vision systems and robotic gauging, with full traceability maintained through barcode tracking and digital batch records. All finished components comply with ISO 9001 and IATF 16949 standards, with first-article inspection reports and PPAP documentation provided upon request.

Typical Ejection Molding Process Specifications

| Parameter | Specification Range |

|---|---|

| Material Compatibility | Aluminum Alloys (6061, 7075), Stainless Steel (304, 316), Tool Steels (H13, S7) |

| Tolerance | ±0.005 mm to ±0.02 mm |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm (polished options available) |

| Production Volume | 100 to 500,000+ units per run |

| Cycle Time | 20–90 seconds (depending on complexity) |

| Ejection Force Capacity | Up to 50 tons |

| Mold Life | 100,000 to 1,000,000 cycles |

| Quality Standard | ISO 9001, IATF 16949, PPAP Level 3 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Component Excellence

In high-stakes metal component production, tolerances measured in microns define success or costly failure. Generic suppliers cannot consistently deliver the dimensional stability, material integrity, and repeatability demanded by aerospace, medical, and energy sectors. Wuxi Lead Precision Machinery bridges this gap. As your dedicated engineering partner, we integrate advanced CNC technology with rigorous quality protocols to transform complex designs into flawless metal components—on time and within budget. Our ISO 9001:2015-certified facility in Wuxi operates under a zero-defect philosophy, where every spindle rotation and tool path is optimized for peak performance. We understand that your reputation hinges on component reliability; ours is built on ensuring yours remains unblemished.

Our technical capabilities are engineered for mission-critical applications. Below are core specifications defining our production envelope:

| Capability | Specification | Impact for Your Project |

|---|---|---|

| CNC Machining | 5-Axis, 0.005mm Tolerance | Complex geometries with zero rework |

| Material Range | Titanium, Inconel, Stainless Steel | Performance under extreme conditions |

| Max Work Envelope | Ø1200mm x 1500mm | Large-scale structural components |

| Surface Finish | Ra 0.4µm to 3.2µm | Optimal fatigue resistance & sealing |

| Lead Time Reduction | 25% vs. Industry Average | Accelerated time-to-market |

This precision is not accidental. Our engineers collaborate with your team from DFM analysis through final inspection, leveraging Renishaw probing systems and CMM validation to eliminate guesswork. We invest in predictive maintenance for all Haas and DMG MORI equipment, ensuring machine uptime exceeds 95%. When your project requires tight-tolerance hydraulic manifolds or biocompatible surgical instrument housings, our process control delivers consistency that passive vendors cannot match.

Choosing a manufacturing partner is a strategic decision impacting cost, compliance, and competitiveness. Wuxi Lead Precision Machinery commits to being your transparent extension—providing real-time production data, material traceability to melt batch, and agile responsiveness to design iterations. We absorb the complexities of precision metal fabrication so you can focus on innovation.

Do not let substandard components compromise your next breakthrough. Contact our engineering team today to discuss how our ejection molding-adjacent metal solutions solve your toughest production challenges. Email [email protected] with your component specifications and target timeline. A dedicated project manager will respond within 24 business hours with a feasibility assessment and actionable path forward. Partner with certainty—partner with Lead Precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.