Technical Contents

Engineering Guide: Efficient Automotive Plastic Machined Parts

Engineering Insight: Efficient Automotive Plastic Machined Parts

In the high-stakes environment of modern automotive manufacturing, efficiency is not merely a performance metric—it is a foundational requirement. Nowhere is this more evident than in the production of plastic machined components, where precision directly influences system reliability, assembly speed, and long-term durability. At Wuxi Lead Precision Machinery, we understand that the shift toward lightweight, high-performance materials in automotive design demands more than just advanced equipment; it requires deep engineering insight and uncompromising control over tolerances.

Plastic materials such as PEEK, PPS, and ULTEM are increasingly replacing metals in critical under-the-hood and safety-critical applications. These polymers offer excellent thermal resistance, chemical stability, and weight savings, but they also present unique machining challenges. Their thermal expansion coefficients differ significantly from metals, and their mechanical behavior under stress requires careful toolpath planning and fixturing strategies. Even minor deviations in dimensional accuracy can lead to sealing failures, misalignment in assemblies, or premature wear—costly outcomes in automotive production.

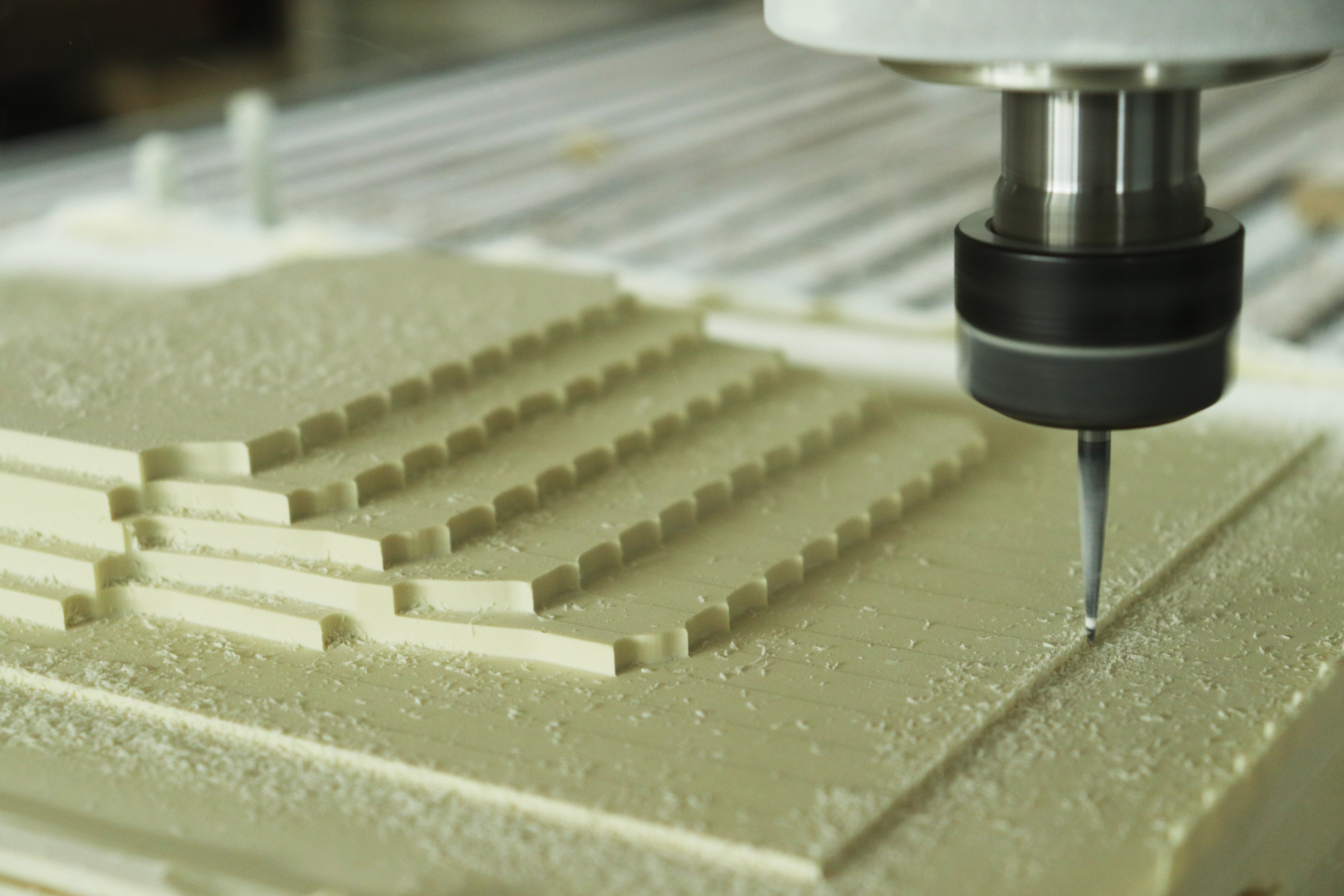

Precision machining of plastic components begins with material understanding. At Lead Precision, our engineers apply decades of accumulated expertise to anticipate how a given polymer will react during and after machining. We account for internal stress relief, moisture absorption, and post-machining dimensional drift to deliver parts that meet exacting OEM specifications consistently. Our CNC processes are optimized for minimal tool engagement and controlled heat generation, preserving material integrity while achieving tolerances as tight as ±0.005 mm.

Our experience extends beyond commercial automotive applications. Having supplied precision-machined components for Olympic-grade equipment and military defense systems, we bring a level of rigor and quality assurance that few in the industry can match. These high-reliability sectors demand zero-defect performance under extreme conditions—standards we apply rigorously to every automotive project we undertake.

Wuxi Lead Precision Machinery operates a fully integrated CNC machining facility equipped with multi-axis milling, turning, and inspection systems. Our quality control protocols include CMM verification, optical measurement, and batch traceability, ensuring that every plastic machined part meets the functional and regulatory demands of modern vehicles.

The efficiency of automotive plastic machined parts is not just about performance in the final assembly—it is also about reducing scrap rates, minimizing rework, and accelerating time-to-market. By combining advanced machining technology with engineering discipline, we help automotive suppliers and OEMs achieve both operational and technical excellence.

| Specification | Detail |

|---|---|

| Material Compatibility | PEEK, PPS, ULTEM, Nylon, Acetal, PTFE, PC, PMMA |

| Tolerance Range | ±0.005 mm to ±0.02 mm (depending on geometry and material) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (customizable) |

| Maximum Part Size | 800 mm × 600 mm × 400 mm |

| CNC Equipment | 3-axis, 4-axis, and 5-axis vertical machining centers |

| Quality Standards | ISO 9001:2015, Full CMM inspection, First Article Inspection (FAI) reports |

Precision Specs & Tolerances

Technical Capabilities for Automotive Plastic Machined Parts

Wuxi Lead Precision Machinery delivers uncompromising precision for mission-critical automotive plastic components through advanced CNC machining and rigorous quality control. Our specialization in engineering-grade polymers—including PEEK, Ultem, Nylon, Acetal, and Polycarbonate—ensures parts meet the thermal, chemical, and structural demands of modern vehicles. Unlike conventional metal-focused workshops, our processes are optimized for the unique behaviors of plastics, minimizing warpage, stress points, and dimensional drift during machining. This expertise is critical for safety systems, sensor housings, fluid handling components, and lightweight structural elements where micron-level accuracy directly impacts vehicle performance and reliability.

Central to our capability is a dedicated fleet of 5-axis CNC machining centers, enabling single-setup production of complex geometries with exceptional repeatability. Multi-axis simultaneous motion eliminates manual repositioning errors, critical for maintaining tight tolerances on intricate features like undercuts, compound angles, and integrated sealing surfaces. Our machines feature high-speed spindles with non-contact tool measurement and thermal compensation systems, ensuring stability during extended production runs of temperature-sensitive plastics. Material-specific strategies—including optimized cutting paths, cryogenic cooling, and custom fixturing—prevent melting, delamination, or residual stress, preserving the inherent properties of high-performance polymers.

Every component undergoes stringent quality validation via Zeiss CONTURA CMM systems, providing full 3D verification against CAD models with traceable NIST-certified results. Our inspection protocol includes first-article reporting per AS9102 standards, in-process checks at defined intervals, and 100% critical feature validation for production batches. Dimensional data is analyzed using statistical process control (SPC) methodologies to proactively identify trends and maintain process capability indices (Cpk > 1.67) across volumes. This closed-loop system guarantees consistency from prototype to high-volume manufacturing, satisfying IATF 16949 requirements for automotive supply chains.

The following table outlines achievable tolerances for common automotive plastic materials under controlled production conditions. These values reflect sustained capability across batches, not isolated best-case scenarios.

| Material Type | Typical Dimensional Tolerance | Maximum Achievable Tolerance | Critical Feature Note |

|---|---|---|---|

| PEEK | ±0.010 mm | ±0.005 mm | Critical for bearing surfaces & seals |

| Ultem (PEI) | ±0.012 mm | ±0.007 mm | Essential for electrical insulation |

| Nylon (PA 66 GF30) | ±0.015 mm | ±0.010 mm | Accounts for moisture absorption drift |

| Acetal (POM) | ±0.012 mm | ±0.008 mm | Critical for gear tooth profiles |

| Polycarbonate | ±0.018 mm | ±0.012 mm | Surface finish sensitive to tool wear |

Beyond machining, we provide engineering collaboration during design phases to optimize part geometry for manufacturability, material selection guidance based on operational environments, and comprehensive documentation for audit readiness. This integrated approach ensures your plastic components achieve target functionality while minimizing production risk and lifecycle costs. Wuxi Lead Precision Machinery operates at the intersection of polymer science and precision engineering—where automotive innovation demands nothing less than absolute dimensional integrity.

Material & Finish Options

Material Selection for High-Performance Automotive Plastic Machined Parts

In the production of efficient automotive plastic machined parts, the choice of base material plays a critical role in determining the final component’s performance, durability, and compatibility with downstream processes. While the end product may be plastic, precision tooling, molds, and fixtures used in plastic machining are typically manufactured from high-grade metals such as aluminum, steel, and titanium. These materials are selected based on mechanical requirements, thermal stability, corrosion resistance, and cost-efficiency over the production lifecycle.

Aluminum is widely favored in automotive plastic machining due to its excellent machinability, lightweight nature, and good thermal conductivity. It is particularly effective for mold cores, cavities, and prototype tooling where rapid cycling and quick turnaround are essential. The 6061 and 7075 aluminum alloys offer a balanced combination of strength and workability, making them ideal for applications requiring tight tolerances and complex geometries.

Steel, especially tool steel variants such as P20, H13, and 4140, provides superior hardness and wear resistance. It is the preferred choice for high-volume plastic machining operations where tool longevity and dimensional stability are paramount. Steel maintains its integrity under prolonged thermal cycling, making it suitable for injection molds and structural components exposed to high stress. Although heavier and more difficult to machine than aluminum, steel’s extended service life often justifies the initial investment.

Titanium, while less common due to its higher cost and machining complexity, offers exceptional strength-to-density ratio and outstanding corrosion resistance. It is typically reserved for specialized applications in high-performance automotive systems where environmental exposure and weight reduction are critical. Its biocompatibility and thermal stability also make it suitable for niche plastic forming tools used in advanced composite or high-temperature polymer processing.

Surface finishing further enhances material performance. Anodizing, particularly Type II and Type III (hard coat), is a key post-machining process for aluminum components. It increases surface hardness, improves wear resistance, and provides electrical insulation. Hard anodizing can yield a surface hardness exceeding 60 HRC, significantly extending tool life in abrasive environments. The process also allows for color coding and improved aesthetic control, which supports quality assurance and part identification in complex assemblies.

The following table outlines key mechanical and thermal properties of the primary materials used in precision tooling for automotive plastic machining:

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | 167 | Prototype molds, low-volume tooling |

| Steel P20 | 980 | 280 | 28.6 | High-volume injection molds |

| Steel H13 | 1,550 | 230 | 34.0 | Hot-runner systems, die casting |

| Titanium Gr5 | 900 | 330 | 7.2 | High-corrosion, high-stress tooling |

Selecting the appropriate material and finish ensures optimal performance, reduced downtime, and lower total cost of ownership in automotive plastic machining operations. At Wuxi Lead Precision Machinery, we leverage material science and precision CNC expertise to deliver tooling solutions engineered for efficiency and reliability.

Manufacturing Process & QC

Precision Production Process for Automotive Plastic Machined Parts

Achieving zero defects in automotive plastic machined components demands a rigorously controlled, phase-gated production process. At Wuxi Lead Precision Machinery, we integrate advanced CNC technology with stringent quality protocols across every stage, from initial concept to high-volume delivery. This systematic approach ensures parts meet exacting automotive safety, performance, and longevity standards while optimizing efficiency.

The process initiates with collaborative Design for Manufacturability (DFM) analysis. Our engineering team works closely with client CAD models, scrutinizing geometry, material selection, and tolerance specifications specifically for plastic substrates. We identify potential machining challenges early—such as thin-wall instability, thermal deformation risks, or complex feature accessibility—and propose refinements. This phase leverages simulation software to predict material behavior under CNC cutting forces and thermal loads, preventing defects at the source. Critical factors like coefficient of thermal expansion and chip evacuation paths are optimized before any material is cut, establishing the foundation for zero defects.

Prototyping serves as the critical validation checkpoint. Utilizing the same high-precision CNC machining centers (5-axis mills, Swiss-type lathes) designated for production, we manufacture functional prototypes from the exact production-grade polymer. Each prototype undergoes comprehensive metrology: CMM verification against CAD nominal data, optical contour scanning for complex surfaces, and application-specific functional testing. Dimensional accuracy, surface finish, and material integrity are meticulously assessed. Any deviation triggers immediate root cause analysis and process adjustment—never a tolerance waiver. This iterative loop continues until prototypes consistently achieve 100% conformance, proving the process capability before scale-up.

Mass Production executes the validated process under relentless real-time quality surveillance. Our CNC cells operate with automated tool presetter calibration, in-process gauging, and closed-loop thermal compensation systems to counteract ambient and machining-induced heat fluctuations inherent in plastics. Statistical Process Control (SPC) monitors critical dimensions continuously, with data feeds triggering automatic machine adjustments if trends approach specification limits. Every component undergoes 100% automated visual inspection for surface defects and dimensional verification via high-speed vision systems or touch-probe routines integrated within the machining cycle. Final audit includes destructive material testing per batch and full First Article Inspection reports. This multi-layered defense system guarantees zero-defect output meeting automotive PPAP Level 3 requirements.

Material selection directly influences process stability. Key automotive plastics and their machinability characteristics are summarized below:

| Material | Max Continuous Use Temp (°C) | Typical Machined Tolerance (mm) | Common Automotive Applications |

|---|---|---|---|

| PEEK | 250 | ±0.005 | Transmission components, seals, sensors |

| Nylon (PA 6/66) | 120-150 | ±0.02 | Brackets, bushings, fluid system parts |

| Acetal (POM) | 100 | ±0.01 | Gears, levers, fasteners, connectors |

| Polycarbonate | 135 | ±0.02 | Lighting housings, instrument clusters |

This integrated Design-Prototype-Production framework, underpinned by advanced CNC capabilities and uncompromising quality gates, is how Wuxi Lead delivers defect-free plastic machined parts that enhance vehicle reliability and reduce total cost of ownership for global automotive leaders.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Automotive Plastic Machined Parts

At Wuxi Lead Precision Machinery, we understand that precision, consistency, and speed are non-negotiable in the automotive manufacturing sector. As a global leader in CNC machining, we specialize in delivering high-performance plastic machined components tailored to the rigorous demands of modern automotive engineering. When you partner with us, you gain more than a supplier—you gain a strategic collaborator committed to advancing your production goals with uncompromising quality.

Our expertise in precision CNC machining enables us to work with advanced engineering plastics such as PEEK, PPS, PTFE, PAI, and ULTEM—materials chosen for their thermal stability, chemical resistance, and mechanical strength. These properties are critical in applications ranging from transmission components and sensor housings to fuel system elements and electric vehicle battery enclosures. Our state-of-the-art 5-axis CNC machines, combined with in-house metrology and real-time process monitoring, ensure micron-level accuracy and repeatability across high-volume and prototype runs alike.

We operate under strict ISO 9001:2015 certified processes, with full traceability and documentation support for every component we produce. Our engineering team collaborates directly with your design and R&D departments to optimize part geometry, material selection, and manufacturability—reducing lead times and minimizing waste without sacrificing performance. From concept validation to full-scale production, we align our workflow with your timeline, enabling faster time-to-market and improved cost efficiency.

Our facility in Wuxi, China, is equipped with automated machining cells and climate-controlled inspection environments, ensuring dimensional stability and surface finish consistency even under large production volumes. With over 15 years of experience serving Tier 1 automotive suppliers and OEMs across Europe, North America, and Asia, we have built a reputation for reliability, technical depth, and responsive service.

Below are key technical specifications that define our machining capabilities for automotive plastic components:

| Specification | Detail |

|---|---|

| Material Compatibility | PEEK, PPS, PTFE, PAI, ULTEM, PVC, POM, PC, Nylon, PEI |

| Tolerance | ±0.005 mm (±0.0002″) |

| Surface Finish | Ra 0.2 µm to 3.2 µm (custom finishes available) |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; precision turning |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP support |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by volume) |

Whether you require low-volume prototypes for testing or high-volume production runs with Just-In-Time delivery, Wuxi Lead Precision Machinery is equipped to support your needs with agility and precision. We treat every project as a partnership, ensuring transparency, technical collaboration, and on-time delivery.

For immediate assistance or to request a quote, contact us at [email protected]. Let us help you achieve superior performance in your automotive plastic machined parts—engineered to exacting standards, delivered with confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.