Technical Contents

Engineering Guide: Dmls Printing Service

Engineering Insight Precision in DMLS Printing Services

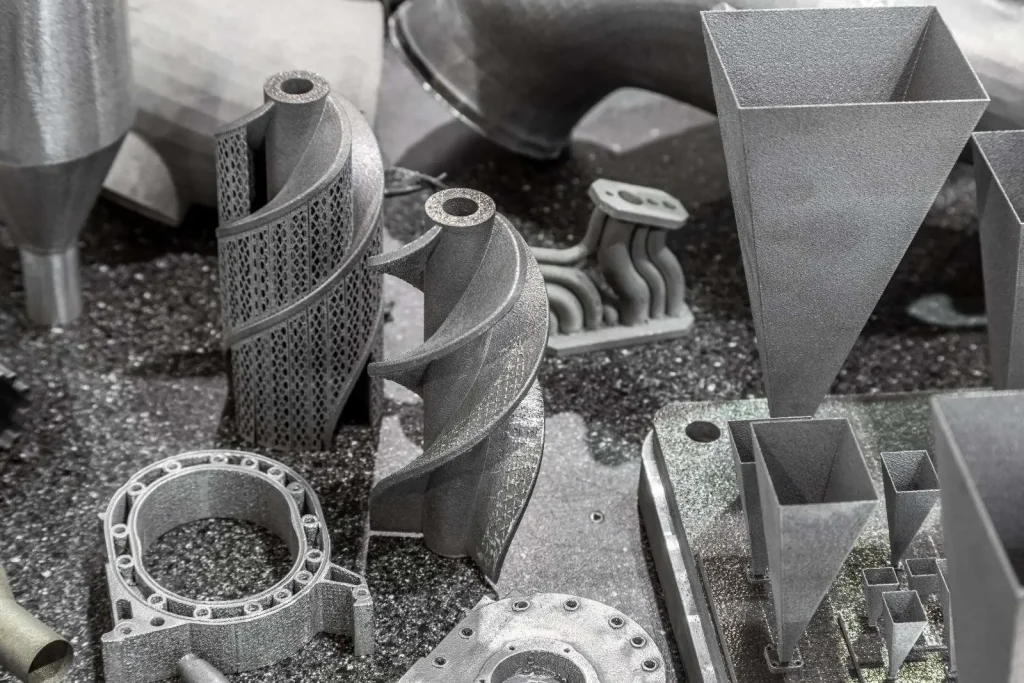

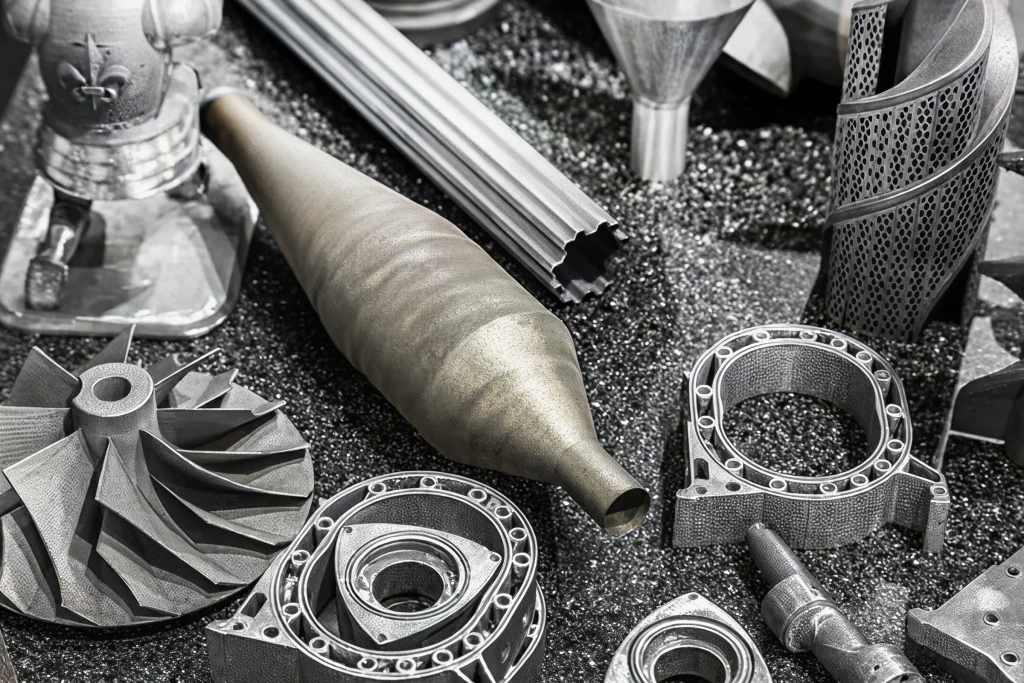

Direct Metal Laser Sintering DMLS transcends prototyping to deliver mission-critical end-use components where dimensional accuracy and material integrity are non-negotiable. At Wuxi Lead Precision Machinery we treat precision not as a target but as a rigorously controlled outcome. Sub-micron thermal gradients during laser melting demand sophisticated compensation algorithms and inert gas management to prevent microstructural defects. Without this control layer adhesion falters internal stresses distort geometries and fatigue resistance plummets—rendering parts unusable in aerospace or medical applications. Our engineering team implements closed-loop monitoring systems that adjust laser power scan speed and hatch spacing in real time ensuring consistent density above 99.95% across every build. This eliminates secondary infiltration processes that compromise mechanical properties.

Material science is equally critical. We exclusively utilize certified aerospace-grade powders including Ti-6Al-4V Inconel 718 and AlSi10Mg with particle distributions tightly controlled between 15–45 microns. Each batch undergoes spectrometry and flowability validation before entering our EOS M 400-4 systems. Post-processing follows equally stringent protocols: stress-relief annealing in vacuum furnaces followed by precision CNC machining of critical interfaces. This hybrid approach guarantees geometric tolerances unattainable through DMLS alone.

Our validation protocols are forged in extreme environments. Components manufactured for Olympic timing systems required motion stability within ±2µm under dynamic loads. Similarly defense sector propulsion components demanded burst pressure resistance exceeding 450 MPa with zero porosity. These projects cemented our understanding that precision in DMLS hinges on the seamless integration of machine calibration material certification and post-build metrology.

The table below summarizes our certified DMLS production capabilities:

| Parameter | Specification | Industry Standard Comparison |

|---|---|---|

| Build Volume | 250 x 250 x 325 mm | Matches EOS M 400-4 |

| Layer Thickness | 20–60 µm adjustable | 30–50 µm typical |

| Dimensional Accuracy | ±0.05 mm for first 50 mm | ±0.1–0.2 mm typical |

| Surface Roughness (As-Built) | Ra 8–12 µm | Ra 10–25 µm typical |

| Material Density | >99.95% | >99.5% typical |

| Common Materials | Ti-6Al-4V Inconel 718 AlSi10Mg 316L | Industry standard alloys |

Wuxi Lead Precision Machinery merges 18 years of CNC mastery with additive innovation. Every DMLS component undergoes 100% CT scanning for internal defects alongside CMM verification of critical datums. This uncompromising approach ensures parts perform identically in the field as they do in simulation. For sectors where failure is not an option precision isn’t measured—it’s engineered. Partner with us to transform complex metal designs into certified reliable assets.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced DMLS (Direct Metal Laser Sintering) printing services tailored for high-performance industrial applications requiring complex geometries, superior material integrity, and micron-level precision. As a leader in custom metal manufacturing, we integrate additive technology with traditional precision engineering to serve aerospace, medical, automotive, and energy sectors with mission-critical components. Our DMLS process builds functional metal parts layer by layer using high-powered lasers to fuse fine metal powders, enabling internal channels, lattice structures, and topology-optimized designs unachievable through conventional methods.

Complementing our DMLS capabilities is a full suite of 5-axis CNC machining resources, allowing for hybrid manufacturing solutions that combine the design freedom of additive with the surface finish and dimensional accuracy of subtractive techniques. This integration ensures that components requiring tight tolerances in critical interfaces or sealing surfaces meet exacting functional requirements. Our 5-axis CNC systems support simultaneous multi-axis motion, enabling single-setup machining of complex contours and undercuts with minimal part handling, reducing cumulative error and improving repeatability.

Quality assurance is embedded throughout our manufacturing workflow. Every DMLS-printed component undergoes rigorous post-processing and non-destructive evaluation, with final validation performed on a Zeiss DuraMax and蔡司 CONTURA G2 Coordinate Measuring Machine (CMM). These high-precision systems verify geometric dimensioning and tolerancing (GD&T) in full 3D space, ensuring compliance with ASME Y14.5 and ISO 1101 standards. Our inspection protocols include first-article inspection (FAI) reporting, full dimensional reports, and batch traceability through serialized data logging.

Our technical capabilities are supported by a controlled build environment, certified material handling, and in-house metallurgical analysis to verify microstructure and mechanical properties. We process a range of high-performance alloys including Inconel 718 and 625, Ti6Al4V (Grade 5), 17-4 PH and 316L stainless steels, AlSi10Mg, and CoCrMo, all sourced from certified suppliers and batch-tested for consistency.

The following table outlines the standard technical specifications and achievable tolerances for our DMLS printing service:

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–50 µm |

| Standard Build Volume | 250 x 250 x 325 mm |

| Maximum Build Volume | 500 x 400 x 400 mm (hybrid setups) |

| Positional Accuracy (X, Y) | ±10 µm |

| Z-axis Accuracy | ±20 µm |

| Feature Resolution (Minimum Hole) | 0.3 mm (via drilling post-process) |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Surface Roughness (polished) | Ra 0.4–1.6 µm |

| Dimensional Tolerance (Machined) | ±0.010 mm (with 5-axis CNC) |

| Wall Thickness (Minimum) | 0.4 mm (unsupported), 0.2 mm (supported) |

| Overhang Angle (Standard) | 45° (with support structures) |

All DMLS builds are optimized using EOSPRINT and Materialise Magics software, with support structure design and orientation analysis to minimize residual stress and distortion. Wuxi Lead Precision Machinery ensures every component meets the highest standards of repeatability, functionality, and quality for demanding industrial environments.

Material & Finish Options

Material Selection for High-Performance DMLS Printing

Selecting the optimal material for Direct Metal Laser Sintering (DMLS) is critical for achieving the required mechanical properties, environmental resistance, and final part functionality in demanding industrial applications. At Wuxi Lead Precision Machinery, we leverage extensive material science expertise to guide clients through this pivotal decision, ensuring the chosen alloy aligns precisely with operational demands and lifecycle requirements. Our focus centers on three foundational material families: Aluminum, Stainless Steel, and Titanium, each offering distinct advantages.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight structural components requiring good thermal conductivity and moderate strength. This material excels in aerospace brackets, heat exchangers, and complex housings where weight reduction is paramount. Post-processing like hot isostatic pressing (HIP) significantly enhances density and fatigue performance for critical applications. Stainless Steels, including 316L for superior corrosion resistance in marine or chemical environments and 17-4PH for high strength after precipitation hardening, are workhorses for fluid handling systems, medical instruments, and tooling. Their inherent durability and biocompatibility make them indispensable across sectors. Titanium Grade 5 (Ti6Al4V) remains the premier choice for aerospace, medical implants, and high-performance motorsport components, offering an exceptional strength-to-weight ratio, outstanding biocompatibility, and excellent resistance to extreme temperatures and corrosion. Its performance justifies the higher material cost in mission-critical scenarios.

Key material properties and applications are summarized below for rapid reference:

| Material | Key Properties | Common Applications | Post-Processing Notes |

|---|---|---|---|

| AlSi10Mg | Lightweight, Good thermal conductivity, Moderate strength | Aerospace brackets, Heat exchangers, Lightweight housings | HIP essential for critical parts; Machining required for tight tolerances |

| 316L Stainless | Excellent corrosion resistance, Ductile, Biocompatible | Marine components, Chemical valves, Medical surgical tools | Stress relief common; Passivation mandatory for corrosion performance |

| 17-4PH Stainless | High strength (after aging), Good corrosion resistance | Mold & die inserts, Aerospace fittings, High-strength shafts | Precise aging heat treatment critical for final properties |

| Ti6Al4V (Grade 5) | High strength-to-weight, Excellent biocompatibility, High temp resistance | Aircraft structural parts, Orthopedic implants, Racing components | Machining challenging; Surface treatments often required for specific wear |

Surface finish significantly impacts part performance and aesthetics, especially for Aluminum DMLS parts. Anodizing is the predominant finishing process. Type II (Sulfuric Acid) anodizing provides standard corrosion and wear resistance with dyeing capability for identification, suitable for general industrial use. For extreme wear environments or electrical insulation needs, Type III (Hardcoat) anodizing delivers a significantly thicker, harder ceramic layer, markedly improving surface durability and temperature resistance. Wuxi Lead Precision Machinery employs tightly controlled anodizing baths and rigorous quality checks to ensure consistent, high-integrity finishes that meet stringent aerospace and medical standards. Material and finish selection is not generic; it requires deep understanding of the operational stresses, environmental exposure, and functional lifespan. Partner with our engineering team early in the design phase to optimize your DMLS part for performance, cost, and manufacturability.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the DMLS printing process begins with meticulous design engineering. Our team collaborates closely with clients to transform conceptual sketches or functional requirements into optimized 3D CAD models. Utilizing advanced simulation software, we conduct structural, thermal, and flow analysis to ensure part integrity under operational conditions. Design for Additive Manufacturing (DfAM) principles are applied rigorously, enabling lightweight structures, internal channels, and complex geometries unachievable through traditional machining. Each model is reviewed for printability, support structure necessity, and material efficiency, ensuring a seamless transition to prototyping. This phase establishes the foundation for zero-defect manufacturing by eliminating design flaws before physical production begins.

Prototyping: Validation Through Precision Fabrication

Once the design is finalized, we proceed to prototype development using our state-of-the-art DMLS systems. Prototypes are printed in the same high-performance alloys intended for final production—ensuring accurate material properties and performance validation. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.03 mm. Functional testing, including pressure, fatigue, and fit-check evaluations, confirms real-world performance. Feedback from this stage is integrated into final design refinements, minimizing risk during mass production. Our closed-loop quality system ensures every iteration is documented and traceable, aligning with ISO 9001 standards and client-specific requirements.

Mass Production: Scalable Excellence with Zero Defects

With design and prototype approval, Wuxi Lead initiates full-scale DMLS production under strictly controlled conditions. Our manufacturing cells operate in climate-regulated environments with real-time monitoring of laser power, layer deposition, and inert gas composition. Each build is supported by automated powder management and post-processing workflows, including stress relieving, support removal, surface finishing, and heat treatment as required. In-process inspections and post-build NDT (non-destructive testing) ensure consistency across batches. We implement Statistical Process Control (SPC) and First Article Inspection (FAI) protocols to maintain tolerances and material homogeneity. Every component is serialized and accompanied by a full quality dossier, enabling complete traceability.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–50 μm |

| Build Envelope | Up to 250 × 250 × 325 mm |

| Positional Accuracy | ±0.03 mm |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Post-Processing Options | Stress relief, HIP, CNC finishing, polishing, coating |

| Supported Materials | Stainless Steel 316L, Inconel 718, Ti6Al4V, AlSi10Mg, CoCr, Tool Steel (Maraging, H13) |

Wuxi Lead Precision Machinery delivers end-to-end DMLS printing services with uncompromising quality. From design to mass production, our integrated approach ensures every component meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical DMLS Production

Direct Metal Laser Sintering represents the frontier of complex, high-integrity metal component manufacturing. At Wuxi Lead Precision Machinery, we transcend standard DMLS service provision by integrating rigorous aerospace-grade process control with deep application engineering expertise. Our facility in Wuxi operates under ISO 9001:2015 and AS9100D certified protocols, ensuring every build meets the uncompromising demands of defense, medical implant, and energy sector applications. We do not merely print parts; we deliver validated solutions where material properties, geometric precision, and traceability are non-negotiable.

Your most challenging projects require a partner who understands the interplay between design intent, material science, and post-processing requirements. Lead Precision provides dedicated engineering support from initial feasibility assessment through final inspection. Our team collaborates directly with your design engineers to optimize topology for additive manufacturing, mitigate residual stress risks, and define precise support structures—reducing iterations and accelerating time-to-qualification. We maintain full in-house control over critical downstream processes including HIP, precision machining, heat treatment, and non-destructive testing, eliminating supply chain vulnerabilities that compromise performance.

Our DMLS Production Capabilities

| Parameter | Specification Detail |

|---|---|

| Materials | Stainless Steel 17-4PH, 316L; Inconel 625, 718; Ti6Al4V ELI; Aluminum AlSi10Mg; Cobalt Chrome |

| Build Volume | 250 x 250 x 325 mm (Standard Platform) |

| Layer Thickness | 20–60 μm (Configurable) |

| Dimensional Accuracy | ±0.05 mm for features < 50 mm |

| Surface Roughness (As-Built) | Ra 12–25 μm (Optimizable via finishing) |

| Post-Processing | HIP, Precision CNC Machining, Stress Relieving, Shot Peening, CMM Inspection |

| Quality Documentation | Full Material Certificates, Build Logs, NDT Reports, First Article Inspection |

This integrated capability set ensures your components achieve required mechanical properties and fatigue resistance—critical for fluid dynamics components, surgical instruments, or turbine hardware operating under extreme conditions. We prioritize repeatability over speed, implementing real-time melt pool monitoring and statistical process control to guarantee batch-to-batch consistency.

Initiate your precision DMLS project with an engineering consultation, not a quotation request. Contact our Applications Engineering team at [email protected] with your target geometry, material specification, and performance requirements. Specify “DMLS Project Inquiry” in the subject line to ensure immediate technical review. Our engineers will respond within 12 business hours with actionable feedback on design viability, lead time, and process validation strategy. For urgent RFQs, include applicable drawings or 3D model files to expedite our technical assessment. Trust Wuxi Lead Precision Machinery to transform your most demanding metal additive concepts into certified, production-ready components—where precision is engineered, not assumed.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.