Technical Contents

Engineering Guide: Dmls 3D Printing Service

Engineering Insight: The Role of Precision in DMLS 3D Printing Services

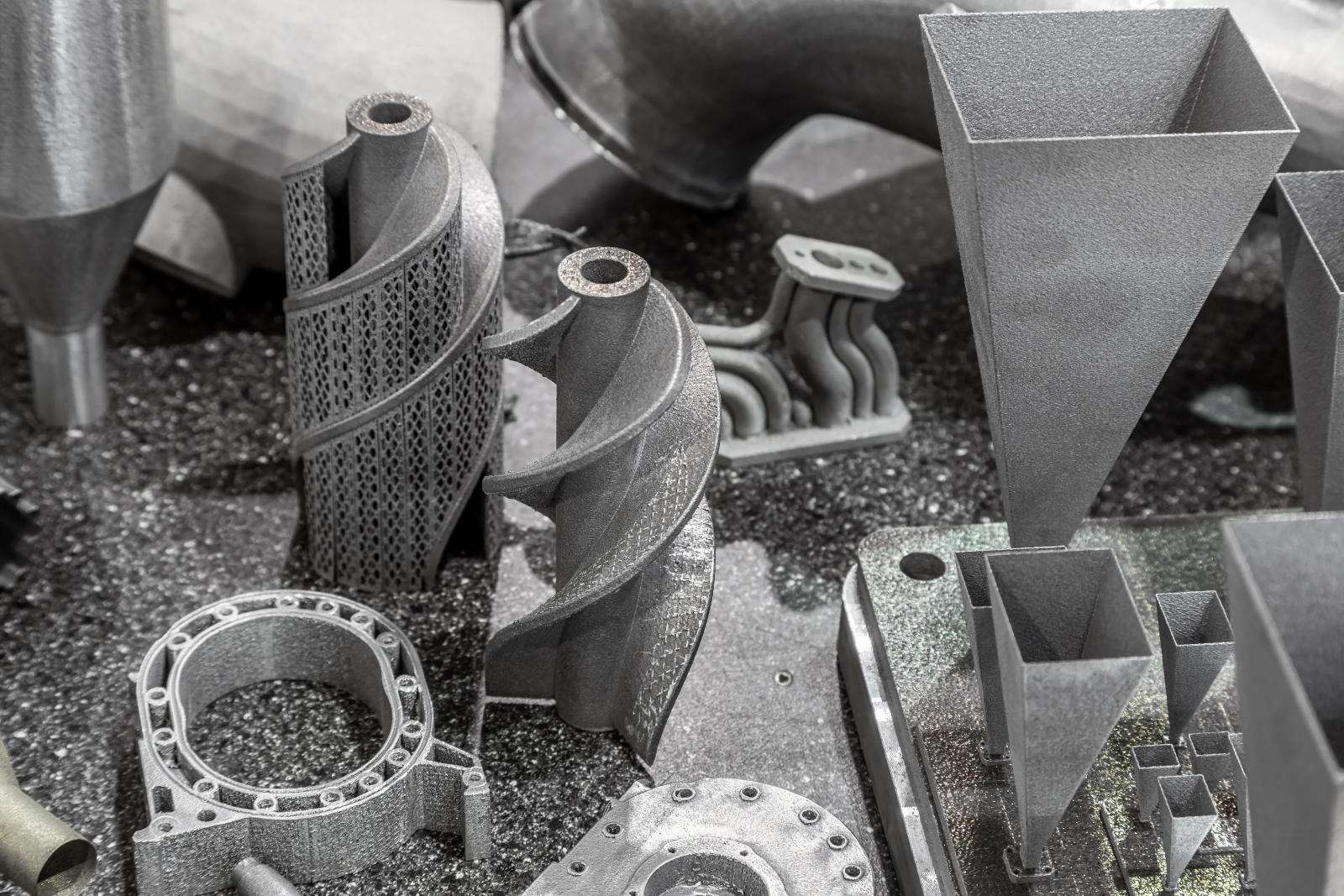

Direct Metal Laser Sintering (DMLS) has redefined the boundaries of custom metal manufacturing, enabling complex geometries, lightweight structures, and rapid prototyping that traditional machining methods cannot achieve. At Wuxi Lead Precision Machinery, we recognize that the true value of DMLS lies not only in its design flexibility but in the precision it delivers at every stage of production. In high-stakes industries such as aerospace, defense, and advanced medical systems, tolerances measured in microns can determine the success or failure of a component. This makes precision not just a specification—but a standard.

Our engineering team approaches every DMLS project with a deep understanding of material behavior, thermal dynamics, and post-processing requirements. The laser sintering process involves melting fine metal powders layer by layer under an inert atmosphere, requiring exact control over laser power, scan speed, and layer thickness. Even minor deviations can lead to residual stress, warping, or porosity—defects that compromise structural integrity. At Lead Precision, we employ real-time monitoring systems and advanced simulation software to predict and correct thermal distortions before final build, ensuring dimensional accuracy and repeatability across production runs.

Precision in DMLS extends beyond the build chamber. Our post-processing protocols—including stress relieving, hot isostatic pressing (HIP), precision machining, and surface finishing—are engineered to meet the most stringent industry standards. Components manufactured for Olympic-grade equipment and military applications demand zero compromise. For example, a titanium lattice structure used in a high-performance athletic prosthetic must balance strength, weight, and fatigue resistance with micron-level consistency. Similarly, a fuel nozzle in a defense-grade turbine engine must withstand extreme temperatures and pressures while maintaining exact flow dynamics.

Wuxi Lead Precision Machinery brings over a decade of specialized experience in high-precision DMLS manufacturing, serving clients who require more than just a printed part—we deliver mission-critical solutions. Our facility is equipped with state-of-the-art metal 3D printers, metrology-grade inspection systems (including CMM and CT scanning), and a quality management system compliant with ISO 9001 and AS9100 standards.

The following table outlines key technical specifications for our DMLS 3D printing service:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 50 µm |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8 – 12 µm |

| Common Materials | Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, Cobalt-Chrome |

| Post-Processing Options | Stress Relieving, HIP, CNC Machining, Polishing, Passivation |

| Quality Standards | ISO 9001, AS9100, Full Material Traceability, First Article Inspection (FAI) Reports |

At Lead Precision, we combine engineering rigor with manufacturing excellence to deliver DMLS components that meet the highest demands of performance and reliability. When precision is non-negotiable, our clients trust us to deliver results—on time, to spec, and beyond expectation.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration of DMLS and CNC Manufacturing

Wuxi Lead Precision Machinery delivers advanced custom metal components through a tightly integrated manufacturing ecosystem, combining cutting-edge Direct Metal Laser Sintering (DMLS) additive technology with high-precision subtractive processes. Our core strength lies in seamlessly bridging the geometric complexity achievable through additive manufacturing with the stringent dimensional accuracy and surface integrity demands of critical applications. This integrated approach ensures parts meet the most exacting aerospace, medical, and industrial requirements, moving beyond prototyping into certified production.

Our DMLS platform utilizes state-of-the-art multi-laser systems capable of processing a wide range of high-performance alloys including Inconel 718, Titanium Ti6Al4V, Stainless Steels (17-4PH, 316L), and Aluminum AlSi10Mg. This foundation enables the creation of intricate internal channels, organic lattice structures, and consolidated assemblies impossible with traditional methods. However, achieving true production readiness for mission-critical components necessitates precision post-processing. This is where our extensive fleet of 5-axis CNC machining centers becomes essential. These machines perform critical secondary operations with micron-level control, including precision boring of internal features, finishing of critical functional surfaces, creation of tight-tolerance mating interfaces, and deburring of complex geometries. The 5-axis capability ensures complex part orientations are machined in a single setup, eliminating cumulative errors and maintaining exceptional geometric accuracy throughout the component.

Rigorous quality control is non-negotiable. Every component undergoes comprehensive verification using our calibrated Coordinate Measuring Machine (CMM) system. Our CMM inspection protocols, aligned with AS9100 and ISO 13485 standards, provide full traceability and dimensional validation against the original CAD model. This includes detailed reporting on critical dimensions, geometric dimensioning and tolerancing (GD&T), surface profile, and positional accuracy. The CMM data directly feeds back into our process control loops, ensuring continuous improvement and unwavering consistency across production batches. This closed-loop quality system guarantees that the theoretical precision of the DMLS build and CNC machining is objectively verified and documented for every part shipped.

The following table details the core technical specifications achievable through our integrated DMLS and 5-axis CNC process:

| Parameter | Capability | Notes |

|---|---|---|

| Materials | Inconel 718, Ti6Al4V, 17-4PH, 316L, AlSi10Mg | Full material certification and traceability available |

| Max Build Volume | 250 x 250 x 325 mm (DMLS) | Optimized for production batch sizing |

| Layer Thickness | 20 – 60 µm | Adjustable based on part geometry and finish requirements |

| As-Built Accuracy | ± 0.05 mm per 100 mm (DMLS) | Highly dependent on geometry; improved significantly by CNC finishing |

| CNC Machined Tolerance | ± 0.005 mm (Critical Features) | Achieved on critical surfaces post-DMLS via 5-axis machining |

| Surface Finish (As-Built) | Ra 10 – 25 µm (DMLS) | Can be improved to Ra 0.8 – 3.2 µm via CNC machining or polishing |

| Post-Processing | Precision CNC, HIP, Stress Relief, Polishing, CMM Inspection | Full in-house capabilities for end-to-end production control |

This synergistic capability—leveraging DMLS for complexity and CNC for precision—positions Wuxi Lead to solve the most challenging metal part requirements. We transform intricate digital designs into fully functional, high-integrity metal components, certified for performance in the most demanding operational environments. Our process delivers not just parts, but guaranteed, documented precision.

Material & Finish Options

Material Selection for DMLS 3D Printing: Aluminum, Steel, and Titanium

When selecting materials for Direct Metal Laser Sintering (DMLS) 3D printing, performance, application environment, and post-processing requirements must align precisely. At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing, offering advanced DMLS solutions with a focus on aluminum, steel, and titanium—three of the most widely used alloys in industrial applications. Each material brings distinct mechanical properties, thermal characteristics, and compatibility with finishing processes such as anodizing, making proper selection critical for optimal part performance.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight structural components requiring good thermal conductivity and moderate strength. This alloy is ideal for aerospace, automotive heat exchangers, and complex housings where weight reduction is a priority. AlSi10Mg exhibits excellent castability and fatigue resistance, making it suitable for dynamic loading environments. When combined with anodizing, aluminum parts gain enhanced surface hardness, corrosion resistance, and aesthetic control—critical for consumer-facing or high-exposure components.

Stainless steel variants such as 316L and 17-4 PH are selected for applications demanding high strength, corrosion resistance, and durability in harsh environments. 316L is widely used in marine, chemical processing, and medical devices due to its superior resistance to chloride corrosion. In contrast, 17-4 PH offers exceptional tensile strength and can be precipitation hardened post-printing, making it ideal for high-stress tooling, valves, and aerospace fittings. While stainless steel is not typically anodized, it can be electropolished or passivated to improve surface integrity and corrosion resistance.

Titanium, especially Ti6Al4V (Grade 5), stands out for its high strength-to-density ratio and outstanding biocompatibility. This alloy is the material of choice in aerospace structural components, medical implants, and high-performance racing parts. Its excellent performance at elevated temperatures and resistance to fatigue and creep make it suitable for extreme operational conditions. Although titanium does not undergo conventional anodizing like aluminum, it can be anodized for color coding and minor surface enhancement, particularly in medical and dental applications.

Below is a comparative overview of key material properties relevant to DMLS 3D printing:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 2.67 | 8–12 | Aerospace ducting, lightweight housings |

| 316L Steel | 550–600 | 300–350 | 8.0 | 35–45 | Marine components, medical devices |

| 17-4 PH Steel | 1000–1200 | 850–1000 | 7.8 | 10–15 | Tooling, valves, high-stress fittings |

| Ti6Al4V | 900–950 | 800–850 | 4.43 | 10–12 | Aerospace, medical implants, motorsports |

Material selection in DMLS is not merely a technical decision—it directly influences manufacturability, lifecycle performance, and total cost of ownership. At Wuxi Lead Precision Machinery, we support clients in matching material and finish options to functional requirements, ensuring every printed component meets the highest standards of precision and reliability.

Manufacturing Process & QC

DMLS Production Process: Precision Engineered from Concept to Volume

At Wuxi Lead Precision Machinery, our Direct Metal Laser Sintering (DMLS) service delivers uncompromising quality for mission-critical metal components. We execute a rigorously controlled three-phase workflow—Design, Prototyping, Mass Production—integrated with our Zero Defects methodology. This ensures seamless scalability while eliminating costly errors, meeting the exacting demands of aerospace, medical, and energy sectors where failure is not an option.

Design Phase Rigor

Our engineering team collaborates closely with clients during initial design, applying deep DMLS process knowledge to optimize geometry for additive manufacturability. We conduct mandatory Design for Additive Manufacturing (DFAM) reviews, identifying potential thermal stresses, support structure needs, and post-processing requirements. Finite Element Analysis (FEA) validates structural integrity under operational loads. Every design file undergoes automated topology optimization and manufacturability simulation using EOSPRINT and Materialise Magics, preventing downstream flaws before the build begins. This proactive validation is the first critical barrier in our Zero Defects chain.

Prototyping Phase Validation

Functional prototypes are produced on the same industrial-grade EOS M 400-4 or SLM 500 systems used for final production, ensuring identical material properties and process parameters. Prototypes undergo comprehensive metrology: 100% first-article inspection via Zeiss CONTURA CMM verifies geometric accuracy against CAD, while micro-CT scanning detects internal porosity. Material certifications (ASTM F75, F138, F1586) and mechanical testing (tensile, fatigue) confirm conformance. Client sign-off on prototype performance data is mandatory, transforming theoretical design into proven, defect-free reality before volume commitment.

Mass Production Excellence

Transitioning to high-volume production leverages our fully automated, climate-controlled production cells. Each build employs real-time melt pool monitoring and layer-wise thermal imaging to detect anomalies instantaneously, triggering automatic process correction. Post-build, components undergo stress-relieving, precision machining (where specified), and surface finishing per ISO 13485 standards. Final inspection includes automated optical scanning against nominal CAD and destructive testing on statistical samples. Every shipment includes full traceability: build logs, material certificates, and inspection reports, guaranteeing documented Zero Defects compliance.

DMLS Process Specifications Across Production Phases

| Parameter | Design Phase | Prototyping Phase | Mass Production Phase |

|---|---|---|---|

| Build Volume | N/A | Up to 500 x 400 x 400 mm | Up to 500 x 400 x 400 mm |

| Layer Thickness | Simulated Optimization | 20-50 µm | 20-50 µm (Controlled) |

| Surface Finish (As-Built) | Predicted via Simulation | Ra 12-25 µm | Ra 10-20 µm (Consistent) |

| Typical Tolerance | ±0.1% (Design Target) | ±0.05 mm | ±0.02 mm (CMM Verified) |

| Material Options | All Supported Alloys | All Supported Alloys | All Supported Alloys (Batch Certified) |

Wuxi Lead’s integrated DMLS workflow transforms complex metal part requirements into defect-free reality. By embedding quality at every phase—from intelligent design through validated prototyping to monitored mass production—we deliver components that perform reliably in the most demanding applications. Trust our AS9100-certified processes to eliminate risk and accelerate your path from innovation to flawless execution.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched DMLS 3D Printing Excellence

When it comes to precision-driven metal manufacturing, Wuxi Lead Precision Machinery stands at the forefront of innovation, engineering integrity, and client-focused service delivery. As a trusted leader in custom metal manufacturing based in China, we specialize in Direct Metal Laser Sintering (DMLS) 3D printing services that transform complex design concepts into high-performance, fully functional metal components. Our advanced capabilities are engineered to meet the rigorous demands of aerospace, medical, automotive, and industrial sectors—where precision, repeatability, and material integrity are non-negotiable.

At Lead Precision, we understand that your success depends on more than just parts—it depends on partnership. That’s why we go beyond standard manufacturing to deliver end-to-end solutions, from initial design consultation and material selection to post-processing and quality assurance. Our state-of-the-art DMLS systems operate in a controlled, ISO-certified environment, ensuring every build meets the highest standards of dimensional accuracy and mechanical performance. With in-house expertise in metallurgy, thermal dynamics, and precision machining, we ensure your components are not only printed to specification but optimized for real-world application.

Our DMLS technology enables the production of geometries that are impossible with traditional manufacturing methods—internal channels, lattice structures, and topology-optimized forms—all while maintaining structural integrity and surface quality. Whether you require rapid prototyping, low-volume production runs, or full-scale manufacturing, our agile systems and responsive team ensure fast turnaround without compromising quality.

We support a wide range of high-performance metal alloys, each selected and processed to meet industry-specific certifications and performance benchmarks. Our process includes full build documentation, first-article inspection reports, and material traceability, ensuring complete compliance for regulated industries.

Below are the key technical specifications of our DMLS 3D printing service:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 50 µm |

| Position Accuracy | ± 0.1 mm / 100 mm |

| Supported Materials | Stainless Steel (316L, 17-4 PH), Inconel 718, Titanium (Ti6Al4V), Aluminum (AlSi10Mg), Cobalt-Chrome (CoCr), Tool Steel (Maraging Steel, H13) |

| Surface Roughness (as-built) | Ra 10 – 15 µm |

| Post-Processing Options | Heat Treatment, HIP, CNC Machining, Polishing, Coating |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting (CMM, CT Scan available) |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally committed to your project’s success. We don’t just print parts—we engineer performance. For expert guidance, custom quotes, or technical consultation, contact us today at [email protected]. Let’s build the future of manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.