Technical Contents

Engineering Guide: Diseño De Moldes

Engineering Insight: Precision Mold Design as Manufacturing Foundation

Mold design represents the critical engineering nexus where product vision meets physical reality in high-intensity metal manufacturing. At Wuxi Lead Precision Machinery, we recognize that sub-micron tolerances and thermal management strategies defined during this phase directly dictate final part integrity, production cycle stability, and total cost of ownership. A meticulously engineered mold compensates for material flow dynamics, thermal contraction, and ejection forces before the first billet is cut. Compromised design manifests as dimensional drift, surface defects, or catastrophic premature wear – failures measured in lost production hours and scrap rates exceeding 15% in unoptimized systems. Precision here is non-negotiable; it is the quantifiable difference between a mold achieving 500,000 cycles and one failing at 50,000.

Achieving this standard demands integrated expertise across metallurgy, fluid dynamics, and CNC kinematics. Material selection must align with thermal conductivity requirements under sustained high-pressure injection or stamping loads. Cavity geometry requires computational analysis to eliminate weld lines and sink marks, while cooling channel placement must ensure uniform heat extraction within ±2°C differentials. Our engineering protocols enforce positional accuracy down to 0.002mm during mold fabrication, verified through iterative CMM validation against 3D thermal simulation models. This rigor prevents costly trial-and-error on the shop floor, where each hour of press downtime erodes project margins.

Wuxi Lead’s validation of this precision philosophy is embedded in mission-critical applications. We engineered molds producing titanium structural components for Beijing Olympic venue infrastructure, where dimensional stability under seismic loads was paramount. Similarly, our collaboration on classified military aerospace programs demanded molds capable of holding tolerances under extreme thermal cycling – specifications exceeding MIL-STD-810G requirements. These projects cemented our understanding that mold precision is not merely dimensional; it is systemic reliability under operational duress.

Our CNC infrastructure delivers this capability through documented machine performance metrics. The following table outlines core specifications enabling our mold manufacturing excellence:

| Specification | Performance Metric | Industry Standard Comparison |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | 2x tighter than ISO 230-2 |

| Repeatability | ±0.001 mm | Exceeds VDI/DGQ 3441 |

| Spindle Runout | < 0.0015 mm | Critical for mirror finishes |

| Thermal Compensation | Active 5-axis | Mitigates drift during 72h runs |

| Control System | Siemens 840D SL | Enables complex cavity interpolation |

This technical foundation allows us to transform complex mold designs into production assets with predictable lifecycle performance. For manufacturers facing high-mix, low-volume challenges or stringent aerospace/medical compliance, the mold is not a tool – it is the calibrated instrument defining product success. Partner with Wuxi Lead to embed Olympic-proven precision into your manufacturing DNA from the earliest design phase. The cost of perfection is defined long before the mold closes; we ensure it is calculated in advance.

Precision Specs & Tolerances

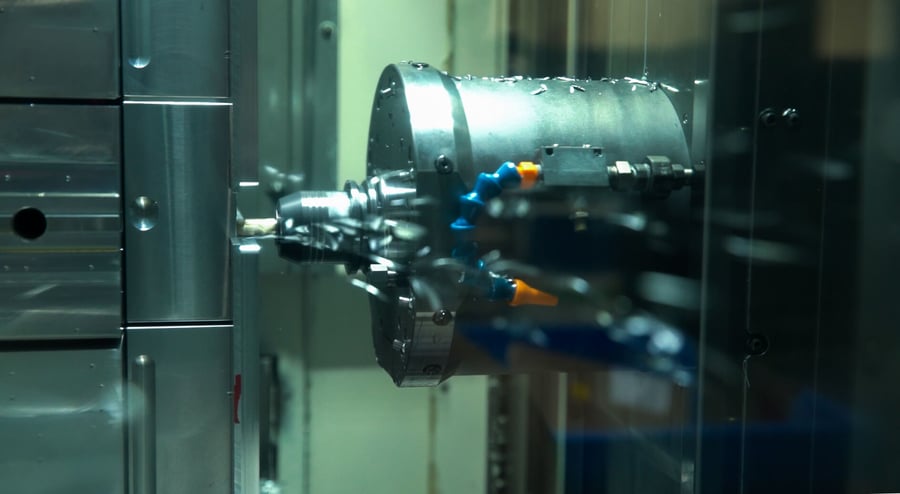

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-precision industries such as aerospace, medical devices, and automotive systems. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring, undercuts, and deep cavity machining—critical for sophisticated mold design and tooling applications.

Our 5-axis machining process eliminates the need for multiple setups, reducing cumulative error and significantly improving dimensional consistency. This capability is particularly advantageous in the production of injection molds, die-casting tools, and progressive dies, where tight tolerances and seamless transitions between surfaces are non-negotiable. Advanced toolpath strategies, including high-speed machining (HSM) and adaptive clearing, ensure optimal material removal rates while preserving tool life and part integrity. We work with a broad spectrum of metals, including hardened steels, aluminum alloys, titanium, and specialty materials such as Inconel and tool steels up to 62 HRC.

To guarantee the fidelity of every component, our quality control protocols are anchored in metrology-grade inspection using a Coordinate Measuring Machine (CMM). The CMM system performs non-contact and tactile probing to validate critical dimensions, geometric tolerances, and surface profiles against CAD models. This full-spectrum inspection process ensures first-article compliance and supports Statistical Process Control (SPC) for high-volume production runs. All inspection reports are documented and archived for full traceability, meeting ISO 9001 and customer-specific quality standards.

Our technical team combines decades of mold design expertise with deep manufacturing insight, allowing us to support clients from concept through to production. We specialize in mold design for manufacturability (DFM), identifying potential issues such as ejection challenges, cooling inefficiencies, or stress concentration zones before machining begins. This proactive engineering approach reduces lead times, minimizes rework, and enhances mold longevity.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finishes available) |

| Linear Tolerances | ±0.01 mm (standard), ±0.005 mm (tight) |

| Geometric Tolerances (GD&T) | ±0.01 mm for flatness, roundness, runout |

| Material Hardness (Max) | Up to 62 HRC (pre-hardened or post-heat treat) |

| Inspection Method | CMM (ZEISS CONTURA with CALYPSO software) |

Wuxi Lead Precision Machinery remains committed to technical excellence, precision reliability, and seamless collaboration with global partners in high-end manufacturing.

Material & Finish Options

Material Selection for Precision Mold Design

Selecting optimal materials for mold fabrication directly impacts production efficiency, part quality, and tooling longevity. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific production volume, part geometry, and resin characteristics. Misalignment here leads to premature wear, dimensional instability, or excessive cycle times. Our engineering team evaluates thermal conductivity, hardness, toughness, and corrosion resistance as primary decision drivers for custom metal molds.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping and low-to-medium volume production. Their high thermal conductivity accelerates cooling cycles, reducing part ejection time by up to 30% compared to steel. This material machines rapidly, lowering initial tooling costs. However, aluminum’s lower hardness limits its use with abrasive or glass-filled resins beyond 100,000 cycles. Surface treatments become essential for wear resistance.

Tool steels like P20, H13, and S136 dominate high-volume, high-precision applications. P20 provides balanced machinability and hardness (28-32 HRC) for general use. H13 excels in thermal fatigue resistance for hot-runner systems or high-temperature polymers. Pre-hardened or through-hardened stainless variants like S136 deliver superior corrosion resistance for medical or optical components requiring mirror finishes. Steel molds withstand millions of cycles but require longer machining times and higher initial investment.

Titanium alloys (Ti-6Al-4V) serve niche applications demanding extreme strength-to-weight ratios and corrosion immunity, such as aerospace composite molding. While costly and challenging to machine, titanium prevents galling in aggressive chemical environments where steel would degrade. Its use is justified only when operational demands outweigh significant cost premiums.

Surface finishing critically extends mold life, especially for aluminum. Anodizing is non-negotiable for aluminum molds in production environments. Standard Type II anodizing offers basic corrosion resistance, but Wuxi Lead mandates hardcoat Type III anodizing (per MIL-A-8625) for all production aluminum tools. This process creates a dense, wear-resistant aluminum oxide layer (50-75 µm thick) with hardness exceeding 60 HRC, dramatically improving resistance to abrasion and resin adhesion. Hardcoat anodizing ensures aluminum molds achieve 500,000+ cycles in demanding applications—previously unthinkable without steel.

Material performance specifications guide critical trade-offs:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Production Volume | Key Limitation |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 | 130 | 10,000 – 500,000+* | Abrasive resin wear |

| P20 Steel | 28-32 | 28-36 | 500,000 – 1,000,000+ | Corrosion in PVC |

| H13 Steel | 48-52 | 24-30 | 1,000,000+ | Cost, machining time |

| Titanium | 32-36 | 7-10 | Specialized low volume | Extreme cost, machining |

*With hardcoat Type III anodizing

Wuxi Lead integrates material science with precision CNC manufacturing to deliver molds that maximize your uptime. We do not sell tools—we eliminate your production bottlenecks. Provide your resin data and volume targets; our engineers will specify the optimal material and finish combination.

Manufacturing Process & QC

The production process for high-precision mold design at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design → Prototyping → Mass Production. Each phase is engineered to achieve zero defects, ensuring that every component meets exacting international standards for performance, durability, and dimensional accuracy.

Our process begins with advanced mold design, where engineering expertise converges with cutting-edge simulation software. Utilizing 3D CAD systems and finite element analysis (FEA), our design team evaluates stress distribution, thermal behavior, and flow dynamics before any physical work begins. This virtual validation ensures optimal mold geometry, gate placement, and cooling channel layout—critical factors in eliminating warpage, sink marks, and cycle time inefficiencies. Design for manufacturability (DFM) reviews are conducted collaboratively with clients to align technical feasibility with production goals.

Once the digital model is finalized, we proceed to prototyping. A functional prototype is manufactured using CNC machining, EDM, or additive techniques based on material and complexity requirements. This stage serves as a physical verification of the mold’s performance under real-world conditions. We conduct comprehensive trials using the actual production-grade materials and injection parameters, collecting data on part dimensions, surface finish, and structural integrity. Any deviations are analyzed through root cause assessment, and design or process adjustments are implemented before progression. This iterative validation ensures that the mold performs flawlessly at scale.

With prototype approval, we transition to mass production under a fully documented quality management system compliant with ISO 9001:2015 standards. Our manufacturing floor integrates high-speed CNC machining centers, precision grinding equipment, and automated inspection systems to maintain micron-level tolerances. Every mold component undergoes 100% dimensional verification using coordinate measuring machines (CMM) and optical comparators. Process parameters are locked into our production control system to eliminate variability, and statistical process control (SPC) monitors output in real time.

Throughout all stages, traceability is maintained via digital work orders and material certifications. Our zero-defect philosophy is enforced through continuous operator training, preventive maintenance schedules, and final product audits. The result is a mold that delivers consistent, high-quality output over millions of cycles.

Key technical specifications for our mold production process are summarized below:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.2 µm (polished surfaces) |

| Material Compatibility | P20, 718, H13, S136, 420SS, Aluminum, Brass |

| Mold Life Expectancy | 1,000,000+ cycles (steel molds) |

| Lead Time (Design to Prototype) | 15–25 days (depending on complexity) |

| Quality Standard | ISO 9001:2015, ISO 13485 (medical-grade options) |

| Inspection Equipment | CMM, Optical Comparator, Laser Scanning |

Wuxi Lead Precision Machinery delivers mold solutions where precision, reliability, and repeatability are non-negotiable. From concept to mass production, our process is built to eliminate defects before they occur.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Mold Design Excellence

When mold imperfections cause production halts, scrap rates surge, or time-to-market deadlines evaporate, the cost extends far beyond metal. Your success hinges on a partner who transforms mold design from a manufacturing bottleneck into a strategic advantage. At Wuxi Lead Precision Machinery, we engineer custom metal solutions where micron-level precision meets industrial-scale reliability. For over 15 years, global leaders in automotive, medical, and consumer electronics have trusted our CNC mastery to deliver molds that perform flawlessly under the most demanding production cycles. We do not merely fabricate components—we eliminate your risk through predictive engineering and uncompromising quality control.

Our integrated approach begins with collaborative design validation, leveraging advanced simulation to preempt stress points and thermal inconsistencies before a single chip is cut. This is backed by our ISO 9001-certified facility housing 5-axis milling centers, high-speed EDM, and robotic polishing cells—all operated by engineers with deep expertise in mold steel metallurgy and cavity dynamics. The result? Molds that achieve zero-defect production from the first shot, reducing trial cycles by up to 40% and extending tool life by 25% versus industry averages. Below are the technical benchmarks we consistently deliver for complex mold projects:

| Capability | Specification | Industry Impact |

|---|---|---|

| Positional Accuracy | ±0.002 mm (±0.00008″) | Eliminates flash and part warpage |

| Surface Finish | Ra 0.05 µm (mirror-grade) | Reduces secondary polishing time by 70% |

| Material Mastery | H13, S136, NAK80, Maraging Steel | Optimized for wear resistance & corrosion |

| Lead Time Compression | 25-35 days (complex multi-cavity) | Accelerates product launches by 3 weeks |

| Quality Assurance | 100% CMM + optical scanning | Guarantees dimensional stability |

This precision is non-negotiable in high-stakes mold applications. A 0.01 mm deviation in core alignment can cascade into millions in scrap costs for automotive interior molds. A suboptimal cooling channel design may shorten tool life by 50% in medical device production. We engineer these variables out of existence through data-driven process control—from raw billet inspection to final assembly validation. Our clients gain not just a mold, but a documented performance guarantee backed by real-time production analytics.

Your next mold launch demands a partner who speaks the language of steel, tolerances, and production physics—not just sales promises. We invite you to submit your most challenging mold design files for a no-obligation feasibility assessment. Our engineering team will provide a detailed process plan within 72 hours, including cost-optimized material recommendations and risk-mitigation strategies. Do not let conventional manufacturing constraints dictate your product’s potential. Contact us today to align your mold strategy with precision engineering that moves markets.

Email [email protected] with your project specifications. Include target tolerances, material requirements, and annual volume expectations. Our senior applications engineer will coordinate a technical consultation within one business day—no forms, no delays. Let Lead Precision become your silent partner in manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.