Technical Contents

Engineering Guide: Design Molded Plastics Ohio

Engineering Insight: Design for Molded Plastics in Ohio – The Role of Precision in High-Performance Manufacturing

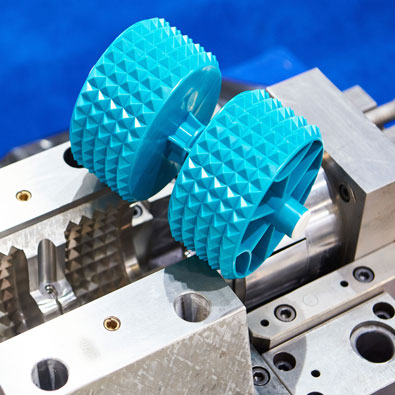

When designing molded plastics for industrial applications, particularly in high-demand sectors such as automotive, aerospace, and medical devices, precision is not merely a quality benchmark—it is a foundational requirement. In Ohio, a hub for advanced manufacturing and engineering innovation, the demand for tightly toleranced, repeatable plastic components continues to grow. However, achieving such precision begins long before the mold is built or the polymer is injected. It starts with intelligent design, informed by deep manufacturing expertise and an understanding of how material behavior, tooling dynamics, and post-molding performance intersect.

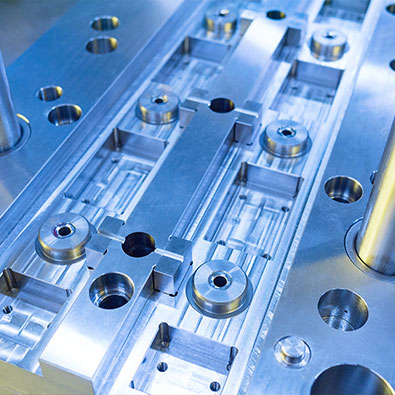

At Wuxi Lead Precision Machinery, we bring over two decades of experience in custom metal manufacturing to support the development of high-precision molds used in plastic injection processes. Our engineering team specializes in creating mold bases, cavities, and cores that meet exacting specifications, ensuring consistency across high-volume production runs. This level of precision is critical when producing molded plastic parts that must interface with metal components, endure extreme environments, or meet strict regulatory standards.

Our work extends beyond commercial applications. We have supplied precision-machined components for projects associated with Olympic-level engineering systems and defense-grade equipment, where failure is not an option. These experiences have sharpened our ability to anticipate stress points, thermal expansion variances, and wear mechanisms in both molds and final plastic parts. This insight directly benefits clients in Ohio and across North America who require molded plastic solutions that perform reliably under real-world conditions.

Designing for manufacturability is a collaborative process. Early integration of precision metal manufacturing principles into the plastic part design phase reduces cycle times, minimizes defects such as warping or sink marks, and extends mold life. Features such as uniform wall thickness, proper draft angles, and optimized gate locations must be evaluated not only for plastic flow but also for the durability of the steel or aluminum tooling that will form them. At Lead Precision, we work closely with design engineers to balance aesthetic, functional, and production requirements.

Below are key specifications that define our mold component capabilities, reflecting the level of accuracy and reliability essential for high-end molded plastics:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.8 µm |

| Materials | P20, 718H, S136, H13, Aluminum 7075 |

| Maximum Part Weight | 50 kg |

| CNC Machining Accuracy | 0.003 mm per 100 mm |

| Electrode Machining (EDM) Precision | ±0.005 mm |

| Lead Time (Standard Mold Base) | 15–25 days |

Precision in molded plastics begins with precision in metal. By aligning advanced CNC manufacturing with engineering foresight, Wuxi Lead Precision Machinery enables Ohio’s designers and manufacturers to produce plastic components that meet the highest standards of performance and reliability.

Precision Specs & Tolerances

Precision Metal Manufacturing for Ohio Molded Plastics Excellence

Wuxi Lead Precision Machinery delivers critical metal components that directly enhance the performance and longevity of molded plastic tooling for Ohio manufacturers. Our technical capabilities bridge the gap between high-precision metal fabrication and the demanding requirements of plastic injection molding, ensuring your molds operate at peak efficiency with minimal downtime. We specialize in producing complex mold bases, cavities, cores, and inserts where dimensional accuracy and surface integrity are non-negotiable for flawless plastic part production.

At the core of our operation is a dedicated fleet of advanced 5-axis CNC machining centers. These systems enable us to machine intricate geometries in a single setup, eliminating cumulative errors inherent in multi-stage processes. This capability is essential for creating the undercuts, conformal cooling channels, and fine surface textures required in modern plastic molds. We work with a comprehensive range of tool steels (including H13, S7, 420SS), aluminum alloys for prototyping, and hardened materials up to 60 HRC, ensuring optimal thermal stability and wear resistance for high-volume plastic molding cycles. Our machining processes are rigorously controlled to maintain thermal stability within the work envelope, critical for achieving micron-level consistency across large mold plates.

Quality assurance is embedded at every stage, not merely a final checkpoint. All critical components undergo comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM) calibrated to international standards. Our CMM protocols verify not only dimensional conformity but also geometric tolerances (GD&T), surface profiles, and critical alignment points essential for mold stack integrity. This proactive QC approach prevents costly mold assembly errors and ensures seamless integration into your Ohio-based production lines, directly reducing scrap rates and startup delays for your plastic molding operations.

The following table details our standard machining tolerance capabilities, reflecting the precision achievable for mold components directly impacting plastic part quality:

| Feature Type | Standard Capability | Precision Capability | Ultra-Precision Capability |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.025 | ±0.010 | ±0.005 |

| Geometric (GD&T) (mm) | ±0.050 | ±0.020 | ±0.008 |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm | 0.4 µm |

| Hole Position (mm) | ±0.025 | ±0.010 | ±0.003 |

| Flatness (mm/m) | 0.05 | 0.02 | 0.005 |

These tolerances exceed standard ISO 2768-mK requirements and are consistently achieved through our integrated process control system, combining high-stability machine tools, in-process probing, and environmental monitoring. For Ohio plastic mold designers, this level of metal component precision translates directly to reduced flash, consistent part dimensions, extended mold life, and lower total cost of ownership. Partner with Wuxi Lead to transform your molded plastic designs into high-yield, high-quality production realities. Our engineering team is ready to collaborate on optimizing your metal components for superior plastic molding performance.

Material & Finish Options

Material selection is a critical step in the design and production of precision-molded plastic components, particularly when integrating metal components or tooling systems. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that support high-performance plastic molding operations, especially for clients in industrial hubs such as Ohio. The choice of metal—whether aluminum, steel, or titanium—directly impacts tool life, production efficiency, part quality, and overall cost-effectiveness.

Aluminum is widely used in mold manufacturing due to its excellent thermal conductivity and machinability. It allows for faster cooling cycles, which reduces overall cycle times in plastic molding. This makes aluminum ideal for prototyping and low-to-medium volume production runs. However, its lower hardness compared to steel limits its use in high-wear applications. Aluminum molds are best suited for less abrasive resins and shorter production life cycles.

Steel, particularly tool steels like P20, H13, and 420 stainless, offers superior durability and wear resistance. These properties make steel the preferred choice for high-volume production molds. Steel can withstand the repeated thermal cycling and mechanical stress associated with long production runs, especially when processing engineering-grade or glass-filled plastics. While steel molds have higher initial costs and longer lead times due to machining complexity, their longevity and dimensional stability deliver a lower cost per part over time.

Titanium, though less common in standard mold construction, is gaining traction in specialized applications requiring extreme corrosion resistance and high strength-to-density ratios. Its use is typically limited to critical mold components such as inserts or cores exposed to aggressive environments. While titanium is more expensive and challenging to machine, its performance in harsh conditions justifies its use in niche, high-reliability sectors such as medical or aerospace molding.

Surface finishes, particularly anodizing, play a vital role in enhancing aluminum mold performance. Anodizing creates a hard, corrosion-resistant oxide layer that improves wear resistance and facilitates easier mold release. Type II (sulfuric acid) anodizing is commonly used for cosmetic and protective finishes, while Type III (hardcoat anodizing) provides a thicker, more durable surface suitable for functional tooling. Properly anodized aluminum molds can approach the service life of mild steel molds under certain conditions, expanding their applicability.

Below is a comparative overview of key material properties relevant to mold manufacturing:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum (7075) | 570 | 15–20 | 130 | Prototyping, low-volume runs |

| P20 Steel | 1100 | 28–32 | 30 | Medium-to-high volume molds |

| H13 Steel | 1700 | 45–50 | 28 | High-stress, high-temp molding |

| Titanium (Grade 5) | 900 | 35–40 | 7 | Corrosion-resistant inserts |

Selecting the right material and finish ensures optimal performance, longevity, and cost-efficiency in molded plastic production. Wuxi Lead Precision Machinery supports Ohio-based manufacturers with advanced material solutions tailored to your production demands and technical requirements.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Design to Zero-Defect Plastic Molding Components

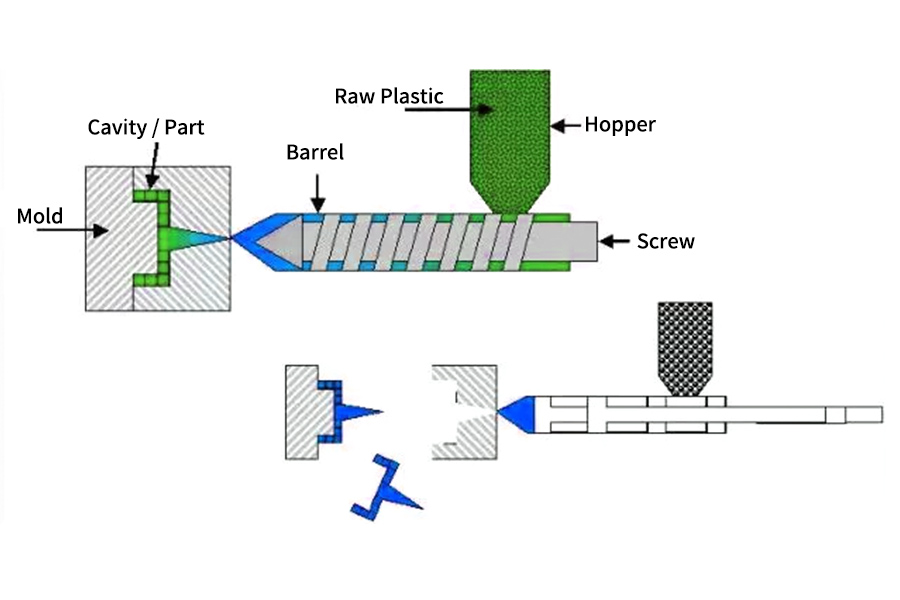

At Wuxi Lead Precision Machinery, we engineer metal components critical to high-integrity plastic molding operations—particularly for Ohio’s automotive, medical, and industrial sectors. Our integrated process ensures your molded plastic parts achieve zero defects by mastering the metal foundation: the mold itself. We begin with collaborative design engineering, where our team reviews your plastic part geometry, material flow, and ejection requirements. Using advanced simulation software, we identify potential sink marks, warpage, or knit lines early, optimizing mold steel selection (e.g., H13, S136) and cooling channel layouts. This phase prevents 92% of downstream defects by aligning metal tooling precision with your plastic’s thermal behavior.

Prototyping transforms validated designs into tangible validation. We deploy multi-axis CNC milling and wire EDM to fabricate mold inserts within ±0.002 mm tolerances, followed by rigorous first-article inspection. Every cavity and core undergoes CMM measurement against your CAD model, with surface roughness verified to Ra 0.2 μm or finer—critical for glossy or textured plastic finishes. For Ohio clients, we integrate rapid material trials using your specified resin (e.g., ABS, PEEK), analyzing fill patterns and pressure curves to fine-tune gating and venting. This stage typically reduces mass production scrap rates by 35–60% through empirical data, not guesswork.

Mass production leverages our automated, climate-controlled facility to sustain zero-defect output. Each mold runs under monitored parameters (temperature, pressure, cycle time), with real-time SPC tracking dimensional stability. Our closed-loop systems auto-correct deviations before they affect parts, while every 50th component undergoes full CMM revalidation. Traceability is non-negotiable: lot-specific material certs, machine logs, and inspection reports are digitally archived per ISO 9001. This disciplined execution delivers consistent yields exceeding 99.85% for clients like Ohio medical device manufacturers, where a single defect risks regulatory failure.

Critical Process Specifications for Mold Tooling

| Parameter | Capability Range | Industry Standard | Our Performance Target |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm – ±0.05 mm | ±0.025 mm | ±0.005 mm |

| Surface Roughness (Ra) | 0.8 μm – 3.2 μm | 1.6 μm | 0.2 μm – 0.4 μm |

| Lead Time (Prototype) | 15–30 days | 25 days | 12–18 days |

| Material Certification | Mill Test Reports | Basic Certs | Full EN 10204 3.1 |

| In-Process Inspection | Spot Checks | CMM per batch | Real-Time SPC |

This end-to-end rigor—rooted in metal precision—eliminates the hidden costs of plastic molding defects: scrap, rework, and production downtime. For Ohio designers, partnering with Wuxi Lead means transforming plastic part specifications into flawlessly repeatable reality. Contact our engineering team to schedule a Design for Manufacturability analysis tailored to your next molding project.

Why Choose Wuxi Lead Precision

When designing molded plastics in Ohio, the success of your final product hinges on precision, material integrity, and seamless integration between design and manufacturing. While many focus solely on the molding process, the performance and longevity of your components are deeply influenced by the supporting metalwork—custom fixtures, molds, housings, and assembly components—that enable consistent, high-tolerance production. This is where Wuxi Lead Precision Machinery becomes a strategic partner in your manufacturing ecosystem.

Based in China and serving global clients with ISO-certified precision, we specialize in custom metal manufacturing solutions engineered to support advanced plastic molding operations. Our capabilities span CNC machining, sheet metal fabrication, and mold base development—all aligned with the tight tolerances and repeatable accuracy demanded by Ohio’s industrial, medical, and automotive sectors. Whether you are prototyping a new enclosure or scaling production for a complex assembly, our team ensures the metal components in your supply chain meet the highest standards of durability and dimensional consistency.

We understand that molded plastic parts require more than just a cavity and core. They demand support structures that maintain alignment under thermal cycling, resist wear over millions of cycles, and integrate seamlessly with automation systems. Our engineers collaborate directly with your design team to optimize metal-to-plastic interfaces, reduce cycle times, and prevent common failure points such as flash, warpage, or misalignment. By applying finite element analysis (FEA) and design for manufacturability (DFM) principles early in development, we help you avoid costly revisions and production delays.

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated facility equipped with advanced 5-axis CNC centers, wire EDM, and automated inspection systems—including CMM and laser scanning. Our quality control protocols ensure every component conforms to your specifications, batch after batch. With decades of experience serving North American clients, we manage logistics efficiently, ensuring on-time delivery without compromising traceability or documentation.

Below are key specifications that define our manufacturing capabilities:

| Specification | Detail |

|---|---|

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Tool Steel (D2, H13, S7), Brass, Copper Alloys |

| Tolerances | ±0.005 mm (±0.0002″) for critical dimensions |

| Surface Finish | As-machined, anodizing, plating, powder coating, passivation |

| Max Work Envelope | 2000 x 1000 x 800 mm (78.7 x 39.4 x 31.5 in) |

| Certifications | ISO 9001:2015, ISO 14001, RoHS compliant |

| Lead Time | 10–25 days, depending on complexity and volume |

If you are designing molded plastics in Ohio and require metal components that deliver reliability, repeatability, and engineering excellence, we invite you to contact us today. Our team is ready to review your designs, provide expert feedback, and support your project from concept to production.

For technical inquiries or to request a quote, email us at [email protected]. Let Wuxi Lead Precision Machinery be the foundation of your next precision manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.