Technical Contents

Engineering Guide: Design Molded Plastics Macedonia

Engineering Insight: Design Molded Plastics Macedonia – The Role of Precision in High-Performance Manufacturing

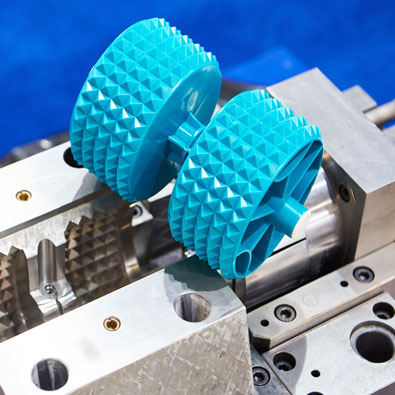

In the evolving landscape of custom metal manufacturing, the integration of design molded plastics—particularly in advanced industrial applications—demands an uncompromising commitment to precision. While plastics may appear less rigid than metals, their performance in mission-critical environments hinges on exacting dimensional accuracy, material consistency, and seamless integration with metal components. This is especially true in Macedonia’s growing industrial sectors, where automation, defense systems, and high-efficiency machinery rely on hybrid assemblies combining molded plastics with precision-engineered metal parts.

At Wuxi Lead Precision Machinery, we understand that precision is not merely a manufacturing standard—it is a foundational engineering principle. With over 15 years of specialized experience serving Olympic-grade equipment suppliers and military-grade defense contractors, our team has developed a deep understanding of how tolerances at the micron level directly impact system reliability, longevity, and performance. Whether producing components for high-speed automation or ruggedized field equipment, the alignment between molded plastic elements and their metal counterparts must be flawless.

One of the most critical challenges in designing molded plastics for integration with metal systems is managing thermal expansion, mechanical stress, and long-term wear. Even minor deviations in wall thickness, draft angles, or gate placement can result in warping, delamination, or structural failure under operational load. Our engineering team applies finite element analysis (FEA) and mold flow simulation to anticipate these risks during the design phase, ensuring that every molded plastic part is optimized for both manufacturability and real-world performance.

Moreover, the synergy between mold tooling precision and secondary metal processing—such as CNC machining, insert molding, or overmolding—requires a vertically integrated approach. At Lead Precision, we maintain full in-house control over both metal fabrication and plastic molding processes, enabling tight feedback loops between design, prototyping, and production. This integration ensures that every component, whether aluminum housing or polycarbonate actuator cover, meets the exact specifications required by high-end clients in Macedonia and beyond.

Our experience with Olympic timing systems—where a millisecond deviation can alter competition outcomes—and military communication enclosures—exposed to extreme temperatures and shock loads—has reinforced the necessity of precision across every project. These applications demand not only compliance with international standards (such as ISO 2768-m and MIL-STD-810) but also a culture of continuous improvement and zero-defect manufacturing.

Below are key specifications that define our precision capabilities in hybrid metal-plastic component manufacturing:

| Specification | Capability | Standard Tolerance |

|---|---|---|

| CNC Machining Accuracy | ±0.005 mm | ISO 2768-m |

| Injection Molding Tolerance | ±0.02 mm | ISO 20457 |

| Material Compatibility | PEEK, PC, ABS, Nylon + Metal Inserts | UL94 V-0 Rated |

| Operating Temperature Range | -40°C to +150°C | MIL-STD-810G Compliant |

| Surface Finish (Plastic) | Ra 0.8 – 3.2 μm | Custom Polish Available |

| Production Lead Time | 15–25 days (Prototype to Pilot) | JIT Delivery Options |

Precision in design molded plastics is not an isolated goal—it is the result of disciplined engineering, advanced tooling, and a proven track record in the world’s most demanding applications. For industrial partners in Macedonia seeking reliable, high-performance components, Wuxi Lead Precision Machinery offers the expertise and infrastructure to deliver excellence on every level.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Molded Plastics

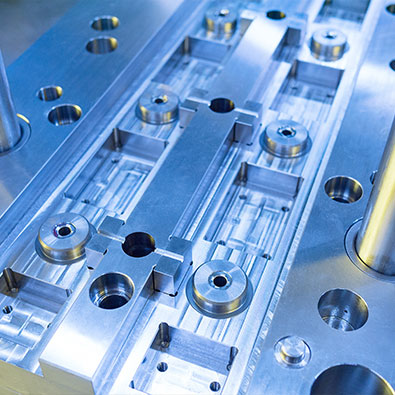

Wuxi Lead Precision Machinery delivers mission-critical metal components essential for high-performance plastic molding applications, including those serving the Macedonia region and global markets. Our expertise lies in transforming complex metal designs into reality with uncompromising accuracy, directly supporting the reliability and efficiency of your injection molding, blow molding, or rotational molding processes. We specialize in producing molds, inserts, cores, cavities, and precision structural components where micron-level tolerances directly impact plastic part quality, cycle time, and tool longevity. This capability is fundamental for manufacturers demanding defect-free plastic outputs in sectors like automotive, medical devices, and consumer electronics.

Our core manufacturing strength is anchored in advanced 5-axis CNC machining centers. Utilizing state-of-the-art equipment from manufacturers like DMG MORI and MAZAK, we achieve simultaneous 5-axis interpolation, enabling the production of highly intricate geometries in a single setup. This eliminates cumulative errors from multiple fixturing stages, critical for complex mold surfaces, undercuts, and internal cooling channels that define modern plastic molding efficiency. Our machines feature high-speed spindles, rigid construction, and thermal compensation systems, ensuring dimensional stability during extended production runs of materials ranging from hardened tool steels (P20, H13, S136) to aluminum and brass. This reduces lead times and significantly enhances part consistency compared to traditional 3-axis methods.

Quality assurance is non-negotiable. Every critical dimension undergoes rigorous validation using calibrated Coordinate Measuring Machines (CMMs), primarily Zeiss CONTURA and GLOBAL series systems. Our inspection process follows ISO 10360 standards, providing full first-article inspection reports (FAIR) and comprehensive dimensional verification against client CAD models and GD&T specifications. This metrology-grade validation, combined with in-process checks and material certifications, guarantees that components meet the stringent requirements necessary for high-cavity molds and tight-tolerance plastic parts, preventing costly production downtime or scrap.

The following table details our standard and achievable tolerance capabilities for critical features, reflecting our commitment to precision in support of demanding plastic molding applications.

| Parameter | Standard Capability | Precision Capability | Ultra-Precision Capability |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 | ±0.002 |

| Angular Features (°) | ±0.05 | ±0.02 | ±0.005 |

| Surface Finish (Ra µm) | 0.8 | 0.4 | 0.2 |

| Positional Tolerance | ±0.015 | ±0.008 | ±0.003 |

| Profile Tolerance | ±0.020 | ±0.010 | ±0.005 |

These specifications represent achievable results under controlled production conditions for qualified materials and geometries. Standard capability denotes routine production tolerance. Precision capability requires optimized fixturing and process control. Ultra-precision capability is achieved for critical features using specialized metrology feedback and extended machining cycles, typical for optical or medical mold components. Surface finish values are attainable on machined surfaces; polished finishes to Ra 0.05 µm are available post-machining.

Partnering with Wuxi Lead ensures your metal components for plastic molding systems are manufactured to the exacting standards required for optimal plastic flow, part ejection, and extended mold life. Our integrated 5-axis CNC and CMM capabilities provide the geometric accuracy and surface integrity that directly translate into reduced plastic part defects, lower production costs, and accelerated time-to-market for your molded products, whether destined for Macedonia or worldwide distribution. We engineer precision that molds success.

Material & Finish Options

Material Selection for High-Performance Molded Plastic Tooling

When designing molded plastic components in demanding industrial environments such as those in Macedonia’s growing manufacturing sector, the choice of tooling and structural materials is critical. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that ensure durability, precision, and cost-efficiency in plastic molding applications. The selection of aluminum, steel, or titanium for molds, fixtures, and support structures directly impacts tool life, surface finish, and production throughput.

Aluminum is often the preferred choice for low-to-medium volume production runs due to its excellent machinability, thermal conductivity, and lightweight properties. Its ability to dissipate heat quickly reduces cycle times in injection molding, improving efficiency. While softer than steel, modern high-strength aluminum alloys such as 7075-T6 offer sufficient wear resistance for many plastic molding applications, especially when enhanced with surface treatments.

Steel, particularly tool steels like P20, H13, and S136, remains the standard for high-volume plastic molding operations. These alloys provide superior hardness, wear resistance, and longevity, making them ideal for molds subjected to thousands or even millions of cycles. Stainless variants such as 420SS are used when corrosion resistance is essential, particularly in molding environments involving aggressive resins or high humidity. While steel is heavier and more expensive to machine than aluminum, its extended service life often justifies the investment.

Titanium, though less common, offers an exceptional strength-to-density ratio and outstanding corrosion resistance. Its use in plastic molding is typically limited to specialized components such as ejector pins or inserts where weight reduction and resistance to galling are paramount. While high material and machining costs restrict its widespread use, titanium’s performance in extreme conditions makes it invaluable for niche, high-reliability applications.

Surface finishing plays a crucial role in mold performance and part quality. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat) anodizing, is a widely used finish for aluminum tooling. It enhances surface hardness, improves wear resistance, and provides electrical insulation. Hard anodizing can increase the surface hardness of aluminum to nearly that of tool steel, significantly extending mold life. Additionally, anodized surfaces offer excellent release properties, reducing the need for mold release agents and minimizing part defects.

For steel molds, nitriding, polishing, and chrome plating are more common, though anodizing is not applicable due to steel’s composition. Titanium can be anodized as well, primarily for color coding or minor corrosion enhancement, but its natural oxide layer already provides robust protection.

Below is a comparative overview of key material properties relevant to plastic molding tooling:

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 570 | 150 | 130 | Prototype & low-volume molds |

| P20 Steel | 900 | 280 | 30 | High-volume injection molds |

| H13 Steel | 1600 | 230 | 35 | Hot-runner molds, high-temp service |

| Titanium Gr5 | 900 | 330 | 7 | Wear-resistant inserts, ejector pins |

Selecting the optimal material and finish requires balancing performance requirements, production volume, and cost. Wuxi Lead Precision Machinery supports clients across Europe, including Macedonia, with engineered solutions tailored to specific molding challenges.

Manufacturing Process & QC

Precision Metal Manufacturing Process for Molded Plastic Component Systems

Wuxi Lead Precision Machinery clarifies a critical distinction: our expertise lies in custom metal manufacturing for industries including plastic molding machinery. We produce the high-precision metal components—such as mold bases, cores, cavities, and ejection systems—that enable the production of molded plastics. This process ensures the dimensional accuracy and durability required for zero-defect plastic part manufacturing, directly supporting clients in Macedonia and globally.

The journey begins with Engineering Design & Feasibility. Our engineers collaborate closely with your team to analyze 3D CAD models, applying deep knowledge of metal behavior under molding stresses. We conduct rigorous Design for Manufacturability (DFM) reviews, optimizing geometry for CNC machining efficiency while meeting stringent tolerance requirements. Material selection is critical; we specify aerospace-grade tool steels or hardened alloys based on your plastic resin type, cycle life demands, and thermal management needs. Finite Element Analysis (FEA) validates structural integrity under injection pressures, preventing costly failures downstream. This phase establishes the non-negotiable blueprint for zero defects.

Precision Prototyping & Validation follows immediately. Using 5-axis CNC milling and wire EDM, we produce functional prototypes from the final production material. This is not a 3D-printed approximation but a true representation of the end part. Every critical dimension undergoes First Article Inspection (FAI) per AS9102 standards, verified through CMM and optical metrology. We subject prototypes to simulated molding cycles, measuring thermal stability, wear resistance, and surface finish against your plastic part specifications. Any deviation triggers immediate design iteration. This stage is where theoretical designs prove real-world viability, eliminating risks before mass production investment.

Zero-Defect Mass Production leverages our fully integrated digital manufacturing ecosystem. Production occurs on ISO 14644 Class 8 cleanroom CNC cells, monitored by real-time SPC software tracking critical parameters like tool wear, coolant concentration, and thermal drift. Each component receives a unique QR code for full traceability—from raw material heat number to final inspection data. In-process checks occur at defined intervals using automated vision systems, while final inspection employs multi-sensor CMMs capable of sub-micron verification. Statistical process control ensures CpK values consistently exceed 1.67, guaranteeing defect rates below 0.1%. Our closed-loop system automatically adjusts machining parameters, making zero defects an engineered outcome, not an aspiration.

The table below summarizes our core production capabilities ensuring reliability for plastic molding applications:

| Parameter | Capability | Standard Compliance | Verification Method |

|---|---|---|---|

| Tolerance Range | ±0.005 mm to ±0.001 mm | ISO 2768-m, DIN 16901 | CMM, Optical Comparator |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm | ISO 1302, VDI 3400 | Profilometer, Visual |

| Material Options | P20, H13, S136, 420SS, Invar | ASTM A681, ISO 4957 | Mill Cert, Spectrometry |

| Max Work Envelope | 1200 x 800 x 600 mm | Custom Fixturing | Laser Tracker |

| Defect Rate Target | < 100 PPM | PPAP Level 3 | SPC Dashboard, FAI Reports |

This integrated approach—grounded in metallurgical science, validated prototyping, and statistically controlled production—ensures the metal components driving your plastic molding operations perform flawlessly from the first shot to the millionth cycle. Wuxi Lead delivers not just parts, but guaranteed process stability for your Macedonian manufacturing success.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Custom Metal Manufacturing Solutions

When designing molded plastics in Macedonia—or anywhere across Southeastern Europe—your success hinges not only on the quality of the plastic component but also on the precision and reliability of the metal tooling that shapes it. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance custom metal manufacturing services tailored to the exacting demands of the injection molding industry. As a trusted partner to global manufacturers, we bridge the gap between innovative plastic design and industrial-grade metal fabrication, ensuring your molds, dies, and tooling systems perform with unmatched consistency and longevity.

Our engineering team brings over 15 years of experience in producing mold bases, core and cavity inserts, ejector systems, and custom fixtures using premium-grade tool steels and advanced CNC machining techniques. Whether your project involves high-cavitation molds for mass production or complex geometries requiring multi-axis precision, we apply strict quality control protocols to meet ISO 9001 standards and your specific technical requirements. We understand that in Macedonia’s evolving manufacturing sector, efficiency, lead time, and cost-effectiveness are critical—our streamlined production process and direct communication model ensure rapid turnaround without compromising on accuracy.

Wuxi Lead serves clients across Europe with seamless collaboration, offering full digital integration from 3D CAD modeling to final inspection reports. Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC centers, wire and sinker EDM systems, surface grinders, and CMM inspection equipment, enabling us to produce components with tolerances as tight as ±0.002 mm. We work with a wide range of materials including P20, 718H, NAK80, H13, and S136 stainless tool steels, ensuring optimal performance under high-pressure, high-temperature molding environments.

Below are key technical specifications that define our manufacturing capabilities:

| Specification | Capability |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling |

| EDM Processing | Wire EDM, Sinker EDM |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 µm (polished or textured) |

| Materials | P20, 718H, NAK80, H13, S136, SKD61, 420SS |

| Quality Standards | ISO 9001:2015, First Article Inspection, CMM Reports |

| Lead Time | 15–25 days (average, depending on complexity) |

We support Macedonian design engineers and manufacturing firms with end-to-end solutions—from initial design review and DFM analysis to final delivery with comprehensive packaging for international shipping. Our team communicates in English and responds to technical inquiries within 4 business hours, ensuring alignment at every stage.

For seamless integration into your molded plastics development cycle, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your strategic partner in achieving superior tooling performance and manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.