Technical Contents

Engineering Guide: Delrin Injection Molding

Engineering Insight: Precision in Delrin Injection Molding

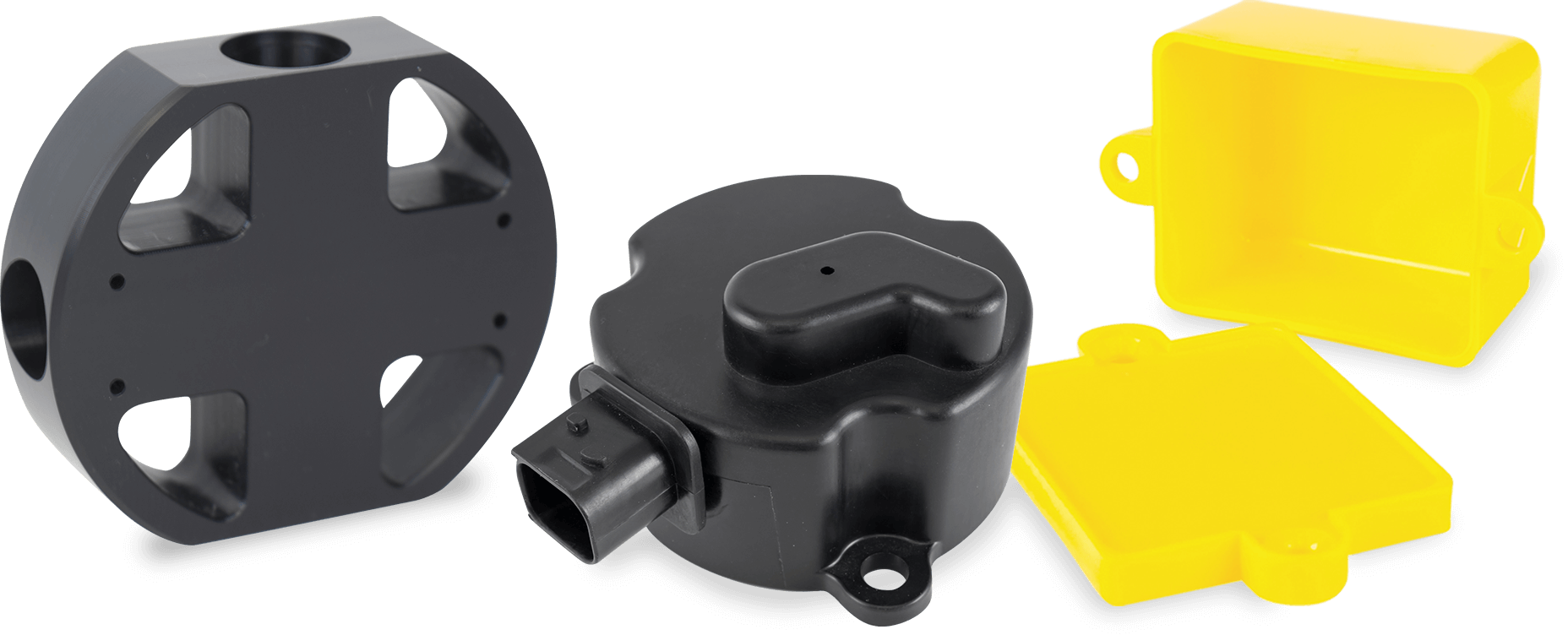

Delrin, a high-performance acetal homopolymer engineered by DuPont, is widely regarded as one of the most dimensionally stable thermoplastics available for precision injection molding. Its combination of high tensile strength, low friction, excellent wear resistance, and minimal moisture absorption makes it ideal for demanding applications in aerospace, defense, medical devices, and high-accuracy industrial components. However, achieving optimal performance from Delrin injection molding hinges critically on precision—both in mold design and process control.

At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-tolerance applications, with over a decade of experience in producing molds and components for engineered polymers like Delrin. Our work extends to projects meeting Olympic-standard tolerances and military-grade specifications, where failure is not an option. These experiences have reinforced a fundamental truth: Delrin’s material advantages can only be fully realized when paired with micron-level precision in mold construction and process execution.

One of the unique characteristics of Delrin is its low shrinkage rate—typically between 1.8% and 2.2%. While this contributes to dimensional stability, it also demands extreme accuracy in mold cavity design. Even minor deviations in mold geometry can result in parts that fail to meet tight assembly tolerances, especially in multi-cavity production runs. At Lead Precision, we utilize CNC-machined steel molds with tolerances held within ±0.002 mm, ensuring repeatability and consistency across production batches.

Thermal control during injection is equally critical. Delrin requires precise melt temperatures (typically 190–210°C) and controlled cooling rates to prevent warpage or internal stresses. Our molding systems integrate closed-loop temperature regulation and real-time pressure monitoring, allowing for consistent filling and packing phases. This level of process control is essential when producing components for applications such as precision gears, bushings, or locking mechanisms—parts where functional fit and long-term reliability are non-negotiable.

Our engineering team conducts rigorous mold flow analysis and first-article inspections using coordinate measuring machines (CMM), ensuring that every Delrin component meets the client’s exact specifications. Whether supporting defense contractors requiring ITAR compliance or medical OEMs needing ISO 13485 certification, our manufacturing protocols are built around traceability, precision, and performance validation.

The following table outlines key process and material specifications for Delrin injection molding as applied in our high-precision production environment:

| Parameter | Value / Range |

|---|---|

| Material Type | Delrin 100, 500, or 900 series |

| Melt Temperature | 190–210°C |

| Mold Temperature | 80–120°C |

| Injection Pressure | 70–120 MPa |

| Cooling Time | 15–30 seconds (part-dependent) |

| Shrinkage Rate | 1.8–2.2% |

| Typical Tolerance | ±0.025 mm (standard), ±0.005 mm (high-precision) |

| Tooling Material | H13, P20, or S136 hardened steel |

| Surface Finish (mold) | SPI A1, A2, or custom polish |

At Wuxi Lead Precision Machinery, we treat Delrin injection molding not merely as a production process, but as an engineering discipline. Our commitment to precision ensures that every component we produce performs reliably in the most demanding environments.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Delrin Injection Molding

Wuxi Lead Precision Machinery delivers exceptional technical execution for Delrin (POM) injection molding projects, leveraging our core expertise in high-precision metal manufacturing to ensure optimal plastic part performance. While specializing in custom metal components, our deep understanding of material behavior, thermal dynamics, and dimensional stability directly translates to superior mold design, fabrication, and part validation for engineering plastics like Delrin. This integrated approach addresses the unique challenges of POM, including moisture absorption, thermal expansion, and crystallization control, ensuring parts meet stringent functional requirements in demanding applications across automotive, medical, and industrial automation sectors.

Our foundation lies in advanced 5-axis CNC machining centers, which enable the production of complex, high-tolerance mold cores, cavities, and inserts from hardened tool steels or pre-hardened alloys. This capability ensures precise replication of intricate geometries and critical sealing surfaces required for Delrin’s low-friction, high-stiffness characteristics. Tight control over mold surface finish (Ra 0.2 µm achievable) minimizes part warpage and enhances dimensional repeatability. Crucially, our metal manufacturing heritage allows us to anticipate and mitigate interactions between mold steel behavior and POM processing parameters, such as optimizing cooling channel placement to manage Delrin’s specific shrinkage rates and crystallization kinetics.

Quality control is non-negotiable. Every Delrin component undergoes rigorous verification using calibrated Coordinate Measuring Machines (CMM) with sub-micron resolution. Our inspection protocol includes first-article validation against CAD models, statistical process control (SPC) during production runs, and final dimensional certification for critical features. This systematic approach guarantees compliance with even the most demanding aerospace (AS9100) or medical (ISO 13485) specifications.

The following table details achievable geometric tolerances for Delrin injection molded parts under controlled conditions, reflecting our standard and precision capabilities:

| Dimension Range (mm) | Standard Capability (± mm) | Precision Capability (± mm) |

|---|---|---|

| ≤ 25 | 0.05 | 0.025 |

| 25 – 100 | 0.08 | 0.04 |

| 100 – 250 | 0.12 | 0.06 |

| > 250 | 0.15 | 0.08 |

Notes: Precision capabilities require optimized mold design, controlled molding environment (70±2°C mold temp, dry material), and post-molding stabilization (24h at 23°C/50% RH). Tolerances exclude draft angles and apply to critical functional features after stabilization.

Material traceability and process documentation are integral to our workflow. We provide full material certifications (including Lot # verification per ASTM D6779), detailed molding parameter logs, and comprehensive CMM reports with every production batch. This transparency ensures traceability and facilitates root-cause analysis if required. By combining our metal manufacturing rigor with specialized polymer processing knowledge, Wuxi Lead Precision Machinery transforms Delrin’s potential into reliable, high-performance components that exceed functional expectations. Partner with us for technically demanding projects where precision, repeatability, and material science expertise are paramount.

Material & Finish Options

Material Selection for High-Precision Delrin Injection Molding Components

When engineering high-performance components for Delrin injection molding applications, material selection plays a critical role in ensuring durability, dimensional stability, and long-term reliability. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for mold tooling used in precision Delrin (POM – Polyoxymethylene) molding. The choice of base metal—aluminum, steel, or titanium—directly influences mold life, cycle time, and surface finish quality.

Aluminum is often selected for prototyping and low-volume production due to its excellent machinability and thermal conductivity. It allows for rapid heat dissipation, reducing cycle times during molding. However, aluminum’s lower hardness makes it less suitable for extended production runs, especially with abrasive additives in Delrin formulations. It performs best in applications requiring fast turnaround and where mold wear is minimal.

Steel, particularly tool steel grades such as H13 or P20, is the standard for high-volume Delrin injection molding. Its superior hardness and wear resistance ensure extended mold life, often exceeding hundreds of thousands of cycles. Steel molds maintain tight tolerances over time and are ideal for complex geometries and high-cavitation tools. While initial machining and tooling costs are higher, the long-term return on investment is significant in mass production environments.

Titanium is less commonly used but offers unique advantages in specialized applications. With an exceptional strength-to-density ratio and outstanding corrosion resistance, titanium is suitable for molds exposed to aggressive environments or where weight reduction is critical. However, its high cost and challenging machinability limit its use to niche aerospace or medical applications.

Surface finishing, particularly anodizing, further enhances mold performance. Anodizing increases surface hardness and wear resistance, especially for aluminum molds. Type II (sulfuric acid) anodizing provides a protective oxide layer and allows for color coding, while Type III (hardcoat anodizing) delivers maximum durability for high-stress applications. For steel and titanium, alternative surface treatments such as nitriding or PVD coatings are typically preferred due to material compatibility.

The following table summarizes key mechanical and thermal properties of these materials relevant to Delrin injection molding tooling:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Typical Mold Life (cycles) | Best Use Case |

|---|---|---|---|---|---|

| Aluminum | 40–50 | 150–180 | 300–500 | 10,000–100,000 | Prototyping, low-volume runs |

| Steel (H13) | 48–52 | 30–35 | 1,500–1,800 | 500,000+ | High-volume, complex molds |

| Titanium | 35–40 | 7–10 | 900–1,200 | 200,000–500,000 | Corrosive environments, aerospace |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production volume, part complexity, and environmental demands. Our expertise ensures optimal mold performance, maximizing efficiency and part quality in Delrin injection molding operations.

Manufacturing Process & QC

Delrin Injection Molding: Precision Execution from Concept to Zero Defects Production

Achieving flawless Delrin (POM) components demands a rigorously controlled process integrating advanced engineering and meticulous manufacturing discipline. At Wuxi Lead Precision Machinery, our Zero Defects philosophy is embedded within every stage, transforming design intent into high-integrity production reality. This systematic approach ensures optimal mechanical properties, dimensional stability, and long-term performance for demanding industrial applications.

The Design Phase establishes the foundation for success. Our engineering team conducts comprehensive Design for Manufacturing (DFM) analysis specifically for Delrin’s unique characteristics. We evaluate wall thickness uniformity, gate location, and ejection strategy to mitigate sink marks, warpage, and internal stresses inherent in semi-crystalline polymers. Finite Element Analysis (FEA) simulates flow behavior and cooling, predicting potential defects before tooling begins. Critical tolerances are defined against ISO 2768-mK standards, ensuring the design is inherently manufacturable at scale. Material selection guidance for specific Delrin grades (e.g., 100, 500, 900) is provided based on required chemical resistance, wear performance, and load conditions.

Prototyping Phase validates the design and process under near-production conditions. We utilize high-precision, CNC-machined aluminum or steel prototype molds, mirroring the final tool’s critical features. Rigorous process parameter optimization occurs here: melt temperature, injection speed, packing pressure, and cooling time are systematically adjusted. Statistical Process Control (SPC) methodologies monitor key dimensions on every prototype part. Dimensional inspection against CAD data using CMMs and optical comparators confirms geometric accuracy within ±0.02mm. Material properties are verified through targeted mechanical testing. This phase identifies and resolves subtle issues, preventing costly errors in mass production.

Mass Production Phase executes the perfected process with unwavering consistency. Production occurs in climate-controlled cleanrooms using all-electric or hybrid hydraulic presses with exceptional repeatability. Real-time process monitoring systems track pressure, temperature, and cycle time, triggering automatic alerts for any parameter drift beyond established control limits. Every batch undergoes stringent in-process and final inspection. Automated vision systems check critical features, while destructive testing on sacrificial samples validates mechanical integrity per ASTM standards. Comprehensive traceability links each component to its specific material lot, machine parameters, and inspection data. This closed-loop system ensures every Delrin part meets the Zero Defects mandate, delivering reliability essential for aerospace, medical, and precision automation sectors.

Critical process parameters for Delrin injection molding are maintained within these precise ranges:

| Parameter | Typical Range | Critical Control Objective |

|---|---|---|

| Mold Temperature | 80°C – 120°C | Minimize warpage, ensure surface finish |

| Melt Temperature | 190°C – 230°C | Prevent degradation, ensure flow consistency |

| Injection Pressure | 80 – 150 MPa | Achieve complete cavity fill without flash |

| Cooling Time | 15 – 45 sec (part dependent) | Maximize crystallinity, dimensional stability |

Wuxi Lead Precision Machinery leverages decades of custom metal manufacturing expertise to produce the ultra-precise molds and execute the disciplined processes required for truly defect-free Delrin components. We partner with you to transform demanding specifications into flawless, high-performance reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Delrin Injection Molding Excellence

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing with a focused expertise in engineering-grade thermoplastics, including Delrin (POM – Polyoxymethylene). Our advanced injection molding capabilities are built to meet the rigorous demands of industries such as automotive, medical devices, industrial automation, and precision instrumentation. When you partner with us, you gain access to a fully integrated manufacturing ecosystem that combines German-level engineering standards with the cost efficiency of Chinese production.

Delrin is renowned for its exceptional dimensional stability, low friction, high stiffness, and excellent wear resistance—making it ideal for precision components that require long-term reliability under dynamic loads. However, molding Delrin to exacting specifications demands more than just machinery; it requires deep material understanding, precision tooling, and strict process control. At Lead Precision, we bring all three together with a commitment to zero-defect manufacturing.

Our facility in Wuxi, China, is equipped with state-of-the-art electric and hybrid injection molding presses ranging from 50 to 1,000 tons, enabling us to handle both prototyping and high-volume production. We design and manufacture custom molds in-house using hardened tool steels, ensuring longevity and consistency. Every production run is supported by real-time process monitoring, statistical process control (SPC), and full traceability—critical for regulated industries.

We understand that every application is unique. That’s why our engineering team collaborates closely with clients from design for manufacturability (DFM) through to final validation. Whether you’re transitioning from metal to Delrin for weight reduction or improving wear performance in a moving assembly, we provide technical guidance to optimize your part geometry, gate placement, and material selection.

Our clients choose us not only for our technical capabilities but also for our responsive communication, transparent pricing, and on-time delivery performance exceeding 98%. As your manufacturing partner, we act as an extension of your engineering team—ensuring your Delrin components perform as intended, every time.

| Specification | Capability |

|---|---|

| Material Expertise | Delrin (POM), Homopolymer & Copolymer grades |

| Molding Press Range | 50–1,000 Tons Clamping Force |

| Tolerance Control | ±0.02 mm for critical dimensions |

| Mold Fabrication | In-house CNC, EDM, Polishing (Class 10,000 Cleanroom Available) |

| Secondary Operations | Ultrasonic Welding, Insert Molding, CNC Finishing, Laser Marking |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection (FAI) Reports |

| Production Scale | Prototypes to Multi-Cavity High-Volume Runs |

Ready to elevate your Delrin injection molding project with a trusted precision partner? Contact us today at [email protected] to speak with one of our engineering specialists. Let Wuxi Lead Precision Machinery bring your high-performance component designs to life—with precision, consistency, and reliability built in.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.