Introduction: Navigating the Global Market for inconel 3d printing

In today’s rapidly evolving industrial landscape, the demand for components that combine intricate geometries with unmatched mechanical performance is higher than ever. Inconel 3D printing—leveraging the strength and high-temperature resilience of nickel-based superalloys—has emerged as a transformative solution for sectors spanning aerospace, energy, automotive, and advanced manufacturing. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the opportunity to access and source Inconel 3D printed parts means gaining a competitive edge in durability, design flexibility, and production agility.

However, entering the market for Inconel 3D printing entails navigating a complex technical, commercial, and logistical environment. The interplay of advanced additive manufacturing techniques (like SLM and EBM), strict material certifications, and evolving global supply chains presents both opportunity and risk—especially in emerging and cross-continental markets such as Kenya or Poland. Buyers must balance considerations like supplier reputation, raw material traceability, part quality assurance, and cost efficiency to ensure successful outcomes.

This guide addresses these challenges head-on by offering a comprehensive, actionable resource for B2B buyers. It covers the entire landscape:

– Types of Inconel suitable for 3D printing and their key applications

– Critical material and powder specifications for optimal part performance

– Manufacturing processes, certifications, and quality control standards

– Global supplier ecosystems, capacity, and sourcing strategies

– Cost structures, lead times, and market dynamics

– Frequently asked questions and practical sourcing tips

Every section is designed to empower buyers with the expertise to evaluate suppliers, navigate technical requirements, and negotiate advantageous terms—regardless of geography or scale. The outcome: faster decision-making, enhanced risk mitigation, and smarter investments in additive manufacturing that drive real business value.

Understanding inconel 3d printing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Selective Laser Melting (SLM) | Fine, precise layer-by-layer process using laser energy | Aerospace parts, medical implants, tooling | High accuracy; supports complex geometries, but slower build rates & potential for porosity |

| Electron Beam Melting (EBM) | Utilizes electron beams in a vacuum; higher build rates | Turbine blades, aerospace, energy sector | Fast production; reduced residual stresses; equipment costly and fine design features limited |

| Direct Energy Deposition (DED) | Material deposited and melted simultaneously, often via robotic arms | Repair/refurbishment, large-scale parts, oil & gas | Suited for large or repaired parts; flexible; surface finish/coarseness can require post-processing |

| Binder Jetting | Powder inkjet binding, followed by sintering | Prototyping, low-stress industrial components | Cost-effective for prototypes; efficient; limited mechanical strength for high-performance uses |

| Hybrid Additive-Subtractive Manufacturing | Integrates 3D printing with CNC machining in a single setup | Aerospace, automotive, custom tooling | High precision; finished parts in one process; high operational complexity and cost |

Selective Laser Melting (SLM)

SLM employs a high-power laser to selectively melt layers of Inconel powder, creating intricate components with high dimensional accuracy. This technique is especially well-suited for aerospace, medical, and high-specification tooling markets where precision and complex designs are paramount. For buyers, SLM enables customization and weight reduction but requires careful management of production variables to prevent porosity and achieve optimal strength. Access to qualified SLM operators and robust quality assurance processes are key purchasing considerations, especially in regions where additive manufacturing expertise may be limited.

Electron Beam Melting (EBM)

EBM involves melting layers of Inconel powder under a vacuum with an electron beam, allowing for faster build speeds and reduced residual stresses compared to laser-based methods. Buyers in sectors such as turbine manufacturing and energy benefit from excellent high-temperature performance and throughput efficiency. However, EBM demands significant upfront investment in equipment and typically delivers slightly coarser feature resolution than SLM. When considering EBM, international buyers should assess logistics for powder supply, spare parts availability, and technical support, particularly in developing markets.

Direct Energy Deposition (DED)

DED uses focused thermal energy (laser or electron beam) to melt Inconel as it is deposited, giving it the flexibility to build or repair large and complex components, often with robotic integration. It is widely applied for part restoration and producing oversized structures in industries like oil & gas and heavy equipment. For buyers, DED’s appeal lies in its repair capabilities and adaptability, but the resulting surface finish often necessitates additional machining. Evaluating vendors with post-processing facilities and evaluating total cost of ownership are important steps before procurement.

Binder Jetting

Unlike fusion-based methods, binder jetting uses a print head to selectively deposit a binding agent onto Inconel powder, followed by sintering to achieve final strength. This process is advantageous for B2B buyers prioritizing rapid prototyping or cost-effective runs of non-critical parts. However, binder jetting cannot match the mechanical properties achieved by fusion-based techniques, limiting its suitability for structural or high-load applications. Buyers should determine if their applications truly need full Inconel performance or if binder-jetted components are sufficient for their requirements.

Hybrid Additive-Subtractive Manufacturing

This methodology combines additive 3D printing with CNC machining in a single, often automated, workflow. The strength of this approach is producing finished Inconel components with tight tolerances and reduced lead times—ideal for bespoke aerospace or automotive applications. For buyers, the capital investment and operational complexity are higher, but the ability to source precision parts rapidly may justify the cost. Evaluating in-country service support, technical training, and part qualification protocols is critical for international buyers considering this advanced solution.

Related Video: B&T SRBS 556 – 3D Printed Inconel Suppressor!

Key Industrial Applications of inconel 3d printing

| Industry/Sector | Specific Application of inconel 3d printing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Turbine engine components (blades, vanes, combustors) | High strength-to-weight, withstands extreme temperatures | Certification standards (e.g., AS9100), traceability, fatigue & creep resistance |

| Oil & Gas | Downhole drilling tools, high-pressure valves | Corrosion resistance, rapid customization | NACE/API compliance, local climate & corrosive conditions, short lead times |

| Power Generation | Gas turbine hot section parts, heat exchangers | Efficiency, reduced downtime, extended lifespan | Material verification, post-processing quality, supply chain resilience |

| Automotive | Lightweight exhaust manifolds, turbocharger housings | Performance boost, complex shapes, emission reduction | Volume scalability, automotive-grade finishing, emission norms adherence |

| Chemical Processing | Reactor components, pumps, fittings | Superior resistance to aggressive chemicals, reliability | Regulatory requirements, compatibility, inspection/certification protocols |

Aerospace: Turbine Engine Components

Inconel 3D printing enables the production of advanced turbine blades, vanes, and combustor parts with intricate internal cooling channels—crucial for jet engines and rocket propulsion. These parts must operate reliably under extreme heat and mechanical loads. For buyers in regions such as Europe and the Middle East, meeting rigorous aerospace certifications (AS9100, Nadcap) and ensuring batch traceability are paramount. Suppliers should demonstrate experience with fatigue and creep testing to guarantee airworthiness and reduce risk in safety-critical applications.

Oil & Gas: Downhole Drilling Tools and Valves

In resource-rich geographies like Africa and South America, Inconel 3D-printed drilling tools and high-pressure valve components are vital due to frequent exposure to corrosive fluids and high pressures. Additive manufacturing provides the ability to rapidly iterate and deliver custom geometries, minimizing costly downtime. Buyers must focus on suppliers that adhere to NACE and API standards, offer detailed documentation, and understand the regional demands—particularly resilience against H2S, CO2, and high salinity.

Power Generation: Gas Turbine Hot Section Parts

Gas turbines, integral to both traditional and renewable-friendly grids, require hot section components able to resist oxidation and thermal fatigue. 3D printing Inconel allows for weight reductions and bespoke cooling solutions, directly improving plant efficiency and flexibility. Procurement teams should prioritize partners who can provide thorough material certifications, robust post-processing (including heat treatment and machining), and contingency plans for timely delivery, as unexpected outages can be costly.

Automotive: Lightweight Exhaust and Turbocharger Housings

Automakers, especially those in emission-regulated markets like Poland, leverage Inconel 3D printing to create lightweight, high-performance exhaust manifolds and turbocharger housings. The technology opens doors to complex, integrated designs that lower emissions and boost vehicle performance. Sourcing priorities include ensuring finishing appropriate for automotive integration, volume production capacity, and compliance with local environmental and safety regulations.

Chemical Processing: Reactor Components, Pumps, Fittings

Chemical plants handling aggressive acids and solvents benefit from Inconel 3D-printed parts (such as pumps, nozzles, and reactor inlets), with tailored geometries for process optimization. Buyers must verify regulatory conformance and demand comprehensive inspection and non-destructive testing documentation. Partnerships with suppliers experienced in custom design and fast-turnaround replacements can provide strong cost and uptime advantages for operations across emerging and mature markets.

Related Video: SLM Metal 3D Printing – the Next Level of Superalloy (Inconel, Titanium) Additive Manufacturing

Strategic Material Selection Guide for inconel 3d printing

Selecting the Optimal 3D Printing Materials for Inconel Applications

When investing in Inconel 3D printing, B2B buyers must navigate a landscape of high-performance alloys, each tailored for specific application demands. While Inconel 718 remains the flagship alloy, alternative materials—including Inconel 625, Hastelloy X, and Maraging Steels—are also routinely considered for additive manufacturing projects. The right material selection determines not only the operational lifespan and safety of end-products but also affects compliance with international standards, supply chain logistics, and overall project economics—factors critical for buyers across Africa, South America, the Middle East, and Europe.

Inconel 718

Key Properties:

Inconel 718 is prized for its excellent tensile, fatigue, and creep strength, retaining mechanical integrity at temperatures up to 700°C. It offers robust resistance to corrosion and oxidation—vital for aerospace, automotive, and energy sector components facing aggressive or high-temperature environments.

Pros:

– Superior mechanical performance over a wide temperature range

– Highly resistant to corrosion and oxidation

– Good weldability among nickel superalloys

– Widely certified (ASTM B637, AMS 5662/5663), simplifying cross-border quality compliance

Cons:

– High cost, especially when compared with more common steels

– Print process susceptible to cracking and porosity; expert process control required

– Post-processing (heat treatment, machining) is energy-intensive

– Lead times can extend due to powder availability in some regions

Impact on Application:

Optimal for aerospace turbine parts, oil & gas valves, and components requiring high-temperature endurance. It’s the standard-bearer when certification, traceability, and repeatability are required.

Special Considerations:

Conforms well to ASTM and DIN norms, easing integration for buyers in Europe and those selling into international supply chains. In resource-constrained markets, higher upfront costs are justified when lifecycle and failure-avoidance are critical.

Inconel 625

Key Properties:

Inconel 625 offers exceptional corrosion resistance—especially to chloride-induced pitting and stress corrosion cracking—making it an optimal choice for marine, chemical processing, and offshore oil environments. It performs reliably from cryogenic temperatures up to 600°C.

Pros:

– Outstanding resistance to corrosive media (acids, seawater, salt spray)

– Good mechanical ductility and weldability

– Easier to print and post-process compared to 718

– Recognized by global standards (ASTM B446, UNS N06625)

Cons:

– Lower strength at high temperatures compared to Inconel 718

– Less suitable for dynamic, high-load, or high-stress environments

– Raw material costs remain high

Impact on Application:

Suited to chemical plant valves, heat exchangers, marine hardware, and exhaust systems where exposure to aggressive media is expected.

Special Considerations:

Favored in regions like the Middle East (for desalination) and Africa’s developing offshore industries. Buyers must verify powder origin and certification, as substandard supply chains can impact performance reliability.

Hastelloy X

Key Properties:

Hastelloy X provides outstanding resistance to oxidation and high-temperature environment stability (up to 1200°C), with strong formability and fabrication characteristics.

Pros:

– Exceptional oxidation resistance at extreme temperatures

– Good formability, even after extended heat exposure

– Well-suited for 3D printing complex geometries

– Standardized (e.g., ASTM B572)

Cons:

– Prone to cracking during additive manufacture; requires advanced process control

– Cost is comparable to Inconel alloys

– Somewhat less common, limiting powder availability in select markets

Impact on Application:

Ideal for combustion chambers, afterburner components, and kiln linings where temperatures reach extremes.

Special Considerations:

Popular with industrial furnace and jet engine manufacturers in Europe and the Middle East. Confirming local standard equivalence (e.g., DIN vs. ASTM) can be crucial for regulatory approval.

Maraging Steel (e.g., 18Ni-300)

Key Properties:

Maraging steels are renowned for their excellent toughness, high strength (rivaling or exceeding superalloys), and ease of heat treatment. They also exhibit good dimensional stability post 3D printing.

Pros:

– High yield and tensile strength, excellent for structural parts

– Superior machinability before aging

– Cost-effective relative to Inconel superalloys

– Well-accepted standards (e.g., ASTM A538)

Cons:

– Significantly lower corrosion and oxidation resistance

– Limited suitability for high-temperature or highly corrosive applications

– Requires heat treatment (aging) to attain maximum properties

Impact on Application:

Often used for tool inserts, dies, rocket motor casings, and structural aerospace components where corrosion is not the primary concern.

Special Considerations:

Cost advantages make it attractive in markets coping with currency volatility or restrictive import tariffs (e.g., Kenya, parts of South America). Buyers must weigh trade-offs on part longevity in harsh environments.

Summary Table

| Material | Typical Use Case for inconel 3d printing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Inconel 718 | Aerospace turbine blades, high-pressure valves, hot gas components | Excellent high-temperature strength and corrosion resistance | Higher procurement and processing costs; complex AM process | High |

| Inconel 625 | Chemical processing parts, marine hardware, exhaust systems | Superior corrosion resistance to aggressive media | Lower high-temp strength than 718; cost remains high | High |

| Hastelloy X | Combustion chambers, furnace hardware, afterburners | Exceptional oxidation resistance at extreme temps | Prone to cracking in AM; less available in some regions | High |

| Maraging Steel (18Ni-300) | Tooling, dies, structural aerospace supports | High strength and ease of post-process machining | Poor corrosion/oxidation resistance; needs aging heat treat | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for inconel 3d printing

Overview of Additive Manufacturing (AM) Stages for Inconel Components

Manufacturing Inconel parts via 3D printing involves a sequence of tightly controlled stages. Understanding each phase is crucial for B2B buyers seeking consistency, performance, and compliance in their supply chains.

1. Material Preparation: Feedstock Quality is Foundational

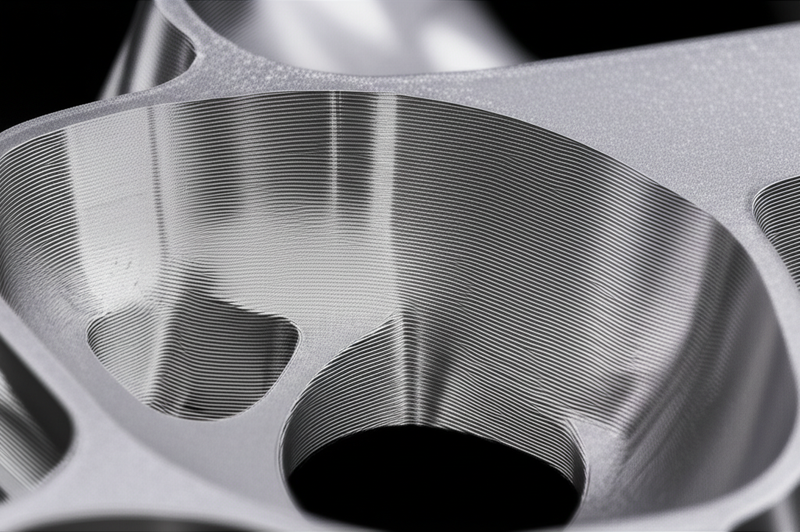

The process begins with the selection and preparation of Inconel alloy feedstock—most commonly Inconel 718 or 625. The feedstock is typically a fine, spherical powder produced by gas atomization. Quality factors include:

- Particle size distribution and morphology: Uniform size and sphericity enhance flowability and packing density.

- Purity and composition: Strict control on elemental composition and minimal contamination (such as oxygen or moisture) is essential.

-

Powder recycling limits: Reused powders must be evaluated for degradation in quality to avoid unwanted defects.

-

Actionable Insight for Buyers:* Always request detailed certificates of analysis (COAs) for powder lots, and verify that powder storage and handling minimize contamination and moisture exposure.

2. Forming: Layer-by-Layer Fabrication

The main additive manufacturing techniques for Inconel alloys are:

- Selective Laser Melting (SLM)/Laser Powder Bed Fusion (LPBF): The most widely adopted technique, utilizing a high-powered laser to selectively melt the powder bed as per the digital design.

- Electron Beam Melting (EBM): Uses an electron beam, favored for certain geometries and reducing residual stresses.

- Direct Energy Deposition (DED): Suitable for large parts or repair applications.

Key Parameters: Scan speed, laser/electron beam power, layer thickness, and powder feed rate—all directly impacting part density, surface finish, and mechanical properties.

- Actionable Insight for Buyers:* Ask suppliers to provide a summary of their AM equipment models, process parameters, and control systems. Well-documented parameters indicate process stability.

3. Post-Processing: Critical for Functional Integrity

After the forming stage, most Inconel parts undergo:

- Heat Treatment: Solution annealing and precipitation hardening to optimize mechanical properties and reduce internal stresses and microsegregation.

- Hot Isostatic Pressing (HIP): Reduces porosity, further improving fatigue and creep properties.

-

Machining and Surface Finishing: Necessary to achieve tight tolerances, remove surface roughness, or meet application-specific criteria (e.g., aerospace surface smoothness, oil & gas sealing surfaces).

-

Actionable Insight for Buyers:* Specify required post-processing steps and surface finish grades as part of procurement contracts to avoid ambiguity and ensure fit-for-purpose components.

Quality Assurance (QA) and Quality Control (QC): Ensuring Reliable Inconel 3D Parts

The complexities of 3D printing Inconel require a holistic QA/QC approach tailored to industry expectations. Robust quality systems protect buyers from costly defects or failed components in critical service.

International Standards and Industry-Specific Compliance

- ISO 9001: Baseline for quality management systems. Essential for all credible suppliers.

- AS9100 (Aerospace), ISO 13485 (Medical), API Q1 (Oil & Gas), CE Marking (EU): Industry-specific certifications demonstrate compliance with relevant safety and quality requirements.

-

Material certificates and traceability: Ensure every batch and even individual parts are traceable from powder to final component.

-

Actionable Insight for Buyers in Africa, South America, the Middle East, and Europe:* Confirm supplier certification status and request recent audit reports. Some regions (e.g., EU) may require additional marking (like CE) for parts entering regulated sectors.

QC Checkpoints: IQC, IPQC, FQC

- Incoming Quality Control (IQC): Verifies powder properties, equipment calibration, and incoming ancillary materials. Powder lots should be sampled and analyzed for consistent morphology, chemistry, and flowability.

- In-Process Quality Control (IPQC): Monitors critical parameters (laser power, temperature, layer thickness) and detects process anomalies in real time. Some advanced systems deploy layer-wise imaging and defect monitoring.

-

Final Quality Control (FQC): Involves nondestructive and destructive testing to ensure conformance to specification.

-

Buyer Focus:* Insist on comprehensive QC data packages with each shipment, including IQC lab results and relevant in-process logs.

Common Testing Methods for Inconel 3D Parts

Buyers should be familiar with the major test types:

- Metallographic analysis: Inspects grain structure, porosity, and phase composition.

- Mechanical testing: Tensile, hardness, creep, and fatigue property measurements—especially at elevated temperatures if relevant to your application.

- Nondestructive Evaluation (NDE): X-ray computed tomography (CT), ultrasonic testing, or dye penetrant inspection to detect internal flaws (inclusions, cracks, voids).

-

Dimensional and surface inspections: Critical given the intricate geometries possible with additive manufacturing.

-

Buyer Note:* Request test certificates and sample inspection reports. Consider specifying acceptance criteria in contracts for key mechanical and NDE results.

Verifying Supplier Quality: Best Practices for International B2B Buyers

For importers in Kenya, Poland, Brazil, Saudi Arabia, and beyond, additional due diligence is essential to navigate cross-border procurement risks.

- Supplier Audits: On-site (when feasible) or virtual audits to evaluate supplier facilities, process controls, certification validity, and QA/QC documentation practices.

- Third-Party Inspections: Engage recognized agencies (SGS, TÜV, Bureau Veritas) to perform pre-shipment inspections or witness critical QC tests.

- Documentation Reviews: Scrutinize process documentation, calibration logs, and traceability records—not just product test results.

-

Sample Orders and Qualification Runs: Start with low-volume proof-of-concept orders, fully tested against your specification before committing to production-scale orders.

-

Tip for Buyers in Developing Markets:* Work with suppliers experienced in international logistics and customs documentation, especially those familiar with local market regulatory approval (e.g., KEBS in Kenya, INMETRO in Brazil).

Regional Certification and Import Nuances

- Europe: CE Marking and REACH compliance may be necessary, in addition to standard QC documentation for customs clearance.

- Middle East: Oil & gas and aerospace buyers should expect API/AS9100 or ISO 29001 certifications as minimum requirements.

- Africa and South America: Varying national standards may require coordination with local regulatory agencies for key documentation, such as country-of-origin certificates or import permits.

- All Regions: Insist on clear, concise, and accessible English-language documentation to avoid misinterpretation and simplify certification reviews by customs or regulators.

Strategic Recommendations for B2B Buyers

- Prioritize suppliers with transparent, auditable QA/QC processes, and a proven track record in your end-use industry.

- Draft detailed product specifications and QC acceptance criteria tailored to your market’s standards and legal requirements.

- Deploy phased supplier onboarding: Begin with initial technical audits, followed by qualification orders and escalation to ongoing supply partnerships contingent upon consistent performance.

- Leverage local representatives or agents where language or regulatory complexity may be a barrier.

- Develop collaborative relationships with suppliers to jointly address technical challenges and continuous improvement opportunities in Inconel 3D printing.

A robust, standards-driven approach to manufacturing and quality assurance is non-negotiable when sourcing 3D-printed Inconel components. By understanding each stage and verifying supplier capabilities, international B2B buyers can mitigate risk and gain a competitive edge in advanced applications.

Related Video: Product Design & Manufacturing Collection workflows: Factory

Comprehensive Cost and Pricing Analysis for inconel 3d printing Sourcing

Understanding the Key Cost Drivers in Inconel 3D Printing Procurement

Inconel 3D printing represents a premium segment of additive manufacturing, driven by the material’s high value and the complexity of the processes required to achieve precise, reliable components. For international B2B buyers—especially in Africa, South America, the Middle East, and Europe—navigating the cost structure is essential for informed sourcing and sustainable supplier relationships.

Primary Cost Components

A thorough grasp of the direct and indirect costs is vital for negotiating contracts and projecting true landed cost. The primary components include:

- Material Costs: Inconel powders (notably 718 and 625 grades) are significantly more expensive than common metal powders due to specialized manufacturing, strict quality requirements, and controlled alloying elements. Purity and powder morphology directly impact performance and price.

- Labor: Expertise is required at every stage—machine operation, parameter optimization, post-processing (like heat treatments), and final finishing. Labor is often higher for complex or tight-tolerance builds, particularly with customized geometries.

- Manufacturing Overhead: Advanced 3D printers (laser or electron beam), inert gas systems, and maintenance generate substantial fixed costs. Overhead also covers power consumption, machine depreciation, and air-handling for powder safety.

- Tooling and Fixtures: While additive manufacturing reduces traditional tooling, temporary fixtures for support, calibration, or complex assemblies still incur setup costs proportional to production runs.

- Quality Control (QC): Non-destructive testing, metallography, chemical analysis, and certifications (e.g., ASTM, ISO, aerospace-specific) add costs but are essential for high-reliability components.

- Logistics: Inconel parts are high-value, sometimes subject to export controls. International freight, insurance, and customs clearance fees—especially when shipping to or from Africa, South America, or the Middle East—can substantially affect the total cost.

- Supplier Margin: Suppliers apply margins to cover risk, R&D, and value-added services. Margins may vary based on order size, complexity, supplier reputation, and regional market dynamics.

Major Price Influencers

- Volume and MOQ: Higher volumes or blanket orders typically attract discounts due to economies of scale in powder procurement, machine utilization, and post-processing.

- Specifications and Customization: Unique geometries, tight tolerances, or proprietary alloys increase machine time, setup, and post-process finishing—raising unit costs.

- Material Grades and Supplier Origin: Certified Inconel powders from reputable sources cost more, but enhance reliability and minimize defects. Local availability may vary: European and Middle Eastern buyers may have easier access to suppliers with certifications, while importation challenges can add to costs in parts of Africa and South America.

- Quality and Certifications: Demanding standards—such as aerospace or medical certifications—require rigorous QC, premium-grade powders, and documentation, all increasing cost.

- Supplier Attributes: Established suppliers with track records in your vertical offer higher reliability but likely command premium pricing. New market entrants may compete aggressively on price but warrant deeper due diligence.

- Incoterms and Payment Terms: EXW and FOB shift more logistics cost/risk to the buyer, while DDP includes more all-in pricing. Payment terms (advance, net 30, L/C) also influence supplier pricing flexibility.

Best Practices for Cost-Effective Sourcing

- Negotiate Based on Order Profile: Bundle multiple parts or opt for longer-term agreements to leverage better pricing; clarify MOQs and explore shared builds to optimize printer uptime and cost per part.

- Assess Total Cost of Ownership (TCO): Compare not just unit price but also logistics, import duties, post-processing needs, and potential delays—especially critical for regions with less established AM supply chains.

- Scrutinize Quality and Traceability: Demand full material traceability and reputable QC documentation to reduce downstream risks from substandard powders or poorly controlled processes.

- Benchmark Multiple Suppliers: Solicit quotations from local and international vendors. For emerging economies, explore regional AM hubs that combine proximity with expertise.

- Request Process Transparency: Insist on breakdowns for material, machine time, post-processing, and QC. This enables more effective negotiation and assessment of price realism.

- Understand Regional Nuances: For buyers in Africa or South America, factor in extra lead times, import/export bureaucracies, and potential local taxes or restrictions. European and Middle Eastern buyers may face higher labor but benefit from advanced supply networks and better access to certified powders.

Disclaimer: All cost insights here are indicative and should be validated with supplier-specific quotations. Price fluctuations are common due to market dynamics, supply chain disruptions, alloy surcharges, and currency shifts.

By carefully analyzing cost structures and negotiating intelligently, international buyers can secure high-performing Inconel 3D printed components at optimal value, while mitigating supply chain and quality risks.

Spotlight on Potential inconel 3d printing Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘inconel 3d printing’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

3D Printing Inconel (3dpmetal.com)

3D Printing Inconel positions itself as a dedicated provider of advanced Inconel 3D printing solutions, leveraging the unique properties of nickel-chromium superalloys for demanding, high-performance applications. The company specializes in producing intricate, precision-engineered components with notable strength, high-temperature resilience, and outstanding corrosion resistance, catering to sectors such as aerospace, automotive, and energy. Their manufacturing capabilities appear to encompass the full suite of additive manufacturing processes optimized for Inconel, employing various powder sizes (typically 15µm to 150µm) to achieve tight tolerances and complex geometries often unattainable with traditional methods.

While explicit details about certifications or proprietary technologies are limited in public materials, 3D Printing Inconel’s in-depth technical guides and product focus indicate a strong commitment to quality, likely aligned with international standards. Their market orientation and technical expertise suggest suitability for international B2B buyers seeking cost-effective, custom-engineered Inconel solutions—especially across Europe, the Middle East, Africa, and South America, where demand for robust, lightweight, and reliable components is growing. Noted strengths include material engineering expertise, application flexibility, and the ability to tackle challenging geometries or operational requirements.

The Top Metal 3D Printer Manufacturers in 2025 (www.3dnatives.com)

Renowned as a key resource hub rather than a standalone manufacturer, The Top Metal 3D Printer Manufacturers in 2025 (featured on 3Dnatives) offers comprehensive insight into more than 40 global producers specializing in advanced metal additive manufacturing, including Inconel 3D printing. Specializing in curated market intelligence, their listings highlight manufacturers with proficiency across Powder Bed Fusion, Directed Energy Deposition, and innovative processes like Cold Spray and Inkjet technologies—crucial for fabricating high-performance Inconel components. Many profiled manufacturers emphasize certifications such as ISO 9001 and demonstrate proven capabilities in delivering robust, quality-assured parts for high-stress applications. The platform is especially valuable for international B2B buyers across Africa, South America, the Middle East, and Europe, providing comparative overviews and facilitating supplier vetting for projects requiring certified, export-ready Inconel 3D printing solutions.

Inconel 718 3D Printing (met3dp.com)

MET3DP Technology Co., LTD, based in Qingdao, China, specializes in additive manufacturing with a strong emphasis on high-performance materials such as Inconel 718. The company offers comprehensive 3D printing solutions, producing complex, high-strength nickel-chromium alloy components tailored for applications requiring heat and corrosion resistance—key considerations in aerospace, energy, and heavy industry. MET3DP demonstrates technical expertise in advanced AM processes and post-processing for Inconel 718, supporting both prototyping and end-use parts. Their approach addresses international B2B demands for reliability and design flexibility, appealing to buyers from Africa, Europe, the Middle East, and South America. While specific certifications are not highlighted, the company positions itself as a global supplier capable of supporting demanding industrial needs.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| 3D Printing Inconel | Inconel AM specialists for demanding industrial sectors. | 3dpmetal.com |

| The Top Metal 3D Printer Manufacturers in 2025 | Global knowledge hub for Inconel 3D printing suppliers. | www.3dnatives.com |

| Inconel 718 3D Printing | Inconel 718 AM solutions for global industries. | met3dp.com |

Essential Technical Properties and Trade Terminology for inconel 3d printing

Key Technical Properties for Inconel 3D Printing

When sourcing Inconel parts via additive manufacturing, it’s essential to understand several core technical specifications that directly impact product quality, supply chain efficiency, and end-use performance.

-

Material Grade (e.g., Inconel 718, 625):

Inconel is a family of nickel-chromium-based superalloys, with grades like 718 and 625 being most common in 3D printing. The material grade defines mechanical strength, temperature resistance, and corrosion protection. For B2B buyers, specifying the right grade during procurement ensures parts meet regulatory and operational requirements, especially in aerospace, energy, or automotive sectors. -

Powder Particle Morphology and Purity:

Quality of the feedstock powder—specifically, particle shape (spherical is ideal) and chemical composition—impacts the print quality, material properties, and consistency. Suppliers should provide detailed powder certification; buyers should verify contamination-free supply to avoid in-service failures or rejection during inspection. -

Dimensional Tolerance and Surface Finish:

Tolerance defines how closely a part matches design dimensions, which is critical for assembly compatibility and performance. Surface finish (measured in Ra, microns) influences wear resistance and fatigue. Buyers should clarify required tolerances and post-processing expectations (machining, heat treatments) in RFQs to reduce rework rates. -

Mechanical Properties (Tensile Strength, Creep, Fatigue):

Inconel 3D-printed components are prized for maintaining high mechanical performance at elevated temperatures. Tensile strength, creep resistance, and fatigue life must be specified based on application. Demanding applications, such as turbines and exhausts, necessitate mechanical property validation, often including independent third-party testing. -

Porosity and Defect Control:

Additive manufacturing can introduce defects such as microcracks or internal pores, which weaken parts. Buyers should require suppliers to conduct and certify non-destructive testing (NDT), such as CT scanning or X-ray, to guarantee internal integrity where safety or compliance is a concern. -

Build Orientation and Anisotropy:

The direction in which a part is built can affect its mechanical properties due to anisotropy. B2B buyers should consult with suppliers to optimize part orientation for performance, especially for load-bearing applications, and demand clear documentation in QC reports.

Common Industry & Trade Terms Explained

Navigating global procurement for advanced materials involves terminology that streamlines supplier-buyer relationships and avoids costly misunderstandings:

-

OEM (Original Equipment Manufacturer):

Refers to the company that manufactures parts or components used in another company’s end products. When purchasing Inconel 3D-printed items, knowing if the supplier is an OEM ensures traceability and alignment with industry standards, particularly relevant for high-integrity applications. -

MOQ (Minimum Order Quantity):

The smallest order a supplier is willing to process, often higher for specialized alloys like Inconel. Clarity on MOQ enables buyers from smaller markets (e.g., Africa, South America) to negotiate or combine orders, improving cost efficiencies. -

RFQ (Request for Quotation):

A formal business process used to invite suppliers to bid on specific parts, quantities, and delivery terms. A well-drafted RFQ for Inconel 3D printing must include technical drawings, tolerance specifications, certification needs, and post-processing instructions, reducing ambiguity and ensuring comparable offers. -

Incoterms (International Commercial Terms):

Standardized trade terms published by the International Chamber of Commerce, indicating which party is responsible for shipping, insurance, import duties, and other logistics. Common Incoterms include EXW, FOB, and DDP. For international buyers, understanding Incoterms safeguards against unexpected costs and logistical disputes. -

Lead Time:

The period from order placement to delivery. Additive manufacturing can reduce lead times for prototyping and low-volume production. Accurate lead time estimates are critical for project planning—especially in industries where downtime is costly. -

Certificate of Conformity/Material Certification:

Official documentation provided by the supplier to certify a part’s compliance with international standards (ASTM, ISO). Buyers should always require these certificates for mission-critical Inconel parts, particularly when dealing with customs or regulated industries.

Actionable Takeaway:

International B2B buyers should use this terminology and specification knowledge to sharpen due diligence, craft precise procurement documents, negotiate confidently, and mitigate supply risks across the Inconel 3D printing supply chain.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the inconel 3d printing Sector

Global Market Landscape and Key B2B Sourcing Trends

Inconel 3D printing has rapidly emerged as a high-value proposition for industries requiring exceptional mechanical properties and design freedom, notably in aerospace, automotive, energy, and medical sectors. The drive towards performance, weight reduction, and supply chain resilience is intensifying demand for additive manufacturing using nickel-based superalloys like Inconel 718. Global forecasts indicate sustained double-digit growth for metal additive manufacturing, with Inconel playing a dominant role in critical applications.

Key market trends for international B2B buyers:

-

Regional Growth and Diversification: As supply chains globally adapt post-pandemic, firms in Africa (e.g., Kenya), South America, the Middle East, and Europe (e.g., Poland, Germany) are increasingly exploring direct importation of Inconel powders, printed parts, and contract manufacturing services. European providers, long-established in this field, are facing new competition from emerging AM hubs in the UAE, Turkey, Brazil, and South Africa, which offer region-optimized pricing and logistics.

-

Technology Evolution: Selective Laser Melting (SLM) and Electron Beam Melting (EBM) remain the preferred 3D printing technologies for Inconel due to their ability to achieve excellent mechanical properties. Improved powder production techniques and in-process quality monitoring are reducing typical challenges like porosity and internal defects, enhancing reliability.

-

Shift Toward End-to-End Digital Supply Chains: Digitization—via secure data exchange, cloud-based design management, and real-time production monitoring—is streamlining international order fulfillment and traceability. B2B buyers are seeking partners with integration capabilities to ensure compliance, IP security, and rapid turnaround.

-

Quality Assurance and Certification: Third-party certifications (e.g., AS9100 for aerospace, ISO 13485 for medical) and robust traceability are now standard expectations. There is a clear shift away from unverified or generic powder sources; traceable, certified supply chains are favored.

-

Localization and Joint Ventures: To mitigate logistics costs and supply risks, buyers in regions like East Africa and Eastern Europe are increasingly engaging in local joint ventures or tech-transfer partnerships to establish regional AM hubs, utilizing imported powder but performing final production and qualification locally.

Action Points for B2B Buyers

- Vet supply chain partners not only on price, but on their ability to provide full material traceability, digital process validation, and recognized international certifications.

- Where possible, consider dual-sourcing from both established (Europe/North America) and emerging regional vendors to balance cost, lead time, and risk.

- Assess partners’ abilities to support customization, rapid prototyping, and iterative design—a key advantage of Inconel AM.

Advancing Sustainability and Ethical Sourcing in Inconel 3D Printing

Environmental stewardship and ethical sourcing are increasingly mandated by global procurement departments and government clients alike. For Inconel 3D printing, sustainability is influenced on several fronts: powder production, AM process efficiency, waste minimization, and the ethical procurement of base metals.

Environmental & Sustainability Perspectives:

-

Material Efficiency and Waste Reduction: Additive manufacturing of Inconel parts (compared to traditional subtractive methods) drastically reduces material scrap, as nearly all input powder is utilized. This not only conserves the high-cost nickel and chromium content but also slashes energy consumption related to remelting and recycling offcuts.

-

Energy Optimization: Modern 3D printing setups integrate energy-efficient lasers and recycled heat systems, further lowering the carbon footprint per component. Suppliers who can document these efforts provide tangible sustainability value to buyers.

-

Recycled and Certified Powders: A key emerging trend is the use of recycled Inconel powder streams—powders reclaimed from previous builds and requalified to stringent specifications—reducing reliance on primary metal extraction. Buyers should look for suppliers offering documented recycled and/or certified ‘green’ materials, such as those carrying ISO 14001 or relevant regional environmental certifications.

Ethical Sourcing and Transparency:

-

Conflict Mineral Awareness: The nickel and chromium in Inconel alloys are frequently sourced from geopolitically complex regions. Responsible suppliers provide detailed chain-of-custody reports, helping buyers avoid exposure to conflict metals or unethical labor practices.

-

Third-Party Auditing and Certification: Look for vendors with established programs for CSR (Corporate Social Responsibility), audited by recognized bodies (e.g., Ecovadis, Sedex), and who publish transparent sustainability performance.

Practical Takeaways for B2B Buyers

- Prioritize suppliers who offer closed-loop powder systems, powder reuse, and environmentally certified production.

- Request full documentation on raw material origins to safeguard against compliance and reputational risks, especially crucial for government and multinational contracts.

- Incorporate sustainability scoring into supplier evaluations and contract awards.

Brief Evolution of Inconel 3D Printing in Global B2B Context

The application of Inconel in additive manufacturing traces back to early 2000s R&D, when aerospace leaders sought rapid prototyping capabilities for turbine components. Initial limitations centered on powder purity and process repeatability. Over the last decade, significant advances in powder atomization, process control software, and qualified printing standards have transitioned Inconel 3D printing from prototyping to serial production. Today, both OEMs and regional contract manufacturers can reliably design and produce structurally critical Inconel parts, with accessible sourcing for buyers worldwide. The technology’s evolution has paralleled greater digital supply chain maturity—making once-exclusive manufacturing capabilities available and affordable to a global B2B buyer base, from Nairobi to Warsaw.

By remaining agile in response to market shifts, integrating robust sustainability standards, and leveraging digital supply chains, international B2B buyers can unlock strategic value and mitigate risk in the growing Inconel 3D printing sector.

Related Video: Incoterms® 2020 Explained for Import Export Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of inconel 3d printing

-

How can I identify reliable suppliers of Inconel 3D printing services for international orders?

Begin by assessing a supplier’s proven experience with Inconel alloys and advanced additive manufacturing (AM) technology. Request case studies, customer references, and certifications (like ISO 9001 or AS9100). Check if the supplier performs in-house quality assurance on printed parts and has expertise in international logistics. For cross-border partnerships, prioritize those with established track records in exporting to your region, clear communication channels, and transparent commercial terms. Factory audits, video inspections, or leveraging trusted third-party sourcing agents are highly recommended, especially for buyers in Africa and South America, where regulatory oversight may vary. -

What are the main customization options available in Inconel 3D printing for industrial buyers?

Inconel 3D printing allows for a range of customizations, including part geometry, wall thickness, internal channels, and surface finishes. Buyers can often specify performance criteria (such as tensile strength or temperature resistance), select additive methods (like SLM or EBM), and request post-processing services such as heat treatment, machining, or coating. Open communication with your supplier about application requirements ensures that technical parameters—like density or grain structure—are tailored to your needs. This flexibility is especially valuable for sectors such as oil & gas and aerospace present across Europe, the Middle East, and Africa. -

What are typical minimum order quantities (MOQ), lead times, and payment terms for international buyers?

MOQs for Inconel 3D printed components can range from single prototype units to small batches, depending on the supplier and part complexity. Lead times usually span from two weeks for simple parts to several months for complex, high-volume orders requiring stringent certifications. International buyers should confirm payment terms upfront—options often include wire transfer, Letters of Credit, or split payments (such as 30% deposit, 70% on completion). For buyers in regions like Kenya or Poland, partnering with suppliers familiar with international trade procedures and flexible MOQs can streamline procurement and reduce upfront risk. -

How is quality assurance maintained, and what certifications should buyers request?

Quality in Inconel 3D printing is confirmed through rigorous in-process monitoring, destructive and non-destructive testing, and documentation. Insist on batch-specific inspection reports and certificates of conformity. Look for suppliers accredited with ISO 9001 (general quality), AS9100 (aerospace), or IATF 16949 (automotive). For certain sectors, material traceability and third-party verification may be mandatory. Buyers from regions with limited local standards enforcement should request detailed quality documentation and, if feasible, arrange for independent inspections before shipment. -

What are the key considerations for international logistics and shipping of 3D printed Inconel parts?

Shipping high-value Inconel components requires careful packaging, insurance coverage, and compliance with export controls and import duties. Clarify Incoterms (such as FCA, EXW, DAP) to understand responsibilities for freight, customs, and risk transfer. Work with logistics providers experienced in handling industrial AM products. For African and Latin American buyers, factor in potential customs delays or regulatory requirements unique to your jurisdiction. Clear labeling, harmonized tariff codes, and pre-coordination with customs brokers can help avoid costly clearance issues. -

What should buyers do if parts do not meet agreed-upon specifications upon arrival?

Promptly document all discrepancies with detailed photographs, inspection reports, and reference to contractual specifications. Notify the supplier immediately, citing relevant quality guarantees or service-level agreements. Most reputable suppliers will offer rework, replacement, or partial refunds in case of non-conformance. For significant disputes, international buyers can benefit from including arbitration clauses in contracts and selecting suppliers who are familiar with cross-border commercial law. Sourcing with staged payments or using escrow services can provide additional leverage and security. -

How does the complexity of Inconel 3D printing impact pricing and sourcing strategies?

Part geometry, dimensional tolerances, mechanical property requirements, and post-processing needs all significantly influence cost. Highly complex designs or strict certification demands may drive prices upward but can deliver better value compared to traditional manufacturing for custom, high-performance parts. Buyers should request itemized quotations, clarify whether design consultation is included, and account for total landed cost (including shipping and tariffs). Partnering with suppliers who offer technical support can reduce iteration cycles and avoid costly errors, a key advantage for emerging markets expanding their AM capabilities. -

Are there region-specific challenges when sourcing Inconel 3D printing services for Africa, South America, the Middle East, or Europe?

Buyers in Africa and South America may face limited domestic expertise, longer shipping times, and increased import costs. Establishing strong communication, local partnerships, and pre-negotiated logistics solutions is essential. Middle Eastern buyers must pay attention to local standards and certification requirements, especially for energy sector applications. In Europe, competition and supplier density are higher, leading to more favorable terms but also tighter quality scrutiny. Regardless of region, understanding local regulations, selecting culturally compatible partners, and maintaining clear documentation are crucial for successful cross-border sourcing.

Strategic Sourcing Conclusion and Outlook for inconel 3d printing

Inconel 3D printing represents a pivotal advancement for B2B buyers seeking robust, high-performance solutions in sectors where reliability and efficiency are non-negotiable. Key takeaways for international buyers include the ability to access complex, custom geometries with Inconel 718 that outperform traditional alloys in demanding environments, paired with the potential to reduce lead times and optimize material utilization. However, buyers must remain vigilant regarding challenges such as managing AM-specific defects, ensuring consistent powder quality, and selecting qualified manufacturing partners with proven expertise.

Why Strategic Sourcing Matters

A well-structured sourcing strategy is essential to unlocking the full benefits of Inconel additive manufacturing. Successful buyers are those who:

– Vet suppliers rigorously, prioritizing those with quality certifications and an established track record in AM for superalloys.

– Invest in supply chain transparency, from powder sourcing to post-processing, to minimize risks related to defects or material inconsistencies.

– Leverage local and global partnerships, particularly in regions like Africa, South America, the Middle East, and Europe, to balance competitive pricing with robust after-sales support and technical know-how.

Looking Forward

As additive manufacturing technologies mature, international buyers are positioned to capture significant value by embracing Inconel 3D printing. Early adopters who deepen technical collaborations, prioritize continual supplier assessment, and invest in staff training will be best equipped to shape the next wave of high-performance manufacturing across their respective markets. Now is the time to act—evaluate your sourcing networks, foster innovation partnerships, and secure your place at the forefront of advanced manufacturing.