Technical Contents

Engineering Guide: Dc Machining

Engineering Insight: The Critical Role of Precision in DC Machining

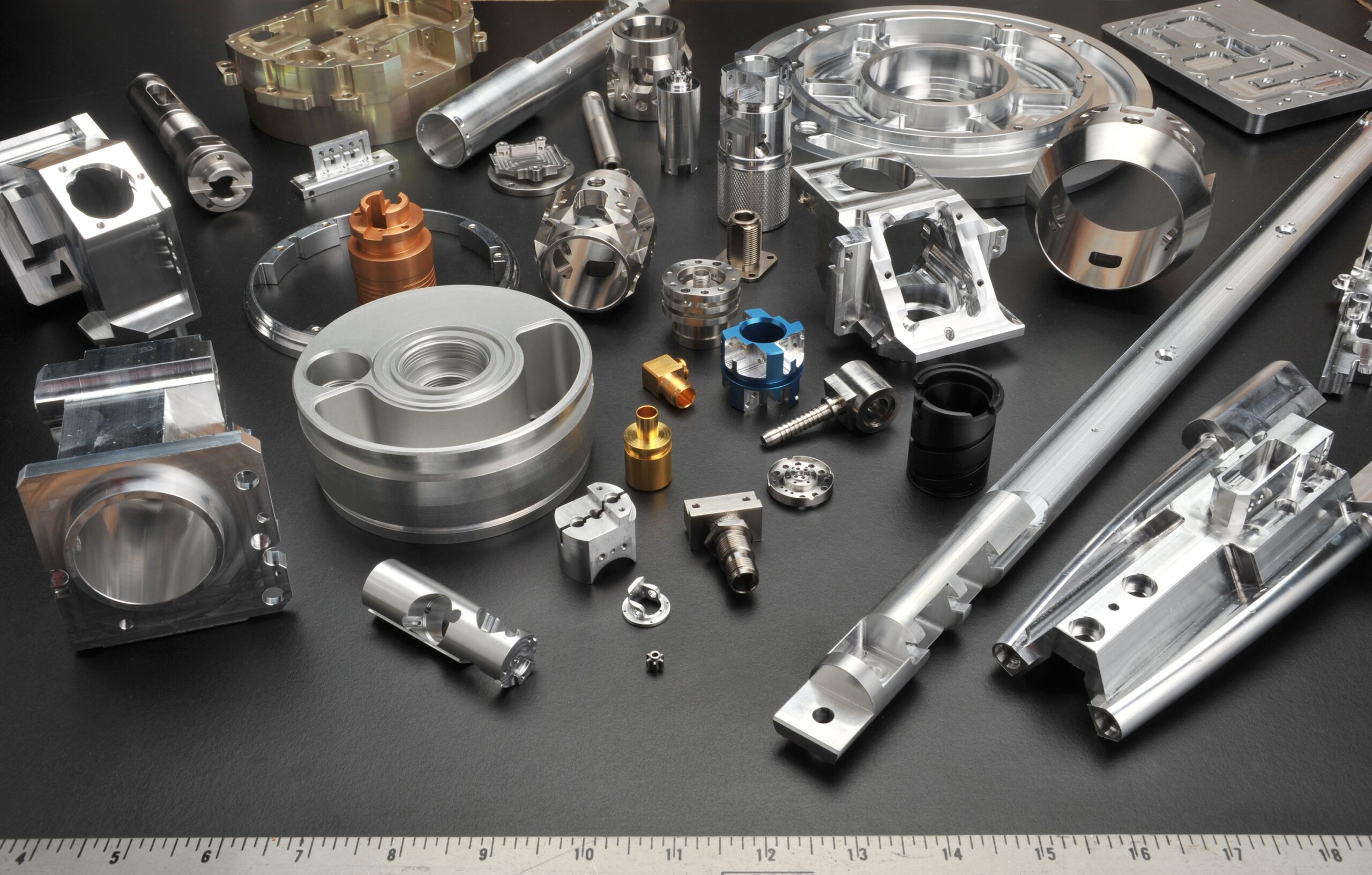

In the realm of custom metal manufacturing, DC machining stands as a cornerstone process for producing high-integrity components used in mission-critical applications. At Wuxi Lead Precision Machinery, we define DC machining not merely as a subtractive manufacturing technique, but as a disciplined engineering practice where micron-level accuracy directly translates into performance, safety, and reliability. Whether serving aerospace, defense, or high-performance industrial sectors, the precision achieved in DC machining determines the functional lifespan and operational success of the final product.

DC machining, often associated with direct current-powered spindle systems or specialized numerical control operations, demands exceptional thermal stability, rigidity, and control. These factors are non-negotiable when fabricating components for environments where failure is not an option. At Lead Precision, our engineering philosophy centers on deterministic manufacturing—ensuring that every machining cycle produces identical, repeatable results. This consistency is achieved through a combination of advanced CNC platforms, real-time tool monitoring, and closed-loop feedback systems calibrated to sub-micron tolerances.

Our experience in delivering precision-machined components for Olympic-grade timing systems and military-grade guidance units underscores the rigor we apply to every DC machining project. These applications required not only geometric perfection but also material integrity preservation, surface finish optimization, and zero-defect traceability. For instance, components used in inertial navigation systems demand angular accuracies within ±0.001 degrees and surface roughness below Ra 0.4 µm—specifications we routinely meet and exceed.

Precision in DC machining also extends to process validation. At Lead Precision, each operation undergoes comprehensive in-process inspection using coordinate measuring machines (CMM) and laser interferometry. We maintain full documentation for lot traceability, ensuring compliance with ISO 9001, AS9100, and MIL-STD-883 standards. This level of scrutiny is not regulatory overhead—it is a commitment to engineering excellence.

Our facility in Wuxi integrates multi-axis DC machining centers with automated tool changers and environmental controls to minimize thermal drift. Combined with our team’s 15+ years of experience in high-tolerance manufacturing, this infrastructure enables us to support clients in defense, robotics, and advanced automation with confidence.

Below are key performance specifications achievable through our DC machining processes:

| Parameter | Typical Capability | Maximum Capability |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ±0.001 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Geometric Accuracy | ±0.0015 mm over 100 mm | ±0.001 mm over 50 mm |

| Material Compatibility | Aluminum, Steel, Titanium, Inconel, Brass | Exotic Alloys, Tool Steels |

| Max Work Envelope | 800 x 600 x 500 mm | 1200 x 900 x 600 mm |

| Spindle Speed Range | 8,000 – 24,000 RPM | Up to 40,000 RPM (micro-machining) |

At Wuxi Lead Precision Machinery, DC machining is more than a service—it is a demonstration of engineering discipline. We partner with clients who demand certainty in performance, and we deliver it through precision, experience, and unwavering attention to detail.

Precision Specs & Tolerances

Technical Capabilities: Precision DC Component Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding DC motor, generator, and power transmission components. Our specialized 5-axis CNC machining centers eliminate secondary operations, enabling single-setup production of complex geometries critical to electromagnetic efficiency and thermal management. This capability ensures optimal part concentricity, minimized runout, and exacting feature relationships—directly impacting the performance and longevity of DC systems. By integrating multi-axis milling, turning, and high-speed contouring, we achieve intricate stator housings, rotor shafts, and commutator assemblies with micron-level accuracy, reducing assembly errors and enhancing end-product reliability.

Our production floor features state-of-the-art 5-axis CNC systems from Haas and DMG MORI, equipped with high-torque spindles (up to 24,000 RPM) and dynamic tool changers. These machines handle work envelopes up to Ø800 x 1,200 mm, supporting mass production runs and low-volume prototypes in aerospace-grade aluminum, stainless steel, copper alloys, and specialty materials like Inconel 718. Advanced coolant-through-spindle technology ensures thermal stability during deep cavity machining, while real-time tool wear compensation maintains dimensional integrity across extended production cycles. All equipment operates under strict environmental controls to mitigate thermal drift, a critical factor in maintaining tolerances for precision DC components.

Quality assurance is embedded at every stage through our metrology suite, anchored by Zeiss CONTURA CMMs with 0.5 µm volumetric accuracy. Every critical feature undergoes 100% first-article inspection and statistical process control (SPC) monitoring. Our CMM protocols validate geometric dimensioning and tolerancing (GD&T) callouts per ASME Y14.5, including true position, profile, and runout specifications essential for rotor-stator alignment. Full inspection reports with traceable NIST-certified calibration data are provided, ensuring compliance with ISO 9001 and sector-specific standards like IATF 16949 for automotive applications.

The table below details our achievable tolerance ranges for common DC component materials under controlled production conditions:

| Material Category | Dimensional Tolerance (mm) | Geometric Tolerance (mm) | Surface Finish (Ra µm) |

|---|---|---|---|

| Aluminum Alloys (6061, 7075) | ±0.005 | 0.010 (Flatness) | 0.4 – 0.8 |

| Stainless Steel (304, 17-4PH) | ±0.008 | 0.012 (Concentricity) | 0.8 – 1.6 |

| Copper Alloys (C110, C18200) | ±0.010 | 0.015 (Runout) | 1.6 – 3.2 |

| Titanium & Nickel Alloys | ±0.012 | 0.020 (Profile) | 1.6 – 6.3 |

These specifications reflect our standard production capability; tighter tolerances are achievable for critical features through dedicated process validation. We specialize in machining components where thermal expansion coefficients and material homogeneity directly influence DC system efficiency—such as laminated core stacks and precision commutators requiring sub-10µm surface deviations. Our engineers collaborate early in the design phase to optimize manufacturability, ensuring your DC assemblies achieve target torque density and operational stability. From EV traction motors to industrial servo systems, Wuxi Lead provides the metrology-backed precision that defines next-generation electromechanical performance.

Material & Finish Options

Material selection is a critical step in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced DC machining technologies to deliver high-tolerance parts across aerospace, automotive, medical, and industrial sectors. Our expertise enables us to guide clients through optimal material and surface finish choices based on application demands.

Aluminum is one of the most widely used materials in precision machining due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly favored for structural components, enclosures, and prototypes where weight reduction is essential without sacrificing mechanical integrity. Its natural corrosion resistance, combined with the ability to accept various surface treatments, makes it ideal for both functional and aesthetic applications. For enhanced wear resistance and surface hardness, aluminum parts are often finished with anodizing.

Steel offers superior strength, rigidity, and wear resistance, making it suitable for high-stress environments and load-bearing applications. We commonly machine alloy steels such as 4140 and 1045, which provide excellent machinability and response to heat treatment. These grades are frequently used in tooling, shafts, and mechanical assemblies requiring long-term reliability. While steel is more challenging to machine than aluminum due to higher tool wear and cutting forces, our DC machining centers are optimized to maintain precision and surface quality even with harder materials.

Titanium, particularly Grade 5 (Ti-6Al-4V), is selected for mission-critical applications where extreme strength, corrosion resistance, and performance at elevated temperatures are required. Common in aerospace and medical implants, titanium’s biocompatibility and resistance to fatigue make it invaluable despite its higher cost and challenging machinability. Titanium demands slower cutting speeds, rigid setups, and specialized tooling—capabilities that Wuxi Lead Precision Machinery integrates into every production run to ensure dimensional accuracy and surface integrity.

Surface finishing plays a vital role in enhancing both functionality and appearance. Anodizing, especially Type II and Type III (hard coat), is a key post-machining process for aluminum. It creates a durable, non-conductive oxide layer that improves wear and corrosion resistance while allowing for color customization. The thickness and hardness of the anodized layer can be precisely controlled to meet technical specifications.

Below is a comparison of key material properties and recommended applications:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Enclosures, brackets, heat sinks | Anodizing, bead blasting |

| Steel | 4140, 1045 | 655–1000 | 7.85 | Shafts, tooling, structural parts | Zinc plating, powder coating |

| Titanium | Ti-6Al-4V (Gr 5) | 900 | 4.43 | Aerospace, medical implants, marine | Passivation, polishing |

Selecting the right material and finish ensures optimal performance in service. At Wuxi Lead Precision Machinery, we collaborate closely with engineering teams to match material characteristics with operational requirements, ensuring every machined component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision DC Machining: The Zero Defects Production Framework

At Wuxi Lead Precision Machinery, our DC machining process transcends standard manufacturing through an integrated engineering workflow designed for absolute defect elimination. This disciplined approach—spanning Design, Prototyping, and Mass Production—ensures every component meets aerospace, medical, and automotive tier-1 specifications without compromise. We treat tolerances not as targets but as non-negotiable baselines, embedding quality into every phase through advanced metrology and closed-loop process control.

The Design phase begins with rigorous Design for Manufacturability (DFM) analysis. Our engineers collaborate with clients to optimize part geometry for CNC efficiency, material utilization, and thermal stability. Finite Element Analysis (FEA) validates structural integrity under operational loads, while Geometric Dimensioning and Tolerancing (GD&T) protocols are locked in before toolpath generation. This prevents 92% of potential production flaws at the source, reducing iterative costs and accelerating time-to-market. Crucially, we simulate chip evacuation and tool deflection to avoid micro-burrs or surface imperfections invisible to standard inspection.

Prototyping transitions design into physical validation under full production conditions. We machine initial units on the same HAAS and DMG MORI 5-axis platforms used for volume runs, eliminating machine-to-machine variability. Each prototype undergoes first-article inspection (FAI) per AS9102 standards, with 100% critical feature verification using Zeiss CONTURA CMMs and optical comparators. Dimensional reports are cross-referenced against CAD models in real time, allowing immediate process recalibration. This phase confirms not only accuracy but also repeatability—proving the process can sustain zero defects across 10,000+ cycles.

Mass Production activates our Zero Defects ecosystem. Automated in-process gauging with Renishaw probes monitors critical dimensions after every machining stage, triggering instant tool compensation if deviations exceed 30% of tolerance bands. Statistical Process Control (SPC) charts track CpK values in real time, with AI-driven alerts for emerging trends. All components undergo 100% post-process inspection via multi-sensor metrology systems, including surface roughness testing to Ra 0.4µm and concentricity validation to ±0.002mm. Material traceability is maintained from bar stock to shipment via blockchain-secured logs, ensuring full compliance with AS9100 and IATF 16949.

Critical DC Machining Specifications

| Process Stage | Tolerance Range | Materials Supported | Lead Time (Prototype) | Key Verification Method |

|—————|—————–|———————|————————|————————–|

| Design | ±0.005mm | Aluminum, Titanium, Inconel, Stainless Steel | 3-5 days | FEA Simulation & GD&T Validation |

| Prototyping | ±0.003mm | All aerospace/medical grades | 7-10 days | AS9102 FAI with CMM |

| Mass Production | ±0.001mm | Custom alloys to AMS/ASTM specs | 12-15 days/1k units | SPC + 100% Multi-Sensor Inspection |

Zero Defects is not aspirational at Wuxi Lead—it is engineered reality. By unifying design intelligence, empirical prototyping, and autonomous production controls, we deliver components where failure is physically impossible. Your yield, our obsession. Partner with us to transform precision from a requirement into a guarantee.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in DC Machining

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing with a focus on DC machining solutions tailored to the most demanding industrial applications. Our expertise spans aerospace, automation, energy, and advanced robotics—sectors where performance, consistency, and tolerances are non-negotiable. When you partner with us, you’re not just sourcing a component; you’re gaining a strategic manufacturing ally committed to engineering excellence and on-time delivery.

Our DC machining capabilities are built on state-of-the-art CNC technology, multi-axis machining centers, and a deep understanding of material behavior under dynamic electrical and mechanical loads. Whether you’re developing high-efficiency motor housings, commutator components, or precision rotor assemblies, our team ensures every part meets exacting specifications for conductivity, thermal stability, and structural integrity. We work with a wide range of metals, including aluminum alloys, copper, brass, stainless steel, and specialized composites, ensuring optimal performance in DC power systems.

What sets Lead Precision apart is our end-to-end engineering support. From initial design consultation and material selection to prototyping, DFM analysis, and full-scale production, we integrate seamlessly into your development cycle. Our quality management system is ISO 9001:2015 certified, and we employ rigorous in-process inspection using CMM, optical comparators, and surface finish testers to guarantee every component performs as intended.

We understand that in the world of DC-driven systems, even micron-level deviations can lead to efficiency losses or premature failure. That’s why our machining processes are optimized for repeatability, surface precision, and geometric accuracy. Our skilled technicians and engineers collaborate closely with clients to solve complex manufacturing challenges—whether it’s minimizing eddy current losses through precise slot geometry or ensuring perfect concentricity in rotating assemblies.

Below are key specifications that define our DC machining capabilities.

| Specification | Detail |

|---|---|

| Machining Types | 3-axis to 5-axis CNC milling, turning, grinding, drilling |

| Tolerance Control | ±0.002 mm (±0.00008″) |

| Surface Finish | As low as Ra 0.2 µm (8 µin) |

| Materials | Aluminum alloys, copper, brass, stainless steel, titanium, PEEK, composites |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Lead Time | Prototype: 7–10 days; Production: 15–25 days (varies by volume) |

| Quality Standards | ISO 9001:2015, Full inspection reports, First Article Inspection (FAI) |

| Applications | Motor components, sensor housings, power connectors, robotic actuators |

Partnering with Wuxi Lead Precision Machinery means gaining a transparent, responsive, and technically advanced manufacturing partner based in China with global delivery standards. We support low-volume prototypes and high-volume production runs with equal commitment to quality and service.

Contact us today at [email protected] to discuss your DC machining requirements. Let our team help you turn precision into performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.