Technical Contents

Engineering Guide: Cutting Service

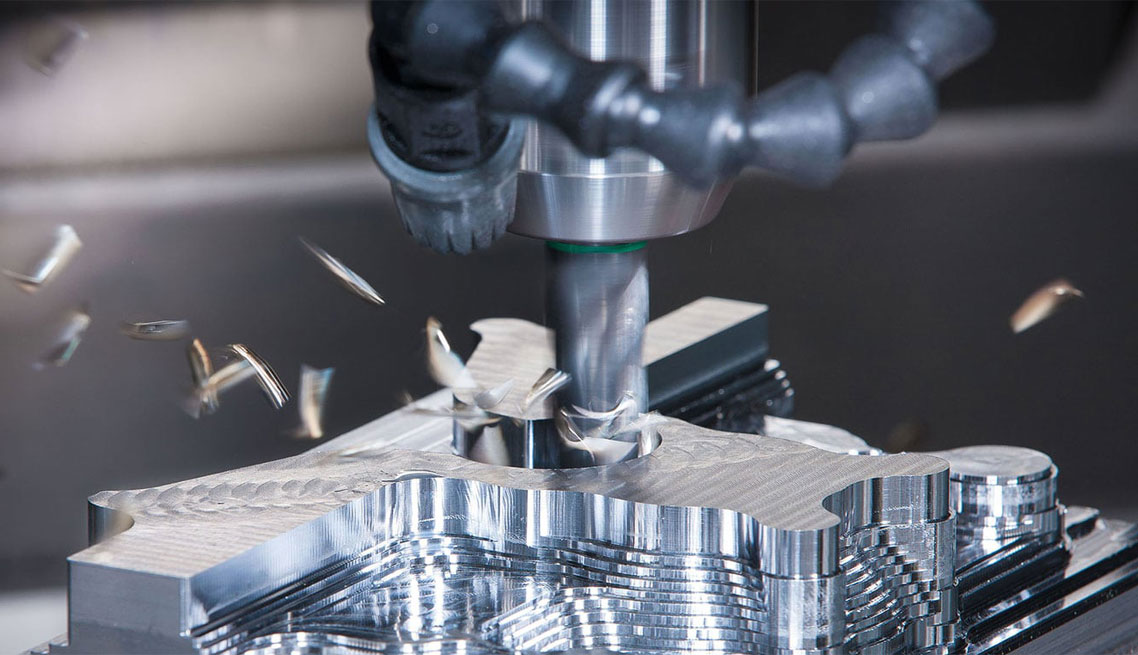

Engineering Insight Precision Cutting Services in Advanced Manufacturing

Precision in metal cutting services transcends dimensional accuracy it directly dictates functional integrity, assembly success, and lifecycle performance of critical components. In aerospace, medical, and defense applications, tolerances exceeding ±0.01mm can trigger catastrophic assembly failures, accelerated wear, or system inefficiencies. Material waste escalates exponentially when secondary operations compensate for initial cutting inaccuracies, inflating costs and lead times. True precision engineering begins with understanding material behavior under thermal and mechanical stress during cutting, selecting optimal toolpaths, and validating machine stability. It requires harmonizing spindle dynamics, feed rates, and coolant strategies to prevent microstructural distortion—especially in exotic alloys like Inconel or titanium where residual stress management is non-negotiable. Without this rigor, even visually flawless parts fail under operational loads, compromising safety and reliability.

Wuxi Lead Precision Machinery operationalizes this rigor through decades of refining high-stakes cutting processes. Our involvement in Beijing Winter Olympics infrastructure projects demanded sub-10μm tolerances for structural titanium components exposed to extreme alpine conditions. Similarly, military-grade ordnance systems we support require absolute repeatability in hardened steel cutting where a single micron deviation risks mission failure. These experiences forged our proprietary process validation framework: real-time thermal compensation algorithms, in-process metrology integration, and multi-axis vibration damping calibrated for materials from beryllium copper to maraging steel. We treat every client project with the same zero-defect mandate applied to national security programs—transforming theoretical tolerances into consistently achieved outcomes.

Our technical capabilities are engineered to eliminate precision compromises. The table below details core specifications achievable across our CNC cutting platforms:

| Parameter | Capability | Relevance |

|---|---|---|

| Positional Accuracy | ±0.005mm | Ensures seamless multi-part assembly |

| Material Thickness | 0.05mm – 300mm | Covers ultra-thin sensors to heavy forgings |

| Surface Finish | Ra 0.2μm (as-cut) | Reduces/eliminates post-processing needs |

| Max Work Envelope | 2000 x 1500 x 800mm | Accommodates large-scale structural parts |

| Material Range | Steels, Al, Ti, Cu, Exotics | Supports diverse industry requirements |

| Machine Platform | 5-Axis Mill-Turn with AI Tuning | Optimizes tool engagement for complex geometries |

Precision cutting is not merely a technical specification—it is a systemic commitment to eliminating variability at every process node. At Wuxi Lead, we deploy military-grade process discipline to transform raw material into mission-critical assets where dimensional certainty is non-negotiable. This philosophy ensures your components perform as engineered, not just as delivered.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for industries requiring high precision and complex geometries. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining technology, which enables us to produce intricate components with superior accuracy, surface finish, and consistency. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across five planes, providing unparalleled flexibility in cutting angles and access to complex part features. This capability significantly reduces the need for multiple setups, minimizing human error and improving overall production efficiency.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure optimal performance during extended production runs. We work with a broad range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, tool steels, and high-temperature superalloys, supporting aerospace, medical, energy, and industrial automation sectors. Each machining program is developed using advanced CAM software, enabling precise toolpath optimization and material removal strategies tailored to the specific part geometry and material properties.

To maintain the highest standards of quality, every component undergoes rigorous inspection using our Coordinate Measuring Machine (CMM) system. The CMM provides full geometric dimensioning and tolerancing (GD&T) verification, ensuring that all critical features meet or exceed customer specifications. Our quality control process is integrated into every production stage—from raw material verification to final inspection—ensuring traceability, repeatability, and compliance with ISO 9001 standards. Additionally, first-article inspection reports and production batch certifications are available upon request.

Our commitment to precision is reflected in the tight tolerances we consistently achieve across diverse part configurations. The following table outlines our standard and high-precision tolerance capabilities:

| Feature Type | Standard Tolerance | High-Precision Tolerance | Measurement Tool |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | CMM, Micrometers |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Pin Gauges, CMM |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | CMM |

| Flatness | 0.05 mm | 0.01 mm | CMM, Optical Flat |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Surface Roughness Tester |

| Angular Features | ±0.1° | ±0.05° | CMM, Precision Protractor |

These specifications demonstrate our ability to meet demanding engineering requirements while maintaining scalability for both prototyping and high-volume production. With a skilled team of CNC programmers, machinists, and quality engineers, Wuxi Lead Precision Machinery ensures that every cutting service delivers precision, reliability, and long-term performance.

Material & Finish Options

Material Selection for Precision Cutting Services: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is foundational to achieving performance, cost-efficiency, and longevity in precision-cut components. At Wuxi Lead Precision Machinery, our CNC cutting expertise is matched by deep material science understanding, ensuring your project specifications translate into flawless execution. Key considerations include mechanical properties, environmental resistance, machinability, and required surface finishes. Aluminum, steel, and titanium represent the core structural metals for demanding applications, each with distinct advantages.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are favored for aerospace, automotive, and consumer electronics due to their exceptional strength-to-weight ratio, inherent corrosion resistance, and excellent thermal/electrical conductivity. They machine efficiently at high speeds, reducing cycle times and costs. Steel, especially stainless grades like 304 and 316L, provides superior strength, hardness, and wear resistance for industrial machinery, medical instruments, and structural components. Its higher density and work-hardening characteristics demand precise toolpath strategies but deliver unmatched durability. Titanium alloys, notably Grade 5 (Ti-6Al-4V), are critical for extreme environments in aerospace, medical implants, and marine applications. They offer extraordinary strength-to-weight ratios, biocompatibility, and resistance to corrosion and high temperatures, though their low thermal conductivity and chemical reactivity necessitate specialized cutting parameters and tooling.

The following table summarizes critical properties influencing CNC cutting performance and application suitability:

| Material Group | Key Alloys | Typical Yield Strength (MPa) | Machinability Rating | Primary Application Drivers |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 240 – 503 | Excellent (A) | Weight reduction, thermal management, cost |

| Steel | 304, 316L, 4140 | 205 – 1020+ | Good to Fair (B-C) | Strength, wear resistance, structural integrity |

| Titanium | Ti-6Al-4V (Gr5) | 880 – 1100 | Poor (D) | Extreme strength/weight, corrosion resistance |

Surface finishing, particularly anodizing for aluminum, is not merely cosmetic but a functional enhancement. Type II (sulfuric acid) anodizing provides robust corrosion resistance and a porous base for dyeing, essential for consumer products and marine hardware. Type III (hardcoat) anodizing creates a significantly thicker, harder ceramic layer (60-70 HRC) for wear resistance in hydraulic components, firearm parts, and high-friction applications. Proper pre-treatment and process control are vital; inconsistent anodizing can lead to dimensional changes or reduced fatigue strength in precision-cut parts. Wuxi Lead integrates finish requirements directly into the machining strategy, ensuring tight tolerances are maintained post-treatment.

Material choice directly impacts cutting tool selection, feed rates, coolant requirements, and overall project economics. Partnering with a manufacturer possessing metallurgical expertise ensures your material selection aligns perfectly with functional demands and manufacturing realities. Wuxi Lead Precision Machinery provides comprehensive consultation, leveraging decades of experience to optimize your material and finish selection for successful, high-value production. Discuss your specific application requirements with our engineering team to determine the ideal solution.

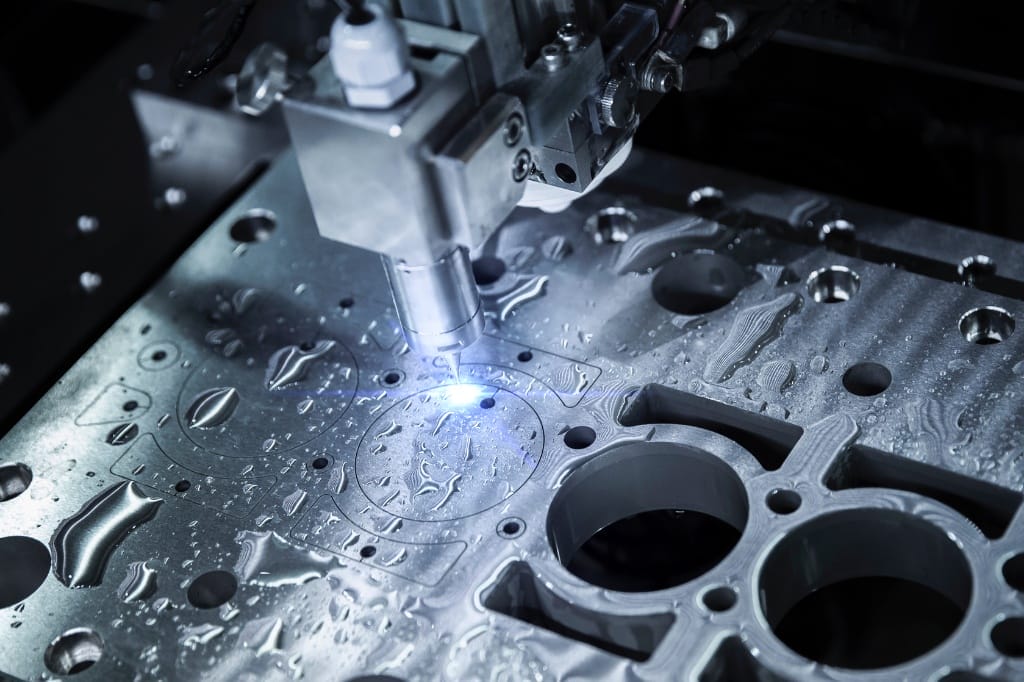

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal cutting service is engineered for precision, consistency, and zero-defect performance across every production phase. We integrate advanced CNC technology with rigorous quality assurance to deliver high-integrity components tailored to exact client specifications. Our end-to-end process spans from initial design consultation through prototyping to full-scale mass production, ensuring seamless transition and uncompromised quality at every stage.

The process begins with collaborative design engineering. Our technical team works directly with client blueprints or CAD models, conducting comprehensive design for manufacturability (DFM) analysis. This step identifies potential challenges early, optimizes material usage, and ensures geometric accuracy while aligning with functional and tolerance requirements. Using industry-leading simulation software, we validate toolpaths and cutting strategies to minimize waste and prevent errors before any material is cut.

Once the design is finalized, we proceed to prototyping. A small batch of components is produced under full production conditions, allowing us to verify dimensional accuracy, surface finish, and material integrity. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning systems. This validation phase ensures that every aspect of the part meets the required ISO and client-specific standards. Feedback from this stage is incorporated into final process adjustments, guaranteeing readiness for scale.

Mass production is executed on our automated CNC machining and cutting platforms, which include multi-axis milling, turning, laser, and waterjet systems. These machines are monitored in real time using integrated sensors and process control software that detect deviations instantly. Our production floor operates under strict ISO 9001-certified protocols, with continuous in-process inspections and statistical process control (SPC) ensuring consistency across thousands of parts. Every operator is trained to uphold zero-defect principles, supported by a traceability system that logs every parameter for full batch accountability.

Our commitment to zero defects is reinforced by a closed-loop corrective action system. Any non-conformance, however minor, triggers immediate root cause analysis and process refinement. This proactive quality culture, combined with state-of-the-art equipment, ensures that clients receive only flawless components, on time and to specification.

The following table outlines key capabilities of our cutting service:

| Specification | Detail |

|---|---|

| Material Compatibility | Aluminum, Stainless Steel, Carbon Steel, Titanium, Brass, Copper, Alloy Steels |

| Tolerance Range | ±0.005 mm to ±0.025 mm depending on process and geometry |

| Maximum Work Envelope | 2000 mm × 1000 mm × 800 mm (L×W×H) |

| Surface Finish | Ra 0.8 µm to Ra 6.3 µm (adjustable per requirement) |

| Production Capacity | Up to 50,000 units per month (scalable with demand) |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), PPAP, FAI, SPC |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days based on order volume |

From concept to completion, Wuxi Lead Precision Machinery delivers precision cutting solutions built on engineering excellence and a relentless pursuit of perfection.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

In the demanding landscape of custom metal fabrication, precision is non-negotiable. Wuxi Lead Precision Machinery stands as your strategic partner for cutting services that exceed industry benchmarks, transforming complex engineering challenges into flawless deliverables. Our ISO 9001-certified facility in Wuxi, China, integrates advanced CNC technology with decades of metallurgical expertise to ensure every component meets the rigorous demands of aerospace, medical, and industrial automation sectors. We do not merely cut metal—we engineer reliability, repeatability, and resilience into every part.

Our cutting-edge infrastructure supports materials ranging from aerospace-grade titanium and Inconel to hardened tool steels and aluminum alloys. Unlike conventional vendors, we prioritize process stability through real-time monitoring, thermal compensation systems, and stringent in-process inspections. This methodology eliminates costly rework and accelerates time-to-market for your critical applications. Below are key capabilities defining our cutting service excellence.

| Specification Category | Performance Standard | Industry Relevance |

|---|---|---|

| Tolerance Control | ±0.005 mm | Ensures seamless integration in high-precision assemblies |

| Surface Roughness | Ra 0.4 μm (typical) | Meets medical and optical surface finish requirements |

| Material Thickness Range | 0.5 mm – 150 mm | Supports micro-components to heavy structural parts |

| Max Work Envelope | 2,500 x 1,250 x 800 mm | Accommodates large-scale industrial components |

| Spindle Speed Range | 20 – 4,000 min⁻¹ | Optimizes cutting parameters for all material grades |

| Lead Time Efficiency | 15–30% faster than industry average | Reduces project bottlenecks through lean workflow management |

Partnering with Lead Precision means gaining a collaborator invested in your success from prototype to volume production. Our engineering team conducts joint feasibility reviews to optimize part geometry, material utilization, and cost-efficiency before a single chip is cut. We provide comprehensive documentation, including first-article inspection reports (FAIR) and material traceability certificates, ensuring full compliance with AS9100 and ISO 13485 standards. This proactive approach mitigates supply chain risks while guaranteeing dimensional integrity across production runs.

For mission-critical components where failure is not an option, our cutting services deliver the confluence of Chinese manufacturing scale and German-engineered precision. We understand that your reputation hinges on the performance of every part we produce—and we uphold that trust through uncompromising quality control and transparent communication.

Initiate your precision manufacturing partnership today. Contact our engineering team directly at [email protected] to discuss your project specifications, request a confidential quotation, or schedule a virtual facility tour. Our specialists respond within 24 business hours to align on technical requirements, capacity planning, and delivery milestones. Let Wuxi Lead Precision Machinery become the cornerstone of your supply chain—where exacting standards meet exceptional execution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.