Technical Contents

Engineering Guide: Custom Roto-Molding

Engineering Precision in Custom Roto-Molding: Beyond Hollow Forming

Custom roto-molding, while often associated with large hollow plastic parts, demands exceptional precision engineering when applied to high-integrity metal components, particularly for aerospace, defense, and critical infrastructure. At Wuxi Lead Precision Machinery, we emphasize that true value lies not merely in achieving the basic shape, but in the unwavering dimensional accuracy, consistent wall thickness distribution, and material integrity throughout the complex thermal cycle. Inadequate control over rotational speed synchronization, oven temperature gradients, or cooling rates introduces microstructural inconsistencies and geometric deviations that compromise part performance under stress or in demanding environments. Precision in roto-molding is non-negotiable for components where failure is not an option; it directly dictates fatigue life, sealing capability, and assembly compatibility within larger systems.

Our engineering approach integrates advanced CNC-controlled rotational axes with multi-zone thermal profiling systems, ensuring perfect balance and uniform heat absorption during the critical sintering phase. We meticulously calibrate dwell times and cooling curves based on material science data, mitigating warpage and internal stresses inherent in the process. This level of control transforms roto-molding from a basic forming technique into a precision manufacturing solution capable of producing near-net-shape metal components with exceptional repeatability. The result is significant material savings, reduced secondary machining, and parts that meet stringent AS9100 or MIL-STD dimensional and metallurgical requirements straight from the mold.

Wuxi Lead Precision Machinery’s expertise is validated through demanding real-world applications. We engineered roto-molded titanium structural elements for Beijing Winter Olympics venue infrastructure, where thermal cycling stability and exact geometric fit were paramount under extreme alpine conditions. Furthermore, our processes consistently produce mission-critical defense components requiring hermetic seals and resistance to explosive decompression, certified to exacting military specifications. This proven track record in environments where precision equals survival underscores our capability.

Key process parameters we rigorously control are reflected in our achievable specifications:

| Parameter | Standard Capability | High-Precision Capability | Measurement Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.5% of nominal | ±0.15% of nominal | CMM (ASME B89.4.1036) |

| Wall Thickness Uniformity | ±8% variation | ±3% variation | Ultrasonic Thickness Gauge |

| Max Part Dimensions (LxWxH) | 2500 x 1500 x 1200 mm | 1800 x 1000 x 800 mm | Laser Tracker |

| Material Temp Control | ±15°C | ±5°C | Calibrated Thermocouples |

| Cycle Time Repeatability | ±3% | ±1% | Process Data Logging |

Partnering with Wuxi Lead means leveraging roto-molding not as a compromise, but as a precision-engineered pathway to complex metal geometries. Our Olympic and defense-grade process discipline ensures your custom components deliver the reliability, performance, and exacting quality demanded by the most advanced industrial applications, turning design intent into flawless physical reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom roto-molding solutions through precision engineering and state-of-the-art manufacturing technologies. Our expertise in custom metal manufacturing enables us to support complex rotational molding applications requiring high structural integrity, tight tolerances, and repeatable accuracy. Central to our technical capabilities is our fleet of 5-axis CNC machining centers, which provide unparalleled flexibility in shaping intricate geometries from a wide range of metals, including aluminum alloys, stainless steel, and specialty-grade materials suitable for industrial and aerospace applications.

The integration of 5-axis CNC technology allows for simultaneous multi-directional cutting, reducing setup cycles and ensuring superior surface finish and dimensional consistency. This capability is essential in producing molds and support components for roto-molding processes where thermal stability, wall uniformity, and long-term durability are critical. Our machining centers operate under strict environmental controls to minimize thermal drift, ensuring micron-level precision across large work envelopes. With a maximum working envelope of 2,500 mm × 1,200 mm × 1,000 mm and high-speed spindle options up to 24,000 RPM, we accommodate both prototype development and high-volume production runs.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), enabling full 3D geometric dimensioning and tolerance (GD&T) validation. Our CMM systems are calibrated to ISO 10360 standards and operate in a temperature-controlled metrology lab to ensure measurement repeatability within ±0.0005 mm. In addition to first-article inspections, we perform in-process and final QC checks, with full traceability and digital reporting provided for each production batch.

Our commitment to precision is reflected in the tolerances we consistently achieve across various feature types. Below is a summary of our standard and precision-level capabilities.

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | CMM, High-Precision Micrometers |

| Angular Alignment | ±0.1° | ±0.05° | CMM, Optical Comparator |

| Hole Diameter (Drilled) | ±0.03 mm | ±0.01 mm | Air Gauges, CMM |

| Hole Position | ±0.05 mm | ±0.02 mm | CMM |

| Surface Finish (Ra) | 3.2 μm | 0.8 μm | Surface Roughness Tester |

| Flatness | 0.05 mm | 0.01 mm | CMM, Precision Blocks |

| Profile Tolerance | ±0.05 mm | ±0.02 mm | CMM, Scanning Probe |

All technical data is validated under controlled production conditions and may vary based on part geometry, material, and customer specifications. Wuxi Lead Precision Machinery maintains ISO 9001:2015 certification and adheres to international standards in documentation, process control, and continuous improvement. Our engineering team collaborates directly with clients to optimize designs for manufacturability, ensuring that every roto-molded component meets the highest benchmarks in performance and reliability.

Material & Finish Options

Material Selection for High-Precision Roto-Molded Components

Selecting the optimal material for custom roto-molded metal components is a critical engineering decision impacting performance, longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we guide clients through this complex process, focusing on application demands, environmental exposure, and regulatory requirements. Aluminum, steel, and titanium represent the primary high-performance alloys for demanding roto-molding applications, each offering distinct advantages. Aluminum alloys, particularly 6061-T6 and 7075-T6, provide an exceptional strength-to-weight ratio and inherent corrosion resistance, making them ideal for aerospace enclosures, automotive structural brackets, and portable medical device housings where weight savings are paramount. Steel, especially 304 and 316 stainless variants, delivers superior tensile strength, wear resistance, and cost-effectiveness for high-load applications like industrial machinery frames, marine hardware, and food processing equipment requiring robust structural integrity and moderate corrosion protection. Titanium, primarily Grade 5 (Ti-6Al-4V), offers the ultimate in strength-to-weight ratio, exceptional biocompatibility, and near immunity to corrosion in harsh environments including seawater and chemical exposure, justifying its use in critical aerospace components, surgical implants, and deep-sea instrumentation despite higher material and processing costs.

The following table summarizes key comparative properties for common roto-molding alloys:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Corrosion Resistance | Key Roto-Molding Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good (atmospheric) | Aerospace brackets, consumer electronics housings | Excellent |

| Stainless Steel 304 | 8.0 | 515 | Very Good | Food processing parts, architectural hardware | Moderate |

| Titanium Ti-6Al-4V | 4.4 | 900 | Exceptional | Medical implants, aerospace fixtures, marine parts | Poor |

Surface finish selection significantly enhances functionality and durability. Anodizing is the predominant and highly recommended post-process for aluminum roto-molded parts. This electrochemical process thickens the natural oxide layer, dramatically improving surface hardness, wear resistance, and corrosion protection. Type II (Sulfuric Acid) anodizing provides a versatile, economical finish suitable for most industrial applications, offering good dyeing capability for color coding. For mission-critical components demanding maximum abrasion resistance and dielectric properties, Type III (Hardcoat) anodizing is essential, producing coatings up to 100 microns thick with hardness approaching sapphire. We rigorously control anodizing parameters including electrolyte concentration, temperature, voltage, and immersion time to ensure consistent, pore-free coatings meeting ASTM B580 and MIL-A-8625 specifications. Steel components typically utilize passivation (for stainless) or precision powder coating for corrosion defense, while titanium often relies on its native oxide layer but can be enhanced with specialized treatments like plasma electrolytic oxidation for extreme wear scenarios. Partner with Wuxi Lead to match material science and surface engineering precisely to your operational environment, ensuring component reliability and value. Our production capabilities fully support the stringent processing requirements of all three base materials and advanced finishing techniques.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the custom roto-molding production process begins with a comprehensive design phase that integrates engineering rigor with client-specific requirements. Our team of senior mechanical engineers collaborates directly with clients to translate conceptual needs into detailed 3D CAD models and technical drawings. Finite element analysis (FEA) and thermal stress simulations are applied to ensure structural integrity and performance under operational conditions. Material selection is carefully evaluated based on environmental exposure, load requirements, and lifecycle expectations. Every design is reviewed for manufacturability, ensuring seamless transition into prototyping. This phase establishes the blueprint for zero-defect manufacturing, where tolerances, surface finishes, and geometric accuracy are defined to micron-level precision.

Prototyping: Validation Before Scale

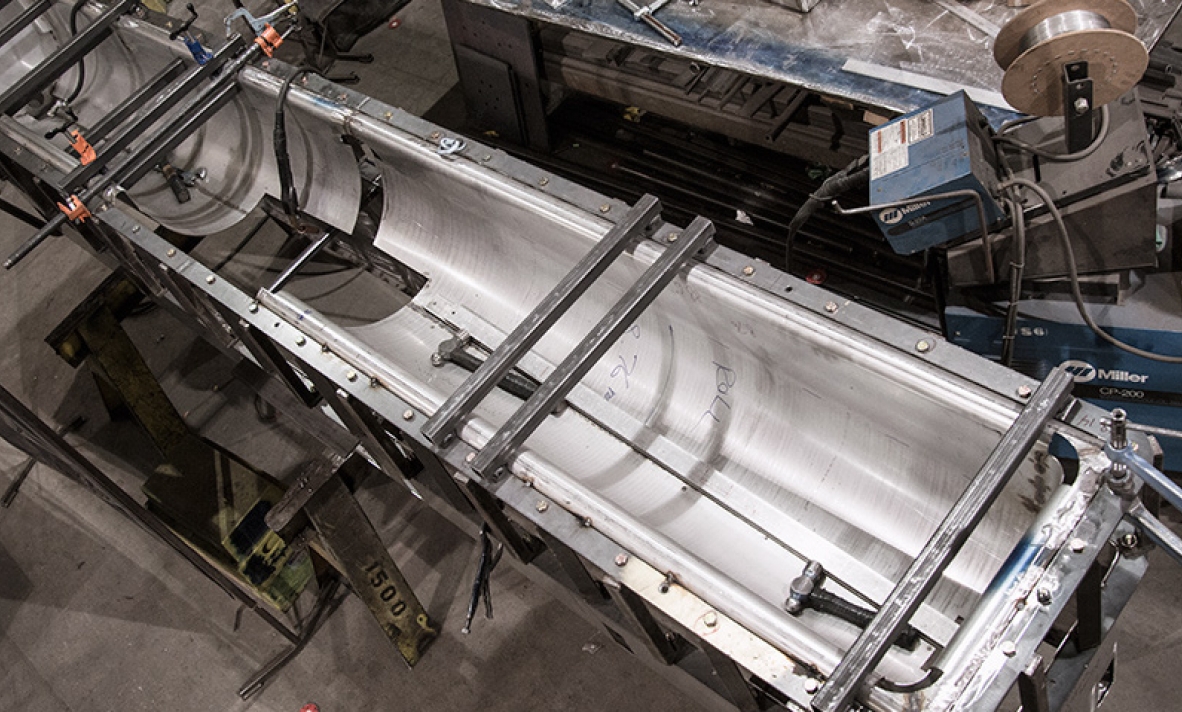

Once the design is finalized, we move into the prototyping stage using high-fidelity roto-molding tooling and controlled thermal cycles. Prototypes are produced on the same class of industrial equipment used in mass production, ensuring accurate representation of final part characteristics. Each prototype undergoes rigorous dimensional inspection via coordinate measuring machines (CMM) and 3D laser scanning to verify conformity to design specifications. Functional testing includes pressure cycling, impact resistance, and thermal stability assessments. Client feedback is incorporated at this stage, allowing for iterative refinement without impacting large-scale output. This validation loop ensures that all potential defects are identified and corrected before full production begins, aligning with our zero-defect philosophy.

Mass Production: Consistency Through Automation and Control

With prototype approval, Wuxi Lead initiates mass production under a fully documented quality management system compliant with ISO 9001 standards. Our roto-molding lines operate with automated loading, precise temperature profiling, and real-time monitoring of rotation speed and cycle duration. Each batch is traceable through serialized process logs, and in-process inspections occur at predefined intervals. Statistical process control (SPC) is employed to detect deviations before they affect output quality. Final inspection includes 100% visual checks and random sampling for mechanical and dimensional verification. All finished components are packaged to prevent transit damage and shipped with full certification dossiers.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel 304/316, Carbon Steel, Aluminum Alloys |

| Wall Thickness Range | 3 mm – 25 mm (adjustable per design) |

| Dimensional Tolerance | ±0.5 mm per meter |

| Surface Finish | Ra ≤ 3.2 µm (standard), custom polishing available |

| Maximum Part Weight | 300 kg |

| Cycle Time Range | 20 – 90 minutes per cycle |

| Quality Standard | ISO 9001:2015, Full Traceability, PPAP Level 3 |

| Lead Time (Prototype) | 15 – 20 working days |

| Lead Time (Mass Production) | 30 – 45 days (varies by order volume) |

At every stage—from design to delivery—Wuxi Lead Precision Machinery enforces a zero-defect mindset through precision engineering, advanced process control, and unwavering commitment to client collaboration.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Roto-Molding Excellence

Selecting the right manufacturing partner for custom rotational molding demands more than just equipment capacity; it requires deep engineering insight, material science expertise, and unwavering commitment to precision. At Wuxi Lead Precision Machinery, we bridge the gap between complex design intent and flawless production reality. Our integrated approach combines decades of rotational molding experience with advanced CNC-controlled process validation, ensuring every component meets the exacting tolerances and structural integrity your application demands. We specialize in transforming challenging polymers and composite materials into high-performance, stress-resistant parts for aerospace, medical equipment, and industrial fluid handling—where failure is not an option.

Our facility operates under ISO 9001-certified protocols, with real-time monitoring of oven temperature gradients, arm speed harmonics, and cooling rates to eliminate warpage and ensure uniform wall thickness. Unlike standard molding houses, we implement finite element analysis (FEA) during the tooling phase to predict material flow and mitigate sink marks, reducing prototyping cycles by up to 40%. This engineering-first methodology delivers parts that consistently achieve ±0.005″ dimensional accuracy and superior impact resistance, even in extreme environments.

Key Technical Capabilities for Demanding Applications

| Capability | Specification | Application Impact |

|---|---|---|

| Material Range | Polyethylene (LLDPE, HDPE), Nylon, PVC, Specialty Composites | Chemical resistance, UV stability, FDA compliance |

| Part Size Envelope | Up to Ø2.5m x 1.8m height | Large tanks, enclosures, structural housings |

| Wall Thickness Control | 2mm – 25mm (±0.2mm tolerance) | Optimized weight vs. structural strength |

| Tooling Precision | CNC-machined aluminum/steel molds | Surface finish Ra ≤ 0.8μm, zero flash |

| Process Validation | In-cycle thermal imaging, pressure mapping | Eliminates voids, ensures homogenous density |

Partnering with Lead Precision means gaining a technical ally invested in your product’s lifecycle success. We collaborate from initial concept sketches through DFMEA reviews, providing material selection guidance and mold-flow simulation data to de-risk your development timeline. Our engineering team speaks your language—literally and technically—with fluent English-speaking project managers and ASME-certified technicians available for direct consultation. Every shipment includes full material traceability documentation and first-article inspection reports aligned to your blueprint’s critical-to-quality characteristics.

Do not compromise on rotational molding quality when your product’s reliability is at stake. Contact our engineering sales team today to discuss how our precision-driven process can solve your toughest manufacturing challenges. Email Contact [email protected] with your project specifications and timeline. We will respond within 4 business hours with a preliminary feasibility assessment and process flow diagram tailored to your requirements. Let Lead Precision become the silent partner behind your next breakthrough product—where engineering rigor meets manufacturing excellence. Schedule your technical consultation now.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.