Technical Contents

Engineering Guide: Custom Precision Machining

Engineering Insight: The Critical Role of Precision in Custom Metal Manufacturing

In the realm of custom precision machining, accuracy is not merely a performance metric—it is the foundation upon which reliability, safety, and functionality are built. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation—measured in microns—can lead to catastrophic failure in high-stakes applications. This is especially true in sectors such as aerospace, defense, and high-performance sports engineering, where components must endure extreme conditions while maintaining exacting tolerances.

Precision machining goes beyond the capability of advanced CNC equipment; it reflects a deep integration of engineering expertise, material science, process control, and quality assurance. At Lead Precision, our decades of experience have been forged in projects demanding the highest levels of consistency and repeatability. Our involvement in supporting components for Olympic-level sporting equipment and mission-critical military systems underscores our commitment to excellence. These applications require not only adherence to tight tolerances but also rigorous documentation, traceability, and compliance with international standards.

In Olympic applications, for example, performance margins are razor-thin. A fraction of a gram in weight or a 5-micron variation in surface finish can influence an athlete’s outcome. Similarly, in military-grade hardware, precision ensures interoperability, durability under stress, and long-term reliability in unpredictable environments. Our engineering team approaches each custom project with the same philosophy: every dimension matters, every surface finish is intentional, and every material property is optimized for the end use.

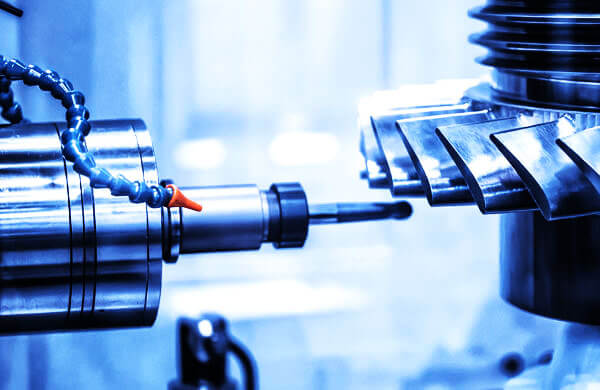

Our facility in Wuxi is equipped with state-of-the-art multi-axis CNC machining centers, coordinate measuring machines (CMM), and in-process inspection systems that allow real-time verification of critical dimensions. This technological backbone, combined with our ISO 9001-certified quality management system, ensures that every part we produce meets or exceeds customer specifications.

Below is a summary of our core machining capabilities, illustrating the precision and versatility we bring to custom metal manufacturing.

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.002 mm (±0.00008 in) |

| Surface Finish | Ra 0.1 µm to Ra 1.6 µm (4 µin to 63 µin) |

| Maximum Work Envelope | 2000 mm × 1200 mm × 800 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| CNC Equipment | 3-axis, 4-axis, 5-axis milling; CNC turning; Swiss-type machining |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 |

| Secondary Processes | Heat treatment, anodizing, passivation, precision grinding |

At Wuxi Lead Precision Machinery, we do not view precision as an added feature—we engineer it into every stage of production. From initial design consultation to final inspection, our goal is to deliver components that perform flawlessly in the most demanding environments. When your application leaves no room for error, trust a partner with a proven track record in custom precision machining.

Precision Specs & Tolerances

Technical Capabilities: Engineering Precision for Demanding Applications

Wuxi Lead Precision Machinery delivers advanced custom precision machining solutions engineered for the most stringent aerospace, medical, and industrial applications. Our core strength lies in integrating cutting-edge multi-axis technology with rigorous quality assurance protocols to achieve exceptional dimensional accuracy and surface integrity on complex metal components. We specialize in transforming intricate designs into high-performance parts, consistently meeting the exacting standards required by global Tier 1 suppliers and OEMs.

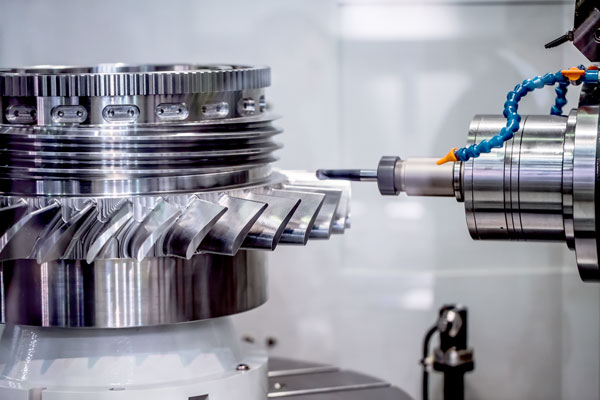

Our manufacturing foundation is built upon a modern fleet of high-torque, high-accuracy 5-axis CNC machining centers. These systems, featuring simultaneous 5-axis interpolation and advanced thermal compensation, enable the production of highly complex geometries—including deep cavities, undercuts, and organic contours—in a single setup. This capability eliminates cumulative errors inherent in multi-setup processes, significantly enhancing part accuracy while reducing lead times and handling damage risks. We routinely machine challenging materials such as titanium alloys (Ti-6Al-4V), Inconel 718, stainless steels (316L, 17-4 PH), aluminum alloys (7075, 6061), and specialized engineering plastics with consistent repeatability. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase to optimize part geometry, material selection, and machining strategy, ensuring manufacturability without compromising functional requirements.

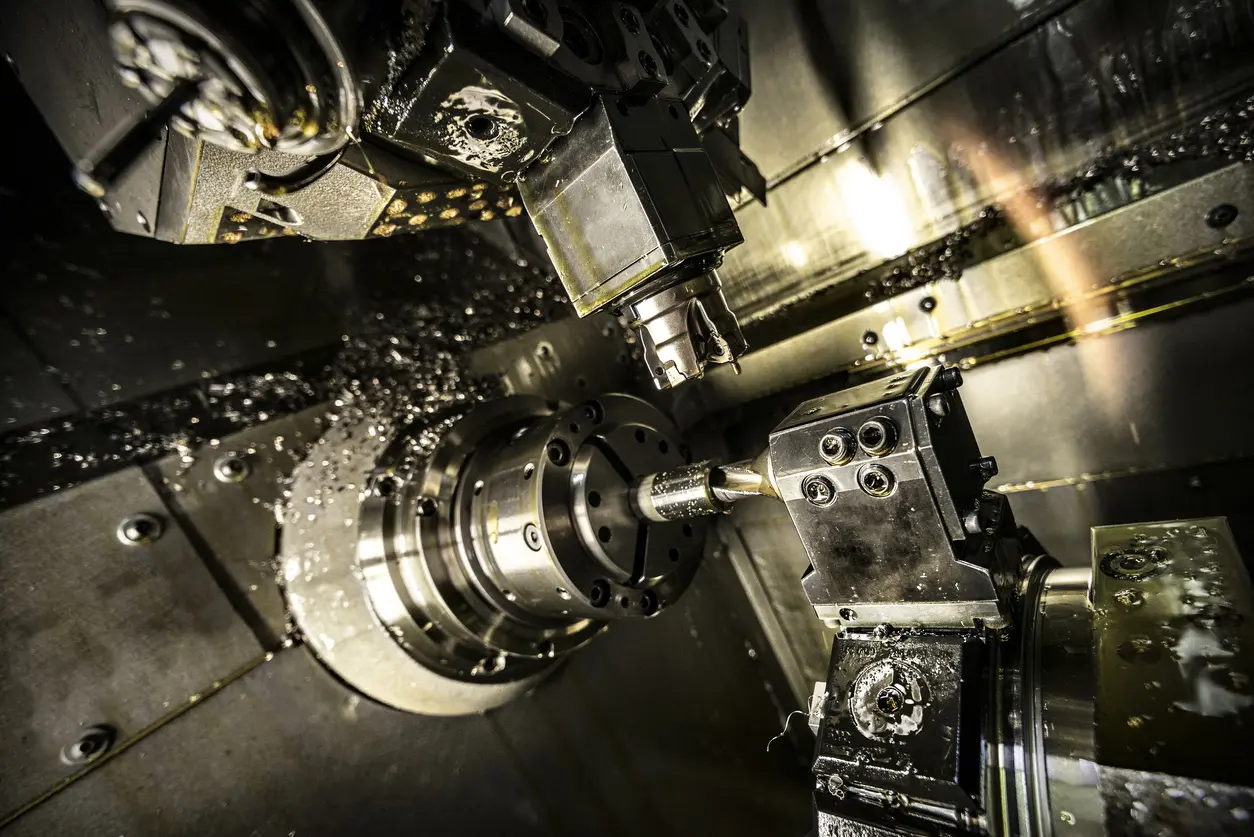

Precision is non-negotiable in critical applications. Wuxi Lead implements a comprehensive, multi-stage quality control system anchored by a certified metrology laboratory. Every critical feature undergoes meticulous verification using state-of-the-art Coordinate Measuring Machines (CMMs) equipped with high-precision probes and advanced software for geometric dimensioning and tolerancing (GD&T) analysis. Our inspection protocols extend beyond final part verification to include in-process checks and statistical process control (SPC) methodologies, ensuring stability throughout production runs. Full traceability of materials, processes, and inspection data is maintained for every component, providing complete auditability essential for regulated industries.

The achievable precision for standard production runs under controlled conditions is reflected in our core tolerance capabilities:

| Feature Type | Typical Tolerance Range (Metric) | Typical Tolerance Range (Imperial) |

|---|---|---|

| Linear Dimensions | ±0.005 mm to ±0.025 mm | ±0.0002″ to ±0.001″ |

| Geometric (GD&T) | 0.010 mm to 0.050 mm | 0.0004″ to 0.002″ |

| Surface Roughness (Ra) | 0.4 µm to 1.6 µm | 16 µin to 63 µin |

| Hole Position | ±0.010 mm | ±0.0004″ |

These specifications represent our standard production capability; tighter tolerances are achievable through specialized processes and rigorous process validation for mission-critical features. Our commitment extends beyond machining to include secondary operations such as precision grinding, honing, and selective plating coordination, ensuring a single-source solution for complex assemblies. Partner with Wuxi Lead Precision Machinery for custom metal manufacturing where uncompromising accuracy, material expertise, and certified quality assurance converge to solve your most demanding engineering challenges. We provide the technical partnership and process rigor required to bring high-value components from concept to certified production.

Material & Finish Options

Material selection is a foundational step in custom precision machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we guide our clients through informed decisions based on application requirements such as load, temperature, corrosion exposure, and weight constraints. Among the most widely used materials in high-precision manufacturing are aluminum, steel, and titanium—each offering distinct mechanical and chemical properties suited to specific industrial environments.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for aerospace, automotive, and electronics applications where lightweight construction and efficient heat dissipation are critical. The most common grades used in precision machining are 6061 and 7075. While 6061 offers good weldability and moderate strength, 7075 delivers higher tensile strength, making it ideal for structural components under high stress. Aluminum is naturally corrosion-resistant due to its oxide layer, but for enhanced durability and surface hardness, anodizing is recommended.

Steel remains the backbone of industrial machinery due to its high strength, wear resistance, and versatility. Alloy steels such as 4140 and 4340 are frequently selected for parts requiring toughness and fatigue resistance, including shafts, gears, and tooling components. Stainless steels like 303 and 304 offer superior corrosion resistance and are widely used in medical devices, food processing, and marine environments. While steel is denser than aluminum and titanium, its mechanical robustness and lower cost make it a preferred choice for heavy-duty applications.

Titanium, particularly Grade 5 (Ti-6Al-4V), is renowned for its exceptional strength-to-density ratio and resistance to extreme environments. It performs reliably under high temperatures and is highly resistant to corrosion, especially in saline or acidic conditions. These properties make titanium indispensable in aerospace, defense, and biomedical implants. However, its high cost and challenging machinability require advanced CNC techniques and tooling strategies, which Wuxi Lead Precision Machinery has mastered through years of specialized production.

Surface finishing plays a crucial role in enhancing material performance. Anodizing, primarily applied to aluminum, creates a controlled oxide layer that improves wear resistance, corrosion protection, and aesthetic consistency. Type II (sulfuric acid) anodizing is standard for general-purpose applications, while Type III (hardcoat anodizing) is used for components exposed to severe abrasion. Anodized layers can also be dyed for identification or branding, without compromising dimensional accuracy.

The table below summarizes key mechanical properties of commonly machined materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications |

|---|---|---|---|---|

| Aluminum | 310 (7075) | 2.8 | 6061, 7075 | Aerospace, Electronics |

| Steel (Alloy) | 950 (4140) | 7.85 | 4140, 4340 | Industrial Machinery, Tools |

| Stainless Steel | 700 (304) | 8.0 | 303, 304, 316 | Medical, Food Processing |

| Titanium | 900 (Ti-6Al-4V) | 4.43 | Gr 2, Gr 5 | Aerospace, Biomedical |

Selecting the right material and finish ensures optimal functionality and longevity of precision components. At Wuxi Lead Precision Machinery, we combine material science expertise with advanced CNC capabilities to deliver custom solutions that meet the highest industry standards.

Manufacturing Process & QC

Custom Precision Machining Production Process: From Design to Zero Defects Delivery

At Wuxi Lead Precision Machinery, our production process for custom metal components is engineered for uncompromising quality in high-stakes industries like aerospace, medical, and semiconductor manufacturing. We eliminate guesswork through a rigorously controlled sequence: Design Validation, Precision Prototyping, and Zero-Defect Mass Production. This methodology ensures every part meets exacting functional and regulatory demands while minimizing time-to-market.

Design validation begins with deep collaboration. Our engineers conduct comprehensive Design for Manufacturability (DFM) analysis, scrutinizing CAD models for geometric feasibility, material suitability, and tolerance stack-ups. We identify potential stress points, tool access constraints, and secondary operation requirements early, preventing costly revisions later. Critical dimensions are cross-referenced against ISO 2768 or client-specific standards, with thermal deformation and residual stress modeling applied for complex geometries. This phase concludes with a signed-off manufacturing plan, locking in process parameters before any metal is cut.

Prototyping transforms validated designs into physical proof. Using the same HAAS DM/VM series 5-axis machining centers and Okuma lathes deployed in full production, we produce 1–5 first-article units under controlled conditions. Each prototype undergoes full CMM inspection against the original CAD file, with surface roughness verified via Mitutoyo SJ-410 profilometers. Dimensional reports, material certs (e.g., EN 10204 3.1), and metallurgical test data are delivered within 72 hours. Clients receive actionable feedback for micro-adjustments—ensuring the prototype isn’t just a sample, but the blueprint for flawless scale-up.

Mass production executes with systemic defect prevention. Every batch leverages Statistical Process Control (SPC) with real-time monitoring of critical parameters: tool wear via Renishaw probes, coolant concentration, and spindle load. In-process inspections occur at defined intervals using automated vision systems and CMMs, with data fed into our MES for trend analysis. Our closed-loop correction system triggers automatic machine recalibration if deviations exceed 70% of tolerance bands. All finished parts undergo 100% first-article inspection and batch-level validation per AS9102 or client-specific protocols.

This integrated approach guarantees measurable quality outcomes, as defined in our production specifications:

| Parameter | Standard Specification | Verification Method | Industry Benchmark |

|---|---|---|---|

| Dimensional Accuracy | ±0.002 mm | CMM (Zeiss CONTURA) | ±0.005 mm |

| Surface Roughness | Ra 0.4 µm (typical) | Profilometer (Mitutoyo) | Ra 1.6 µm |

| Process Capability (Cpk) | ≥1.67 | SPC Data Analysis | ≥1.33 |

| Material Certification | EN 10204 3.1/3.2 | Mill Test Reports | 2.2 |

| Defect Rate | ≤25 PPM | Final Audit + CMM | ≤500 PPM |

Wuxi Lead Precision Machinery delivers zero-defect outcomes by treating design, prototyping, and production as a single continuum—not isolated stages. Our process eliminates waste, ensures regulatory compliance, and provides the repeatable precision that defines mission-critical manufacturing. Partner with us to transform your most demanding designs into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Precision Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-performance industries, precision is not a luxury—it’s a requirement. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering CNC-machined components that meet the most demanding engineering standards. Our advanced capabilities, combined with decades of technical expertise, position us as the ideal manufacturing partner for global OEMs, aerospace firms, medical device developers, and industrial innovators.

When you partner with Lead Precision, you gain more than a supplier—you gain a committed collaborator. From the initial design consultation to final inspection and global delivery, our engineering team works closely with yours to ensure every component is manufactured to exact specifications. We leverage state-of-the-art CNC turning, milling, and multi-axis machining centers to produce parts with tolerances as tight as ±0.001 mm. Our ISO 9001-certified quality management system ensures consistency, traceability, and compliance across every production run—whether prototyping or high-volume manufacturing.

Our facility is equipped to handle a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, and specialized engineering plastics. With in-house capabilities spanning precision turning, 5-axis milling, grinding, and surface finishing, we deliver fully finished parts that require no secondary operations. This vertical integration reduces lead times, lowers costs, and ensures complete control over quality.

We serve clients across North America, Europe, and Asia, providing seamless communication in English and technical documentation in full compliance with international standards. Our responsive project management team ensures real-time updates, detailed work instructions, and full transparency throughout the production cycle.

Below is an overview of our core manufacturing specifications:

| Specification | Capability |

|---|---|

| Machining Processes | CNC Turning, 3-5 Axis Milling, Multi-Spindle Machining, Grinding |

| Tolerances | ±0.001 mm to ±0.005 mm |

| Maximum Work Envelope | 1200 mm (X) × 800 mm (Y) × 750 mm (Z) |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Copper, Engineering Plastics |

| Surface Finishes | As-machined, Anodizing, Plating, Passivation, Powder Coating |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP, GD&T |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

| Certifications | ISO 9001, RoHS Compliance, Material Traceability (Mill Certs) |

Choosing the right manufacturing partner is critical to your product’s success. At Wuxi Lead Precision Machinery, we combine cutting-edge technology with a customer-first philosophy to deliver precision-engineered components that perform. We invite you to experience the difference of a true engineering partnership.

Contact us today at [email protected] to discuss your next project. Let Lead Precision be the foundation of your manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.