Technical Contents

Engineering Guide: Custom Plastics Fabrication

Engineering Insight: The Critical Role of Precision in Custom Plastics Fabrication

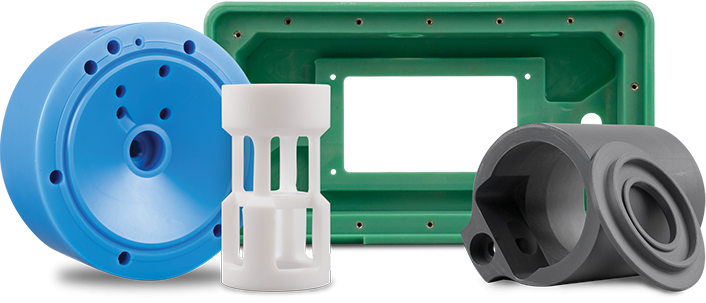

In the realm of advanced manufacturing, custom plastics fabrication has emerged as a cornerstone for industries demanding lightweight, corrosion-resistant, and electrically insulating components. While often grouped with traditional metalworking disciplines, plastics fabrication presents unique engineering challenges—material variability, thermal sensitivity, and dimensional stability—making precision not merely a performance metric, but a foundational requirement. At Wuxi Lead Precision Machinery, we apply the same rigorous standards to plastic component manufacturing as we do in our core sheet metal operations, ensuring seamless integration across hybrid assemblies used in aerospace, medical devices, and high-performance industrial systems.

Precision in plastics fabrication begins with material science comprehension. Unlike metals, thermoplastics such as PEEK, PTFE, and polycarbonate exhibit significant thermal expansion and viscoelastic behavior. Machining these materials demands adaptive toolpaths, specialized cutting tools, and environmental controls to mitigate warping or microfractures. Our CNC machining centers operate under tightly regulated conditions, with in-process metrology ensuring tolerances remain within ±0.005 mm—a benchmark developed through years of producing mission-critical components.

Our expertise in precision engineering is validated through high-stakes applications. Wuxi Lead has delivered components for Olympic-grade sporting equipment, where consistency and reliability directly impact athletic performance. More notably, we have supported defense sector programs requiring ITAR-compliant production and traceability, reinforcing our capability to meet military-grade specifications. These experiences underscore our understanding that in custom plastics fabrication, a deviation of even a few microns can compromise sealing integrity, structural load distribution, or electrical insulation properties.

Beyond machining, our end-to-end process includes precision bending, solvent welding, and automated inspection using coordinate measuring machines (CMM) and laser scanning. This holistic approach ensures that every fabricated plastic component—whether a complex enclosure, insulating bracket, or fluid handling manifold—meets the exact functional and regulatory demands of its application.

The integration of plastics into precision sheet metal assemblies further highlights the need for cross-material expertise. At Lead Precision, we engineer for compatibility, accounting for differential thermal expansion and mechanical stress between plastic and metal elements. This systems-level insight allows us to deliver fully assembled subunits ready for final integration, reducing our clients’ assembly time and quality risk.

Below are key technical specifications we maintain across our custom plastics fabrication services:

| Specification | Capability | Notes |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Achieved under climate-controlled environment |

| Material Compatibility | PEEK, PTFE, ABS, Polycarbonate, PVC, Acrylic | Custom material sourcing available |

| Maximum Work Envelope | 2000 x 1200 x 100 mm | For milling and routing operations |

| Surface Finish | Ra 0.8–3.2 μm | Adjustable per functional or aesthetic requirements |

| Quality Standards | ISO 9001:2015, ITAR compliance available | Full traceability and documentation |

At Wuxi Lead Precision Machinery, we treat custom plastics fabrication not as a secondary process, but as an extension of precision engineering. Our proven track record in Olympic and military projects reflects our commitment to excellence—where every micron matters, and every component performs.

Precision Specs & Tolerances

Technical Capabilities: Precision Plastics Fabrication

Wuxi Lead Precision Machinery applies advanced metalworking discipline to the demanding field of custom plastics fabrication. Our core strength lies in translating complex engineering specifications into high-integrity plastic components, leveraging capabilities typically associated with aerospace and medical-grade metal production. This precision-driven approach ensures dimensional stability and functional reliability critical for demanding end-use applications across industries like semiconductor handling, fluidics, and precision instrumentation.

Our primary manufacturing platform is a dedicated fleet of 5-axis CNC machining centers, specifically configured and maintained for optimal plastic material processing. Unlike standard 3-axis systems, 5-axis technology enables the complete machining of intricate geometries—including deep cavities, undercuts, and complex organic shapes—in a single setup. This eliminates cumulative fixture errors inherent in multi-operation workflows. Crucially, our machines utilize specialized high-speed spindles, non-marring fixturing solutions, and meticulously calibrated toolpaths designed to manage the unique thermal expansion, chip evacuation challenges, and potential for stress cracking associated with engineering thermoplastics such as PEEK, Ultem, PTFE, and Acetal. Material-specific parameters for feed rates, spindle speeds, and coolant strategies are rigorously applied to prevent melting, burring, or internal stress generation.

Rigorous quality control is non-negotiable. Every critical dimension undergoes verification using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMM systems, operating within ISO 17025 accredited environmental conditions, provide micron-level traceable measurement data. This metrology backbone validates geometric tolerances, surface finishes, and critical feature relationships against the original CAD model, ensuring absolute conformance before shipment. Statistical Process Control (SPC) methodologies are embedded in production runs to monitor capability and guarantee batch-to-batch consistency.

The achievable precision for stable engineering plastics under controlled conditions is documented below. Note that tolerances are material-dependent and may require specific design considerations for ultra-thin walls or highly flexible polymers.

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Applicable Standard Reference |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm (±0.002″) | ±0.025 mm (±0.001″) | ISO 2768-mK |

| Geometric (Flatness) | 0.05 mm (0.002″) | 0.025 mm (0.001″) | ISO 1101 |

| Geometric (True Position) | Ø0.10 mm (Ø0.004″) | Ø0.05 mm (Ø0.002″) | ASME Y14.5 GD&T |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 0.8 µm (32 µin) | ISO 1302 |

This documented capability, combined with our systematic approach to material handling, process validation, and metrology, delivers components that meet the exacting demands of high-value assembly. Wuxi Lead transforms challenging plastic fabrication requirements into reliably produced, functionally superior parts, minimizing downstream assembly issues and enhancing your product’s performance lifecycle. We partner with clients to optimize designs for manufacturability while relentlessly pursuing the tightest tolerances your application necessitates.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication for Custom Plastics Applications

In custom plastics fabrication, particularly when integrating structural or protective metal components, material selection plays a pivotal role in determining product performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision sheet metal fabrication that supports high-end plastic assemblies, requiring careful pairing of metals with polymers. The most commonly used metals in such hybrid systems are aluminum, steel, and titanium—each offering distinct mechanical, thermal, and chemical properties.

Aluminum is the preferred choice for lightweight, corrosion-resistant enclosures and frames. Its excellent machinability and thermal conductivity make it ideal for applications involving heat dissipation or where weight reduction is critical, such as in automation housings or medical device chassis. Grade 6061-T6 is widely used due to its balanced strength and weldability, while 7075-T6 offers higher strength for more demanding environments.

Steel, particularly stainless steel grades like 304 and 316, provides superior strength and resistance to mechanical wear. It is best suited for structural supports, brackets, and fixtures exposed to harsh environments or high mechanical loads. The inherent rigidity of steel ensures dimensional stability in precision assemblies, making it a reliable partner for engineered plastics such as PEEK or Ultem in industrial machinery.

Titanium, though more costly, delivers an exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in saline or high-temperature conditions. It is typically reserved for aerospace, defense, or high-performance medical applications where longevity and reliability outweigh initial material cost. Grade 5 (Ti-6Al-4V) is the most common titanium alloy used in fabrication due to its enhanced mechanical properties.

Surface finishing is equally critical in ensuring long-term performance and aesthetic quality. Anodizing is the most effective finish for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paint or primers. Type II (sulfuric acid) anodizing is standard for general applications, offering a clear or colored finish, while Type III (hardcoat anodizing) provides a thicker, harder surface suitable for high-wear environments.

Below is a comparative overview of key material specifications relevant to precision fabrication:

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310 – 570 | 2.7 | High (with anodizing) | Enclosures, heat sinks, frames |

| Stainless Steel | 304, 316 | 505 – 620 | 8.0 | Very High | Brackets, fixtures, supports |

| Titanium | Ti-6Al-4V (Grade 5) | 900 – 950 | 4.5 | Exceptional | Aerospace, medical, marine |

At Wuxi Lead, we guide clients through material and finish selection based on environmental exposure, mechanical requirements, and lifecycle expectations. Proper integration of metal components enhances the functionality and reliability of custom plastic systems, ensuring optimal performance in demanding industrial applications.

Manufacturing Process & QC

Custom Plastics Fabrication: Precision Production Process

At Wuxi Lead Precision Machinery, our custom plastics fabrication process is engineered for uncompromising quality and zero defects, from initial concept to full-scale delivery. This structured workflow ensures dimensional accuracy, material integrity, and functional reliability for demanding industrial applications. We integrate advanced engineering controls at every stage to eliminate waste and guarantee client specifications are met without deviation.

The Design Phase begins with rigorous collaboration between our engineering team and the client. Utilizing Siemens NX and SolidWorks, we develop detailed 3D CAD models incorporating strict Design for Manufacturability (DFM) principles specific to plastics. This critical step identifies potential stress points, draft angle requirements, wall thickness inconsistencies, and assembly interfaces before any material is cut. Finite Element Analysis (FEA) simulates real-world loads and thermal behavior, ensuring the design is optimized for both performance and producibility. Client sign-off on the validated digital model is mandatory, establishing the definitive blueprint for all subsequent stages and preventing costly downstream errors.

Prototyping transitions the digital design into physical validation. We employ rapid CNC milling, precision 3D printing (SLA/SLS), or soft-tool injection molding based on the part’s complexity and end-use requirements. Each prototype undergoes comprehensive metrology using Zeiss CMMs and optical comparators against the original CAD data, verifying critical dimensions, surface finishes, and material properties. Functional testing under simulated operational conditions is performed to confirm fit, form, and function. This phase is not merely a sample check; it is a vital failure-mode prevention step where any discrepancies trigger immediate design or process refinement, ensuring the mass production run launches with zero unresolved issues.

Mass Production leverages our automated CNC machining centers (HAAS, DMG MORI), multi-cavity injection molding systems, and robotic finishing cells, all operating under strict Statistical Process Control (SPC). Real-time monitoring of critical parameters—temperature, pressure, cycle time, and tool wear—is integrated directly into our MES. Every component undergoes 100% automated optical inspection (AOI) for surface defects and critical dimensions, supplemented by in-process CMM spot checks per AS9102 standards. Material traceability is maintained from raw pellet to finished part. This closed-loop system, combined with our ISO 9001-certified quality management protocols, ensures consistent output where defects are impossible to escape detection, delivering true zero-defect batches for mission-critical applications.

Key Process Specifications

| Phase | Critical Parameters Monitored | Tolerance Capability | Lead Time (Typical) | Primary QA Method |

|---|---|---|---|---|

| Design | DFM Compliance, FEA Stress/Deflection, Draft Angles | N/A | 3-10 Days | CAD/CAM Validation, Client Sign-off |

| Prototyping | Dimensional Accuracy, Surface Finish, Material ID | ±0.05 mm | 5-15 Days | CMM, Optical Comparator, Functional Test |

| Mass Production | Melt Temp, Injection Pressure, Cycle Time, Tool Wear | ±0.02 mm (Machined) | 2-8 Weeks | 100% AOI, SPC Charts, AS9102 CMM |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Precision-Driven Custom Plastics Fabrication

In the rapidly evolving landscape of industrial manufacturing, the integration of high-performance plastics into precision engineering applications has become a defining factor in product innovation, durability, and cost efficiency. At Wuxi Lead Precision Machinery, we specialize in advanced custom plastics fabrication, merging decades of engineering expertise with state-of-the-art CNC technology to deliver components that meet the most stringent industry standards. Our capabilities extend beyond conventional sheet metal fabrication, embracing a comprehensive approach to hybrid manufacturing where engineered polymers meet metal systems in seamless synergy.

Our facility in Wuxi, China, is equipped with multi-axis CNC machining centers, precision laser cutters, and automated forming systems, all calibrated to handle a wide range of thermoplastics including PEEK, PTFE, UHMW, ABS, and polycarbonate. Whether you require tight-tolerance enclosures, wear-resistant guides, insulating components for electrical systems, or custom molded structural parts, our team ensures dimensional accuracy down to ±0.02 mm and superior surface finish consistency. We understand that plastics behave differently than metals under thermal and mechanical stress, which is why our engineers apply material-specific compensation algorithms and toolpath optimization techniques to guarantee repeatability and long-term performance.

We serve industries where reliability is non-negotiable—medical device manufacturing, semiconductor processing, automation systems, and high-end transportation equipment. Our clients rely on us not just as a supplier, but as a technical partner who can support design for manufacturability (DFM), material selection, prototyping, and full-scale production. From concept validation to just-in-time delivery, we align our processes with your project timelines and quality benchmarks.

Our integrated quality management system is ISO 9001-certified, and we conduct rigorous in-process inspections using coordinate measuring machines (CMM) and optical comparators. Every batch is traceable, and material certifications are provided as standard. We also offer secondary services such as ultrasonic welding, solvent bonding, silk screening, and custom packaging to streamline your supply chain.

Below are key technical specifications for our custom plastics fabrication services:

| Parameter | Specification |

|---|---|

| Material Compatibility | PEEK, PTFE, UHMW, ABS, PC, PVC, Acetal, Nylon |

| Tolerance Range | ±0.02 mm to ±0.05 mm |

| Maximum Part Size | 1200 mm × 600 mm × 200 mm |

| Surface Finish (Ra) | 0.8 µm to 3.2 µm (adjustable) |

| Machining Processes | CNC Milling, CNC Turning, Laser Cutting |

| Secondary Operations | Drilling, Tapping, Beveling, Polishing |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Production Batch) | 10–15 working days |

Collaborating with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem designed for agility, precision, and long-term partnership. We are committed to solving complex fabrication challenges with responsive engineering support and scalable production capacity.

Contact us today at [email protected] to discuss your next custom plastics fabrication project. Let Lead Precision be the foundation of your innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.