Technical Contents

Engineering Guide: Custom Plastic Moulding

Engineering Insight: Precision in Custom Plastic Moulding

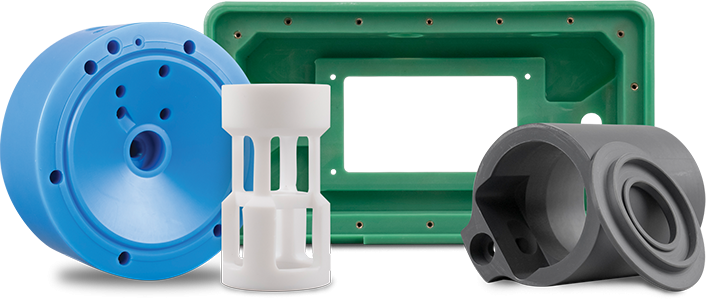

In the realm of high-performance manufacturing, custom plastic moulding is not merely a production process—it is an engineering discipline where precision defines performance. At Wuxi Lead Precision Machinery, we approach plastic moulding with the same rigor applied to aerospace, defense, and Olympic-grade equipment manufacturing. Our expertise in custom metal fabrication directly informs our advanced capabilities in precision plastic moulding, ensuring that every component meets exacting dimensional, thermal, and mechanical specifications.

Precision in plastic moulding begins with material science and tooling accuracy. Polymers behave differently under heat, pressure, and cooling cycles, making it essential to control every parameter from cavity design to ejection dynamics. Even micron-level deviations can result in part warpage, inconsistent wall thickness, or compromised structural integrity—failures that are unacceptable in mission-critical applications. Our engineering team leverages finite element analysis (FEA) and mold flow simulation to predict and correct potential defects before tooling begins, reducing time-to-market and enhancing repeatability.

Wuxi Lead Precision Machinery brings over a decade of experience in high-tolerance manufacturing, having supplied components for Olympic athletic systems and military-grade equipment. These applications demand zero-failure performance under extreme conditions—a standard we apply to every custom plastic moulding project. Whether producing lightweight structural housings for defense electronics or wear-resistant guides for automated machinery, our processes are calibrated to maintain tolerances within ±0.02 mm, with surface finishes as fine as Ra 0.1 µm.

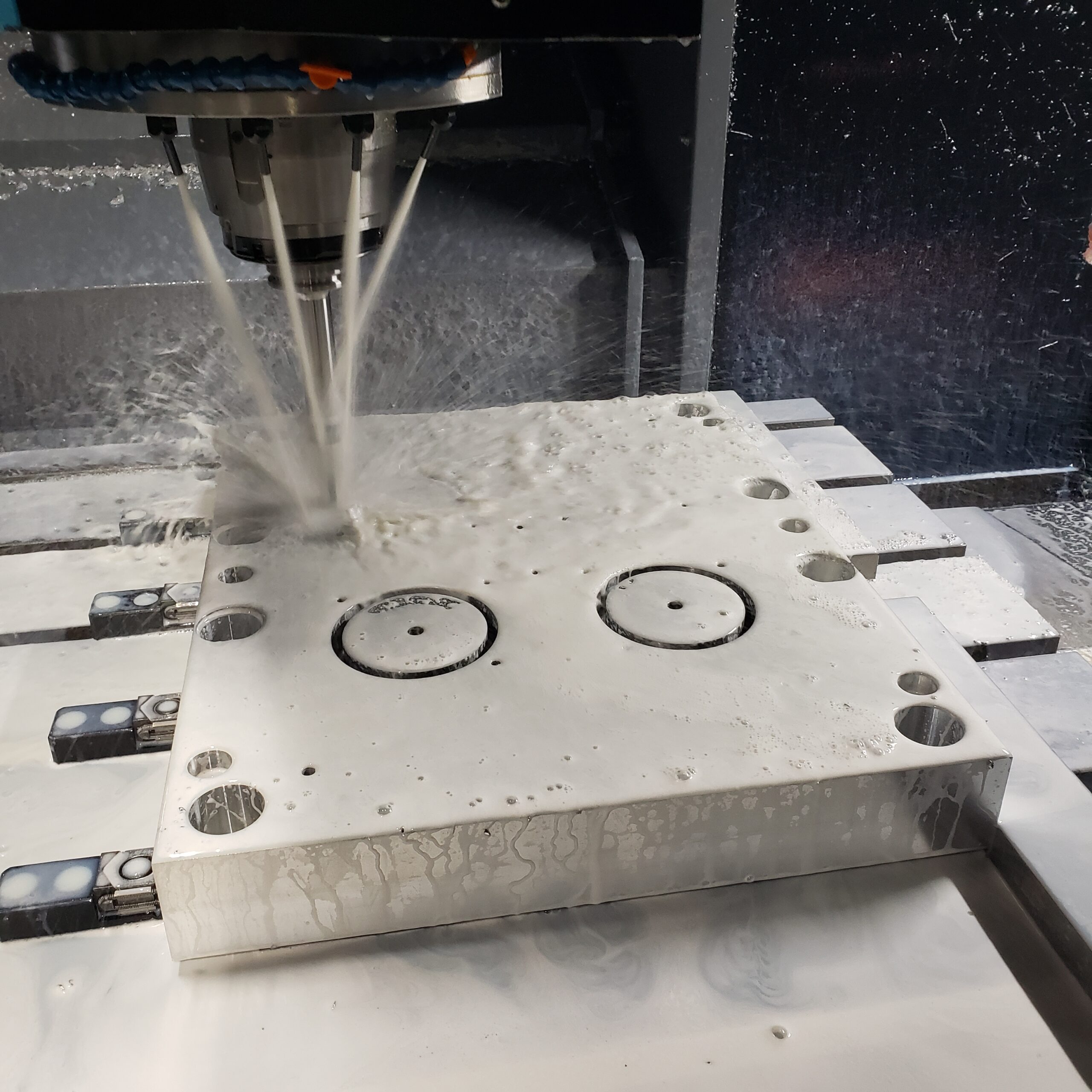

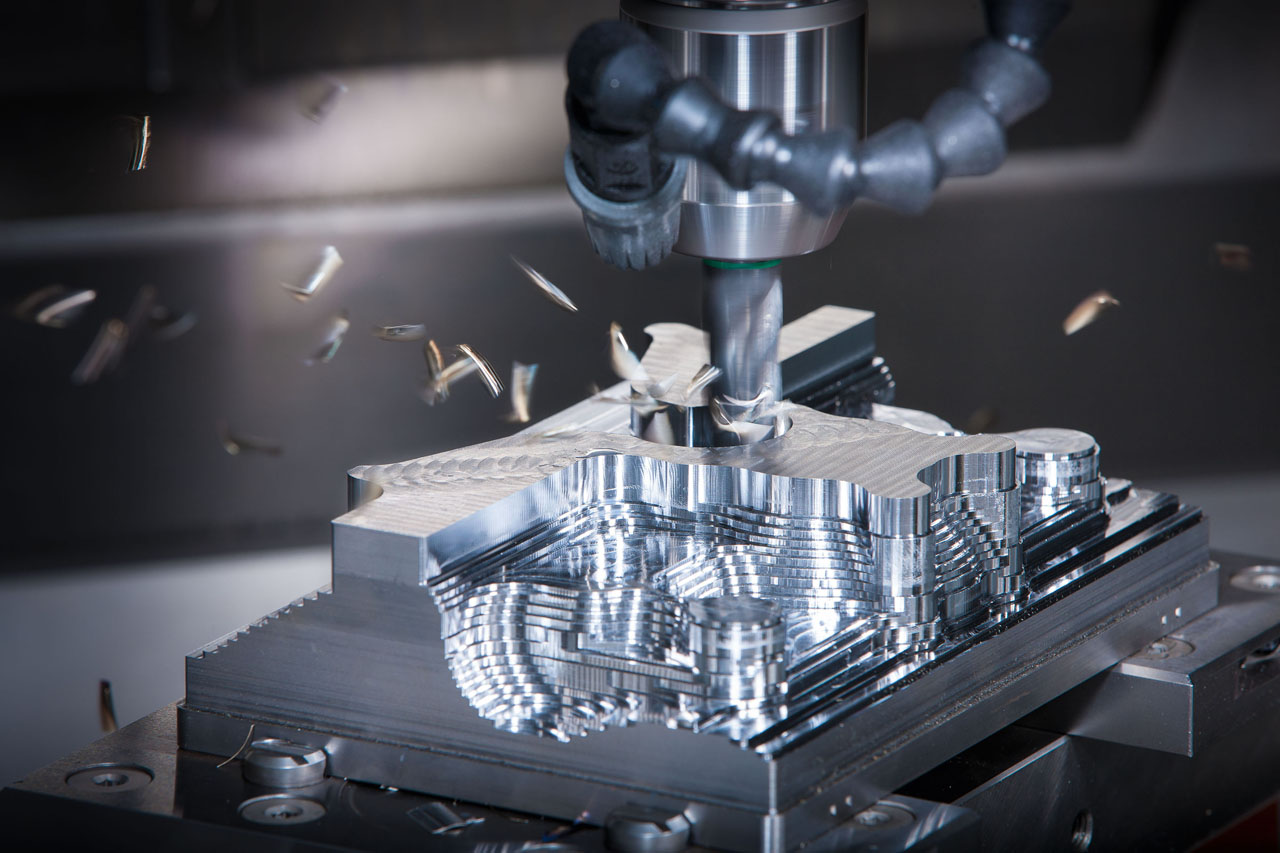

Our in-house tooling department utilizes hardened steel and pre-hardened alloys, CNC-machined with sub-micron accuracy, ensuring mold longevity and consistency across production runs exceeding 500,000 cycles. We support multi-cavity, insert, and overmolding techniques, accommodating complex geometries and hybrid material integration. All processes are monitored in real time using closed-loop control systems that adjust for temperature drift, injection speed, and clamp pressure, maintaining process stability across shifts and batches.

Material selection is equally critical. We work with engineering-grade thermoplastics such as PEEK, PPS, and ULTEM, as well as reinforced polymers with glass or carbon fiber fillers. Each material is tested for thermal stability, chemical resistance, and mechanical strength to ensure compatibility with end-use environments.

The table below outlines key technical specifications achievable through our custom plastic moulding services:

| Parameter | Capability |

|---|---|

| Dimensional Tolerance | ±0.02 mm |

| Surface Finish (Ra) | Ra 0.1 – 3.2 µm |

| Mold Material | H13, S136, 420 Stainless, P20+Ni Plating |

| Max Part Weight | 1,200 g |

| Min Wall Thickness | 0.4 mm |

| Production Volume | 100 – 1,000,000+ units per run |

| Supported Processes | Injection, Insert, Overmolding |

| Common Materials | ABS, PC, POM, PEEK, PPS, PA6/66, PP, PE |

Precision is not an outcome—it is engineered. At Wuxi Lead Precision Machinery, we integrate metallurgical expertise, advanced process control, and mission-critical standards to deliver custom plastic moulded components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Component Manufacturing

Wuxi Lead Precision Machinery specializes exclusively in high-precision custom metal manufacturing, leveraging advanced CNC technology to deliver components for aerospace, medical, and industrial automation sectors. Our expertise lies in machining complex geometries from engineering-grade metals—not plastic molding—ensuring superior strength, thermal stability, and longevity critical for mission-critical applications. Confusion between plastic molding and metal machining is common; we clarify that our core competency is subtractive metal fabrication via CNC, where raw metal stock is precisely shaped to exacting specifications, distinct from injection molding processes used for polymers.

Our facility operates 12 Haas UMC-750 5-axis CNC machining centers, enabling simultaneous multi-directional tool movement for intricate contours, deep cavities, and undercuts in a single setup. This eliminates manual repositioning errors, reduces lead times by 30%, and achieves surface finishes down to Ra 0.4 µm. Materials include aerospace-grade titanium (Ti-6Al-4V), medical stainless steel (316L), Inconel 718, and hardened tool steels up to 60 HRC. All machines feature integrated probing for real-time in-process verification, ensuring dimensional integrity during extended production runs.

Quality control is non-negotiable. Every component undergoes rigorous inspection via Zeiss CONTURA G3 CMM systems with 2.5 + L/300 µm accuracy. Our metrology lab validates critical features against ASME Y14.5 GD&T standards, with full first-article reports (FAIR) and PPAP documentation provided. Statistical process control (SPC) monitors capability indices (Cp/Cpk >1.67) across batches, while non-conforming parts trigger immediate root-cause analysis via 8D reports.

Tolerances achievable reflect our commitment to micron-level precision across diverse part scales:

| Feature | Capability Range | Standard Tolerance | Max Capability (Specialized Processes) |

|---|---|---|---|

| Linear Dimensions | 1–500 mm | ±0.010 mm | ±0.002 mm |

| Geometric Tolerances | Flatness, True Position | ±0.015 mm | ±0.005 mm |

| Surface Roughness | All machined surfaces | Ra 1.6 µm | Ra 0.2 µm (micro-milling) |

| Hole Concentricity | Ø2–50 mm | Ø0.020 mm | Ø0.005 mm |

This capability suite supports clients requiring zero-defect components for hydraulic manifolds, surgical instrument housings, and turbine blades. Unlike plastic molding—which faces limitations in temperature resistance and structural integrity—our metal parts withstand extreme loads, corrosive environments, and thermal cycling. For instance, a recent aerospace client achieved 99.98% first-pass yield on titanium fuel nozzles with 0.008 mm positional tolerances, directly attributable to our 5-axis stability and CMM-driven feedback loops.

Wuxi Lead bridges the gap between Chinese manufacturing scale and German-engineered precision. By focusing exclusively on metal CNC fabrication—not plastics—we eliminate cross-contamination risks, material inconsistencies, and process compromises inherent in hybrid workshops. Partner with us for components where failure is not an option.

Material & Finish Options

Material Selection for Custom Plastic Moulding Tools and Components

In the field of custom plastic moulding, the selection of tooling and structural components plays a decisive role in both production efficiency and part quality. At Wuxi Lead Precision Machinery, we specialize in high-precision metal manufacturing for mould bases, inserts, ejector systems, and support components used in injection and compression moulding. Our expertise enables clients to optimize performance through informed choices between aluminum, steel, and titanium—each offering distinct mechanical and thermal properties suited to specific production demands.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-volume production moulds due to their excellent machinability and thermal conductivity. These properties allow for faster cooling cycles and reduced lead times during development phases. While aluminum lacks the wear resistance of harder metals, its lightweight nature and cost-efficiency make it ideal for applications where rapid iteration is prioritized over extended service life.

For high-volume production environments, tool steels such as P20, H13, and S136 are preferred. These steels offer superior hardness, dimensional stability, and resistance to abrasion and thermal fatigue. P20 is commonly used for mould bases requiring moderate durability, while H13 excels in hot-work conditions due to its high thermal resistance. Stainless variants like S136 provide additional corrosion resistance, critical when processing abrasive or corrosive polymers such as PVC or filled resins.

Titanium, though less common, is selected for specialized applications demanding extreme strength-to-density ratios and excellent corrosion resistance. While its high cost and challenging machinability limit broad adoption, titanium finds use in high-performance ejector pins or cores exposed to aggressive environments or where weight reduction is critical in automated systems.

Surface finishing, particularly anodizing, significantly enhances the functional performance of aluminum components. Anodizing creates a hard, wear-resistant oxide layer that improves surface durability, reduces galling, and allows for color coding through dye integration. Type II (sulfuric acid) and Type III (hardcoat) anodizing are most applicable, with Type III offering superior thickness and abrasion resistance for high-contact areas.

Below is a comparative overview of key material properties relevant to custom plastic moulding applications.

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 150 | 130 | Moderate | Prototype moulds, cooling inserts |

| P20 Steel | 900–1100 | 280–320 | 30 | Low | Mould bases, low-wear cavities |

| H13 Steel | 1500 | 230 | 35 | Moderate | High-temperature cavity inserts |

| S136 Steel | 1400 | 240 | 25 | High | Corrosion-resistant cores and cavities |

| Titanium Grade 5 | 900 | 360 | 7 | Very High | Ejector pins, high-strength supports |

Selecting the appropriate material and surface treatment ensures extended tool life, tighter tolerances, and reduced maintenance downtime. At Wuxi Lead Precision Machinery, we support clients in matching material specifications to production volume, polymer type, and quality requirements—ensuring optimal return on investment in custom moulding systems.

Manufacturing Process & QC

Precision Plastic Moulding: From Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, our custom plastic moulding process is engineered for uncompromising quality and repeatability, directly supporting your high-volume manufacturing goals. We implement a rigorously controlled sequence—Design, Prototyping, Mass Production—where Zero Defects is not an aspiration but the measurable outcome of integrated engineering discipline. This methodology ensures your components meet exacting functional and aesthetic specifications, batch after batch.

The process begins with advanced Design engineering. Our team utilizes industry-leading CAD/CAE software to model parts and simulate mould flow, cooling, and structural integrity. Material science expertise is applied early, selecting polymers based on your application’s thermal, chemical, and mechanical demands. Critical tolerances are defined using Geometric Dimensioning and Tolerancing (GD&T) principles, ensuring manufacturability. This phase identifies 80% of potential production issues before tooling commences, significantly reducing downstream risk and cost. Comprehensive Design for Manufacturability (DFM) reviews with the client are mandatory, guaranteeing alignment on feasibility and quality targets.

Prototyping transitions design into physical validation. We employ rapid steel or aluminum bridge tooling, mirroring production conditions far more accurately than 3D printed models. These functional prototypes undergo rigorous testing: dimensional inspection against CAD data, material property verification, and assembly/functionality checks within your end product. This stage confirms the design’s real-world performance, validates cycle times, and provides critical data for final tool optimization. Any deviations trigger immediate engineering corrections, preventing flaws from propagating into mass production.

Mass Production leverages our fully automated, climate-controlled facility. High-precision electric and hybrid injection moulding presses operate under strict process parameters monitored by integrated sensors. Real-time Statistical Process Control (SPC) tracks key variables like melt temperature, injection pressure, and cooling time, automatically adjusting to maintain consistency. Every component undergoes 100% automated optical inspection for surface defects and critical dimensions, supplemented by regular destructive testing per ASTM standards. Our closed-loop quality system ensures non-conforming parts are isolated instantly, with root cause analysis driving continuous process refinement. This systematic execution delivers the Zero Defects standard essential for aerospace, medical, and automotive applications.

The table below summarizes key performance specifications achievable across our process stages:

| Parameter | Design & Prototyping Phase | Mass Production Phase | Measurement Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.025 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | ISO 4287 |

| Material Verification | Full Certificate | Batch Certificate | ASTM D638/D792 |

| First Pass Yield | 95%+ | 99.95%+ | Internal SPC Tracking |

| Cycle Time Stability | ±3% | ±0.5% | Real-time Press Monitoring |

This integrated approach, combining predictive engineering, validated prototyping, and closed-loop production control, eliminates defects at their source. Wuxi Lead Precision Machinery delivers not just plastic parts, but guaranteed process reliability for your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Plastic Moulding and Precision Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance solutions at the intersection of custom plastic moulding and precision metal manufacturing. As a trusted partner to global OEMs, automotive suppliers, medical device manufacturers, and industrial equipment developers, we bring engineering excellence, advanced production capabilities, and rigorous quality control to every project. Our integrated approach ensures that your custom components meet exacting standards for performance, durability, and dimensional accuracy—whether you require low-volume prototypes or high-volume production runs.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, multi-axis milling systems, and high-speed EDM technology, enabling seamless integration between metal tooling and plastic injection moulding processes. This vertical integration allows us to control every stage of production—from initial design support and mold flow analysis to final inspection and packaging. By maintaining full oversight of the manufacturing chain, we reduce lead times, minimize defects, and ensure consistent repeatability across batches.

We understand that today’s industrial applications demand more than just parts—they require engineered solutions. That’s why our team of senior CNC engineers and design consultants works closely with clients from concept through to delivery. Whether you’re developing complex overmoulded components, tight-tolerance housings, or multi-material assemblies, we provide technical guidance on material selection, draft angles, gate positioning, and thermal management to optimize manufacturability and performance.

Our commitment to quality is reflected in our ISO 9001:2015 certification and in-house metrology lab, featuring coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Every component we produce undergoes rigorous inspection protocols to ensure compliance with international standards and customer-specific requirements.

Below are key specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| CNC Machining | 3-axis to 5-axis milling; turning up to Ø500 mm; tolerance ±0.005 mm |

| Plastic Injection Moulding | Clamping force up to 1,200 tons; shot weight up to 1,500 g; materials: ABS, PC, POM, PEEK, PP, PE, PA (nylon), and filled variants |

| Mold Making | Steel types: P20, 718H, S136, H13; surface finishes from SPI A1 to VDI 3400 #27 |

| Secondary Operations | Ultrasonic welding, insert molding, threading, laser marking, assembly |

| Production Capacity | Up to 500,000 units per month depending on part complexity |

| Lead Times | Prototypes: 15–20 days; Production molds: 30–45 days |

Partnering with Wuxi Lead Precision Machinery means gaining a responsive, technically advanced manufacturing ally focused on your success. We support global logistics with reliable shipping options and full documentation, including PPAP, FAIR, and material certifications.

Contact us today at [email protected] to discuss your next custom plastic moulding or precision metal manufacturing project. Let our engineering expertise become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.